Professional Documents

Culture Documents

AIR VISION Static and Dynamic Loads of The Fans ENG PDF

AIR VISION Static and Dynamic Loads of The Fans ENG PDF

Uploaded by

SOMSUBHRA DEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AIR VISION Static and Dynamic Loads of The Fans ENG PDF

AIR VISION Static and Dynamic Loads of The Fans ENG PDF

Uploaded by

SOMSUBHRA DECopyright:

Available Formats

Air Vision,

Static and dynamic loads of fans on the foundations

The static load of the fan consists in its own weight in N (Newton).

However the fan is a rotating machine not perfectly balanced, even when it is new. Furthermore, during the

rotation, the fan may be used with gases including corrosive, clogging or abrasive dust which are able to

deteriorate the balancing of the fan and consequently cause an additional load on static one called dynamic.

The dynamic load is the cyclic force applied to the fan bearings when the gravity center of the dynamic parts (hub

+ shaft + coupling (or pulley)) does not match with the rotational center. Like any centrifugal force, the dynamic

load is function of the rotor’s mass, the square of the rotational speed and the distance between the center of

rotation and the center of gravity called eccentricity.

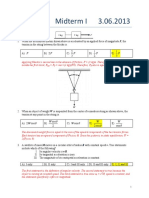

Dynamic load of new fan.

We define the quality of a balancing, G, as the product of the rotor vibration velocity ω (rad/s) by the specific

unbalance eper (µm or gr.mm/kg). For example, if an impeller rotates at 1480 RPM and the balancing quality is G

6.3; the angular velocity ω = 1480x2π / 60 = 155 rad/s and the specific unbalance is eper = G / ω x 10³ (µm) =

40.6 µm (or gr.mm/kg).

This equal to say that grade 6.3 allows a deviation of 40.6 µm between the center of rotation and the rotor’s

center of gravity at the speed of 1480 RPM.

If the rotor’s mass is 530 kg, then the nascent centrifugal force due to the residual unbalancing is:

F= m x ω² x eper = 530 x 155² x 40.6 x 10-6=509 N. (a)

Realistic dynamic load

This last value is however a theoretical value and the calculation of the cyclic centrifugal force must be assigned

with a service coefficient taking into account a misalignment, corrosion or clogging during the period of service. All

those last causes can potentially be the reason of a substantial

increase of the forces applied cyclically to the bearings and therefore

to the machine’s frame. When calculating the foundations, a realistic

dynamic load must be applied to ensure enough machine’s resistance

to the maximum vibration level. The formula (a) becomes:

F= m x ω² x eper x S.

Some manufacturers are using the value corresponding at 1/3 of the

rotor’s weight. It is according our opinion not enough: the practice in

heavy industrial environment shows that the fan can be subject to

dynamical loads much more important. To ensure security the

dynamical load that we use is equal to 3 times the rotor’s weight and

must be added to the static load for the calculation of the foundations.

Avenue Jean Monnet, 1 Louvain-La-Neuve 1348 Belgium Tel: +32(0)10/47.00.80 info@airvision.be www.airvision.be

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Faraday's LawDocument35 pagesFaraday's LawMasterArvinNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Edexcel Physics IGCSE Equations A4 VersionDocument1 pageEdexcel Physics IGCSE Equations A4 Versionlelon81No ratings yet

- 3 Laws of Motion Lesson Plan - KODIGODocument5 pages3 Laws of Motion Lesson Plan - KODIGODaniel LorioNo ratings yet

- List of Physics Derivation STPM Term 1Document4 pagesList of Physics Derivation STPM Term 1Wong Chai YenNo ratings yet

- Gardener Forcc Paid: With PaiseDocument4 pagesGardener Forcc Paid: With PaiseKhelan MehtaNo ratings yet

- Unit 2 - Pos Vel AccDocument1 pageUnit 2 - Pos Vel Accapi-323795755No ratings yet

- Formative Test WORK, ENERGY AND POWERDocument4 pagesFormative Test WORK, ENERGY AND POWERNeil De GuzmanNo ratings yet

- Newton'S 3 Law of Motion: The Law of Action Reaction Law of InteractionDocument27 pagesNewton'S 3 Law of Motion: The Law of Action Reaction Law of InteractionMark Jay BongolanNo ratings yet

- Chapter 2 2-017.2 (Basis)Document3 pagesChapter 2 2-017.2 (Basis)Jamiel CatapangNo ratings yet

- Physics Question BankDocument161 pagesPhysics Question BankNidhiNo ratings yet

- MODUL 1 FizikDocument14 pagesMODUL 1 FizikMohd HafizuddinNo ratings yet

- FIRST Question Is Compulsory: Department of Electrical and Electronics EngineeringDocument1 pageFIRST Question Is Compulsory: Department of Electrical and Electronics EngineeringsyammalaNo ratings yet

- 第2章Document1 page第2章rogerNo ratings yet

- Global Photovoltaic Potential Country RankingsDocument63 pagesGlobal Photovoltaic Potential Country RankingsK'anchaq RamArNo ratings yet

- Chapter 8: Conservation Laws The Continuity EquationDocument7 pagesChapter 8: Conservation Laws The Continuity EquationMadhumika ThammaliNo ratings yet

- Question 871 (Answer For Assignment)Document2 pagesQuestion 871 (Answer For Assignment)Oj GrantNo ratings yet

- Lecture 5 - Energy, Work and PowerDocument4 pagesLecture 5 - Energy, Work and Powergeorgesnomicos_60346No ratings yet

- HSC Physics AnalysisDocument5 pagesHSC Physics AnalysisChris AndersonNo ratings yet

- Department of Education: Science 4Document4 pagesDepartment of Education: Science 4Cherry UnaNo ratings yet

- Derivatives of Follower MotionDocument2 pagesDerivatives of Follower MotionSourabh SinhaNo ratings yet

- AP Physics Uniformly Accelerated Motion LabDocument2 pagesAP Physics Uniformly Accelerated Motion LabinfofluffNo ratings yet

- S7 Q3 Week-1-2Document10 pagesS7 Q3 Week-1-2joan marie PeliasNo ratings yet

- Test Paper Moving Charges and MagnetismDocument17 pagesTest Paper Moving Charges and MagnetismHARSHIT KHANNANo ratings yet

- Distance vs. Displacement: What Is The Difference Between Distance and Displacement?Document21 pagesDistance vs. Displacement: What Is The Difference Between Distance and Displacement?CaloykOoy Danday DueñasNo ratings yet

- Dynamics LectureDocument79 pagesDynamics LectureKarl TuberaNo ratings yet

- Lect13 14 PDFDocument14 pagesLect13 14 PDFKen LouieNo ratings yet

- Physics M1 SolutionsDocument7 pagesPhysics M1 SolutionsjudeNo ratings yet

- Electromagnetic Induction Ravindra KumarDocument21 pagesElectromagnetic Induction Ravindra KumarDakshya Chandra100% (2)

- 1C Electrostatics (64-88)Document25 pages1C Electrostatics (64-88)Arnav Vikas Garg100% (1)

- Circular Motion Study MaterialDocument31 pagesCircular Motion Study MaterialSuchay SawardekarNo ratings yet