Professional Documents

Culture Documents

06 Troubleshooting

Uploaded by

AldiNayafaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 Troubleshooting

Uploaded by

AldiNayafaCopyright:

Available Formats

5.

Troubleshooting

5-1-1 Items to be checked first

1) The input voltage should be rating voltage 10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2) Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 5 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of cables.

Otherwise the airconditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below it is a symptom not related to the

malfunction of the airconditioner.

NO Operation of air conditioner Explanation

1 The STD operation indication LED blinks when a It indicates power is on. The LED stops blinking if the operation

power plug of the indoor unit is plugged in for the first time. ON/OFF button on the remote control unit is pushed.

2 In a COOL operation mode, the compressor does not In happens after a delay of 3 minutes when the compressor is reoper-

operate at a room temperature higher than the setting ated. The same phenomenon occurs when a power is on.

temperature that the IN DOOR FAN should operate. As a phenomenon that the compressor is reoperated after a delay of

In a HEAT operation mode, the compressor does not 3 minutes, the indoor fan is adjusted automatically with reference

operate at a room temperature lower than the setting to a temperature of the air blew

temperature that indoor fan should

operate.

3 Fan speed setting is not allowed in AUTO or DRY mode. The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

4 Compressor stops operation intermittently in DRY mode. Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

5 Compressor of the outdoor unit is operating although it is When the unit is turned off while de-ice is activated, the compressor

turned off in a HEAT mode. continues operation for up to 9 minutes (maximum) until the deice is

completed.

6 Timer LED only of the indoor unit lights up and the Timer is being activated and the unit is in ready mode.

air conditioner does not operate. The unit operates normally if the timer operation is cancelled.

7 The compressor and indoor fan stop intermittently in HEAT The compressor and indoor fan stop intermittently if room temperature

mode. exceeds a setting temperature in order to protect the compressor from

overheated air in a HEAT mode.

8 Indoor fan and outdoor fan stop operation intermittently in The compressor operates in a reverse cycle to remove exterior ice in a

a HEAT mode. HEAT mode, and indoor fan and outdoor fan do not operate intermit-

tently for within 20% of the total heater operation

9 The compressor stops intermittently in a COOL mode or DRY The compressor stops intermittently or the fan speed of the indoor unit

mode, and fan speed of the indoor unit decreases. decreases to prevent inside/outside air frozen depending on the

inside/outside air temperature.

4) Indoor unit observes operation condition of the air conditioner, and displays self diagnosis details

on the display panel.

Display

NO Self Diagnosis

Standard Timer Nature Power

1 (GREEN) X X X Restore from power failure (input initial power)

2 X X X Indoor unit Room sensor Er ror (open or short)

3 (GREEN) X X Indoor unit heat exchanger temperature sensor Error (open or short)

4 X X X Indoor fan malfunctioning (for speed is below 450rpm)

5 X X In case that the communication between the indoor unit and outdoor unit is not made for 60 seconds

Outdoor sensor Error (open or short)

6 (GREEN) X X - Outdoor sensor

- Pipe sensor A, B

7 (GREEN) X The malfunction ot 4way valve in heat mode operation.

Samsung Electronics 5-1

5-1-2 Set up the Model option

❈ If you make the replacement of the ASS’Y CONTROL-IN or MAIN PCB ,

Be sure to be set up the model option as follow the steps

Remote controller operation

Applicable key Display status

method as per the step

1st step

Method)

1 Remove the battery of

remote controller

2 Press the temperature

raise/down key simultane-

ously

3 Insert the battery again

(Result)

If the screen of remocn dis-

plays as shown in the right,

go to the second step

2nd step

Method)

If the first digit of LCD is 0

on the remocon screen, go

to the 3rd step.

❊ If it is 1, press the mode

key once to change to 0

and go to the 3rd step.

3rd step

Method)

Press the marked key to

input the option number.

example) 021E31

Result)

Go to 4th step if it displays

as shown in the right

(The number increases

from 1~9, and A, b, C, d, E,

F whenever pressing the

key.)

5-2 Samsung Electronics

Troubleshooting

Remote controller operation Applicable key Display status

method as per the step

4th step

Method)

After completion of 3rd step,

and if the MODE KEY is

pressed once,

1. 1~3 steps are saved inter -

nally

2. If the first number at the

time is “1”, it is correct and

so go to 5th step

❊ If pressing mode key and

the first digit becomes 0, the

screen of 1~3 steps can be

seen.

5th step

Method)

Pressing the marked key to

input the option number.

example) 142285

Result)

If it displays as shown in the

right go to the 6th step

ERROR MODE 2. When all lamps ( ) are flickering

6th step

1. When the lamp(STANDARD( ), NATURE( ), with the sound of Dididiring,

Method)

TIMER( ) is flickering → failute of option input → The current option input is different from that

When pressing the opera-

tion ON/OFF key with the After removing the set power cord and insert it of already input one: Check the option number

direction of remote con- again, pressing the operation on/off key to retry correctly and if it is correct, press the key once

troller for set, the sound and if the condition is same, EPROM is deffcec- more to input the option. (check correctly)

“Ding, or Diriring is heard tive or misinsertted. So replace the PCB. → If the option is not input at the time and the

and then the input of option all lamps are continuously flickering ; since it is

is completed. the case that the option number is out of the

input range, check the option number again and

❊ Refer to the right side if do again the steps from 1 - 6steps

the error appears.

Samsung Electronics 5-3

Troubleshooting

<Table of the option code>

MODEL OPTION CODE

AD18B1(B2)E09

016223-1000EA

MH18ZA1(A2)-09

AD19B1(B2)E07

015553-1000B7

MH19ZA1(A2)-09

AD19B1(B2)E12

015553-10023F

MH19ZA1(A2)-12

AD24B1(B2)E12

017553-10021d

MH24ZA1(A2)-12

AD26B1(B2)E12

-

MH26ZA1(A2)-12

AD26B1(B2)E07

-

MH26ZA1(A2)-07

5-4 Samsung Electronics

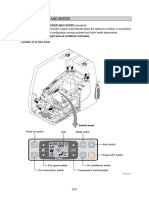

5-2 Checking and Testing Operations (Outdoor Unit)

To complete the installation, perform the following checks and tests to ensure that

the air conditioner is operating correctly.

1. Review all the following elements in the installation:

• Installation site strength

• Piping connection tightness to detect any gas leakages

• Connection wiring

• Heat-resistant insulation of the piping

• Drainage

• Earthing wire connection

• Correct operations (follow the steps below)

• Room select switch in the indoor unit

2. Apply the power to the outdoor unit.

- Check the fuse (250V~, 5A) : The fuse is open when the power line

(L, N) is short.

3. Check the connection of PCB communication of outdoor unit.

OUTDOOR UNIT (Check whether the red LED of outdoor unit PCB is flickering.)

• The communication lamp is flickering after the display of each unit on

the outdoor PCB display part. (every one second).

LED is not flikering, if the connection is bad or the room select switch is

located in the wrong position.

- LED lamp (red) flickering after display of A (0.5 sec)

- LED lamp (red) flickering after display of b (0.5 sec)

- LED lamp (red) flickering after display of C (0.5 sec)

Note : PCB switch “C” is used for triple split multi air conditioner.

Result : If all of three units display lamps are flickering, the connection

wires and the room option connections are good.

If the lamp is not flickering, check as follows:

A. Check the display part of indoor unit of each unit (A,B) after outdoor

unit PCB switch S/W-A is on.

Check the status of each unit indoor room select switch.

A : PCB display (Adjust the select switch suitable to the unit A, B.)

B : Red LED - A unit : STANDARD LED on, TIMER LED flickering

C : PCB switch - B unit : STANDARD LED on, TIMER and NATURE LED flickering

- C unit : STANDARD LED on, TIMER and NATURE, POWER LED

flickering (In case of triple split multi air conditioner)

UNIT STANDARD TIMER NATURE POWER

A

B

C

Lamp ON Lamp OFF Lamp Flasher

B. Check the communication connection of outdoor unit PCB

(Check whether the red LED of outdoor unit PCB is flickering).

The communication lamp is flickering after the display of each unit on the

outdoor unit PCB. (every one second)

- LED lamp (red) is flickering after display of A (0.5 sec)

- LED lamp (red) is flickering after display of b (0.5 sec)

- LED lamp (red) is flickering after display of C (0.5 sec)

Result: If all of three units display lamps are flickering, the connection

wires and the room option connections are good.

4. Check the test operation status by pressing the PCB switch

S/W-A and S/W-B of outdoor unit.

• Check the operation status by pushing the switch one at time.

• Perform the test operation only for the unit selected last.

• Check the pipe pressure and the other operation status during the test

operation.

• Check items when the error occurs during the test operation (each unit)

- Check there is enough refrigerant.

- Check pipe connections.

Samsung Electronics 5-5

Troubleshooting

DISPLAY EXPLANATION REMARK

Outdoor sensor error (Short/Open) Be sure to check after applying the power

to the outdoor unit.

Outdoor A cond pipe sensor er ror (Short/Open)

Outdoor B cond pipe sensor er ror (Short/Open)

Outdoor C cond pipe sensor er ror (Short/Open)

A unit test operation error Display when the test operation finishes.

• When the pipe temperature difference of

B unit test operation error indoor unit (pipe temperature 4 minutes before

- Actual pipe temperature) is less than 5˚C.

C unit test operation error

A unit test communication error Be sure to check during the test operation.

B unit test communication error

C unit test communication error

A,B,C unit all communication error Display of power application.

A room test operation OK Display 4 minutes after the COMP is on.

B room test operation OK

C room test operation OK

•Normal operation

Communication unit number display : A unit Unit A,B and C are changed every one second.

Communication unit number display : B unit The communication lamp is flickering after

display of each unit.

Communication unit number display : C unit (possibility to check the communication status)

•During the test operation the unit under test

(In case of triple split multi air conditioner) is on and off every 0.25s.

Refrigerant leaks

High temperature of the A cond

High temperature of the B cond

5-6 Samsung Electronics

Troubleshooting

5-3 Fault Diagnosis by Symptom

5-3-1 No Power (completely dead)-Initial diagnosis

1) Checklist :

(1) Is input voltage normal?

(2) Is AC power linked correctly?

(3) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2) Troubleshooting procedure

Remove power cord and plug in

again in approx. 5 seconds

Is operation lamp blinking?

NO

YES

YES Does operation start when YES

Is DC voltage of PCB run/stop button on the remote Normal

display normal? controller unit pushed?

NO NO

Is rating voltage ±10% range Is transmission display of the NO Refer to remote control

Replace PCB applied to the remote controller unit blinking? unit fault diagnosis

display primary side (~,~)

of the “BD71” YES

NO Is "beep"sound heard from the main

NO unit?

•Check linkage between YES

power cord and Is DC voltage of the PCB module NO Replace PCB

terminal tap normal? module.

•Check fuse YES

5VDC Is voltage of #60 (indoor fan) of DC12V

the micom normal? YES

Is 14~18VAC appear in Is voltage at SS71(indoor fan)

the secondary side (+, -)

of “BD71” DC5V

NO YES 10ms

YES NO

NO

Check connections Replace

compressor 4-way RY71, RY73,

Replace valve, outdoor fan and RY72 and

SMPS PARTS indoor fan. SS71

Is output voltage of ICO2 normal?

Is voltage at #52 terminal of the micom

normal? YES NO

Check PCB pattern.

Replace ICO2

10ms Replace main PCB.

YES NO

Is voltage output terminal of

Are voltage at #48 and #49 of the TLP180(PC02) normal?

NO micom normal?

YES NO

Replace resonator (X301)

250ns

OK Replace TLP180(pc02)

YES

Is operation normal?

NO Replace

YES micom

OK

Samsung Electronics 5-7

5-3-2 When the power voltage is not available

1) Inspection items

(1) Is the power voltage is normal? (The rating voltage ±10% range)

(2) Is the power cord is correctly connected and is the contact good?

(3) Does the sound “ting” come out with the operation lamp (green) flickering when the

power is applied?

If it is not flickering, do inspect and repair in accordance with the following inspection

sequence.

2) Inspection sequence

Apply the power

Is the operation lamp

No trouble Y of indoor unit on when Y Is the operation lamp flickering with the

(normal) the operation /stop but- sound of “ting”?

ton of remote controller

is pressed?

N

N

Is the communication

N N Check of the installation method

Check of remote signal of remote con- Is the outdoor power connected normally?

controller troller surely sent and and electrical circuit

received ?

Y Y

Is there no problem

Y between the connector

Normal Y

of Ass’y display PCB and Is the fuse (F701, 250V, 3.15A) of PCB open? Replace the fuse (250V, 3.15 A).

the receiving module?

N

N

Replace of Ass'y dis-

play PCB

Is the voltage at Socondary side of trans- N Transformer is out of order -

former of PCB (TN71)? (AC15V~AC25V) replace

Y

Is the output voltage of voltage regulator N Repair and replace the power

IC (KA 7812) DC 10V and 12V? source rectifying diode (D101-

D105) and KA7812.

Y

Is the output voltage of electrostatic voltage N

regulator IC (KA 7805) DC 4.5 V - 5.5 V? KA7805 is out of order - replace

Replace the main PCB of indoor unit

5-8 Samsung Electronics

Troubleshooting

5-3-3 No Power (Outdoor unit)

1) Inspection items

(1) Á Is the power source normal (The rating Voltage ±10% range)?

(2) Is the outdoor power connected normally? ((1) of terminal : L, (2) of terminal : N, (3) of termi-

nal : communication) ?

(3) Check whether the display of outdoor PCB(SEG1) is shown in the order of A- B - C when the

power is applied.

If the display (SEG 1) is not shown the inspection and repair shall be performed in the

sequence of the following:

2) Inspection sequence

Put the power off and put it on after 5

seconds.

Check the com-

Normal of Y munication of PCB Y Is the display of PCB shown in the

outdoor PCB and whether the sequence of A-B-C?

LED 1 is continu-

ously flickering. N

N

Are the power cord ((1) L, (2) N) and N Reinstall the power cord and commu -

communication line (3) of outdoor termi- nication line with the reference of

nal block connected correctly? installation manual.

Y

After watching the display of PCB

Is the terminal of PCB terminal (RY71, N board, assemble the color and

Replace the 72, 73) are assembled in the correct shape of housing correctly as fol-

transformer position? lows:

Y BLK

Replace the fuse Y

Is the fuse open? (F701) BLK

(F701) 250V 3.15A.

N

WHT

Measurement of resistance Insert the primary side of power trans- RED

N of power transformer N former in the terminal GT01 and then is

Are they as follows? the voltage of secondary side normal? RED

1st side 190 ~ 210Ω (AC 15V- AC 25V)

2nd side 0.9 ~ 1.1Ω

Y

Y Y

Is the fuse (F101, 250V 2 A) blown out? Replace the fuse F101 (250V 2 A).

Assemble the transformer

in the normal way. N

N Check and Replace the rectifying

Check whether the output voltage of diode of power side (D101 - D104)

IC01 (KA 7812) is DC 12V. and KA 7812.

Y

N

Check whether the output voltage of Replace the IC 02 (KA7805)

IC02 (KA 7805) is DC 5V.

Y

Replace the outdoor unit Ass'y main PCB.

Samsung Electronics 5-9

Troubleshooting

5-3-4 When the fan of indoor unit does not operate

1) Inspection items

(1) Is the power voltage normal?

(2) Is the connector of indoor fan with the good contact? (CN73)

(3) Is the soldering status of running condenser (CR71) with the good contact?

(4) Is connector of the Hall IC with the good contact (CN 43) ?

(5) Is the indoor fan rotating when it is under operation mode?

(6) Is the FAN LED (green) flickering when the indoor fan stalled (for more than 15 seconds) and

the trouble condition of speed detecting part?

Put the power off and put it on after 5 seconds.

Y

N If the power is not available (indoor

Is the operation lamp flickering for 3 minutes and

then put off? unit), item no 5-3-1.

Y

Error occurs after the Y If the operation /stop button of the remote controller N

indoor unit fan motor is is pressed, is the operation lamp flickering and then Replace of indoor unit PCB Ass'y.

rotating for 15 seconds? is the indoor fan rotating after 5~6 seconds?

(FAN Lamp flickering)

Y

Y

Y Is AC 120V and higher shown across the indoor

Replacement of indoor

unit fan motor. fan connector (CN73) ?

N

N Is the type of MICOM (IC 04) Pin no.

63 old type ?

120Hz

Is the pin no. 12 of IC 06 (KID 65003) N Replace the IC 06 (KID 65003) and

the old type? SS71(G3MB202pl).

120Hz

Is the pin no 25 of MICOM N

Replace Q401 (Ksc 945Y).

the old type?

Replace the indoor unit PCB Ass'y due to the

Micom defect.

5-10 Samsung Electronics

Troubleshooting

5-3-5 When the outdoor unit fan does not operate

1) Inspection items

(1) The outdoor unit fan motor operates only when the operating conditions are satisfied and is

selected by the RY74(LOW) and PY75(HI) to rotate.

(2) Is the power voltage normal?

(3) Is the contact of outdoor unit fan motor (CN 73) good?

(4) Is the winding resistance of outdoor unit fan motor 58Ω at Hi side and 143Ω at low side?

(5) The outdoor unit fan motor operates with Hi at over 28°C and low at below 26°C during the

cooling operation, and operates with Hi at below 14°C and low at over 15°C during the heating

operation.

2) Inspection sequence

Apply the power to the outdoor unit and operate the indoor unit.

N

Is the indoor unit under operating conditions? Normal (operation off)

Y

Y

Is it operating in the High speed?

Normal

N

Is the voltage shown across the connector (1)↔(3) Y Check the winding resistance of outdoor unit fan

((1)↔(5))(the rating voltage ±10% range)? motor winding resistance → Replace

N

Y Contact bad of RY 74(Low), RY 75(High)

Is no. 11 ( 12) of IC 06 at low? (DC 0.7 V)

→ Replace

N

Y Defect of IC06 output

Is pin no. 48(49) of IC 04 (MICOM) at High (DC 5 V)?

→ Replace

N

Is the outdoor unit fan motor under the operating Y Defect of IC 04(MICOM) - replace the IC 04 or PCB

conditions? ass’y

N

Normal

* Operating specification of the FAN of outdoor unit

(1) When the COMP is under the COMP ON condition during the cooling and heating operation,

Hi or LOW operation is selected according to the temperature condition of outdoor room.

(2) When A room and B room are mixed to operate , it is always under low operation.

(3) Perform the comp ON/OFF control in the dry mode.

(4) When it is under the operation of anti-freezing, overload protection, defrost operation, it may

be Low, high or Off.

(5) Hi = High speed, Low = Low speed

Samsung Electronics 5-11

Troubleshooting

5-3-6 When the UP/DOWN Louver Moter Does Not Operate. (Initial Diagnosis)

1) Checklist :

(1) Is input voltage normal?

(2) Is the UP/DOWN louver motor properly connected with the connector (CN61)?

2) Troubleshooting procedure

Remove power cord and plug in again in approx. 5 seconds.

Y

Is operating lamp blinking? Check as in the procedure "No Power

Y parts". Refer to page 5-6.

Does operation start when swing button of the remote con- Y

Normal

trol unit pushed?

Voltage at pin #33-#36 of micom (ICO4) N

Micom (IC04) is faulty.

change?(Squarewave)

Volatge at pin #13, #14, #15, #16 of IC05 (KID65003) N

Driver IC05 (KID65003) is faulty.

change?(Squarewave)

UP/DOWN louver motor is faulty.

5-12 Samsung Electronics

Troubleshooting

5-3-7 If Operation By Remote Control Unit Is Impossible. (Initial Diagnosis)

1) Troubleshooting procedure

Remove power cord and plug in again approx. 5 Seconds

N

Is operation lamp blinking? Check as in the procedure “NO Power

parts”. Refer to page 5-6.

Y

“ “ sound heard from the indoor unit when Y

Normal

ON/OFF button on the remote control unit pushed?

Y

Voltage of battery less than 2.5V (Remote Control Unit)? Replace battery.

N

LCD display status of REMOCON normal? LCD is faulty.

Transmission display lamp ( ) blinking when N

Replace button.

ON/OFF button on the remote control unit pushed?

N

Voltage at PIN #30 of Remocon Micom change? Micom is faulty.

N

Voltage at collecter of Q601 or Q602 change?

Q601(C4375Y) or Q602(C1623Y) is faulty.

Y IR LED(CL-1L5EU) is faulty.

N

Voltage at pin #26 of micom (IC04) change (INDOOR UNIT)?

Receiver module is faulty.

Y

Micom (IC04) is faulty.

Samsung Electronics 5-13

Troubleshooting

5-3-8 When the 4 way valve (A,B) is not operating

1. Inspection items

(1) Are the 4 way valve A and B under the operating conditions?

(When the COMP A (4 way valve A ) and COMP B (4 way valve B) are on during the

heating operating)

(2) Is the power voltage normal?

(3) Is the connecting of 4 way valve A (CN 75) and B (CN 76) good?

2) Inspection sequence

Put off the outdoor unit power and put it on again after 5 seconds.

Select the heating operation of A(B) room by the remote controller.

N

Has 3 minutes passed after selection of A(B) room heating? Keep 4 way valve off.

Y

Y

Is the 4 way valve A(B) on? Normal

N

Is the voltage shown across the 4 way valve A(B) connector Y Defect of RY 76 (RY 77) contact and coil →Replace

(CN 75, CN 76) ? the Relay

N

Y

Is the pin no 47(46) of IC 04 ( MICOM) at high (DC 5V) ? Defect of IC 06 (IC 07 ) output →Replace

N

Y Defect of IC 04(MICOM) - replace the IC 04 or PCB

Is the 4 way valve A (B) under operating conditions?

ass’y

N

Normal

*4 way valve operating conditions

(1) During the defrost control, put the 4 way valve A(B) off.

(2) During the heating operation put the 4 way valve A(B) on.

(3) The changeover of heating to cooling : put the 4 way valve off immediately (in case of B and C

room).

(4) The changeover of cooling to heating : it is on after 170 seconds delay.

5-14 Samsung Electronics

Troubleshooting

5-3-9 When the compressor does not operate

1) Inspection items

(1) Is the COMP A under the operating conditions? (cooling operating of A, B(C) room)

(2) Is the power voltage normal? (the rating voltage ±10% range)

(3) Are the connector connection of COMP A(RY 72, 73) and B(RY 71) good?

(4) The COMP A(B) is operated on and off in accordance with the operating conditions of indoor

unit of A (B. C) room.

2) Inspection sequence

Apply the outdoor power and operate the indoor unit A(B.,C)

in the cooling mode.

N

Is the comp A under the operating condition? Normal (comp A (B ) off)

Y

N

Has 3 minutes passed COMP A(B) after the power initial Keep Comp A (B ) of f

and COMP on/off

Y

Is comp A (B) on? Normal

Y

N *Refer to the power measuring terminal

Is the voltage (the rating voltage ±10% range) shown Y Defect of comp A (B) and running condenser

across the terminal of Comp A(B) power applied? → Replace

Is the voltage of pin no. 14, 13( 15) at low Y Defect of Ry 72, 73 (Comp B) and Ry 71(comp A) con-

(DC 0.7V)? tact and coil → Replace

N

Is the voltage of pin no. 50, 51 (52) of IC 04 (micom) at Y Defect of IC 06 output

high (DC 5V)? → Replace

N

Y Defect of Ic 04 (micom)

Is comp A (B ) under the operating condition?

→ Replace

N

Normal

(comp A (B ) off)

* Comp A (B ) operating conditions

(1) Comp A : Comp on /off control in accordance with the A room during the heating and cooling

indoor unit operation

(2) Comp B : Comp on /off control in accordance with the B(C) room during the heating and cool-

ing indoor unit operation

BLK

RY72

(3) (4)

* Comp A(B ) power measuring terminal BLK

(1) Comp A measuring ; RY 73 (4) ↔ RY 72 (4) (3)

RY71

(4)

(2) Comp B measuring ; RY 71 (4) ↔ RY 72 (4) WHT

RED

(3) Power input ; RY 72 (3) ↔ RY 73(3) (3)

RY73

(4)

RED

Samsung Electronics 5-15

5-4 PCB Inspection

5-4-1 Cautions for Part Replacement

1. The human body carries much static 5. When soldering the lead wires of any new

electricity. Before touching a part for repair, part, be sure to polish them using an emery

replacement or the similar purpose, be sure paper or the like before solding them.

to touch a grounded metallic portion by Since the lead wires of any new part are

hand to let the static electricity go through covered with an oxide film, solder cannot

the matallic portion to the earth. adhere to the lead wires if not polished.

Espectially when handling any micro

computer or IC, carefully remove such static 6. When soldering any part, care should be

electricity before touching them. exercised not to apply any high-wattage

soldering iron to the part for a long time.

2. When repairing any part on a work bench, Some parts are of so low a heat resistance

be sure to place an insulative sheet on the that they may be broken or have the

bench and always keep the sheet surface properties changed if a soldering iron is so

neat without any metal fragments. If any applied (Otherwise, the pattern may

such fragment touches a part, a secondary possibly be separated and raised).

trouble will possibly be caused in the part.

7. The heat of the soldering iron should be

3. Before replacing any parts, be sure to turn transfered to the entire object to be soldered.

off the power supply. If such replacement is If the solder pieces are not well fused due to

done with the power supply kept on, an insufficient transfer of the heat from the

electric shock, short circuit or destruction of soldering iron, no satisfactory electrical

a part may result. continuity can be assured even if the

soldered objects appear well connected to

4. During replacement or repair of a part, each other.

carefully handle it : The printed circuit

board has fine lead wires (jumper wires) and 8. The solder used should be limited to a

glass-made parts (diode) on its substrate. minimum. If excessive solder is used, it will

So if a circuit board is roughly handled, such cause inter-pattern contact, which may

lead wires and parts will be easily broken or cause malfunction of the circuit.

damaged by bending or shock.

5-4-2 Procedure

The parts should be replaced in the following procedure.

Check for any faulty part.

Detach the faulty part.

Replace it with a new part.

Check the operation of the new part.

The repair is completed.

5-16 Samsung Electronics

Troubleshootin

g

5-4-3 Detailed Procedure

No. Malfunction Checking point (symptoms) Causes

1 Pull out the power plug from the 1. Is the broken? 1. Voltage over

AC terminal and confirm the fuse 2. Indoor unit fan motor short-circuit.

on the PCB assembly

2 Turn the power on. Voltage check

If lamp blinks trouble is not

related to the items 1 through 4 1. AC voltage at both end of transformer Primary? 1. Irregular power code or power fuse,

on the right. the rating voltage ±10% range or poor wiring.

2. AC voltage at both end of transformer secondary? 2. Transformer is faulty.

14- 18Vac

3. DC voltage at OUT and GND of IC01 3. Power circuit is faulty.

(KA7812)? 12VDC

4. DC voltage at OUT and GND of IC02? 5VDC 4. Power circuit is faulty.

5. DC voltage at Q201 Base and GND change? 5. Q201 is faulty.

squarewave D101~D104 (IN4007)

3 Set TURBO operating mode when Voltage check

RMC switch pushed after a delay

of 3 minutes. 1. Voltage of relay (RY71, 72, 73) coil Voltage at 1. Relay(RY 71) coil is open.

(A-unit and B-unit) pin#13, 14, 15 of IC07 : 12VDC IC6(KID65003A) is faulty.

2. Voltage at RY72 No 3 and RY71 No 3 , 2. Relay contactor is faulty or Relay is

RY72 No 3 and RY73 No 3 , the rating voltage faulty

±10% range

4 Set operating mode when RMC 1. Compressor does not operate. 1. Temperature of Heat exchange

switch pushed. is lower.

1. TURBO mode

2. PCB is faulty.

3. Room sensor or Heat exchanger

temperature sensor is faulty

5 Set operating mode when 1. Voltage at 3 5 both ends of CN73 : 1. Indoor unit fan motor is faulty.

RMC switch pushed. above 180V~

1. [FAN] mode

2. Fan speed [Hi] 2. Indoor unit fan motor does not operate. 2. Poor connection of indoor fan motor

3. Continuously operation and connector of RPM sensing (CN43)

Samsung Electronics 5-17

5-5 Fault Diagnosis of Major Parts

Parts Diagnosis

Temp.Sensor Measure resistance with a tester.

Heat ex. Sensor Normal 8KΩ~27KΩ at ambient temperature (+0°C ~ +30°C)

Abnormal ∞, O Ω … open or short

Indoor Fan Motor Measure resistance between terminals (CN73) with a tester

Normal At ambient temperature (10°C ~ 30°C)

between Resistance

Red, Yellow 190 ±10Ω

Red, Blue 170 ±10Ω

Abnormal

Measure the voltage between ground and signal wire of the fan motor (CN43)

Normal

between Voltage

Gray, Orange 05V~4.5V

Yellow, Orange 5V

Abnormal Abnormal if voltage does not change from 0V to 5V.

Outdoor Fan Motor Normal At ambient temperature (10°C ~ 30°C)

between Resistance Remark

Red, Yellow 143±10Ω Low

Blue, Red 58±10Ω High

Abnormal ∞, O Ω … open or short

Stepping Motor Measure resistance between red wire and each terminal.

(UP/DOWN swing motor) Normal Approx. 380Ω at ambient temperature (20°C ~30°C)

Abnormal ∞, O Ω … open or shor t

5-18 Samsung Electronics

MEMO

Samsung Electronics 5-19

You might also like

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Fujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Troubleshooting: 12-1 Basic Breakdown Diagnosis ItemsDocument9 pagesTroubleshooting: 12-1 Basic Breakdown Diagnosis ItemsKönyves GergelyNo ratings yet

- Samsung AQV Inverter Service ManualDocument6 pagesSamsung AQV Inverter Service ManualkelleterreNo ratings yet

- AQ12FANDocument9 pagesAQ12FANhdave32No ratings yet

- YR-F02 Manual HighlightsDocument12 pagesYR-F02 Manual HighlightsDioneNo ratings yet

- Troubleshooting: 12-1 Items To Be Checked FirstDocument22 pagesTroubleshooting: 12-1 Items To Be Checked FirstgcharalNo ratings yet

- RS20CCSLDocument4 pagesRS20CCSLJorge JaramilloNo ratings yet

- High Wall Inverter Service ManualDocument16 pagesHigh Wall Inverter Service ManualEsteban Andres FigueroaNo ratings yet

- Alignment and AdjustmentDocument6 pagesAlignment and AdjustmentZoran19731No ratings yet

- Troubleshooting: 4-1 Setting Option Setup MethodDocument26 pagesTroubleshooting: 4-1 Setting Option Setup Methodsonic8659No ratings yet

- Operator Manual - ClimaAIRE II - ENGDocument2 pagesOperator Manual - ClimaAIRE II - ENG2ndpostaNo ratings yet

- Sharp Ops PDFDocument28 pagesSharp Ops PDFsonubudsNo ratings yet

- Wired Remote Controller: Model Spx-Rck3Document10 pagesWired Remote Controller: Model Spx-Rck3Valentin BanicaNo ratings yet

- 1812 说明书-25TDocument37 pages1812 说明书-25Tjackson camilo tovar gonzalezNo ratings yet

- Fault CodesDocument6 pagesFault CodesLuis Miguel Mojica AgudeloNo ratings yet

- AE CC 01 ManualDocument18 pagesAE CC 01 ManualZawYeLinNo ratings yet

- TroubleshootingDocument13 pagesTroubleshootinggladiaNo ratings yet

- Troubleshooting: 12-1 Items To Be Checked FirstDocument22 pagesTroubleshooting: 12-1 Items To Be Checked FirstZoran19731No ratings yet

- Functions and operation guide for refrigeration productDocument12 pagesFunctions and operation guide for refrigeration productFrederman RodasNo ratings yet

- A CDocument11 pagesA CPutra JawaNo ratings yet

- User Manual Ac750 Af555 PDFDocument4 pagesUser Manual Ac750 Af555 PDFPatrick O'neillNo ratings yet

- User Manual - YCZ-A003 PDFDocument37 pagesUser Manual - YCZ-A003 PDFEdward ToroNo ratings yet

- Carel Pjez Field GuideDocument2 pagesCarel Pjez Field GuideFrio GobalNo ratings yet

- User Manual: Hasr09A Hasc09A Hasr12A Hasc12A Hasr24A Hasc24A Hasr30C Hasc30CDocument28 pagesUser Manual: Hasr09A Hasc09A Hasr12A Hasc12A Hasr24A Hasc24A Hasr30C Hasc30CPeter WilliamsNo ratings yet

- 8 Series Service GuideDocument34 pages8 Series Service GuidetrutleptNo ratings yet

- Stulz C-Tech 10Document8 pagesStulz C-Tech 10Ismet KoracNo ratings yet

- NA6888 User GuideDocument5 pagesNA6888 User GuideSergio SantosNo ratings yet

- Test refrigerator functions and troubleshoot issuesDocument45 pagesTest refrigerator functions and troubleshoot issuesInderNo ratings yet

- Ducted (71DQ6A54010)Document22 pagesDucted (71DQ6A54010)memelo3No ratings yet

- Temptron 616 Operation ManualDocument21 pagesTemptron 616 Operation Manualcamilo go100% (1)

- SH 09 12 BPH X Service ManualDocument52 pagesSH 09 12 BPH X Service ManualBobi GorgievskiNo ratings yet

- SAT Support Info 1110a PDFDocument12 pagesSAT Support Info 1110a PDFQuang PhanNo ratings yet

- Arc452a4 PDFDocument21 pagesArc452a4 PDFVõ Hoàng Nhật KhánhNo ratings yet

- Pro T701 Thermostat Operations Manual ENDocument6 pagesPro T701 Thermostat Operations Manual ENTerrence JonesNo ratings yet

- Gree AC Modes SummaryDocument28 pagesGree AC Modes SummaryossadentNo ratings yet

- User's Manual: Remote ControllerDocument8 pagesUser's Manual: Remote ControllerAnoolNo ratings yet

- TroubleshootingDocument34 pagesTroubleshootingFernando MadeiraNo ratings yet

- MTS-SUPER MTSC-SUPER - Operating ManualDocument40 pagesMTS-SUPER MTSC-SUPER - Operating ManualhectorNo ratings yet

- BM2 24H+Installation+InstructionsDocument7 pagesBM2 24H+Installation+InstructionsremediospereiraNo ratings yet

- 3-5 Aire AcondicionadoDocument7 pages3-5 Aire AcondicionadoJorge RojasNo ratings yet

- Inventor Manual IDIDocument47 pagesInventor Manual IDIDani100% (1)

- CP Preeva DG Fx05Document12 pagesCP Preeva DG Fx05King_bear87No ratings yet

- Gree Remote Controller ManualDocument9 pagesGree Remote Controller Manualshoaib hassanNo ratings yet

- Wired Controller XK01Document42 pagesWired Controller XK01leonardo aldunate cisternasNo ratings yet

- Frigidaire AEQ7000CES1 Dryer Tech SheetDocument8 pagesFrigidaire AEQ7000CES1 Dryer Tech Sheetservice4u51No ratings yet

- Service Manual Air ConditionerSAMSUNGDocument47 pagesService Manual Air ConditionerSAMSUNGClaudiu Radu100% (1)

- Haier Manual y Fallas InglesDocument44 pagesHaier Manual y Fallas Inglesvladimir11071No ratings yet

- NA6843 User Guide SummaryDocument5 pagesNA6843 User Guide SummaryFelixPNo ratings yet

- Reference InformationDocument48 pagesReference InformationproyectoariesNo ratings yet

- 151LDocument60 pages151LGuillermo HernandezNo ratings yet

- Airwell Dci Inverter Diagnostics Air SMDocument8 pagesAirwell Dci Inverter Diagnostics Air SMJorge Marrero DiazNo ratings yet

- T616 enDocument19 pagesT616 enZulfiqar AliNo ratings yet

- Pehd 16 25Document32 pagesPehd 16 25FUEN_MURCIA100% (1)

- Reemote-C-man MC ENDocument12 pagesReemote-C-man MC ENOlger Saul Alfaro DuarteNo ratings yet

- Install Air Conditioner ManualDocument20 pagesInstall Air Conditioner ManualGUSTAVO FREIRENo ratings yet

- 0eb748d60c5c70256637df5444a5ce2bDocument10 pages0eb748d60c5c70256637df5444a5ce2bh5ghf3yerNo ratings yet

- Manual Remote ControllerDocument106 pagesManual Remote ControllerMarian Nicolae HenzuleaNo ratings yet

- Alegria Remote Controller Manual1 PDFDocument8 pagesAlegria Remote Controller Manual1 PDFOscarRaudalesNo ratings yet

- Operating Instructions: For Model Laboratory RefrigeratorDocument5 pagesOperating Instructions: For Model Laboratory RefrigeratorPablo González de PazNo ratings yet

- Robin Grayson Gold Recovery Method73Document1 pageRobin Grayson Gold Recovery Method73Senthilkumar PragasamNo ratings yet

- Goat Milking Stand Plans PDFDocument6 pagesGoat Milking Stand Plans PDFcowboyNo ratings yet

- Catalogue - Hilux - 2021 (1) - 0Document6 pagesCatalogue - Hilux - 2021 (1) - 0Hermawan AnggraeniNo ratings yet

- Nero Soundtrax ManualDocument54 pagesNero Soundtrax ManualrbNo ratings yet

- Kyocera FS-600 Parts Manual PDFDocument19 pagesKyocera FS-600 Parts Manual PDFliviumaraNo ratings yet

- PMAS-Arid Agriculture University RawalpindiDocument3 pagesPMAS-Arid Agriculture University RawalpindiAli AzanNo ratings yet

- Implementation of Shortest Path in Packet Switching Network Using Genetic AlgorithmDocument6 pagesImplementation of Shortest Path in Packet Switching Network Using Genetic Algorithmeditor_ijarcsseNo ratings yet

- Calculatio SheetDocument88 pagesCalculatio SheetLe LeNo ratings yet

- 3 Voter CounterDocument12 pages3 Voter CounterSheikh Abdul Wahab100% (2)

- Coil Caliburn GDocument1 pageCoil Caliburn GLukman Arsyanto WibowoNo ratings yet

- Easyscan2 Short ManualDocument8 pagesEasyscan2 Short ManualRamon RelosaNo ratings yet

- Multimaster 300 XDocument2 pagesMultimaster 300 Xcamelod555No ratings yet

- Brown Slidey T-PlansDocument4 pagesBrown Slidey T-PlansPhillipe El Hage0% (1)

- RDshimano 5500 ManualDocument4 pagesRDshimano 5500 ManualOleg MelnikovNo ratings yet

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Las 2Document3 pagesLas 2James Honrubia (titobibot)No ratings yet

- Estimating Power Demand Using Diversity FactorDocument31 pagesEstimating Power Demand Using Diversity FactorRamesh Ananthanarayanan0% (1)

- Chapter 10Document9 pagesChapter 10J.K HomerNo ratings yet

- DBMS Lab ManualDocument199 pagesDBMS Lab ManualMoulika Chowdary100% (1)

- Choke SlideDocument23 pagesChoke SlideCharles Adefemi Omowole100% (1)

- Linear Programming: Artificial Variable Technique: Big - M MethodDocument4 pagesLinear Programming: Artificial Variable Technique: Big - M MethodFatima Al-DoskiNo ratings yet

- M-Tech Industrial Training Report on Production Management at KELDocument51 pagesM-Tech Industrial Training Report on Production Management at KELniyassalim100% (1)

- (Multi V Task) Technical Seminar - Multi V AHU Solution - FinalDocument36 pages(Multi V Task) Technical Seminar - Multi V AHU Solution - FinalPaulo Augusto GarayNo ratings yet

- NetWare Is A Network Operating System Developed by NovellDocument23 pagesNetWare Is A Network Operating System Developed by NovellIndhukanth PvNo ratings yet

- Larsson Quotation Sample Lsh320m-0.4-VvvfDocument7 pagesLarsson Quotation Sample Lsh320m-0.4-VvvfvinayNo ratings yet

- Srs On Quora Com 364482795 Srs On Quora ComDocument13 pagesSrs On Quora Com 364482795 Srs On Quora Comayush dwivediNo ratings yet

- Ieee 1578-2007 PDFDocument32 pagesIeee 1578-2007 PDFNataGBNo ratings yet

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoNo ratings yet

- Check Valve VickersDocument15 pagesCheck Valve Vickersعلي عائشة100% (1)

- Schneider Price ListDocument22 pagesSchneider Price ListAbhishek RajputNo ratings yet