Professional Documents

Culture Documents

Dmm-II Assignment Test

Uploaded by

Sai Srinivas Bodapati0 ratings0% found this document useful (0 votes)

21 views2 pagesOriginal Title

Dmm-II Assignment test

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesDmm-II Assignment Test

Uploaded by

Sai Srinivas BodapatiCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Assignment test 3 & 4

1) A leather belt 9 mm × 250 mm is used to drive a cast iron pulley 900 mm

in diameter at 336 r.p.m. If the active arc on the smaller pulley is 120° and

the stress in tight side is 2 MPa, find the power capacity of the belt. The

density of leather may be taken as 980 kg/m3, and the coefficient of friction

of leather on cast iron is 0.35.

2) It is required to design a V-Belt drive to connect a 7.5kW, 1440rpm

induction motor to a fan, running at approximately 480rpm, for a service of

24hr per day. Space is available for a centre distance of about 1m

3) It is required to design a chain drive to connect a 5 kW, 1400 rpm electric

motor to a drilling machine. The speed reduction is 3:1.The centre distance

should be approximately 400 mm. (i) Select a proper roller chain for the

drive (ii) Determine pitch circle diameters of driving and driven sprockets iii)

Determine the number of chain links (iv) Specify the correct centre distance

between the axis of sprockets.

4) A double- threaded power screw, with ISO metric trapezoidal threads, is

used to raise a load of 300 kN. The nominal diameter is 100 mm and the pitch

is 12 mm. The coefficient of friction at screw threads is 0.15.Neglecting

collar friction, Calculate: (i) torque required to raise the load (ii) torque

required to lower the load and (iii) efficiency of the screw.

5) A pair of worm and worm wheel is designated as 3/60/10/6.The worm is

transmitting 5 KW power at 1440 rpm to the worm wheel. The coefficient of

friction is 0.1 and the normal pressure angle is 200. Determine the

components of the gear tooth force action on the worm and the worm wheel.

Assignment 5

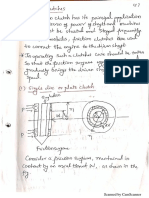

1) Design a cast iron piston for a single acting four stroke diesel engine

with the following data Cylinder bore = 300mm Length of stroke =

250mm Speed = 600 rpm Brake mean effective pressure = 0.6 MPa

Maximum gas pressure = 4MPa Fuel consumption = 0.25 kg per BP

per h l/d ratio for bush in small end of connecting rod = 1.5 Assume

suitable data if required and state the assumptions made.

2) A four stroke diesel engine has the following specifications Brake

power = 5 kW, Speed = 1200 rpm, indicated mean effective pressure =

0.35 N/mm2, Mechanical efficiency = 80%. Determine i) Bore and

length of the cylinder ii) Thickness of the liner iii) Thickness of the

cylinder head iv) Size, number and pitch of studs.

3) Design a trunk type cast iron piston for a 4-stroke diesel engine with

the following specifications: cylinder bore = 250 mm, stroke length =

375 mm, speed = 600 rpm, maximum gas pressure = 5 MPa, indicated

mean effective pressure = 0.8 MPa, rate of fuel consumption = 0.3

Kg/BP/H, higher calorific value of fuel = 44 MJ/Kg, mechanical

efficiency = 80%. Sate clearly the design decision taken.

4) A connecting rod is to be designed for a high speed, four stroke IC

engine. The following data are available. Piston diameter=88mm;

Mass of reciprocating parts=1.6kg; Length of the connecting rod

(centre to centre)=300mm; Stroke=125mm; RPM=2200 (when

developing 50kw); Possible over speed=3000rpm; compression ration

= 6.8:1; Probable explosion pressure=3.5MPa. Design and draw fully

dimensioned drawing of the connecting rod.

5) The following data is given for the cap and bolts of the big end of the

connecting rod. Engine speed=1500rpm length of the connecting rod

=320mm length of stroke=140mm mass of reciprocating parts=1.75kg

length of crank pin=54mm diameter of the crank pin=38mm

permissible tensile stress for the bolts=120MPa permissible bending

stress for cap=120MPa Calculate the nominal diameter of the bolts and

thickness of the cap for the big end.

6) A cylinder of a four stroke diesel engine has the following

specifications: Brake power = 5 kW Speed = 600 rpm Indicated mean

effective pressure = 0.5 MPa Make suitable assumptions and calculate

a) Bore and length of the cylinder liner b) Thickness of the cylinder

liner c) Thickness of the cylinder head.

You might also like

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- AECD QuestionsDocument7 pagesAECD QuestionssbkNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- Jomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyDocument2 pagesJomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyEric MajaoNo ratings yet

- AT8611 Lab QuestionsDocument9 pagesAT8611 Lab QuestionsChirpiNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411No ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- Akışkanlar Mek.Document6 pagesAkışkanlar Mek.Sai PranayNo ratings yet

- Chapter Wise Questions Bank MD-iiDocument6 pagesChapter Wise Questions Bank MD-iiinderpreet singhNo ratings yet

- IC engine component design problemsDocument4 pagesIC engine component design problemsTamene TesfayeNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Machine Design I TutorialDocument3 pagesMachine Design I TutorialbngelotrNo ratings yet

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- Dts Important Ques 2 16 MarksDocument5 pagesDts Important Ques 2 16 MarksBas RamuNo ratings yet

- Design of Transmission System-QbDocument5 pagesDesign of Transmission System-QbGanapathi SekaranNo ratings yet

- 3 Tutorial IC EngineDocument3 pages3 Tutorial IC EnginevattuNo ratings yet

- FlywheelDocument2 pagesFlywheelSaravanan MathiNo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- Design of Transmission Systems - Important QuestonsDocument5 pagesDesign of Transmission Systems - Important QuestonsPost BoxNo ratings yet

- IC Engine PartsDocument2 pagesIC Engine PartsSushil Kumar SinghNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- I Assignment - MTech - DPTDocument1 pageI Assignment - MTech - DPTDaniel C. RibuNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Me 2352 - DTS Q BankDocument5 pagesMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Me 7 Sem Design of Mechanical Drives 3560 Summer 2019Document2 pagesMe 7 Sem Design of Mechanical Drives 3560 Summer 2019djniksthehearteditorNo ratings yet

- Design of Transmission SystemsDocument6 pagesDesign of Transmission SystemsSelva KumarNo ratings yet

- Some Possible QuestionsDocument1 pageSome Possible QuestionsMANIKANDAN S (PA2011002040064)No ratings yet

- Design of Transmission Systems Model ExamDocument3 pagesDesign of Transmission Systems Model ExamrajkumardotcomNo ratings yet

- Me 7 Sem Design of Mechanical Drives Winter 2017Document2 pagesMe 7 Sem Design of Mechanical Drives Winter 2017djniksthehearteditorNo ratings yet

- DMDDocument4 pagesDMDSantosh AloneNo ratings yet

- Machine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsDocument3 pagesMachine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsNILESH SUTHARNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- MGM College of Engineering Assignment on Machine Design ProblemsDocument1 pageMGM College of Engineering Assignment on Machine Design ProblemsmrinalsinghrawatNo ratings yet

- Design of Transmission Systems examDocument3 pagesDesign of Transmission Systems examCyril JasonNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Tutorial 02 Turning Moment Diagram and Flywheel - 2Document1 pageTutorial 02 Turning Moment Diagram and Flywheel - 2snafuxxspartanNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Team SkillsDocument11 pagesTeam SkillsSai Srinivas BodapatiNo ratings yet

- ConveyersDocument10 pagesConveyersSai Srinivas BodapatiNo ratings yet

- Feasibility Criteria ApproachDocument10 pagesFeasibility Criteria ApproachSai Srinivas BodapatiNo ratings yet

- TEAM SKILLS GROUP PROJECTDocument11 pagesTEAM SKILLS GROUP PROJECTSai Srinivas BodapatiNo ratings yet

- C++ Tutorial: Where We Use C++ LanguageDocument101 pagesC++ Tutorial: Where We Use C++ LanguageSai Srinivas BodapatiNo ratings yet

- B V Raju Institute of Technology Index: Vishnupur, Narsapur, Medak DistrictDocument1 pageB V Raju Institute of Technology Index: Vishnupur, Narsapur, Medak DistrictSai Srinivas BodapatiNo ratings yet

- Dom Unit 1Document51 pagesDom Unit 1Sai Srinivas BodapatiNo ratings yet

- Production Function and IsoquantsDocument32 pagesProduction Function and IsoquantsSai Srinivas BodapatiNo ratings yet

- Unit-I: Introduction To Managerial EconomicsDocument42 pagesUnit-I: Introduction To Managerial EconomicsSai Srinivas BodapatiNo ratings yet

- Dom Unit 3Document36 pagesDom Unit 3Sai Srinivas BodapatiNo ratings yet

- Dom Unit 1Document51 pagesDom Unit 1Sai Srinivas BodapatiNo ratings yet

- Dom Unit 2Document68 pagesDom Unit 2Sai Srinivas BodapatiNo ratings yet

- Jntuk 2 1 FM&HM Nov 2017 Q.PDocument8 pagesJntuk 2 1 FM&HM Nov 2017 Q.Psai100% (1)

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Utah Section From Mineral Yearbooks 1948-1967Document580 pagesUtah Section From Mineral Yearbooks 1948-1967Russell HartillNo ratings yet

- HYDX-6 Specifications in EnglishDocument4 pagesHYDX-6 Specifications in Englishcototo33No ratings yet

- 123Document21 pages123Evans MagalhãesNo ratings yet

- 1987 CBR1000F Factory Service ManualDocument290 pages1987 CBR1000F Factory Service Manualmihaimarton100% (3)

- Todo Sobre El Bio DmeDocument21 pagesTodo Sobre El Bio DmeFernadez Ramos CarolayNo ratings yet

- CAT 3516 B and 3516 B High Displacement EnginesDocument1 pageCAT 3516 B and 3516 B High Displacement EnginesHemant RasamNo ratings yet

- Cat 16m Grader BrochureDocument24 pagesCat 16m Grader BrochureSauro GordiniNo ratings yet

- July 2014 GEARSDocument76 pagesJuly 2014 GEARSRodger BlandNo ratings yet

- Measure Bitumen Spray RateDocument3 pagesMeasure Bitumen Spray RateDilhara WickramaarachchiNo ratings yet

- Methodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsDocument16 pagesMethodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsErick RodriguesNo ratings yet

- Komatsu - PC 5500 PDFDocument639 pagesKomatsu - PC 5500 PDFlfoncea1977100% (1)

- MF 200-Series Workshop Sec WatDocument0 pagesMF 200-Series Workshop Sec WatSelmirije2No ratings yet

- Schade Stockyards and Blending 160812Document4 pagesSchade Stockyards and Blending 160812MarcNo ratings yet

- Four Stroke Cycle EnginesDocument1 pageFour Stroke Cycle EnginesIrshad AfridiNo ratings yet

- Physics LadakhDocument10 pagesPhysics LadakhAdarsha NNo ratings yet

- Thermal Engineering and Gas Dynamics: Air CompressorDocument11 pagesThermal Engineering and Gas Dynamics: Air CompressorFno FnoNo ratings yet

- Scooptram ST14: Underground Loader With 14-Tonne CapacityDocument8 pagesScooptram ST14: Underground Loader With 14-Tonne CapacityMiguel Salvador Torres Silva'No ratings yet

- AGS0260D: Diesel Generator Set 250/275 kVADocument4 pagesAGS0260D: Diesel Generator Set 250/275 kVAMiraNo ratings yet

- Synchronous Motor Drives - Electrical4uDocument3 pagesSynchronous Motor Drives - Electrical4uandy williamNo ratings yet

- Controlling Oxygen Sensors With An Automotive MicrocontrollerDocument81 pagesControlling Oxygen Sensors With An Automotive MicrocontrollerANIAPIERONI100% (1)

- Ford Injectors Coding With Focom Fip enDocument5 pagesFord Injectors Coding With Focom Fip endalioroxanaNo ratings yet

- Project Profile-LPG Bottling PlantDocument6 pagesProject Profile-LPG Bottling PlantSagarTak50% (4)

- Biomass To ChemicalsDocument20 pagesBiomass To ChemicalsNishantKashyapNo ratings yet

- Mass Balance For Biomass and Biogas Production From Organic WasteDocument14 pagesMass Balance For Biomass and Biogas Production From Organic WastedavidchemwenoNo ratings yet

- ECM TERMINAL FUNCTIONSDocument17 pagesECM TERMINAL FUNCTIONSJeni100% (1)

- Nissan Fault Codes - Reading Nissan ECU Fault Codes and Instructions and DirectionsDocument3 pagesNissan Fault Codes - Reading Nissan ECU Fault Codes and Instructions and Directionshowie_v_nNo ratings yet

- CAT 3126 Eletric DiagramaDocument6 pagesCAT 3126 Eletric DiagramaCarlos Coy100% (18)

- Rocker Arm & Valve Train Geometry - Circle Track Magazine All PagesDocument5 pagesRocker Arm & Valve Train Geometry - Circle Track Magazine All PagesDinesh Kumar SNo ratings yet

- Timing Kit Instructions - 50 DegreesDocument5 pagesTiming Kit Instructions - 50 DegreesMike Apple100% (1)

- MO EGS 1200 engine tools and measurement guideDocument4 pagesMO EGS 1200 engine tools and measurement guideSyahriantoNo ratings yet