Professional Documents

Culture Documents

APP A Detail Site Survey Work Plan - Rawa

APP A Detail Site Survey Work Plan - Rawa

Uploaded by

Nurcahyo Djati WOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APP A Detail Site Survey Work Plan - Rawa

APP A Detail Site Survey Work Plan - Rawa

Uploaded by

Nurcahyo Djati WCopyright:

Available Formats

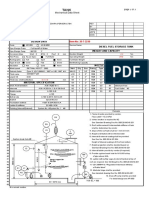

Detail Site Survey Work Plan - Piping Eng Dept.

Rawa Power Generation Project FEL-3

ConocoPhillips (Grissik) Ltd

PIPING

Day Date Time Activities

1 18-Dec-12 06:00 ~ 08:00 Travel from Soekarno Hatta Airport (Jakarta) to Jambi Airport

08:00 ~ 11:00 Travel from Jambi Airport to Grissik Station

11:00 ~ 14:00 Administration, permit and Safety induction

2 19-Dec-12 RAWA STATION

05:30 - 06:30 Break Fast

06:30 - 07:00 Preparation (working briefing/orientation)

07:00 ~ 12:00 Take photos and check equipments space & location, ensure enough

space for equipment itself and pipe routing. The Equipments : Fuel Gas

Filter Coalescer, Gas Engine Generator, Lube Oil Drain Sump.

Take photos and check pipe support existing based on pre-feed piping

plan layout

1. Has proper location

2. Any clash with pipe or other discipline

3. Sketch required detail support

Take photos, check and identify availibility tie-in point

1. TP-003: Install a new line 2"-GF-AA1-60-0470-H with (1ea) 150# RF

flange and 3"-AA Ball Valve tie in to line existing 2"-GF-AA1-60-0234.

2. TP-004: Install a new line 2"-GF-AA1-60-0480-H with (2ea) 150# 2" RF

flange tie in to Fuel Gas Filter Coalescer Skid 60SAJ-001A.

3. TP-005: Install a new line 2"-GF-AA1-60-0517-H with (2ea) 150# 2"

RF flange tie in to Fuel Gas Filter Coalescer Skid 60SAJ-001A.

4. TP-006: Install a new line 2"-VA-AA2-60-0515 with (1ea) 150# 1" RF

flange tie in to outlet 60-PSV-0108.

1. TP-014: Install a new line 2"-GF-AA1-60-0471-H with (2ea) 150# 2" RF

flange tie in to Fuel Gas Filter Coalescer Skid 60SAJ-001B.

2. TP-015: Install a new line 2"-GF-AA1-60-0524-H with (2ea) 150# 2" RF

flange tie in to Fuel Gas Filter Coalescer Skid 60SAJ-001B.

3. TP-016: Install a new line 2"-VA-AA2-60-0522 with (1ea) 150# 1" RF

flange tie in to outlet 60-PSV-0208.

12.00 ~ 13.00 Lunch Break

13.00 ~ 16.00 Take photos, check and identify availibility tie-in point

1. TP-007: Install a new line no. 2"-GF-AA1-60-0532, tie in to Gas Engine

Generator 82SEG-001A with 150# 1" RF Flange.

2. TP-008: Install a new line no. 8"-VA-AA2-82-0473, tie in from Gas

Engine Generator 82SEG-001A with 150# 8" RF Flange to Exhaust to Safe

Location.

3. TP-009: install a new line with (1 ea) 1"-BA-GA-8-1-0549 Ball Valve,

and (1 ea) 1”-150# Flanges from 82SEG-001A to Drain Bucket.

4. TP-010: install a new line with (1 ea) 2"-BA-AA-3-1-0550 Ball Valve,

and (1 ea) 2”-150# Flanges from 82SEG-001A to Drain Bucket.

5. TP-011: install a new line with (1 ea) 2"-BA-AA-3-1-0551 Ball Valve,

and (1 ea) 2”-150# Flanges from 82SEG-001A to Drain Bucket.

6. TP-012: Install a new line no. 2"-OL-AA2-82-0518, tie in from Gas

Engine Generator 82SEG-001A with 150# 1" RF Flange and (1ea) 1"-BA-

GA-8-1-0552 Ball Valve to Lube oil Drain Sump.

7. TP-013: install 3/4" SS tubing with (1 ea) 3/4”-150# Flanges from

82SEG-001A to Instrument Air System.

16:00 ~ 17:00 Wrap-up

Detail Site Survey Work Plan - Piping Eng Dept.

Rawa Power Generation Project FEL-3

ConocoPhillips (Grissik) Ltd

PIPING

Day Date Time Activities

3 20-Dec-12 05:30 - 06:30 Break Fast

06:30 - 07:00 Preparation (working briefing/orientation)

07:30 ~ 11:30 Continue take photos, check and identify availibility tie-in point

8. TP-017: Install a new line no. 8"-GF-AA1-60-0481, tie in to 82SEG-

001B with 150# 1" RF flange.

9. TP-018: Install a new line no. 8"-VA-AA2-82-0475, tie in from Gas

Engine Generator 82SEG-001B with 150# 8" RF Flange to Exhaust to Safe

Location.

10. TP-019: install a new line with (1 ea) 1"-BA-GA-8-1-0558 Ball Valve,

and (1 ea) 1”-150# Flanges from 82SEG-001B to Drain Bucket.

11. TP-020: install a new line with (1 ea) 2"-BA-AA-3-1-0559 Ball Valve,

and (1 ea) 2”-150# Flanges from 82SEG-001B to Drain Bucket.

12. TP-021: install a new line with (1 ea) 2"-BA-AA-3-1-0560 Ball Valve,

and (1 ea) 2”-150# Flanges from 82SEG-001B to Drain Bucket.

13. TP-022: install a new line with (1 ea) 1"-BA-GA-8-1-0051 Ball Valve,

and (1 ea) 1”-150# Flanges from 82SEG-001B to Lube Oil Drain Sump.

14. TP-023:install 3/4" SS tubing with (1 ea) 3/4”-150# Flanges from

82SEG-001B to Instrument Air System.

12:00 ~ 13:00 Lunch Break

13:00 ~ 16:00 KERI CAMP

Take photos and check equipments space & location, ensure enough

space for equipment itself and pipe routing. The Equipments : Diesel

Engine Generator, Diesel Storage Tank.

Take photos and check pipe support existing based on pre-feed piping

plan layout

1. Has proper location

2. Any clash with pipe or other discipline

3. Sketch required detail support

Take photos, check and identify availibility tie-in point

14. TP-001: Install a new line no. 2"-OF-AA1-68-0477, tie in to Diesel

Engine Generator 84SEG-002 with 150# 3/4" RF Flange.

15. TP-002:install a new line with (1 ea) 3/4"-BA-GA-8-1-0037 Ball Valve,

and (2 ea) 3”-150# Flanges from 84SEG-002 to Drain Bucket.

16. TP-024: install a new line with (1 ea) 3/4"-BA-GA-8-1-0021 Ball Valve,

and (2 ea) 3”-150# Flanges from 84SEG-002 to Drain Bucket.

17. TP-025: install a new line with (2 ea) 3”-150# Flanges from 84SEG-002

to Drain Bucket.

16:00 ~ 17:00 Wrap-up

4 21-Dec-12 06:00 ~ 08:00 Close out administration

08:00 ~ 14:00 De-mobilization from Sumpal to Jambi Airport

15:00 ~ 17:00 Flight back to Jakarta

Employee Signature Lead Engineer

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mazda5 Manual ServiceDocument344 pagesMazda5 Manual Servicegosman iosifNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mack Vmac III E7 Etech Wiring PDFDocument9 pagesMack Vmac III E7 Etech Wiring PDFGustavo PaezNo ratings yet

- Toyota Caldina ST-215 1999 ECU PinoutDocument7 pagesToyota Caldina ST-215 1999 ECU PinoutIshtiaq Arain88% (16)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Engine Disassembly PDFDocument15 pagesEngine Disassembly PDFMichael Hernandez50% (4)

- DUCATI HyperMotard SP Work Shop ManualDocument881 pagesDUCATI HyperMotard SP Work Shop ManualAnonymous omGSHUEQ100% (3)

- Crane ds1Document2 pagesCrane ds1Nurcahyo Djati WNo ratings yet

- Suzuki DT6 (84-85)Document30 pagesSuzuki DT6 (84-85)OsPetersonNo ratings yet

- Diesel Tank SizingDocument7 pagesDiesel Tank SizingNurcahyo Djati W100% (2)

- CNG O&MDocument15 pagesCNG O&MNurcahyo Djati W0% (1)

- MH-WH Instruction ManualDocument107 pagesMH-WH Instruction Manualsercopetrol67% (6)

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- 2012 01 - Pipeline Route Selection Right of Way - Mustang PDFDocument3 pages2012 01 - Pipeline Route Selection Right of Way - Mustang PDFNurcahyo Djati WNo ratings yet

- Examen de Mecanica AutomotrizDocument2 pagesExamen de Mecanica AutomotrizOmarzinho Hualmayuno100% (1)

- Capex Opex..Document6 pagesCapex Opex..Nurcahyo Djati WNo ratings yet

- VENDOR LIST CNG As 100510Document4 pagesVENDOR LIST CNG As 100510Nurcahyo Djati WNo ratings yet

- Air Compressor DWGDocument1 pageAir Compressor DWGNurcahyo Djati WNo ratings yet

- Blowdown RepDocument3 pagesBlowdown RepNurcahyo Djati WNo ratings yet

- Basic Testing Pajero 1991Document12 pagesBasic Testing Pajero 1991nadaNo ratings yet

- EASA TCDS E.067 - Issue 02 - 20180417Document12 pagesEASA TCDS E.067 - Issue 02 - 20180417je_carD23No ratings yet

- Dmm-II Assignment TestDocument2 pagesDmm-II Assignment TestSai Srinivas BodapatiNo ratings yet

- PDF Caterpillar 3516 CompressDocument60 pagesPDF Caterpillar 3516 CompressPhạm Hữu PhướcNo ratings yet

- Yamaha XT250 Parta Cataloge 1980-1984Document56 pagesYamaha XT250 Parta Cataloge 1980-1984Haragán Del MonteNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 091252-1049-E1Document29 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 091252-1049-E1Blayne OsbornNo ratings yet

- Web8 PDFDocument6 pagesWeb8 PDFSampurnoNo ratings yet

- 53 WK 57Document44 pages53 WK 57Navid EbrahimniaNo ratings yet

- L10 - M11 - ISM CPL Short Block and Long Block Cross ReferenceDocument19 pagesL10 - M11 - ISM CPL Short Block and Long Block Cross ReferencesolutionsmcNo ratings yet

- Hks Evc4 ManualDocument13 pagesHks Evc4 ManualDustin SetayeshNo ratings yet

- Studi Kasus Kerusakan Silinder Liner Engine PC PDFDocument46 pagesStudi Kasus Kerusakan Silinder Liner Engine PC PDFApril KukuhNo ratings yet

- Caterpillar Engine Service Manual CT S Eng d353Document7 pagesCaterpillar Engine Service Manual CT S Eng d353CarlosNo ratings yet

- Electric Diagram: YZF155 2019 (B2P1)Document3 pagesElectric Diagram: YZF155 2019 (B2P1)Devi KhoirudinNo ratings yet

- SECTION 303-12 Intake Air Distribution and Filtering - 2.0L Duratec-HE (MI4) /2.3L Duratec-HE (MI4)Document7 pagesSECTION 303-12 Intake Air Distribution and Filtering - 2.0L Duratec-HE (MI4) /2.3L Duratec-HE (MI4)Tiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- C8D5,C11D5 (0050,1.1) new-1Document107 pagesC8D5,C11D5 (0050,1.1) new-1service.petrenkoNo ratings yet

- Fdocuments - in 2002 Mitsubishi Fuso Truck Fm657 Service Repair Manual 1595638455Document14 pagesFdocuments - in 2002 Mitsubishi Fuso Truck Fm657 Service Repair Manual 1595638455simonruiz1No ratings yet

- Iveco N45 Tm2aDocument3 pagesIveco N45 Tm2aDave Wallace100% (2)

- Benelli Leoncino 500 Parts ListDocument74 pagesBenelli Leoncino 500 Parts ListollebliajimNo ratings yet

- PC 99907 2605 01 FH500V As19 enDocument14 pagesPC 99907 2605 01 FH500V As19 enSaša JuraNo ratings yet

- PROCEDIMIENTO - Cylinder Head - DisassembleDocument9 pagesPROCEDIMIENTO - Cylinder Head - DisassembleSERTECC SASNo ratings yet

- The Path To Misfire DetectionDocument9 pagesThe Path To Misfire DetectionDaniel Dario Greig SalazarNo ratings yet

- Engine Data SheetDocument2 pagesEngine Data SheetFolk ThiagoNo ratings yet