Professional Documents

Culture Documents

Aft Cooler Ds

Aft Cooler Ds

Uploaded by

Nurcahyo Djati WOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aft Cooler Ds

Aft Cooler Ds

Uploaded by

Nurcahyo Djati WCopyright:

Available Formats

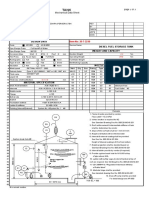

CLIENT : PT Perusahaan Gas Negara (Persero) Tbk. REV.

PROJECT : SOUTH SUMATRA-WEST JAVA GAS PIPELINE PROJECT DATE

BY

EPC LOGO JOB NO : CHKD

DOC NO : AFTER COOLER APPVD

MECHANICAL DATASHEET APPVD

Item No. : 20-E-1110 A/B/C l FOR PROPOSAL ¡ FOR PURCHASE ¡ AS BUILT Page 3 of 3

No. of Unit :3 No. of Bay/Unit : 1 No. of Bays in Parallel : 2 0 CONSTRUCTION

Selection :- Type :- Draft : Forced 1 Design / Test Pressure : 1150 / As per code psig

Surface/Unit Finned : by vendor ft2 2 Design Temperature : 270 o

F

Bare Tube : by vendor ft2 3 Construction Code : ASME VIII DIV. 1 & API 661

Total Heat Exchanged / MTD (for reference) : 2.23E+07 BTU/hr / 44.8 oF 4 Bundles Headers

OVERALL HEAT TRANSFER RATE 5 Size (maximum) # note 6 : No Passes # note 6 : 4

Finned Tube : by vendor BTU/h.ft2.oF 6 No/Bay : 1 Type : Plug

Bare Tube, Service : by vendor BTU/h.ft2.oF 7 Bundle : In Parallel : In Series : 2 No (Nozzles Size) In : 1 (8" ASME #600)

Bare Tube, Clean : by vendor BTU/h.ft2.oF 8 Bays : In Parallel : In Series : 1 No (Nozzles Size) out : 1 (6" ASME #600)

TUBE SIDE DATA 9 No Tube Rows : by vendor Rating & Facing : WNRF

Fluid Circulated : Hydrocarbon Gas 10 Frame : A-516 Gr. 70 Tube/Tubesheet Code : ASME Sec. VIII DIV. 1, Add. 2001

Total Fluid Entering : 141000x1.1 kg/hr 11 Slope : 1% Header Mat. : A-516 Gr. 70

In Out 12 Tube Gasket Mat. : Soft Iron

Temperature : 236.2 125 o

F 13 Material : A-179 Plug Mat. : A-105

Vapor : 141000x1.1 141000x1.1 kg/hr 14 Type : Seamless Corrosion Allowance : 3 mm

Liquid : - - kg/hr 15 Outside Diameter : by vendor mm TI / PI Connect : No / No

Steam : - - kg/hr 16 Thickness # note 6 : (BWG #12) 2.77 mm Chemical Cleaning : No

Water : - - kg/hr 17 No/Bundle : by vendor Miscellaneaous (see note)

Noncondesable : - - kg/hr 18 Length # note 6 : 9000 mm Structure : A 36 / SS 400 or Equivalent

Vapor Mol. Wt. Avg : - - 19 Tri. Pitch # note 6 : 66.54 mm Louvers : YES, Pneumatic type of louver, manual settings, Aluminium

20 Walkways : Header Steel

Avg Viscosity Liquid/Vapor : - / note 7 - / note 7 cP 21 Fins Fan Guards : Steel

Avg Density Liquid/Vapor : - / note 7 - / note 7 kg/m3 22 Material : Aluminium Vibr. Switch : Yes (#note 9) Explotion proof

Avg Spec. Heat Liquid/Vapor : - / note 7 - / note 7 kcal/kg.oC 23 Outside Diameter : by vendor mm Steam Coils In / Out : No

Avg Thermal Conduct Liquid/Vapor : - - / - kcal/m.h.oC 24 Density No/Meter : by vendor Insect Screen : Yes (#note 8)

Latent Heat : - - / - kcal/kg.oC 25 Type : Groove & Embeded Junction Box : Yes, Explotion proof (IP 55)

Pour Point : - - o

F 26 MECHANICAL EQUIPMENT

Pressure In : 1065 - psig 27 MECHANICAL EQUIPMENT Motor

Pressure Drop Allow / Calc : 15 / - psi 28 Fans Mfr/Model/Type : by vendor

Fouling Resistance : 0.00146 ft2.h.oF/BTU 29 Mfr / Model : by vendor RPM : 1500

AIR SIDE DATA 30 No/Bay : 2 or more (#note 10) Power (HP) : by vendor

Total Air Quantity : by Vendor kg/hr(20oC, 1 atm) 31 No of Blades : by vendor Enclosure : IP 55

Air Quantity per Fan : 182663 ACFM 32 Speed : by vendor rpm Hazardous Area : Class I, Div.2, Group C & D

Face Velocity : 9.58 ft/s 33 Power/Fan (minimum) : by vendor HP Temperature Rise Class : B Service Fac. : 1

Temperature In / Out : 93 / by Vendor o

F 34 Diameter : by vendor mm Insulation Class : F Method Start : D.O.L (# note 11)

Fouling Resistance : 0.00195 ft2.h.oF/BTU 35 Pitch : Manual Settings Supply System : 380 V/3 phase/50 Hz

Static Pressure : 0.786 in H2O 36 Pitch Angle : by vendor : 220 V/1 phase/50 Hz (for space heater)

Altitude above Sea Level : 62 - 82 m 37 Blade Mat'l/Hub Mat'l : Aluminium / Aluminium Speed Reducer

SPL at 1 m beside equipment : 85 dB (A) 38 Type : V-Belt

Wind speed : 58.7 ft/s, ASCE 7 -2002 39 Ratio : by vendor

Seismic factor : Zone 3, UDC 699841 - 1987 or UBC-1997 40 Brand : FENNER or Equivalent

Item combined with same fans 41 Note :

Estimation Weight Bundle : by Vendor Ton/unit 42 7. Properties of fluid :

Shipping : by Vendor Ton/unit 43 Vapor Properties Inlet Gas (at 1065 Psig) Outlet Gas (at 1050 Psig)

Test/Full of Water : by Vendor Ton/unit 44 Temperature ºF 245 205 165 125 245 205 165 125

Note : 47 Viscosity cP 0.0161 0.0156 0.0151 0.0146 0.0161 0.0156 0.0150 0.0145

1. Vendor shall comply with Specification for After Cooler (Doc. No.: 005-20-M-SP-202) 48 Density lb/ft3 3.134 3.394 3.715 4.124 3.088 3.344 3.658 4.059

2. Vendor shall comply with Individual Specification for Induction Motors (Doc. No.: 005-20-E-SP-205) 49 Spec Heat Btu/lb-ºF 0.5909 0.5872 0.5886 0.5984 0.5900 0.5861 0.5872 0.5965

3. Vendor shall comply with General Specification for Electrical Equipment in Package Unit 50 Thermal cond. Btu/hr-ft-ºF 0.0282 0.02654 0.02502 0.02365 0.0281 0.0265 0.0250 0.0236

(Doc. No.: 005-20-E-SP-209) 51 8. Insect screen shall be provide by vendor at suction side of fan. The total opening area of the insect screen shall be considered for fan

4. Vendor shall provide anti condensation heaters for electric motor 52 selection. Size of the screen will be informed later

5. Vendor shall comply with Specification for Painting and Protective Coatings (Doc. No.: 005-20-M-SP-204) 53 9. Vibration cut-out shall be manual, externally reset type and shall have sensitively adjustment

6. Vendor can propose another size of tube length, tube OD, tube thickness, triangular pitch, bundles width, 54 10. Decided by vendor

detail of fins, pass & row configuration for the performance optimization 55 11. Star-Delta starting method shall be applied if the motor rating is 30 kW and above, see Doc. No.: 005-20-E-SP-205

56

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- 4773.1-2015 - Masonry in Small Buildings - DesignDocument109 pages4773.1-2015 - Masonry in Small Buildings - DesignMark Carroll-Chilts100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CS 1102 - Unit 3 Programming AssignmentDocument3 pagesCS 1102 - Unit 3 Programming AssignmentKareem Nabil0% (4)

- Diesel Tank SizingDocument7 pagesDiesel Tank SizingNurcahyo Djati W100% (2)

- Capex Opex..Document6 pagesCapex Opex..Nurcahyo Djati WNo ratings yet

- VENDOR LIST CNG As 100510Document4 pagesVENDOR LIST CNG As 100510Nurcahyo Djati WNo ratings yet

- Capex OpexDocument5 pagesCapex OpexNurcahyo Djati WNo ratings yet

- CNG O&MDocument15 pagesCNG O&MNurcahyo Djati W0% (1)

- Air Compressor DWGDocument1 pageAir Compressor DWGNurcahyo Djati WNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Crane ds1Document2 pagesCrane ds1Nurcahyo Djati WNo ratings yet

- 2012 01 - Pipeline Route Selection Right of Way - Mustang PDFDocument3 pages2012 01 - Pipeline Route Selection Right of Way - Mustang PDFNurcahyo Djati WNo ratings yet

- Blowdown RepDocument3 pagesBlowdown RepNurcahyo Djati WNo ratings yet

- More Math Games & Activities From Around The World ManteshDocument174 pagesMore Math Games & Activities From Around The World ManteshFrancis Rivero100% (1)

- Index of C++ ProgramsDocument2 pagesIndex of C++ ProgramspranshavsNo ratings yet

- D5C Touch SwitchDocument8 pagesD5C Touch SwitchMuhamad PriyatnaNo ratings yet

- 1.3.7 High - and Low-Level Languages and Their TranslatorsDocument4 pages1.3.7 High - and Low-Level Languages and Their TranslatorsRana Hassan TariqNo ratings yet

- Micro Electronic PillDocument2 pagesMicro Electronic PillDevendra Singh RajpurohitNo ratings yet

- Digital Datasets For Chapter 7: In-Situ TestingDocument1 pageDigital Datasets For Chapter 7: In-Situ TestingorizaNo ratings yet

- ISD1700Document24 pagesISD1700Kevin De La CruzNo ratings yet

- Bread & Pastry Production Grade 7/8 ExploratoryDocument43 pagesBread & Pastry Production Grade 7/8 ExploratoryPRINCESS VILLANo ratings yet

- Geometric Characteristics of Pull-Apart Basins: ResearchDocument8 pagesGeometric Characteristics of Pull-Apart Basins: ResearchAntonioNo ratings yet

- Three-Phase Unbalanced System With PV SystemsDocument22 pagesThree-Phase Unbalanced System With PV SystemsAum4Eng HelpNo ratings yet

- 01 - PDC Study of Step Response of First Order SystemDocument8 pages01 - PDC Study of Step Response of First Order SystemNeena Regi100% (1)

- Microsoft Project Training Deck For BeginnersDocument81 pagesMicrosoft Project Training Deck For Beginnersrvnkrish24No ratings yet

- Base EngineDocument22 pagesBase EngineLukaČubelićNo ratings yet

- MStat PSB 2018 PDFDocument2 pagesMStat PSB 2018 PDFabhayNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- IP Access Lists: Objective Lab TopologyDocument5 pagesIP Access Lists: Objective Lab TopologyTomas Rodriguez RamirezNo ratings yet

- TOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementDocument5 pagesTOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementShanks XDNo ratings yet

- ID Proses Berpikir Kritis Peserta Didik DalDocument11 pagesID Proses Berpikir Kritis Peserta Didik DalChristian GintingNo ratings yet

- Learning The Software-MATLABDocument3 pagesLearning The Software-MATLABKratagya SinghalNo ratings yet

- Synopsis of GSM Based Remote Electricity Billing SystemDocument52 pagesSynopsis of GSM Based Remote Electricity Billing SystemHemant PatelNo ratings yet

- VAKEV Advanced Mathematics S6 SBDocument540 pagesVAKEV Advanced Mathematics S6 SBvigiraneza0No ratings yet

- Nicol Prism-ExplainedDocument2 pagesNicol Prism-ExplainedAnshuman MahapatraNo ratings yet

- Nominal Performance: Principal Dimensions - MMDocument1 pageNominal Performance: Principal Dimensions - MMUlil Amri100% (2)

- Soft Ground Tunneling Design and Construction-NGS Fourth Monthly Lecture Series On 7th Feb 2019Document29 pagesSoft Ground Tunneling Design and Construction-NGS Fourth Monthly Lecture Series On 7th Feb 2019Bigyan UpadhayayNo ratings yet

- Minkovski Ghosh1990Document35 pagesMinkovski Ghosh1990wongtheenguyenNo ratings yet

- Anatomy, Lecture 2, Joints (Lecture Notes)Document12 pagesAnatomy, Lecture 2, Joints (Lecture Notes)Ali Al-QudsiNo ratings yet

- Balancing Without Phase ReadingDocument2 pagesBalancing Without Phase Readingvirtual_56No ratings yet

- TWW Scrapwood Jewelry Box Metric V1Document7 pagesTWW Scrapwood Jewelry Box Metric V1Victor Parvan100% (1)