Professional Documents

Culture Documents

1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of Engineering

Uploaded by

Chadaram JagadishOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of Engineering

Uploaded by

Chadaram JagadishCopyright:

Available Formats

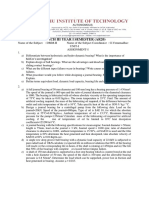

SIR CR REDDY COLLEGE OF ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

1 St ASSIGNMENT SECTION-A&B

3-1 SEMESTER DMM-2

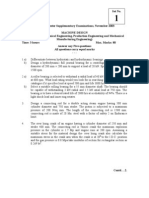

1. a) A particular bearing application provides a life of 5000 hours for 90% reliability.

What are the corresponding lives for 50% and 99% reliability?

b) The following data is given for a full, hydrodynamic bearing:

Journal speed =1440 rpm, journal diameter = 60 mm, Bearing length = 60 mm, radial

clearance = 0.06 mm, Radial load = 3 kN, viscosity of lubricant = 30 cP. Assume that

total heat generated due to friction in bearing is carried by the total lubricant flow.

Calculate: (a) coefficient of friction (b) minimum oil thickness (c) flow requirement,

(d) temperature rise, (e) power lost in friction.

2.a)Design crank pin and crank web of an overhung crankshaft for a 300 × 350 mm single

cylinder vertical engine using the following data:

The engine is vertical and the crank is at the top dead centre position

Maximum gas pressure = 2.5 MPa; (L/r) ratio = 4.5

Assume suitable data and state the assumptions made.

b) Differentiate between an overhung crankshafts and centre crank shafts.

3. Design a cast iron piston for a single acting four stroke engine from the following

data;

Cylinder Bore = 100 mm; Stroke = 120 mm; Speed = 2000 rpm;

Maximum gas pressure = 5 MPa; Break Mean Effective Pressure = 0.5 MPa

Fuel consumption is 0.15 kg per kW hour break power.

4. The section of a crane hook is trapezium. At the critical section, the inner and outer

sides are 40 mm and 25 mm respectively and depth is 75 mm. The center of curvature

of the section is at a distance of 60 mm from the inner fibers and the load line is 50

mm from the inner fibers. Determine the maximum load that the hook can carry if the

maximum stress is not to exceed 120 MPa

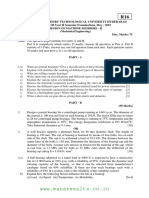

5. a) Following data is given for a 3600 hydrodynamic bearing. Journal diameter=100mm,

bearing length=100mm, radial load=50kN, journal speed=1440 rpm, radial

clearance=0.12 mm, viscosity of lubricant =16 Cp. Calculate: i) Minimum oil film

thickness, ii) Coefficient of friction and iii) Power lost in friction.

b) A single row deep groove ball bearing No.6002 is subjected to an axial thrust of

1000 N and a radial load of 2200 N. Find the expected life that 50 % of the bearings

will complete under this condition.

6. a) Under what forces the big end bolts and the cap are designed in the connecting rod?

b) Design a connecting rod for a single cylinder four stroke diesel engine with the

following data: Power =7.5kW, Mechanical efficiency =80%, length of connecting

rod =0.3m, weight of reciprocating pumps= 20N, speed=1500 rpm with possible

over speed of 2500 rpm. Assume suitable missing data.

7. a) What are the advantages and disadvantages of aluminum piston?

b) Design a Cast Iron piston for a single acting four stroke engine for the following

data: Cylinder bore = 100 mm, Stroke = 125 mm, Maximum gas pressure= 5 N/mm2,

Indicated mean effective pressure = 0.75 N/mm2,

Mechanical efficiency=80%, fuel

consumption= 0.15 kg/break power/ hour, higher calorific value of fuel = 42x103

kj/kg, speed=2000 rpm, Any other data required for the design may be assumed.

8. a) Explain the design procedure to determine the resultant stresses in a crane hook.

b) A central horizontal section of a hook is a trapezium with inner width =80 mm, outer

width =50 mm, and depth=150 mm, the center of curvature of the section is at a

distance of 120 mm from the inner fiber and the load line is 100 mm from the inner

fiber. What maximum load the hook will carry, if maximum stress is not to exceed

120 MN/m2.

9. a) Select a ball bearing for an industrial machine press fit onto a shaft and intended

for continuous 8-hour per day operation at 1800 rpm. Radial and thrust loads are

1.2 and 1.5 kN, respectively, with light-to-moderate impact.

b) A 100-mm-diameter shaft is supported by a bearing of 80-mm length with a

diametral clearance of 0.10 mm. It is lubricated by oil having a viscosity of 50 m

Pa-s. The shaft rotates 600 rpm and carries a radial load of 5000 N. Estimate the

bearing coefficient of friction and power loss.

10. The following data is given for the cap and bolts of the big end of the connecting rod:

Engine speed = 1500 rpm; Length of connecting rod = 320 mm

Length of stroke = 140 mm; Mass of reciprocating parts = 1.75 kg

Length of crank pin = 54 mm; Diameter of crank pin = 38 mm

Permissible tensile stress for bolts and Caps = 120 MPa

Calculate the nominal diameter of bolts and thickness of cap for the big end.

11. a) The cylinder of a four-stroke diesel engine has the following specifications:

Cylinder bore = 150 mm; Maximum gas pressure = 3 MPa

Allowable tensile stress = 50 MPa.

Determine the thickness of cylinder wall. Also, calculate the apparent and net

circumferential and longitudinal stresses in cylinder wall.

b) State the function of the Piston rings in an internal combustion engine.

12. Calculate, using Winkler’s formula, the maximum distance d for which tangential

stress does not exceed 80 MPa on the cross section A-B of the frame shown in

Figure 1. Also locate the neutral axis. Given load P = 25 kN

You might also like

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- AECD QuestionsDocument7 pagesAECD QuestionssbkNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Dmm-II Assignment TestDocument2 pagesDmm-II Assignment TestSai Srinivas BodapatiNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- Machine Design I TutorialDocument3 pagesMachine Design I TutorialbngelotrNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- AT8611 Lab QuestionsDocument9 pagesAT8611 Lab QuestionsChirpiNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- Mechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Document4 pagesMechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Harpinder GotraaNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME)Document3 pagesWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNo ratings yet

- Machine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsDocument3 pagesMachine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsNILESH SUTHARNo ratings yet

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsDocument3 pagesDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoNo ratings yet

- Machine DesignDocument6 pagesMachine DesignRishi SinghNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 pagesMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNo ratings yet

- Assignment 01Document2 pagesAssignment 01Ratan Sadanandan O MNo ratings yet

- MD-III - TUT - 5 and 6Document5 pagesMD-III - TUT - 5 and 6Sushil ThakkarNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- WWW Manaresults Co inDocument4 pagesWWW Manaresults Co inGod deva123No ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- Date: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinDocument2 pagesDate: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinsathishskymechNo ratings yet

- Design of Machine Members - II April 2017Document8 pagesDesign of Machine Members - II April 2017Abhishek Goud AkkapalliNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Previous Exam QuestionsDocument8 pagesPrevious Exam QuestionssallyreffatNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- Machine Component Design QuestionsDocument6 pagesMachine Component Design Questionssuneel kumar rathoreNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Shearing Stress Distribution in Typical Cross-Sections:: Rectangular X-SectionDocument12 pagesShearing Stress Distribution in Typical Cross-Sections:: Rectangular X-SectionBadNo ratings yet

- CAB CAM RecordDocument49 pagesCAB CAM RecordChadaram JagadishNo ratings yet

- Mechatronics Ass2Document11 pagesMechatronics Ass2Chadaram JagadishNo ratings yet

- Cad Cam Part-2 (Abacus)Document19 pagesCad Cam Part-2 (Abacus)Chadaram JagadishNo ratings yet

- Unit 4Document85 pagesUnit 4Chadaram JagadishNo ratings yet

- Iem Unit-IDocument14 pagesIem Unit-IChadaram JagadishNo ratings yet

- Boats PDFDocument6 pagesBoats PDFphanickNo ratings yet

- Part-Bb Questions: Essay FamilyDocument2 pagesPart-Bb Questions: Essay FamilyChadaram JagadishNo ratings yet

- Of Computersystems. Quality, To: IntegratedDocument2 pagesOf Computersystems. Quality, To: IntegratedChadaram JagadishNo ratings yet

- Aircraft Refrigeration Systems ExplainedDocument9 pagesAircraft Refrigeration Systems ExplainedChadaram Jagadish100% (1)

- 2020-21 3-2 Metrology (R1632031) Assignment-I ModifiedDocument1 page2020-21 3-2 Metrology (R1632031) Assignment-I ModifiedChadaram JagadishNo ratings yet

- Industrial Engineering Concepts, Plant Layouts, Productivity FactorsDocument1 pageIndustrial Engineering Concepts, Plant Layouts, Productivity FactorsChadaram JagadishNo ratings yet

- Sir C R Reddy College of Engineering, Eluru Department of Mechanical Engineering Assignment-1Document2 pagesSir C R Reddy College of Engineering, Eluru Department of Mechanical Engineering Assignment-1Chadaram JagadishNo ratings yet

- HMT 2 Assignment-20-21-II SemDocument1 pageHMT 2 Assignment-20-21-II SemChadaram JagadishNo ratings yet

- Batch-1: Department of Mechanical EngineeringDocument3 pagesBatch-1: Department of Mechanical EngineeringChadaram JagadishNo ratings yet

- R&ac Assin - 2 - 2021Document1 pageR&ac Assin - 2 - 2021Chadaram JagadishNo ratings yet

- 2020-21 3-2 Metrology (R1632031) Assignment-I ModifiedDocument1 page2020-21 3-2 Metrology (R1632031) Assignment-I ModifiedChadaram JagadishNo ratings yet

- III - II Sem Exam Fee NoticeDocument1 pageIII - II Sem Exam Fee NoticeChadaram JagadishNo ratings yet

- Instrumentation & Control Systems Assignment - IiDocument1 pageInstrumentation & Control Systems Assignment - IiChadaram JagadishNo ratings yet

- Lecture 14b - Industrial Robotics - CH 8Document20 pagesLecture 14b - Industrial Robotics - CH 8RAJAGOPAL MNo ratings yet

- 1) A) Explain The Simple Air Refrigeration System and Derive A N Expression For Cop of The System ? (Co-1) B)Document1 page1) A) Explain The Simple Air Refrigeration System and Derive A N Expression For Cop of The System ? (Co-1) B)Chadaram JagadishNo ratings yet

- Second Assignment Questions of IRDocument3 pagesSecond Assignment Questions of IRChadaram JagadishNo ratings yet

- Go MS 39Document7 pagesGo MS 39Chadaram JagadishNo ratings yet

- CamScanner Scans PDF DocsDocument12 pagesCamScanner Scans PDF DocsChadaram JagadishNo ratings yet

- Ramachandra College of Engineering: EluruDocument2 pagesRamachandra College of Engineering: EluruChadaram JagadishNo ratings yet

- Solving Transportation Problem Using Vogel's Approximation Method, Stepping Stone Method & Modified Distribution MethodDocument38 pagesSolving Transportation Problem Using Vogel's Approximation Method, Stepping Stone Method & Modified Distribution MethodChadaram JagadishNo ratings yet

- 31 BT Sup Not June2021Document2 pages31 BT Sup Not June2021Chadaram JagadishNo ratings yet

- Learner's Licence Form GuideDocument1 pageLearner's Licence Form GuideChadaram Jagadish JagadishNo ratings yet

- TPProject Final 1Document8 pagesTPProject Final 1Chadaram JagadishNo ratings yet

- SSC JE Application IncompleteDocument2 pagesSSC JE Application IncompleteChadaram JagadishNo ratings yet

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDocument28 pagesIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNo ratings yet

- w638 Fuse Box and Relay Diagram 1996 2003Document5 pagesw638 Fuse Box and Relay Diagram 1996 2003Radek Caver Johánek50% (2)

- AKSA 6.49L Inline 6 Turbo Diesel Engine SpecsDocument3 pagesAKSA 6.49L Inline 6 Turbo Diesel Engine SpecsChristian Rivera FloverNo ratings yet

- Copper Brass Radiator Catalog 2018Document206 pagesCopper Brass Radiator Catalog 2018carlosg801100% (1)

- EuroVan 2.4 L Diesel Engine Wiring DiagramDocument5 pagesEuroVan 2.4 L Diesel Engine Wiring DiagramCsaba Váradi50% (2)

- Hydraulic Mining Excavator RH120E Service Training GuideDocument20 pagesHydraulic Mining Excavator RH120E Service Training GuideOsvaldo UrbanoNo ratings yet

- C200 - CDPF SystemDocument12 pagesC200 - CDPF SystemKada Ben youcefNo ratings yet

- CX 8Document624 pagesCX 8Phap NguyenNo ratings yet

- 3sgte PARTSDocument2 pages3sgte PARTSchaNo ratings yet

- D4204T5 EngineDocument52 pagesD4204T5 EngineCristian100% (7)

- 1997 Supra - SpecifiationsDocument6 pages1997 Supra - SpecifiationsRain SongNo ratings yet

- 113-Flexible Pilot Plant Technology For Evaluation of Unconventional Feedstocks and ProcessesDocument19 pages113-Flexible Pilot Plant Technology For Evaluation of Unconventional Feedstocks and ProcessesjosejuanramosNo ratings yet

- Alternator replacement guide for agricultural and construction equipmentDocument6 pagesAlternator replacement guide for agricultural and construction equipmentEdwin CañonNo ratings yet

- IC Engine PDFDocument40 pagesIC Engine PDFDiyar NezarNo ratings yet

- ME LAB 3 Steam Power Plant Assessment ReportDocument19 pagesME LAB 3 Steam Power Plant Assessment ReportBryan TanNo ratings yet

- Biofuel Lab ReportDocument7 pagesBiofuel Lab ReportMaxWitt100% (3)

- 15-Parts List ELS12 MK2Document150 pages15-Parts List ELS12 MK2Mehar Tariq GoheerNo ratings yet

- Form Inspeksi Welding MachineDocument2 pagesForm Inspeksi Welding MachineDodi kurniawanNo ratings yet

- Balance Diesel Oil Noviembre 2022Document1 pageBalance Diesel Oil Noviembre 2022Jaime Orlando Quiroz AlarconNo ratings yet

- Sullair 185 Operators ManualDocument70 pagesSullair 185 Operators ManualLouis ThevenotNo ratings yet

- V 2203 Di T Eb Rand 3: Interpreting Kubota™ Engine Serial and Model NumbersDocument1 pageV 2203 Di T Eb Rand 3: Interpreting Kubota™ Engine Serial and Model NumbersfjaristizabalNo ratings yet

- HKT Catalog PDFDocument37 pagesHKT Catalog PDFlasithNo ratings yet

- D3E80022B06-Engine Mechanical PDFDocument191 pagesD3E80022B06-Engine Mechanical PDFMartin VelikovNo ratings yet

- Application 2459772Document8 pagesApplication 2459772Antonio Tineo VennerNo ratings yet

- Camshaft - Install: Desarmado y ArmadoDocument4 pagesCamshaft - Install: Desarmado y ArmadoHector VillegasNo ratings yet

- Scuderia Topolino - Technical AdviceDocument130 pagesScuderia Topolino - Technical AdviceNikNo ratings yet

- Manual For HHO Kit For ScooterDocument6 pagesManual For HHO Kit For ScooterHHO Mart100% (5)

- Underground Mining Loader: Engine Operating SpecificationsDocument28 pagesUnderground Mining Loader: Engine Operating SpecificationsYorky Edgardo CastilloNo ratings yet

- SodaPDF Splitted LG856H.bookDocument30 pagesSodaPDF Splitted LG856H.bookleogerguzNo ratings yet

- MTU 12V4000 DS1550: Diesel Generator SetDocument5 pagesMTU 12V4000 DS1550: Diesel Generator SetTran PhuocNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet