Professional Documents

Culture Documents

Machine Design Exam Questions on Gears, Bearings and Other Mechanical Components

Uploaded by

NILESH SUTHAR0 ratings0% found this document useful (0 votes)

25 views3 pagesThis document is an exam for a Machine Design course covering various topics related to machine elements like gears, bearings, shafts, and other mechanical components. The exam contains 5 questions with 3 parts each, testing students on their understanding of topics like gear design, bearing design, cylinder design, and material handling systems. It provides instructions to attempt all questions and use provided references and data as needed. It also specifies the duration, total marks, and format of the exam.

Original Description:

Original Title

2171909 (4)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is an exam for a Machine Design course covering various topics related to machine elements like gears, bearings, shafts, and other mechanical components. The exam contains 5 questions with 3 parts each, testing students on their understanding of topics like gear design, bearing design, cylinder design, and material handling systems. It provides instructions to attempt all questions and use provided references and data as needed. It also specifies the duration, total marks, and format of the exam.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views3 pagesMachine Design Exam Questions on Gears, Bearings and Other Mechanical Components

Uploaded by

NILESH SUTHARThis document is an exam for a Machine Design course covering various topics related to machine elements like gears, bearings, shafts, and other mechanical components. The exam contains 5 questions with 3 parts each, testing students on their understanding of topics like gear design, bearing design, cylinder design, and material handling systems. It provides instructions to attempt all questions and use provided references and data as needed. It also specifies the duration, total marks, and format of the exam.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Seat No.: ________ Enrolment No.

___________

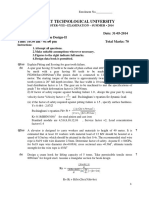

GUJARAT TECHNOLOGICAL UNIVERSITY

BE - SEMESTER–VII (NEW) EXAMINATION – WINTER 2018

Subject Code: 2171909 Date: 03/12/2018

Subject Name: Machine Design

Time: 10:30 AM TO 01:30 PM Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

4. Use of Design data book is allowed Bhandari/PSG.

MARKS

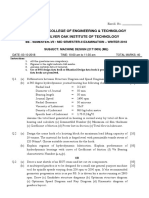

Q.1 (a) Why pressure angle is generally taken as 200? What is its effect? 03

(b) Explain desirable properties of bearing materials used for sliding 04

contact bearings.

(c) Design a pair of CI spur gear to transmit 12 kW having pinion speed 07

of 200 rpm. The speed reduction required is 2:1. Assume face width

as 3 times circular pitch. The minimum number of teeth on pinion is

24. Check your design in all failures considering the following data;

Pressure angel 14.50 full depth involute, Factor of safety 1.5.

The modulus of elasticity for pair is 0.8 * 10 N/mm2,

5

Error in manufacturing is not to exceed 0.05 mm,

Allowable bending stress for CI as 45 N/mm2,

Surface endurance stress as 280 N/mm2.

Q.2 (a) What is the function of cylinder liners in IC Engines? List down the 03

reasons for liner distortion.

(b) Give the classification of wire ropes and explain its construction with 04

neat sketches.

(c) Design a helical gear to transmit 30 kW from the following data; 07

Helix angle = 300, Speed of pinion = 1500 rpm,

0

Pressure angle = 20 FDI, Velocity ratio = 4,

No of teeth on pinion = 24, Static stress for CI = 55 N/mm2,

BHN for pinion and gear material = 350,

Young’s modulus of elasticity for pinion and gear material = 2.1 *

105 N/ mm2.

OR

(c) Draw layout diagram of gear box, ray diagram and speed chart for a 07

multi-speed gear box of a radial drilling machine required to give

eight steps. The power from motor to the input shaft of gear box is

transmitted by a V-belt drive with a speed reduction of 1:6. The

minimum and maximum spindle speeds are 70 rpm and 1800 rpm

respectively.

Q.3 (a) Explain the rang ratio in gear box design. 03

(b) Explain in brief about mountings of bearings. 04

(c) Calculate the maximum radial load that the journal can carry and 07

operate at hydrodynamic condition for the following data of a full

journal bearing. Journal diameter = 60 mm, bearing length = 60 mm,

radial clearance = 0.06 mm, minimum film thickness = 0.006 mm,

journal speed = 1440 rpm, viscosity of lubricant = 20 cP.

For the above calculated load, find the power lost in friction.

OR

1

Q.3 (a) Differentiate between Arithmetic, Geometric and Harmonic 03

Progressions in case of design of gear box.

(b) A deep groove ball bearing has a rated static and dynamic load 04

capacity of 4150 N and 4750 N respectively. The bearing has to take

an axial load of 2075 N and a radial load of 4000 N. Find the expected

life of the bearing.

(c) A worm and worm wheel gear drive is designated as 2 / 41 / 10 / 8. 07

The drive is used to obtain a speed reduction of 20.5 from an input

speed of 1450 rpm. Material of the worm wheel is Sand Cast and

Chilled Phosphor Bronze, while the worm is made of Case-hardened

alloy steel. Determine the power transmitting capacity of the drive

based on beam strength.

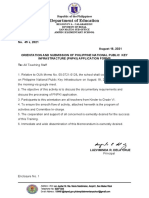

Q.4 (a) What are the two most usual causes of failures of the crank shafts? 03

(b) Explain the classification cranes using different standards. 04

(c) The cylinder of a four-stroke diesel engine has the following 07

specifications:

Break Power = 7.5 kW, Speed = 1400 rpm, Indicated mean effective

pressure = 0.35 MPa, Mechanical efficiency = 80 %, Maximum gas

pressure = 3.5 MPa.

The cylinder liner and head are made of grey cast iron FG 260 having

UTS 260 N/mm2 and poisons ratio 0.25. The studs are made of plain-

carbon steel having yield stress 380 N/mm2. The factor of safety for

all parts is 6. Calculate: (i) bore and length of the cylinder liner,

(ii) thickness of the cylinder liner, (iii) thickness of cylinder head,

(iv) size, number and pitch of studs.

OR

Q.4 (a) Explain the aspect of heat generation in design of worm gears. 03

(b) A bearing is subjected to the following work cycle: radial load of 04

4450 N, 6675 N and 2225 N at 150 rpm, 600 rpm, and 300 rpm for

30 % of time, 10 % of time, and for remaining time of the cycle

respectively. The inner ring rotates and the loads are steady. Find the

expected life of this bearing in hours, by considering the static and

dynamic load carrying capacities of the bearing as 10013 N and

14952 N respectively.

(c) Design a cast iron piston for a single acting four stroke engine for the 07

following specifications. Cylinder bore = 100mm, stroke = 120 mm,

maximum gas pressure = 0.65 MPa,

Fuel consumption = 0.227 kg/kW/hr, speed = 2200 rpm.

Assume the following data;

Allowable stresses in CI = 37.5 N/mm2,

Allowable stresses for piston rings = 90 N/mm2,

Assume suitable data.

Q.5 (a) Discuss the different types of piston rings and function of each one 03

of it.

(b) How the rolling contact bearings are designed having probability of 04

survival other than 90 percent?

(c) An elevator at the construction site is required to raise building 07

materials weighing 5.5 KN. A maximum velocity of 1 m/s is attained

in one second while raising the materials. The lift of material is 25 m.

The drum diameter is 40 times the rope diameter. Find the number of

6 X 19 wire ropes required if 12 mm diameter ropes are used.

Assume: diameter of wire dw= 0.063 d, area of rope Ar= 0.38 d2, mass of

rope = 0.0036 d2 kg/m, Er = 84000 N/m2, breaking strength = 385 d2, factor

of safety = 5. d is diameter of rope.

2

OR

Q.5 (a) What is material handling? What are the essentials of good material 04

handling system?

(b) A 3600 full journal bearing operates under the following 10

specifications:

Journal Diameter = 70 mm, bearing length = 70 mm,

Journal speed = 960 rpm, steady radial load = 12 KN,

Viscosity of lubricant = 16 cP, Mass density of oil = 880 kg/m3,

Specific heat = 1.76 kJ/kg 0C, bearing clearance ratio (r/c) = 800,

Average heat transfer coefficient = 20 W/m2-0C.

Determine the required flow rate of oil. Also find the temperature of

oil film and the bearing surface area for the desired heat transfer, if

the ambient temperature is 300C. Assume that all heat generated in

the bearing is carried away by the oil.

*************

You might also like

- Be Winter 2022Document2 pagesBe Winter 2022shivamparmartechNo ratings yet

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityHarshit PatelNo ratings yet

- GTU BE-SEMESTER-VII Machine Design Exam QuestionsDocument2 pagesGTU BE-SEMESTER-VII Machine Design Exam QuestionsNILESH SUTHARNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- 2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIDocument4 pages2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIMayur DhanokarNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- 2019 May ME402-A - Ktu QbankDocument3 pages2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- Design of Machine Elements-II Exam QuestionsDocument9 pagesDesign of Machine Elements-II Exam QuestionsPrasinNo ratings yet

- Machine Design - II: (Also Old Sem-VI Equivalence) (126112)Document2 pagesMachine Design - II: (Also Old Sem-VI Equivalence) (126112)Harshal DesaleNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhardwaj UpadhyayNo ratings yet

- Be Summer 2022Document3 pagesBe Summer 2022Karan SheladiyaNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- LL, LLLLLLRLLLLL: - Machine and DrawingDocument2 pagesLL, LLLLLLRLLLLL: - Machine and DrawingMayur DhanokarNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocument2 pagesSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNo ratings yet

- Design of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Document2 pagesDesign of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Rohit RangariNo ratings yet

- MDDocument4 pagesMDMiraj RajputNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Nikesh rampariyaNo ratings yet

- Machine Design-II EME602 2012-13Document4 pagesMachine Design-II EME602 2012-13nitin_johriNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- UPTU 2013-14 Machine Design - II EME 602Document4 pagesUPTU 2013-14 Machine Design - II EME 602nitin_johriNo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Design of Mechanical Drives w17Document4 pagesDesign of Mechanical Drives w17aniket ingle100% (1)

- Question Paper - Design of Machine Elements 2 Oct-19-October - 2019Document2 pagesQuestion Paper - Design of Machine Elements 2 Oct-19-October - 2019ChanduNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- Computer Aided DesignDocument2 pagesComputer Aided DesignRushabh PatelNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganNo ratings yet

- No of Pages Course Code:: Fig.1 Fig 2Document4 pagesNo of Pages Course Code:: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- 181605-181902-MD - IiDocument3 pages181605-181902-MD - IiRushabh PatelNo ratings yet

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 pagesNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- DMDDocument4 pagesDMDSantosh AloneNo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityamit UpadhyayNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- CatalogDocument12 pagesCatalogjonz afashNo ratings yet

- Jenny Randles - Mind Monsters - Invaders From Inner Space (1990)Document219 pagesJenny Randles - Mind Monsters - Invaders From Inner Space (1990)DirkTheDaring11100% (15)

- Paul Ramesh Forensic Neuro Psychological InterviewDocument43 pagesPaul Ramesh Forensic Neuro Psychological Interviewnonam2100% (2)

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- jrc122457 Dts Survey Deliverable Ver. 5.0-3Document46 pagesjrc122457 Dts Survey Deliverable Ver. 5.0-3Boris Van CyrulnikNo ratings yet

- MCC-2 (Intermediate & Finishing Mill)Document17 pagesMCC-2 (Intermediate & Finishing Mill)Himanshu RaiNo ratings yet

- COT English 3rd PrepositionDocument14 pagesCOT English 3rd PrepositionGanie Mae Talde Casuncad100% (1)

- Efficiently Transfer Stock Between PlantsDocument6 pagesEfficiently Transfer Stock Between PlantsSantosh KumarNo ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- Management Science PDFDocument131 pagesManagement Science PDFAngela Lei SanJuan BucadNo ratings yet

- Find Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Document3 pagesFind Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Gopal AggarwalNo ratings yet

- Function Apollo Amadeus: Sign In/OutDocument16 pagesFunction Apollo Amadeus: Sign In/OutMabs GaddNo ratings yet

- Memo-on-Orientation and Submission of PNPKIDocument5 pagesMemo-on-Orientation and Submission of PNPKICoronia Mermaly LamsenNo ratings yet

- Ac and DC MeasurementsDocument29 pagesAc and DC MeasurementsRudra ChauhanNo ratings yet

- SchoolopeningdocxDocument1 pageSchoolopeningdocxElena BarsukovaNo ratings yet

- 720-C-001 (Vent Wash Column)Document4 pages720-C-001 (Vent Wash Column)idilfitriNo ratings yet

- Cryptography and Network Security": Sir Syed University of Engineering & TechnologyDocument5 pagesCryptography and Network Security": Sir Syed University of Engineering & TechnologySehar KhanNo ratings yet

- Sta. Rosa, Lapu-Lapu City, Cebu PhilippinesDocument8 pagesSta. Rosa, Lapu-Lapu City, Cebu PhilippinesMet XiiNo ratings yet

- August Morning WorkDocument20 pagesAugust Morning Workapi-471325484No ratings yet

- TOS - MathDocument4 pagesTOS - MathGeorge Ezar N. QuiriadoNo ratings yet

- Performance Evaluation and Life Testing of The SPT-100Document12 pagesPerformance Evaluation and Life Testing of The SPT-100ThaSupaflyNo ratings yet

- Circuit Diagram Eng 5582-2-01Document95 pagesCircuit Diagram Eng 5582-2-01edolzaNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- Reliability Centered Maintenance (RCM)Document6 pagesReliability Centered Maintenance (RCM)Hoang Thanh VanNo ratings yet

- 2013 Sunchaser Brochure PDFDocument12 pages2013 Sunchaser Brochure PDFKelly SimpsonNo ratings yet

- EXPERIMENT 4B - HOW STRONG IS YOUR CHOCOLATE - Docx - 2014538817Document6 pagesEXPERIMENT 4B - HOW STRONG IS YOUR CHOCOLATE - Docx - 2014538817Shekaina Joy Wansi ManadaoNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet

- Node - Js 8 The Right Way: Extracted FromDocument11 pagesNode - Js 8 The Right Way: Extracted FromRodrigo Románovich FiodorovichNo ratings yet

- Technical Report Writing For Ca2 ExaminationDocument6 pagesTechnical Report Writing For Ca2 ExaminationAishee DuttaNo ratings yet

- The Reading Process PDFDocument1 pageThe Reading Process PDFAdy OliveiraNo ratings yet