Professional Documents

Culture Documents

Four Stroke Cycle Engines

Uploaded by

Irshad AfridiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Four Stroke Cycle Engines

Uploaded by

Irshad AfridiCopyright:

Available Formats

Four Stroke Cycle Engines

A four-stroke cycle engine is an internal combustion engine that utilizes four distinct

piston strokes (intake, compression, power, and exhaust) to complete one operating

cycle. The piston make two complete passes in the cylinder to complete one operating

cycle. An operating cycle requires two revolutions (720°) of the crankshaft. The four-

stroke cycle engine is the most common type of small engine. A four-stroke cycle

engine completes five Strokes in one operating cycle, including intake, compression,

ignition, power, and exhaust Strokes.

Intake Stroke

The intake event is when the air-fuel mixture is introduced to fill the combustion

chamber. The intake event occurs when the piston moves from TDC to BDC and the

intake valve is open. The movement of the piston toward BDC creates a low pressure in

the cylinder. Ambient atmospheric pressure forces the air-fuel mixture through the open

intake valve into the cylinder to fill the low pressure area created by the piston

movement. The cylinder continues to fill slightly past BDC as the air-fuel mixture

continues to flow by its own inertia while the piston begins to change direction. The

intake valve remains open a few degrees of crankshaft rotation after BDC. Depending

on engine design. The intake valve then closes and the air-fuel mixture is sealed inside

the cylinder.

Compression Stroke

The compression stroke is when the trapped air-fuel mixture is compressed inside the

cylinder. The combustion chamber is sealed to form the charge. The charge is the

volume of compressed air-fuel mixture trapped inside the combustion chamber ready

for ignition. Compressing the air-fuel mixture allows more energy to be released when

the charge is ignited. Intake and exhaust valves must be closed to ensure that the

cylinder is sealed to provide compression. Compression is the process of reducing or

squeezing a charge from a large volume to a smaller volume in the combustion

chamber. The flywheel helps to maintain the momentum necessary to compress the

charge.

When the piston of an engine compresses the charge, an increase in compressive force

supplied by work being done by the piston causes heat to be generated. The

compression and heating of the air-fuel vapor in the charge results in an increase in

charge temperature and an increase in fuel vaporization. The increase in charge

temperature occurs uniformly throughout the combustion chamber to produce faster

combustion (fuel oxidation) after ignition.

The increase in fuel vaporization occurs as small droplets of fuel become vaporized

more completely from the heat generated. The increased droplet surface area exposed to

the ignition flame allows more complete burning of the charge in the combustion

chamber. Only gasoline vapor ignites. An increase in droplet surface area allows

gasoline to release more vapor rather than remaining a liquid.

The more the charge vapor molecules are compressed, the more energy obtained from

the combustion process. The energy needed to compress the charge is substantially less

than the gain in force produced during the combustion process. For example, in a

typical small engine, energy required to compress the charge is only one-fourth the

amount of energy produced during combustion.

The compression ratio of an engine is a comparison of the volume of the combustion

chamber with the piston at BDC to the volume of the combustion chamber with the

piston at TDC. This area, combined with the design and style of combustion chamber,

determines the compression ratio. Gasoline engines commonly have a compression ratio

ranging from 6:1 - 10:1. The higher the compression ratio, the more fuel-efficient the

engine. A higher compression ratio normally provides a substantial gain in combustion

pressure or force on the piston. However, higher compression ratios increase operator

effort required to start the engine. Some small engines feature a system to relieve

pressure during the compression stroke to reduce operator effort required when starting

the engine.

Ignition Event

The ignition (combustion) event occurs when the charge is ignited and rapidly oxidized

through a chemical reaction to release heat energy. Combustion is the rapid, oxidizing

chemical reaction in which a fuel chemically combines with oxygen in the atmosphere

and releases energy in the form of heat.

Proper combustion involves a short but finite time to spread a flame throughout the

combustion chamber. The spark at the spark plug initiates combustion at approximately

20° of crankshaft rotation before TDC (BTDC). The atmospheric oxygen and fuel vapor

are consumed by a progressing flame front. A flame front is the boundary wall that

separates the charge from the combustion by-products. The flame front progresses

across the combustion chamber until the entire charge has burned.

Power Stroke

The power stroke is an engine operation Stroke in which hot expanding gases force the

piston head away from the cylinder head. Piston force and subsequent motion are

transferred through the connecting rod to apply torque to the crankshaft. The torque

applied initiates crankshaft rotation. The amount of torque produced is determined by

the pressure on the piston, the size of the piston, and the throw of the engine. During the

power Stroke, both valves are closed.

Exhaust Stroke

The exhaust stroke occurs whenspent gases are expelled from the combustion chamber

and released to the atmosphere. The exhaust stroke is the final stroke and occurs when

the exhaust valve is open and the intake valve is closed. Piston movement evacuates

exhaust gases to the atmosphere.

As the piston reaches BDC during the power stroke combustion is complete and the

cylinder is filled with exhaust gases. The exhaust valve opens, and inertia of the

flywheel and other moving parts push the piston back to TDC, forcing the exhaust gases

out through the open exhaust valve. At the end of the exhaust stroke, the piston is at

TDC and one operating cycle has been completed.

You might also like

- General Equipment Knowledge-Diesel EngineDocument177 pagesGeneral Equipment Knowledge-Diesel EngineEhab Gamal Eldin BarakatNo ratings yet

- Accord 2008-2012 EngineDocument50 pagesAccord 2008-2012 EngineAntonio GonzalezNo ratings yet

- FP Diesel Dodge Truck - DigipubzDocument68 pagesFP Diesel Dodge Truck - DigipubzRafael GarciaNo ratings yet

- Applied Thermal Engineering: Prof. K. K.SHARMADocument69 pagesApplied Thermal Engineering: Prof. K. K.SHARMAKaran100% (1)

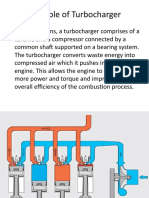

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- Defender 110Document12 pagesDefender 110Agustin EstergaardNo ratings yet

- How Diesel Engines WorkDocument23 pagesHow Diesel Engines WorkBabu Stunner100% (1)

- Compression Ignition EngineDocument7 pagesCompression Ignition Engineurmale50% (2)

- 4 Stroke Petrol EngineDocument11 pages4 Stroke Petrol EngineAnkit Joshi50% (4)

- Water FloodingDocument94 pagesWater FloodingOlusegun OyebanjiNo ratings yet

- Citroen Xsara Wiring DiagramsDocument20 pagesCitroen Xsara Wiring Diagramsscribd222111186% (44)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Diesel Engine - FundamentalDocument20 pagesDiesel Engine - FundamentalSoumen BhattaNo ratings yet

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDocument27 pagesFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- Prepared By: Muhammad Hilmi Bin ZaidDocument44 pagesPrepared By: Muhammad Hilmi Bin ZaidTimothy Del Valle100% (1)

- Benfree From AxensDocument2 pagesBenfree From AxensWong Yee SunNo ratings yet

- Marine EngineeringDocument52 pagesMarine EngineeringJerick Navarro Navarro100% (4)

- Product Catalogue All Types of Solenoid DelphiDocument13 pagesProduct Catalogue All Types of Solenoid DelphiManmohan SinghNo ratings yet

- IC EngineDocument65 pagesIC EngineDuggi Shanmukha ViharNo ratings yet

- PowerScreen Cheiftain 1700 Parts ManualDocument343 pagesPowerScreen Cheiftain 1700 Parts ManualDodom Bird50% (6)

- Four Stroke Engine Cycles and TimingDocument27 pagesFour Stroke Engine Cycles and TimingOğuz Çavdar100% (1)

- Analysis and Optimum Design Chasis of Three Wheel Auto Rickshaw Passenger VehicleDocument16 pagesAnalysis and Optimum Design Chasis of Three Wheel Auto Rickshaw Passenger VehiclenahomNo ratings yet

- National Crane 500E2 Operators ManualDocument94 pagesNational Crane 500E2 Operators ManualRoamir Alayon MalaveNo ratings yet

- EIM 9 Quarter Electrical ToolsDocument35 pagesEIM 9 Quarter Electrical ToolsJe Ann OlaytaNo ratings yet

- Stroke and CyclesDocument6 pagesStroke and Cyclesjohn connoNo ratings yet

- 1514285118329-Notes ALP InductionDocument97 pages1514285118329-Notes ALP InductionKhirod SahuNo ratings yet

- First Semester:-Course Title: Applied Thermodynamics TopicDocument8 pagesFirst Semester:-Course Title: Applied Thermodynamics TopicHafeez AliNo ratings yet

- Internal Combustion Engine TypesDocument35 pagesInternal Combustion Engine TypesMuhammad FaizNo ratings yet

- Gas Turbine: Rotary Engine Energy Combustion Compressor ChamberDocument11 pagesGas Turbine: Rotary Engine Energy Combustion Compressor ChamberRauf DogarNo ratings yet

- Analyzing Tumble Motion in Engines Through SimulationDocument8 pagesAnalyzing Tumble Motion in Engines Through SimulationLorant BordasNo ratings yet

- Experiment No.7 ObjectiveDocument3 pagesExperiment No.7 Objectivefarah nazNo ratings yet

- PISTON VS JET: KEY DIFFERENCESDocument27 pagesPISTON VS JET: KEY DIFFERENCESSamarth SNo ratings yet

- Lesson V Automobile Engine, and The Four-Stroke CycleDocument5 pagesLesson V Automobile Engine, and The Four-Stroke CycleNicolas AntiguaNo ratings yet

- Lab Report 13 14Document8 pagesLab Report 13 14waleed rajpootNo ratings yet

- Internal Combustion EnginesDocument32 pagesInternal Combustion Enginespramodkb_cusatNo ratings yet

- Lesson 2Document8 pagesLesson 2Polaris PenidoNo ratings yet

- Final ReportDocument42 pagesFinal ReportNimish PandeNo ratings yet

- Suction/Intake Stroke: Guledew, Aaron B BSIT-2Document2 pagesSuction/Intake Stroke: Guledew, Aaron B BSIT-2Jagabi Aeron Jay GuledewNo ratings yet

- 4 Stroke Ignition SystemDocument33 pages4 Stroke Ignition Systemspruhatech0% (1)

- Basic Mech Civil EnggDocument94 pagesBasic Mech Civil EnggVel MuruganNo ratings yet

- Ic Engines: Four Stroke Cycle Diesel EnginesDocument11 pagesIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNo ratings yet

- Internal Combustion EngineDocument46 pagesInternal Combustion EngineJoseph Rebanal AlmanzaNo ratings yet

- IC Engines AutomobilesDocument91 pagesIC Engines Automobileskapun kumar nayakNo ratings yet

- Reciprocating Engines Section BDocument45 pagesReciprocating Engines Section BJuly TadeNo ratings yet

- EngineDocument35 pagesEnginesarah rashaNo ratings yet

- IC enginesDocument17 pagesIC enginesS V Garata ReddyNo ratings yet

- Diesel CycleDocument11 pagesDiesel CycleEng Osama HusamNo ratings yet

- Me 56Document9 pagesMe 56RhizhailNo ratings yet

- IC EnginesDocument8 pagesIC EnginesNo MINo ratings yet

- Operation of 4-Stroke Cycle EnginesDocument1 pageOperation of 4-Stroke Cycle EnginesRhea NasamNo ratings yet

- Diesel EngineDocument2 pagesDiesel EnginechanchalsadhNo ratings yet

- Meec Prelim CompilationDocument16 pagesMeec Prelim CompilationBen Aldrian IbañezNo ratings yet

- List of Experiments: Lab In-Charge Hod MeDocument41 pagesList of Experiments: Lab In-Charge Hod MeAshiq HussainNo ratings yet

- Four-Stroke Diesel Engine CyclesDocument10 pagesFour-Stroke Diesel Engine Cyclesmechjobs4meNo ratings yet

- Four Stroke Engine - by SaisaekwanhlaineDocument14 pagesFour Stroke Engine - by Saisaekwanhlainesaisae KwanhlaineNo ratings yet

- Basic automobile engineering assignmentDocument47 pagesBasic automobile engineering assignmentGautam PrajapatNo ratings yet

- LECTURE-2_ENGINEDocument91 pagesLECTURE-2_ENGINEHeleana Faye BundocNo ratings yet

- Two and Three Wheeler NotesDocument49 pagesTwo and Three Wheeler NotesAbishek AbhNo ratings yet

- Lect 2Document13 pagesLect 2khalid mustafaNo ratings yet

- ICE Notes (Unit 2)Document78 pagesICE Notes (Unit 2)Karamvir SinghNo ratings yet

- Diesel CycleDocument7 pagesDiesel CycleRehman MansuriNo ratings yet

- 4-2-SDocument142 pages4-2-SMuhammad RazaNo ratings yet

- 4 Stroke Diesel Engine ArslanDocument5 pages4 Stroke Diesel Engine ArslanMuhammad Arslan AfzalNo ratings yet

- Differences Between Petrol and Diesel EnginesDocument48 pagesDifferences Between Petrol and Diesel EnginesSafiullah MangrioNo ratings yet

- Unit2 1 10Document10 pagesUnit2 1 10mohd AdilNo ratings yet

- Engine 4 StrokeDocument16 pagesEngine 4 Strokeelsoukkary100% (2)

- Experiment No 11Document6 pagesExperiment No 11ayesha amjadNo ratings yet

- Engines ExplainedDocument64 pagesEngines ExplainedSujithNo ratings yet

- 04 Basic Schematic Diagram of A Rotary Drilling Rig PDFDocument3 pages04 Basic Schematic Diagram of A Rotary Drilling Rig PDFSakthivel Swaminathan50% (2)

- Jet Pump Test RigDocument7 pagesJet Pump Test RigIrshad AfridiNo ratings yet

- Fundamentals/Preparatory Classes: Subject: PolityDocument36 pagesFundamentals/Preparatory Classes: Subject: PolityIndira DeetaNo ratings yet

- Reciprocating Pump Components Working UsesDocument1 pageReciprocating Pump Components Working UsesIrshad AfridiNo ratings yet

- Reciprocating Pump Components Working UsesDocument1 pageReciprocating Pump Components Working UsesIrshad AfridiNo ratings yet

- Four Stroke Cycle EnginesDocument1 pageFour Stroke Cycle EnginesIrshad AfridiNo ratings yet

- Design and Development of Smart Speed Breaker Ijariie8556 PDFDocument5 pagesDesign and Development of Smart Speed Breaker Ijariie8556 PDFsumeet shindeNo ratings yet

- ETC Pra 6Document6 pagesETC Pra 6ELENo ratings yet

- A Review of Power Battery Thermal Energy Management PDFDocument18 pagesA Review of Power Battery Thermal Energy Management PDFHARSHIT KUMARNo ratings yet

- The 1.8 Turbo Gasoline: Drive Your IdeasDocument4 pagesThe 1.8 Turbo Gasoline: Drive Your Ideasmechatronics overviewNo ratings yet

- Carnwal: Extravagant by DesignDocument32 pagesCarnwal: Extravagant by DesignGajendra SinghNo ratings yet

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaNo ratings yet

- Efficiency Comparison Between Series Hybrid Bike and Traditional BikeDocument7 pagesEfficiency Comparison Between Series Hybrid Bike and Traditional BikewilliamNo ratings yet

- Coples RaptorDocument36 pagesCoples RaptorNadia AlvaradoNo ratings yet

- Hydraulic COP 1838ME Rock Drills COP 1838HE: Overhauling Instructions ForDocument72 pagesHydraulic COP 1838ME Rock Drills COP 1838HE: Overhauling Instructions ForrolandNo ratings yet

- Literature Review On Feasibility Study o PDFDocument4 pagesLiterature Review On Feasibility Study o PDFSana IdreesNo ratings yet

- India Nippon Electricals LimitedDocument26 pagesIndia Nippon Electricals Limitedsumit kumarNo ratings yet

- C&W HAND BOOK-27.03.2015 - With HeadingDocument464 pagesC&W HAND BOOK-27.03.2015 - With Headingjoby100% (2)

- Success Story of Tata MotorsDocument43 pagesSuccess Story of Tata MotorsHarshit GroverNo ratings yet

- AJR Breif ProfileDocument13 pagesAJR Breif ProfilesajalNo ratings yet

- Boxer BM 150Document36 pagesBoxer BM 150MATEO FRANCISCO REINOSO GOMEZNo ratings yet

- Parts Manual 2N-3010Document221 pagesParts Manual 2N-3010Sergiy SVNo ratings yet

- My PPT On CVTDocument16 pagesMy PPT On CVTSaurabh Shekhar100% (1)

- Classification of CarsDocument13 pagesClassification of CarsPRATICK RANJAN GAYENNo ratings yet

- United India Insurance Company Limited: MR Ayyaraju MDocument4 pagesUnited India Insurance Company Limited: MR Ayyaraju MAdm RajaNo ratings yet

- Heavy Attachment ToolsDocument62 pagesHeavy Attachment ToolsLuis JesusNo ratings yet