Professional Documents

Culture Documents

Pages From CAR 145 - DSV-2

Uploaded by

saradeepsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From CAR 145 - DSV-2

Uploaded by

saradeepsCopyright:

Available Formats

CA FORM 6 Appendix VI

CAR-145 APPROVAL RECOMMENDATION REPORT

PART 1: GENERAL

Name of organisation:

Approval reference:

Requested approval rating:

CA Form 3 dated*:

EASA / FAA FAR 145 Cert No. (If app.)

Address of Facility Audited:

Period covered under Audit: From: To:

Date(s) of Audit: Audit reference(s):

Persons interviewed:

DGCA Official(s) Names: Signature(s):

DGCA office: Date of Form 6 Part 1 completion:

*delete as appropriate

Issue 02, R3, 14th June 2017 100

CAR-145 APPROVAL RECOMMENDATION REPORT CA FOR

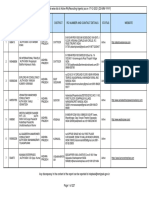

PART 2: CAR -145 COMPLIANCE AUDIT REVIEW

The five columns may be labeled & used as necessary to record the approval class &/or

product line reviewed. Against each column used of the following CAR-145 sub-paragraphs

please either tick (√ ) the box if satisfied with compliance or cross (X ) the box if not satisfied

with compliance and specify the reference of the Part 4 finding next to the box or enter N/A

where an item is not applicable, or N/R when applicable but not reviewed.

Para Subject

145.25 Facilities

145.30 Personnel

Certifying Staff and

145.35

Support staff

Record of Airworthiness

145 36 review Staff

145.40 Equipment, Tools, etc

Acceptance of

145.42

Components

145.45 Maintenance Data

145.47 Production Planning

145.A.48 Performance of

maintenance

Certification of

145.50

Maintenance

145.55 Maintenance Records

145.60 Occurrence Reporting

145.65 Procedures & Quality

145.70 See Part 3

145.75 Privileges of AMO

145.80 Limitations on AMO

145.85 Changes to AMO

145.90 Continued Validity

DGCA officer(s): Signature(s):

DGCA office Date of Form 6 part 2 completion

Issue 02, R3, 14th June 2017 101

CAR -145 APPROVAL RECOMMENDATION REPORT CA FORM 6

PART 3: Compliance with 145.A.70 Maintenance organisation exposition

Please either tick (✓) the box if satisfied with compliance; or if not satisfied with compliance and

specify the reference of the Part 4 finding; or enter N/A where an item is not applicable; or N/R

when applicable but not reviewed.

Part 1 Management

1.1 Corporate commitment by the accountable manager

1.2 Safety and Quality Policy.

1.3 Management personnel.

1.4 Duties and responsibilities of the management personnel.

1.5 Management Organisation Chart.

List of Certifying staff , support staff and airworthiness review staff

1.6

(Note: a separate document may be referenced).

1.7 Manpower resources.

General description of the facilities at each address intended to be

1.8

approved.

1.9 Organisations intended scope of work.

Notification procedure to DGCA regarding changes to the organisation's

1.10

activities/ approval / location / personnel

1.11 Exposition amendment procedures.

Part 2 Maintenance Procedures

2.1 Supplier evaluation and subcontract control procedure.

Acceptance/inspection of aircraft components and material from outside

2.2

contractors.

Storage, tagging, and release of aircraft components and material to

2.3 aircraft maintenance.

2.4 Acceptance of tools and equipment.

2.5 Calibration of tools and equipment

2.6 Use of tooling and equipment by staff (including alternate tools).

2.7 Cleanliness standards of maintenance facilities.

Maintenance instructions and relationship to aircraft/aircraft component

2.8

manufacturers' instructions including updating and availability to staff

2.9 Repair procedure.

2.10 Aircraft maintenance programme compliance

2.11 Airworthiness Directives procedure

2.12 Optional modification procedure.

2.13 Maintenance documentation in use and its completion of same.

2.14 Technical record control.

Issue 02, R3, 14th June 2017 102

CAR -145 APPROVAL RECOMMENDATION REPORT CA FORM 6

PART 3: Compliance with 145.A.70 Maintenance organisation exposition

2.15 Rectification of defects arising during base maintenance

2.16 Release to service procedure

2.17 Records for the operator.

2.18 Reporting of defects to DGCA /Operator/Manufacturer

2.19 Return of defective aircraft components to store.

2.20 Defective components to outside contractors

2.21 Control of computer maintenance record systems

2.22 Control of man-hour planning versus scheduled maintenance work.

2.23 Critical maintenance tasks and error-capturing methods

2.24 Reference to specific maintenance procedures.

2.25 Procedures to detect and rectify maintenance errors.

2.26 Shift / task handover procedures.

Procedures for notification of maintenance data inaccuracies and

2.27 ambiguities to the type certificate holder.

2.28 Production planning procedures

Part L2 Additional Line Maintenance Procedures

L2.1 Line maintenance control of aircraft components, tools, equipment, etc.

L2.2 Line maintenance procedures related to servicing/fuelling/de-icing

L2.3 Line maintenance control of defects and repetitive defects

L2.4 Line procedure for completion of technical log

L2.5 Line procedure for pooled parts and loan parts

L2.6 Line procedure for return of defective parts removed from aircraft

Line procedure critical maintenance tasks and error-capturing methods

L2.7

Part 3 Quality System Procedures

3.1 Quality audit of organisation procedures.

3.2 Quality audit of aircraft

3.3 Quality audit remedial action procedure.

3.4 Certifying staff and support staff qualification and training procedure.

3.5 Certifying staff records.

Issue 02, R3, 14th June 2017 103

CAR -145 APPROVAL RECOMMENDATION REPORT CA FORM 6

PART 3: Compliance with 145.A.70 Maintenance organisation exposition

3.6 Quality audit personnel

3.7 Qualifying inspectors.

3.8 Qualifying mechanics

3.9 Aircraft / aircraft component maintenance tasks exemption process control.

3.10 Concession control for deviation from organisation's procedures.

3.11 Qualification procedure for specialised activities such as NDT, welding

etc.

3.12 Control of manufacturers' and other maintenance working teams

3.13 Human Factors training procedure

3.14 Competence assessment of personnel

3.15 Training procedures for on-the job training as per Section 6 of

Appendix III to CAR 66

3.16 Procedure for the issue of the recommendation to DGCA for the

issues of a CAR 66 licence in accordance with 66.B.105.

Part 4

4.1 Contracted operators

4.2 Operator procedures/paperwork

4.3 Operator record completion

Part 5 Appendices

5.1 Sample Documents

5.2 List of sub-contractors

5.3 List of Line maintenance locations

5.4 List of CAR-145 organisations

Date of Form 6 part 3 completion:

MOE Reference: MOE Amendment:

DGCA official(s): Signature(s):

DGCA office Date of Form 6 Part 3 completion:

CAR -145 APPROVAL RECOMMENDATION REPORT CA FORM 6

Issue 02, R3, 14th June 2017 104

Part 4: Findings CAR-145 Compliance status

Each level 1 and 2 finding should be recorded whether it has been rectified or not and should

be identified by a simple cross reference to the Part 2 requirement. All non-rectified findings

should be copied in writing to the organisation for the necessary corrective action.

Audit Corrective action

Part 2 or 3

reference(s): Level

reference

Findings Date Due Date Closed Reference

Issue 02, R3, 14th June 2017 105

CAR -145 APPROVAL RECOMMENDATION REPORT CA FORM 6

Part 5: CAR-145 Approval or continued approval or change recommendation*

Name of organisation:

Approval reference: Audit reference(s):

The following CAR -145 scope of approval is recommended for this organisation:

Or, it is recommended that the CAR -145 scope of approval specified in CA Form 3 referenced

...................................................... be continued.

Name of recommending DGCA Officer: Signature of recommending DGCA Officer:

DGCA office:

Date of recommendation:

Form 6 review (quality check) :

Date:

*delete as appropriate

Issue 02, 8th October, 2013 106

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- CAP 3300 - Appendix C STAT of ComplianceDocument6 pagesCAP 3300 - Appendix C STAT of CompliancesaradeepsNo ratings yet

- CAP 3300 - Appendix A APPL - ESTB ATS INDocument13 pagesCAP 3300 - Appendix A APPL - ESTB ATS INsaradeepsNo ratings yet

- Operations Circular: Subject: Helicopter Emergency Medical Services (Hems)Document57 pagesOperations Circular: Subject: Helicopter Emergency Medical Services (Hems)saradeepsNo ratings yet

- Pages From D2F-F7Document1 pagePages From D2F-F7saradeepsNo ratings yet

- CAP 3300 - Appendix B AOP Schedule of EventsDocument8 pagesCAP 3300 - Appendix B AOP Schedule of EventssaradeepsNo ratings yet

- Air Operator Certification Manual CAP 3300: Scheduled Commuter & NSOP AirplanesDocument5 pagesAir Operator Certification Manual CAP 3300: Scheduled Commuter & NSOP AirplanessaradeepsNo ratings yet

- Government of India Technical Centre, Opp Safdurjung Airport, New DelhiDocument6 pagesGovernment of India Technical Centre, Opp Safdurjung Airport, New Delhiarjun vsNo ratings yet

- Overview of Aircraft Maintenance - AviationHuntDocument11 pagesOverview of Aircraft Maintenance - AviationHuntsaradeeps0% (2)

- Ca Form 19-08BDocument3 pagesCa Form 19-08BsaradeepsNo ratings yet

- AME Apprenticeship PDFDocument1 pageAME Apprenticeship PDFsaradeepsNo ratings yet

- Maintenance Management & Engineering TrainingDocument19 pagesMaintenance Management & Engineering TrainingsaradeepsNo ratings yet

- Brochure AS 9100 D AQS Sys Nov 2019 PDFDocument2 pagesBrochure AS 9100 D AQS Sys Nov 2019 PDFsaradeepsNo ratings yet

- Guide To Out of Phase Tasks and MaintenaceDocument1 pageGuide To Out of Phase Tasks and MaintenacesaradeepsNo ratings yet

- Electro Contact Cleaner (LPS-03116)Document10 pagesElectro Contact Cleaner (LPS-03116)TariqNo ratings yet

- A9EA - Rev20 VT-ELX PDFDocument20 pagesA9EA - Rev20 VT-ELX PDFsaradeepsNo ratings yet

- Pages From UM - Iss 2 ParikshaDocument2 pagesPages From UM - Iss 2 ParikshasaradeepsNo ratings yet

- Aac04 2017Document153 pagesAac04 2017Panneer SelvamNo ratings yet

- 2013 05 24 - ICAO Session II PDFDocument16 pages2013 05 24 - ICAO Session II PDFsaradeepsNo ratings yet

- Electrical SafetyDocument9 pagesElectrical SafetysaradeepsNo ratings yet

- Procedure For AME Licence - Basic Licence PDFDocument8 pagesProcedure For AME Licence - Basic Licence PDFsaradeepsNo ratings yet

- 2013 05 24 - ICAO Session II PDFDocument16 pages2013 05 24 - ICAO Session II PDFsaradeepsNo ratings yet

- Party Food - Order Form - 2015Document1 pageParty Food - Order Form - 2015saradeepsNo ratings yet

- PN AME (Feb)Document2 pagesPN AME (Feb)saradeepsNo ratings yet

- ElecSafety GenDocument113 pagesElecSafety GenRamar MurugasenNo ratings yet

- PN - AME Apprenticeship TrainingDocument2 pagesPN - AME Apprenticeship TrainingIndian kingNo ratings yet

- 5 00lopDocument2 pages5 00lopsaradeepsNo ratings yet

- Ata - 28 (Nov-19)Document2,663 pagesAta - 28 (Nov-19)saradeepsNo ratings yet

- DHL Express Packing Guide en PDFDocument13 pagesDHL Express Packing Guide en PDFshrikantmsdNo ratings yet

- 5 30Document8 pages5 30saradeepsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Repayment LetterDocument3 pagesRepayment Lettersunil kr verma100% (1)

- Chase Credit Card ApplicationDocument4 pagesChase Credit Card ApplicationJames McguireNo ratings yet

- Henkel: Building A Winning Culture: Group 09Document11 pagesHenkel: Building A Winning Culture: Group 09sheersha kkNo ratings yet

- Sustainable Entrepreneurship DefinedDocument13 pagesSustainable Entrepreneurship Definedmsohaib7No ratings yet

- Tourism Merchandise As A MeansDocument16 pagesTourism Merchandise As A MeansSean O'ConnorNo ratings yet

- Official Receipt PDFDocument1 pageOfficial Receipt PDFJohn Rey CastillanoNo ratings yet

- Case Study 3Document4 pagesCase Study 3Anwar Iqbal50% (2)

- Benefits of Centralized LearningDocument8 pagesBenefits of Centralized LearningAqeel ShaukatNo ratings yet

- Accounting Concepts and AssumptionsDocument3 pagesAccounting Concepts and AssumptionsMiriam RapaNo ratings yet

- Currensee Correlation - OANDADocument1 pageCurrensee Correlation - OANDAwim006100% (1)

- HSE CaseDocument95 pagesHSE CaseHafiz Akhtar100% (3)

- Roshan ProjectDocument253 pagesRoshan ProjectAmit PrajapatiNo ratings yet

- Ra List Report Updatedupto17dec2021Document227 pagesRa List Report Updatedupto17dec2021Geetha KarunakaranNo ratings yet

- 12 Chapter2Document36 pages12 Chapter2lucasNo ratings yet

- Demat Account Details of Unicon Investment SolutionDocument53 pagesDemat Account Details of Unicon Investment SolutionManjeet SinghNo ratings yet

- Cost ScannerDocument290 pagesCost ScannerRodloNo ratings yet

- Diongzon V Mirano (Ethics)Document1 pageDiongzon V Mirano (Ethics)MMACNo ratings yet

- Employment Application Form - Ver2 (1) .0Document7 pagesEmployment Application Form - Ver2 (1) .0ranjithsutariNo ratings yet

- Feasibility Study Final 1Document40 pagesFeasibility Study Final 1Andrea Atonducan100% (1)

- Procurement KPIs - NCTDocument22 pagesProcurement KPIs - NCTMohamed ElnagdyNo ratings yet

- Presentation detailingto3DdetailingforRCDetailing PDFDocument39 pagesPresentation detailingto3DdetailingforRCDetailing PDFErnie ErnieNo ratings yet

- PAGCOR Site Regulatory ManualDocument4 pagesPAGCOR Site Regulatory Manualstaircasewit4No ratings yet

- The 5 Whys: A Ridiculously Simple Yet Essential Problem Solving ToolDocument3 pagesThe 5 Whys: A Ridiculously Simple Yet Essential Problem Solving ToolSridhara MunimakulaNo ratings yet

- PSPM AA025 - ANSWERS CHAPTER 7 Absorption Costing and Marginal CostingDocument7 pagesPSPM AA025 - ANSWERS CHAPTER 7 Absorption Costing and Marginal CostingDanish AqashahNo ratings yet

- Melissa Schilling: Strategic Management of Technological InnovationDocument25 pagesMelissa Schilling: Strategic Management of Technological Innovation143himabinduNo ratings yet

- Answers Installment Sales Dayag PDFDocument11 pagesAnswers Installment Sales Dayag PDFAshNor Randy100% (1)

- Molson Brewing CompanyDocument16 pagesMolson Brewing CompanyVictoria ColakicNo ratings yet

- Wa0010.Document7 pagesWa0010.nitish.thukralNo ratings yet

- Dow Chemicals: Company SnapshotDocument4 pagesDow Chemicals: Company SnapshotamritnsNo ratings yet

- SME Bank, Inc. v. de GuzmanDocument16 pagesSME Bank, Inc. v. de GuzmanKrisNo ratings yet