Professional Documents

Culture Documents

GM50H Engine Controller

Uploaded by

gunawan67%(3)67% found this document useful (3 votes)

3K views3 pagesOriginal Title

GM50H_Engine_Controller

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

3K views3 pagesGM50H Engine Controller

Uploaded by

gunawanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

GM50H Configuration and installation instructions Ver1.

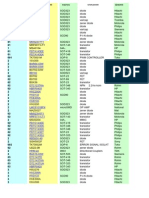

GM50H Configuration and installation 0:disabled P16 Safety delay 3~240S(10S)

instructions 1:VD0 40℃-120℃

Ver1.0

Water

2:Datcon High 0~99S(30S)

Alarm output

Brief Introduction P03 Temperature P17 0:alarm output disabled

3:Huanghe 40℃-120℃ time

GM50H is one light and low price-orientated module used for Sensor 99:alarm output all th e time

4:3015238 40℃-120℃

demonstrating engine RPM,water/oil temperature, oil 0:disabled

5:Self-defined P18 Alarm function

pressure, battery voltage and Hours. The users can adjust 1:available

0:disabled

and set the parameters by the button on the front face in

1:VD0 40℃-120℃ Note: both of the input voltage and speed sensor can

order to meet the different requests. Besides, it uses the

2:Datcon High check the RPM, please choose one option for setting only (if

European-style terminals for connection which is more

convenient for installation and detachment. Oil 3:HUANGHE 40℃-120℃ available for both options, then the result from speed sensor

Parameters adjustment P04 Temperature 4:3015238 40℃-120℃ is on priority);

Press “PROG” for 2 seconds and release it when the LED Sensor 5:Changfa OEM If the system checked the oil pressure is over "the crank oil

shows “P-00” which means the system comes into edition 6:Jiangsu OEM 140℃ pressure value"(P15) or "crank RPM value"(P14) once the

page and the first option is shown. Press "+" or "-" to choose module is connected with main power, then it will regard the

7:Shanghai OEM 150℃

the option you need and press “PROG” to step into the genset as cranked successfully.(Over speed alarm doesn't

8:Self-defined

adjustment page;Press "+" or "-" to adjust the value you want belong to this condition), which means the alarm will occur

Over-speed 0~6000RPM(1650RPM) after the safety delay when the fault is checked. The alarms

to change, then Press “PROG” to revert back to last layer and P05

Alarm (Alarm disabled if value is “0”) should be cleared after the module disconnects with power.

press “PROG” again for 2 seconds so that the value can be Over-speed

saved and the system will exit from this mode. P06 0.0~5.5S(0.5S) Specification

Delay

Please note if the users need to set the sensor curve: the DC Supply: 8~36 V continuous

Low Oil 0~1100 KPA(100KPA)

system comes into the sensor curve setting page if the LED P07 Consumption Power:MAX 1 W

Pressure (Alarm disabled if value is “0”) Sensor Resistance:0~1000Ohm

shows “nu.1”. Press "+" or "-" to choose the curve value you

need and press “PROG” to step into the adjustment page; 50~180℃(95℃) Magnetic Input Frequency:Freq 100Hz~15kHz

High

then press “PROG” to revert back to last layer and press P08 ((Alarm disabled if value is Magnetic Pick-up Voltage Input Range:AC 3~65 V

Temperature

“PROG” again for 2 seconds so that the value can be saved “180”) Input Power Signal: AC40~280V(45~70Hz)

and the system will exit from this mode. 50~180℃(105℃) RPM Accuracy:deviation≦±1%;

High Oil

P09 (Alarm disabled if the value is Oil Pressure Accuracy:0-1100KPA, deviation≦±2.5%;

Notes: it is valid for the changed value once adjusted. Temperature

Parameters “180”) Water Temperature Accuracy:10-120℃, eviation≦±2.5%;

P10 Sensor Delay 0.5~10.0S(5.0S) Oil Temperature Accuracy:10-150℃ deviation≦±2.5%;

Code parameter Range(default)

Battery Voltage Accuracy:deviation≦±1%;

5.0~28.0V(9.0V) Accumulation Time :0-9999Hours;

P00 Flywheel Teeth 0~300(0) Low battery

P11 (Alarm disabled if the value is Min Time Record :0.1Hours;

Voltage Alarm

0 :available 1:30 “5.0”) Alarm Output: Neg- output, Max DC1A;

Frequency

(50Hz-1500RPM) 0:Page changed manually Operation Temperature:-20~65℃;

P01 to P12 Page-change 1:Page changed

1 :disabled 1:60 Storage Temperature:-40~85℃;

RPM automatically

(50Hz-3000RPM) Ingress Protection:IP54(The front face after installation);

0:disabled Self-recycling Size (W * H * D):100mm*100mm*77mm;

P13 1~120S(5S)

1:VD0 10bar Interval Installation Size (W * H):91mm*91mm;

Oil Pressure 2:Datcon 10bar RPM for start Weight:150 g

P02 P14 200~1000RPM(600RPM)

Sensor 3:Huanghe 10bar success

4:3015237 10bar Oil Pressure

5:Self-defined P15 for start 138-412KPA(206KPA)

success

GM50H Configuration and installation instructions Ver1.0

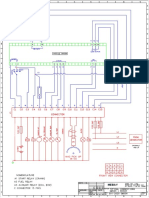

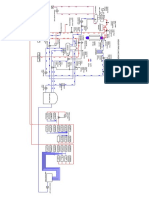

Diagram

You might also like

- GM50H MK2 Series Configuration and Instructions Ver1.3-0809 博策Document4 pagesGM50H MK2 Series Configuration and Instructions Ver1.3-0809 博策mateus oliveiraNo ratings yet

- EMS28 User Guide V1 - 5Document7 pagesEMS28 User Guide V1 - 5Anas Basarah100% (1)

- BX50H With Gm50h-Def-1 PDFDocument1 pageBX50H With Gm50h-Def-1 PDFJuan José Tovar PérezNo ratings yet

- Sx440, STAMFORD ManualDocument4 pagesSx440, STAMFORD ManualSarawut PipeNo ratings yet

- Alarms Programmed Through Code ForDocument2 pagesAlarms Programmed Through Code ForAbdul Manan75% (4)

- Multi-Instrument With Control and Protection Device For Genset Unit TYPE SPG-120/20Document12 pagesMulti-Instrument With Control and Protection Device For Genset Unit TYPE SPG-120/20lejocolsaNo ratings yet

- Exciter control system diagramDocument1 pageExciter control system diagramRusmiyanto Yanto100% (3)

- Proportional Control Valve 2M25-RGC2Document3 pagesProportional Control Valve 2M25-RGC2Wellington Andrade100% (1)

- Avr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Document2 pagesAvr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Jose Pirulli100% (1)

- DKG 307 User ManualDocument29 pagesDKG 307 User ManualTani100% (2)

- 12061903206177Document33 pages12061903206177George Jhonson33% (6)

- Sensor Ga 30Document26 pagesSensor Ga 30Romer SimpsonNo ratings yet

- IN NT MRS 2 0 0 X Fast User GuideDocument2 pagesIN NT MRS 2 0 0 X Fast User GuideMaylen Rivas100% (1)

- MAM690 DiagramDocument5 pagesMAM690 Diagramsteve@air-innovations.co.za100% (1)

- DC5xD MKII Series Configuration and Instructions V1.0-20180608Document11 pagesDC5xD MKII Series Configuration and Instructions V1.0-20180608Alvaro Gomez Gomez100% (10)

- Diagram LCG2Document1 pageDiagram LCG2Edgar De50% (2)

- Basler Decs-100 AVR ManualDocument83 pagesBasler Decs-100 AVR ManualKawarauNo ratings yet

- Leroy Somer r448 Automatic Voltage RegulatorDocument16 pagesLeroy Somer r448 Automatic Voltage RegulatorTauck Htun Linn100% (3)

- XS 400B-03Document13 pagesXS 400B-03George Vasiliou100% (11)

- Dse5510 Diagram PDFDocument1 pageDse5510 Diagram PDFRodrigo ObregonNo ratings yet

- Governor Controller (GAC ESD5111) - DatasheetDocument5 pagesGovernor Controller (GAC ESD5111) - Datasheetazhan77No ratings yet

- Deep Sea 5110Document2 pagesDeep Sea 5110Mahmoud Elbakry100% (2)

- Manual Deep Sea 520Document19 pagesManual Deep Sea 520MH..202380% (5)

- MITSUBISHI DIESEL ENGINE TECHNICAL INFORMATION MANUALDocument13 pagesMITSUBISHI DIESEL ENGINE TECHNICAL INFORMATION MANUALSalman Arif100% (2)

- Engine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFDocument159 pagesEngine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFJavier Everest50% (2)

- MANY0730A.GB AirMaster P1 - Positive Displacement ApplicationDocument11 pagesMANY0730A.GB AirMaster P1 - Positive Displacement Applicationsebastian100% (4)

- CMD 2 ManualDocument30 pagesCMD 2 ManualAbdul Manan60% (5)

- Cat 3456 PDFDocument2 pagesCat 3456 PDFKhaled KamelNo ratings yet

- Dse8610 Installation InstDocument2 pagesDse8610 Installation Instbugoff700100% (3)

- Heavy duty pressure controls data sheetDocument30 pagesHeavy duty pressure controls data sheetZawZawAung7650% (4)

- CAM680Document20 pagesCAM680mirmilos100% (3)

- Powercommand 40-02 TRANSFER Switch ControlDocument5 pagesPowercommand 40-02 TRANSFER Switch ControlWagnerNo ratings yet

- Volvo TAD750VE Engine WiringDocument3 pagesVolvo TAD750VE Engine WiringArtur Daneshwar100% (2)

- Generator controller instructionsDocument2 pagesGenerator controller instructionsElizabeth Myers94% (16)

- DSE6020 Programming ManualDocument62 pagesDSE6020 Programming Manualamelito_guab72100% (9)

- Speed Relay spr-p06Document3 pagesSpeed Relay spr-p06Elect Yan Lumoso100% (2)

- Parameter Viewing and Configuration (Caterpillar PC Software)Document29 pagesParameter Viewing and Configuration (Caterpillar PC Software)wagner_guimarães_1No ratings yet

- LT3-N Single Phase Generator PresentationDocument75 pagesLT3-N Single Phase Generator Presentationubaldo caraballo100% (1)

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDocument3 pagesDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteNo ratings yet

- Ems39 EngDocument4 pagesEms39 EngDaniel AsquiNo ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFKo Thet100% (5)

- Dse7510 Installation InstDocument2 pagesDse7510 Installation InstZakia Nahrisyah100% (1)

- Deif Operating ManualDocument54 pagesDeif Operating ManualRidzuan Syns93% (14)

- 501eng Deep SeaDocument2 pages501eng Deep Seajadi purwonoNo ratings yet

- Edc IiiDocument1 pageEdc Iiidientumd89% (18)

- Noris ArrangementDocument59 pagesNoris Arrangementsjsship100% (3)

- 6000TMDocument39 pages6000TMnam vo100% (3)

- Cummins ActuatorDocument4 pagesCummins ActuatorLaiq Zaman100% (1)

- (Woodward) DPG-2201-001 Digital Governor - User ManualDocument40 pages(Woodward) DPG-2201-001 Digital Governor - User ManualAbdulrahman Al HuribyNo ratings yet

- Wiring Diagram To Comap PDFDocument1 pageWiring Diagram To Comap PDFMERTAL JAYA ABADI50% (2)

- Guard Evolution ManualDocument38 pagesGuard Evolution ManualJaffer HussainNo ratings yet

- HARSEN GU610A Controller Brief Introduction Harsen™ UDocument4 pagesHARSEN GU610A Controller Brief Introduction Harsen™ UammNo ratings yet

- XMTG-818(T) digital temperature controller manualDocument6 pagesXMTG-818(T) digital temperature controller manualyesdanNo ratings yet

- 116 UserDocument4 pages116 UserWinston diaz valeraNo ratings yet

- 116 UserDocument4 pages116 UserMohamed Yahya100% (1)

- Delta DT3 ManualDocument21 pagesDelta DT3 ManualGrosu NicolaeNo ratings yet

- Temperature Controller Catalog - EngDocument9 pagesTemperature Controller Catalog - EngJuan Gervacio OrtegaNo ratings yet

- DKG-116 Manual and Remote Start Unit Control PanelDocument2 pagesDKG-116 Manual and Remote Start Unit Control PanelDave WallaceNo ratings yet

- Ai-208 V7.6Document7 pagesAi-208 V7.6Anonymous h2rz52No ratings yet

- Gu320a PDFDocument4 pagesGu320a PDFbambangNo ratings yet

- AC Servo Drive: Operation ManualDocument147 pagesAC Servo Drive: Operation ManualjassemNo ratings yet

- FJ4000A4-21 MonitorDocument8 pagesFJ4000A4-21 Monitorgunawan100% (1)

- CAT Fuel Priming Pump Parts List r1Document2 pagesCAT Fuel Priming Pump Parts List r1gunawanNo ratings yet

- Dry Start Priming Procedure For 3500 Machine Engines With Electronic Unit Injection (EUI) (1250 1258) ... 1994 - 12 - 05 #SEPD02350006 CaterpillarDocument2 pagesDry Start Priming Procedure For 3500 Machine Engines With Electronic Unit Injection (EUI) (1250 1258) ... 1994 - 12 - 05 #SEPD02350006 CaterpillargunawanNo ratings yet

- CAT Fuel Water Separators PDFDocument2 pagesCAT Fuel Water Separators PDFgunawanNo ratings yet

- CAT Fuel Water Separators PDFDocument2 pagesCAT Fuel Water Separators PDFgunawanNo ratings yet

- Automatic Transfer SwitchDocument13 pagesAutomatic Transfer SwitchAid KaradzaNo ratings yet

- H PDFDocument2 pagesH PDFAdilson Melo de MouraNo ratings yet

- Product Profile: 60 V, 300 Ma N-Channel Trench MOSFETDocument13 pagesProduct Profile: 60 V, 300 Ma N-Channel Trench MOSFETgunawanNo ratings yet

- SMD MarkcodesDocument308 pagesSMD Markcodestraianbasescuromania72% (32)

- Avanza - Wiring DiagramDocument33 pagesAvanza - Wiring DiagramAnugrah Raden85% (41)

- Boiler Line Diagram SteamDocument1 pageBoiler Line Diagram SteamgunawanNo ratings yet

- Eng KTM-800Document47 pagesEng KTM-800gunawanNo ratings yet

- Schrack RM732024 DatasheetDocument4 pagesSchrack RM732024 Datasheetpaula09No ratings yet

- Level Instrument Study - Utilities: Hindustan Urvarak and Rasayan Limited Barauni & SindriDocument20 pagesLevel Instrument Study - Utilities: Hindustan Urvarak and Rasayan Limited Barauni & SindrivinayNo ratings yet

- Cam SwitchesDocument11 pagesCam SwitchesSanjeev SinghNo ratings yet

- Tes VCB PG en 031215Document80 pagesTes VCB PG en 031215Anthony BarbachanNo ratings yet

- Report Statics Group 5Document10 pagesReport Statics Group 5Amir IskandarNo ratings yet

- Compatibility of Analog Signals For Electronic Industrial Process InstrumentsDocument20 pagesCompatibility of Analog Signals For Electronic Industrial Process InstrumentsFrancisco MoyaNo ratings yet

- Heat Transfer Chapter One and TwoDocument74 pagesHeat Transfer Chapter One and TwoTariku Negash100% (2)

- Chapter 1 FluidsDocument39 pagesChapter 1 FluidsnrhdyaaNo ratings yet

- SC475 Cummins GeneratorDocument4 pagesSC475 Cummins GeneratorChen CarolineNo ratings yet

- Parameter Design For A 6.78-MHz Wireless Power Transfer SystemDocument12 pagesParameter Design For A 6.78-MHz Wireless Power Transfer Systemagmnm1962No ratings yet

- Dynamics - Kinematics 1 PDFDocument11 pagesDynamics - Kinematics 1 PDFChuck Dave DiazNo ratings yet

- Energy Management System in HEV Using PI ControllerDocument5 pagesEnergy Management System in HEV Using PI ControllerSekhar ReddyNo ratings yet

- Distributor Stock List PartsDocument3 pagesDistributor Stock List PartsGerardo MaciasNo ratings yet

- IJIREEICE1 S Sandeep Power Quality ImprovementDocument7 pagesIJIREEICE1 S Sandeep Power Quality ImprovementJuan Dela CruzNo ratings yet

- Electrical Load List - Rev. 00Document7 pagesElectrical Load List - Rev. 00swarupananda mohantyNo ratings yet

- Pan Pearl River Delta Physics Olympiad 2017Document9 pagesPan Pearl River Delta Physics Olympiad 2017Matheus PinheiroNo ratings yet

- Pdu Lab Manual 104Document94 pagesPdu Lab Manual 104Rana FaizanNo ratings yet

- Electromagnetic Relays Explained (K2Document30 pagesElectromagnetic Relays Explained (K2Vairaperumal KNo ratings yet

- (Week 2, Day 1, Activity # 4) : TLE 9 - ICT (Third Quarter)Document6 pages(Week 2, Day 1, Activity # 4) : TLE 9 - ICT (Third Quarter)armand lagriaNo ratings yet

- Force and Motion Unit PlanDocument5 pagesForce and Motion Unit Planapi-499815701No ratings yet

- 01.phy Jee Main Original 01.02.2021Document26 pages01.phy Jee Main Original 01.02.2021Bramha ArpnamNo ratings yet

- Physics Investigatory ProjectDocument18 pagesPhysics Investigatory ProjectMoghanNo ratings yet

- Siemens Simodrive ManualDocument436 pagesSiemens Simodrive ManualMariel Lopez ValdezNo ratings yet

- Ee2302 Emii Nov 2010Document2 pagesEe2302 Emii Nov 2010Belayneh TadesseNo ratings yet

- tdb4 U200Document3 pagestdb4 U200bansalrNo ratings yet

- Common Data For Q. - 51 and Q.52: Visit Us At: WWW - Nodia.co - inDocument2 pagesCommon Data For Q. - 51 and Q.52: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Wind Power For StudentsDocument33 pagesWind Power For StudentsFarah Sofhia Mohd ZinNo ratings yet

- 377674main Black Hole MathDocument126 pages377674main Black Hole Mathapi-253006610No ratings yet

- Hsslive XI Physics ResonanceColumn1Document1 pageHsslive XI Physics ResonanceColumn1Saajan MaharjanNo ratings yet

- DC Load FlowDocument5 pagesDC Load Flowstrange_kid82100% (1)