100% found this document useful (3 votes)

983 views7 pagesDiesel Tank Sizing

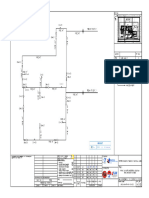

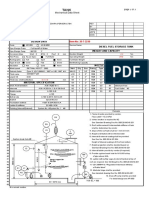

This document provides calculations for sizing a diesel day tank. It determines that the required total working volume for the tank is 2.835 cubic meters based on the diesel production capacity and estimated total holding time. The working volume of the provided tank is 2.84 cubic meters, which meets the required volume. The document also includes calculations to determine dimensions for the bottom outlet nozzle and working height of the tank.

Uploaded by

Nurcahyo Djati WCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

983 views7 pagesDiesel Tank Sizing

This document provides calculations for sizing a diesel day tank. It determines that the required total working volume for the tank is 2.835 cubic meters based on the diesel production capacity and estimated total holding time. The working volume of the provided tank is 2.84 cubic meters, which meets the required volume. The document also includes calculations to determine dimensions for the bottom outlet nozzle and working height of the tank.

Uploaded by

Nurcahyo Djati WCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd