Professional Documents

Culture Documents

Jsa For Piping (FRP) Work

Uploaded by

You1993100%(2)100% found this document useful (2 votes)

523 views10 pagesThe document is a job safety analysis template for piping (FRP) work that identifies potential hazards at each job step and recommended controls. Step 1 involves preparing materials and equipment, with hazards including worker injury, damage to materials/equipment, falling hazards, and being hit by objects. Recommended controls include safety orientations, providing proper PPE, conducting toolbox meetings, confirming work permits and barricades, following loading/unloading procedures, and using signal men.

Original Description:

JSA

Original Title

JSA FOR PIPING (FRP) WORK

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a job safety analysis template for piping (FRP) work that identifies potential hazards at each job step and recommended controls. Step 1 involves preparing materials and equipment, with hazards including worker injury, damage to materials/equipment, falling hazards, and being hit by objects. Recommended controls include safety orientations, providing proper PPE, conducting toolbox meetings, confirming work permits and barricades, following loading/unloading procedures, and using signal men.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

523 views10 pagesJsa For Piping (FRP) Work

Uploaded by

You1993The document is a job safety analysis template for piping (FRP) work that identifies potential hazards at each job step and recommended controls. Step 1 involves preparing materials and equipment, with hazards including worker injury, damage to materials/equipment, falling hazards, and being hit by objects. Recommended controls include safety orientations, providing proper PPE, conducting toolbox meetings, confirming work permits and barricades, following loading/unloading procedures, and using signal men.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 10

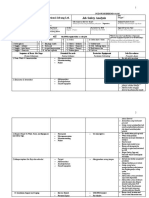

Sheet 1 of 10

JOB NO. REV

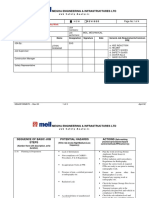

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

JOB SAFETY ANALYSIS (TEMPLATE)

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

PIPING (FRP) WORK

PEKERJAAN PIPA (FRP)

1. Preparation Frequent Physical W 2 5 M Safety Supervisor 2 2 L

orkers injury orientation/induction HSE Officer

(Transporting material Berkali-kali Fisik Pengawas,

Pekerja terluka Pengarahan tentang

and equipment) D keselamatan Petugas

Persiapan amage of Provide HSE

(Pengangkutan material/ approved and required PPE

equipment Menyediakan Alat Pelindung

material dan Kerusakan Diri (APD) yang dibutuhkan

peralatan) material/peralatan dan disetujui

F Conduct

alling hazard Tool Box Meeting

Potensi bahaya Melaksanakan Tool Box

terjatuh Meeting

H Confirming

it by permit, working area,

Terkena oleh barricade and required sign

board must be provide first.

Konfirmasi tentang ijin kerja,

tempat kerja, barikade dan

tanda-tanda peringatan yang

dibutuhkan harus disediakan

terlebih dahulu

Access road

for material/equipment must

be confirmed with MC

Akses jalan untuk

material/peralatan harus

dikonfirmasikan dengan MC

Follow-up

accepted work procedure

Ikuti prosedur kerja yang

telah disetujui

Proper

loading and unloading

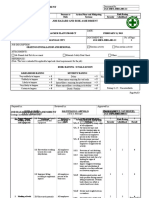

Sheet 2 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

method

Metode bongkar dan muat

yang tepat

Signal man

must be stand by all time

Signal Man harus selalu

berada ditempat kerja setiap

waktu

2. Marking One Time Physical Hit by 2 1 L Provide Supervisor 1 1 L

approved and required PPE Pengawas

(Survey work) Sekali Fisik Terkena oleh

Menyediakan Alat Pelindung

Menandai/pekerjaan Tools Diri (APD) yang dibutuhkan

survei broken dan disetujui

Alat-alat rusak Conduct

Tool Box Meeting

Melaksanakan Tool Box

Meeting

Tools and

equipment must be checked

and approved.

Alat-alat dan perlengkapan

harus dicek dan disetujui

3. Working at height Each time Physical W 4 5 H Provide Supervisor 2 3 M

Fisik orkers injury approved and required PPE HSE Officer

Bekerja di ketinggian Kadang- to conduct

Pekerja terluka Menyediakan Alat Pelindung

kadang Falling Diri (APD) yang dibutuhkan periodic

from height dan disetujui check.

Terjatuh dari Conduct Pengawas,

ketinggian Tool Box Meeting Petugas

Falling Melaksanakan Tool Box HSE

hazard Meeting melaksana

Potensi bahaya Post the kan

terjatuh work area with warning signs pengecek

Stumble and barricades an secara

Tersandung Tempatkan tanda peringatan berkala

dan barikade di tempat kerja

Safety

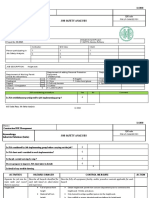

Sheet 3 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

harness must be worn at

height 1.5 meter and above

Ketinggian 1,5 meter lebih

harus memakai Safety Body

Harnnes

Provide

safety line/life line to hook up

the safety harness

Menyediakan tali pengaman

untuk mencantolkan Safety

Body Harnnes

Proper

access ladder to be used and

secured

Akses tangga yang akan

digunakan harus layak dan

aman

Properly

stacking and storage of

materials. Overloading of

materials is prohibited.

Penumpukan dan

penyimpanan material yang

tepat. Dilarang menumpuk

material terlalu berlebihan.

Tools and

materials shall be secured

properly during working

Material dan alat-alat harus

aman selama pekerjaan

No blockage

accessibility along the

platform

Tidak ada yang menghalang-

halangi akses jalan

sepanjang papan perancah

Enough and

sufficient lighting to be

installed for night working.

Sheet 4 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

Pemasangan penerangan

secukupnya untuk pekerjaan

malam

Check and

identify all overhead electrical

lines around the scaffolding

Cek dan identifikasi semua

jalur listrik di sekitar

perancah

Ensure that

the safe distance to the live

overhead electrical lines

Memastikan bahwa jarak

adalah aman dari jalur listrik

4. Installation of Each time Physical Finger 4 5 H Provide Supervisor 2 3 M

Fisik injuries approved and required PPE HSE Officer

Scaffolding Kadang- Pengawas,

Jari terluka Menyediakan Alat Pelindung

Pemasangan kadang Falling Diri (APD) yang dibutuhkan Petugas

perancah hazard dan disetujui HSE

Potensi bahaya Conduct

terjatuh Tool Box Meeting

Falling Melaksanakan Tool Box

from height Meeting

Terjatuh dari Only

ketinggian competent scaffolders are

Hit by allowed to erect scaffold

Terkena oleh Hanya scaffolder yang

berkompeten yang

diperbolehkan memasang

perancah

Erection

area need to be barricaded

Area pemasangan harus

dibarikade

At height 1,5

meter and above, use of

Safety Body Harness

Ketinggian 1,5 meter lebih

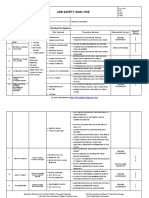

Sheet 5 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

harus memakai Safety Body

Harnnes

All

scaffolding shall be tagged

and inspected prior to be

used

Semua perancah harus di

tag dan diinspeksi sebelum

digunakan

Appropriate

signboards need to be in

place

Tanda-tanda peringatan

yang sesuai harus dipasang

ditempat kerja

Use only

RATCHET to tighten the

clamps

Untuk mengencangkan

kelem hanya menggunakan

kunci ratchet

Ensure that

scaffolding procedure is

implemented

Memastikan bahwa prosedur

perancah telah dilaksanakan

5. Hot work Each time Physical W 4 5 H Provide Supervisor 2 3 M

orkers injury (cut, approved and required PPE HSE Officer

(grinding/cutting, Kadang- Fisik

burn) Menyediakan Alat Pelindung to conduct

welding) kadang Pekerja terluka Diri (APD) yang dibutuhkan periodically

(terpotong, dan disetujui check

Pekerjaan yang

terbakar) Conduct Pengawas,

berhubungan dengan Spark and Tool Box Meeting Petugas

fire Melaksanakan Tool Box HSE

panas/api

Percikan api dan Meeting melaksana

(menggerinda/memot api Tools and kan

Electrical equipment must be checked pengecek

ong, mengelas)

hazard and approved. an secara

Sheet 6 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

Potensi bahaya Alat-alat dan perlengkapan berkala

listrik harus dicek dan disetujui

Obtained

the hot work permit

Mendapatkan ijin kerja yang

berhubungan dengan

panas/api

Use the

approved industrial cable,

electrical fittings and other

electrical appliance.

Menggunakan kabel

industri , perlengkapan

elektrik, dan alat-alat elektrik

lainnya yang telah disetujui.

Hot work

area must be barricaded and

signed.

Tempat pekerjaan yang

berhubungan dengan

panas/api harus dibarikade

dan diberi tanda peringatan

Ensure that

suitable fire extinguisher and

fire blanket shall be used.

Memastikan bahwa alat

pemadam api ringan (APAR)

dan selimut api digunakan

All

flammable material should be

kept away from the hot work

area.

Semua material yang mudah

terbakar harus dijauhkan dari

area pekerjaan yang

berhubungan dengan

panas/api

6. Installation of FRP Each time Physical Unic 4 5 H Provide Supervisor 2 3 M

Sheet 7 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

pipe using Unic Crane Kadang- Fisik Crane/Crane approved and required PPE HSE Officer

Failure Menyediakan APD yang to conduct

or Cranes kadang Kegagalan Unic dibutuhkan dan diseujui periodically

Pemasangan pipa Crane/Cranes Conduct check.

FRP menggunakan Struc Tool Box Meeting Pengawas,

k against by the Melaksanakan Tool Box Petugas

Unic Crane atau

lifted equipment Meeting HSE

Cranes Tertabrak oleh Ensure the melaksana

peralatan yang Unic Crane/Crane are kan

diangkat positioned on the firm ground pengecek

Finge Memastikan bahwa Unic an secara

r injuries Crane/Crane berada diposisi berkala

Jari terluka yang benar-benar kuat

Fallin Inspect and

g hazard ensure the crane and the

Potensi bahaya lifting gears are in good

terjatuh condition.

Hit by Memeriksa dan memastikan

Terkena oleh crane dan roda gigi dalam

kondisi bagus

Signal man

must stand by all time.

Signal man harus selalu

berada ditempat setiap

waktu

Follow the

rigging calculation.

Ikuti kalkulasi tali-temali

Experienced

and competent rigger /

signalman to be used for

these lifting activities.

Rigger yang berpengalaman

dan berkompeten yang akan

dipakai pada kegiatan

pengangkatan tersebut

Close or

barricade the work area and

put warning signage.

Sheet 8 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

Tutup atau barikade tempat

kerja dan tempatkan tanda-

tanda peringatan

Only

competent and certified

operator can operate the

crane.

Hanya operator yang

berkompeten dan

bersertifikat yang dapat

mengoperasikan Crane

Use correct

tools for all tasks

Penggunaan alat-alat yang

tepat untuk semua

tugas/pekerjaan

Proper

loading and unloading

method

Metode bongkar dan muat

yang tepat

7. House Keeping During work Physical S 2 2 L Provide Foreman

tumble approved and required PPE

Kebersihan performed Fisik HSE Officer

Tersandung Menyediakan APD yang

Selama S dibutuhkan dan disetujui Mandor,

pekerjaan lip off Appoint Petugas

berlang- Terpeleset some persons to clean during HSE

S work on going

sung cratch Menunjuk seseorang untuk

Tergores membersihkan tempat kerja

D selama pekerjaan

ust berlangsung

Debu Watch the

D step during cleaning

isturb other Perhatikan langkah selama

parties melakukan aktivitas

Mengganggu pembersihan

aktivitas Inform other

Sheet 9 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

Designated Risk Rating after

Risk Rating Recommended Job Procedure

Sequence Of Basic Frequency Person Recommendation

No Hazards Consequences

Job Steps of Activity Prob’ty Severity Ranking Prob’ty Severity Ranking

(1) (2) (1)x(2) (1) (2) (1)x(2)

kelompok yang parties/workers/other

lain. persons that cleaning work is

W on going

orkers/others Informasikan kepada

persons get kelompok lain, pekerja,

injured bahwa pekerjaan

Pekerja/orang pembersihan sedang

lain terluka berlangsung

Risk = Probability/ Likelihood x Severity/ Consequence

Ranking

Score Level Probability Description Severity Index Description

13-25 High 5 Frequent The event is expected to 5 Catastrophic Death, permanent serious environment

occur in most circumstance damage, multiple facilities damage, toxic

Sheet 10 of 10

JOB NO. REV

PT. WASA MITRA ENGINEERING

HEALTH, SAFETY AND ENVIRONMENTAL PLAN DOC. NO.:

A

HAZARD IDENTIFICATION RISK ASSESSMENT CONTROL

(MECHANICAL WORK) DATE

release off site, huge financial loss

Lost time accident, permanent/ partial

6-12 Medium 4 Probable Will Occur frequently 4 Major disability, non permanent environmental

damage, high financial loss

Medical treatment required/ work restriction,

1-5 Low 3 Occasional Will occur several time 3 Moderate/ Serious high financial loss, on site released

contained with outside assistance

Unlikely, but can First aid treatment, on site release

2 Unlikely reasonable be expected to 2 Minor immediately contained, medium financial

occur loss

Unlikely to occur, but No affecting work performance, no injury,

1 Improbable 1 Negligible

possible low financial loss

You might also like

- JSA. Electrical PullingDocument2 pagesJSA. Electrical PullingSajid Hussain100% (1)

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- 12 JSA FlushingDocument5 pages12 JSA FlushingYosua SitumorangNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 pagesULSADO-JSA - Installation of Temporary Fence GateKelvin TanNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Jsa - Bar BendingDocument1 pageJsa - Bar BendingHARSHAD100% (1)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa - Cutting and WeldingDocument2 pagesJsa - Cutting and WeldingSantos Rex50% (2)

- TEIPL-JSA-044 Maintenance Vehicle, Machine or Const EqmntsDocument4 pagesTEIPL-JSA-044 Maintenance Vehicle, Machine or Const Eqmntsba ratnaparkheNo ratings yet

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Jsa Assembling & Erection Gantry CraneDocument4 pagesJsa Assembling & Erection Gantry CraneputrasejahtraNo ratings yet

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Siamex Webinar (A) - 001 For Funding - 3RD Final Promotion - 31ST July 2021Document4 pagesSiamex Webinar (A) - 001 For Funding - 3RD Final Promotion - 31ST July 2021gabrielNo ratings yet

- CA3 - Application Report - Nur HidayahDocument8 pagesCA3 - Application Report - Nur HidayahNur HidayahNo ratings yet

- 10 JSA Excavation, Lowering, Back FillingDocument8 pages10 JSA Excavation, Lowering, Back FillingYosua SitumorangNo ratings yet

- Hse-Cbn-Jsa-Lighting Pole & Junction Box InstallationDocument7 pagesHse-Cbn-Jsa-Lighting Pole & Junction Box Installationmalimsaidi_160040895No ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDocument6 pagesJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaNo ratings yet

- Jsa For Blowing of Air in Underground PipesDocument4 pagesJsa For Blowing of Air in Underground PipesMohammed MinhajNo ratings yet

- 54 FGD-JSA - Pickling & Passivation WorkDocument5 pages54 FGD-JSA - Pickling & Passivation WorkRamesh Babu Palnati100% (1)

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobDocument3 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobYosua SitumorangNo ratings yet

- Job Safety Analysis: Department: (Bagian/fungsi)Document9 pagesJob Safety Analysis: Department: (Bagian/fungsi)Yosua SitumorangNo ratings yet

- JSA For Washing and Air BlowingDocument3 pagesJSA For Washing and Air BlowingMohammed MinhajNo ratings yet

- JSA Formwork Rebar Dan Puring at SB#1Document7 pagesJSA Formwork Rebar Dan Puring at SB#1Yosua SitumorangNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- JSA Install Pipe Support and CagingDocument5 pagesJSA Install Pipe Support and CagingYosua Situmorang100% (1)

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- HIRADC Installation PipeDocument4 pagesHIRADC Installation PipeamizanNo ratings yet

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghNo ratings yet

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeepNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- JSA FOR Moving and Handling MaterialsDocument3 pagesJSA FOR Moving and Handling Materialswahyu nugrohoNo ratings yet

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- Jsa Lifitng Gantry FabricationDocument3 pagesJsa Lifitng Gantry FabricationOsiobe EwomazinoNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument4 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- JSA Insulation OKI 18-07-2016Document9 pagesJSA Insulation OKI 18-07-2016FerdyCodetzNo ratings yet

- JSA-For Lifting Activity by CraneDocument3 pagesJSA-For Lifting Activity by CraneEman MantoNo ratings yet

- Fire Fighting JSADocument14 pagesFire Fighting JSANikhil Manjrekar83% (6)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument5 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- Risk Assessment Foundation WorkDocument2 pagesRisk Assessment Foundation WorkMihirduttaNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa Working at HeightDocument4 pagesJsa Working at HeightDedy Kurniawan100% (1)

- Jsa ConcretingDocument4 pagesJsa ConcretingRavi thokalNo ratings yet

- Jsa For WeldingDocument2 pagesJsa For WeldingMohamed Samir50% (2)

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDocument3 pagesJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNo ratings yet

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast SlabMohammed Minhaj100% (3)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- HIRADC Scaffolding, Isolation Energy, Bekerja Di KetinggianDocument3 pagesHIRADC Scaffolding, Isolation Energy, Bekerja Di KetinggianLutfiNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Yosua SitumorangNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JOB ANALISYS SAFETY All WorkDocument11 pagesJOB ANALISYS SAFETY All WorkMansur SaifudinNo ratings yet

- Jsa For DC HV Test For MV Cable 02Document7 pagesJsa For DC HV Test For MV Cable 02ramadh diyyazNo ratings yet

- BP Alaska Safety Handbook (BP ASH) PDFDocument130 pagesBP Alaska Safety Handbook (BP ASH) PDFVan Sot100% (2)

- Construction Site Safety HandbookDocument217 pagesConstruction Site Safety Handbookjoshappy246No ratings yet

- The Five Whys' Analysis: Leadership and Worker Involvement ToolkitDocument1 pageThe Five Whys' Analysis: Leadership and Worker Involvement ToolkitYou1993No ratings yet

- Jsa For Piping (FRP) WorkDocument10 pagesJsa For Piping (FRP) WorkYou1993100% (2)

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorYou1993100% (2)

- Crane Inspector - Candidate Handbook - 060118a PDFDocument46 pagesCrane Inspector - Candidate Handbook - 060118a PDFYou1993No ratings yet

- Emergency Call MK - 400-500 MWDocument1 pageEmergency Call MK - 400-500 MWYou1993100% (1)

- Boom Supported Elevating Work Platform Pre-Use Inspection ChecklistDocument1 pageBoom Supported Elevating Work Platform Pre-Use Inspection ChecklistYou1993No ratings yet

- Jacks - Preuse Checklist: Standard Operating Procedure: Cross ReferenceDocument1 pageJacks - Preuse Checklist: Standard Operating Procedure: Cross ReferenceYou1993No ratings yet

- Sce-List-Trainer-Packages-Without-Prices-En 2019 PDFDocument2 pagesSce-List-Trainer-Packages-Without-Prices-En 2019 PDFmfonseca31No ratings yet

- Nota Kuliah (2) MAINTAIN QUALITY CONTROL (QC) SERVICED PRODUCTDocument14 pagesNota Kuliah (2) MAINTAIN QUALITY CONTROL (QC) SERVICED PRODUCTMohd HakimNo ratings yet

- Week 8 CoursewareDocument9 pagesWeek 8 CoursewareMariaEzzaSyUyNo ratings yet

- Assignment On Financial ManagementDocument22 pagesAssignment On Financial ManagementSimran VirmaniNo ratings yet

- Computerized Accounting in Ghana The Shi PDFDocument8 pagesComputerized Accounting in Ghana The Shi PDFKhalid AhmedNo ratings yet

- Assignment - Entrepreneurial SkillsDocument2 pagesAssignment - Entrepreneurial SkillsGuruSeeker1150% (2)

- Mobile Virtual Network Operators in The Sultanate of OmanDocument9 pagesMobile Virtual Network Operators in The Sultanate of Omanknpsingh7092No ratings yet

- Thakur Polytechnic Diploma in Computer EngineeringDocument22 pagesThakur Polytechnic Diploma in Computer EngineeringParth MehtaNo ratings yet

- Strategic Management Concepts Competitiveness and Globalization 11th Edition Hitt Solutions ManualDocument26 pagesStrategic Management Concepts Competitiveness and Globalization 11th Edition Hitt Solutions ManualBrettFreemanrefc100% (43)

- UnicornHRO Premium Services OverviewDocument5 pagesUnicornHRO Premium Services OverviewEliot BernsteinNo ratings yet

- 3i Chapter 1Document7 pages3i Chapter 1Raoul Julian S. SarmientoNo ratings yet

- Cnc-Mc-And-Automation 5th Sem121755-May-2019Document2 pagesCnc-Mc-And-Automation 5th Sem121755-May-2019Lovelysingh LovelyNo ratings yet

- Brochure BI Ekonomi MADANI A 2Document1 pageBrochure BI Ekonomi MADANI A 2ABDUL AZIZ HOW BIN ABDULLAH (MOE)No ratings yet

- Department of Trade and Industry: 3L Publication Code 380-20170714-41Document4 pagesDepartment of Trade and Industry: 3L Publication Code 380-20170714-41paympmnpNo ratings yet

- AssignmentDocument13 pagesAssignmentSmashed PotatoNo ratings yet

- Pink Rose Watercolor Organic Creative Project PresentationDocument8 pagesPink Rose Watercolor Organic Creative Project PresentationLenesia AgathaNo ratings yet

- Nakamura Lacquer Company Case Study - Castillo, Charisse R.Document11 pagesNakamura Lacquer Company Case Study - Castillo, Charisse R.Cha CastilloNo ratings yet

- D365 Business Central Implementation PackageDocument17 pagesD365 Business Central Implementation PackageAnh Bao Tran DuongNo ratings yet

- D.light CaseDocument19 pagesD.light CaseKshitijNo ratings yet

- Candidate Brief PVC International UEADocument17 pagesCandidate Brief PVC International UEAFiaz HussainNo ratings yet

- MOD 1 - Introduction On Cost AccountingDocument10 pagesMOD 1 - Introduction On Cost Accountingzach thomasNo ratings yet

- YieldDocument15 pagesYieldcrisNo ratings yet

- Practice - Pivot TableDocument27 pagesPractice - Pivot TablerthedthbdethNo ratings yet

- l4m7 Questions 1Document19 pagesl4m7 Questions 1Dejanira ScottNo ratings yet

- Capital Budgeting Case 4Document4 pagesCapital Budgeting Case 4Expert AnswersNo ratings yet

- 08.LAMPIRAN 3 - BDD Lampiran 27 Senarai Semak Audit Dalaman ABMS ABMS Internal Audit Checklist30 Dan 31 Jan2024Document53 pages08.LAMPIRAN 3 - BDD Lampiran 27 Senarai Semak Audit Dalaman ABMS ABMS Internal Audit Checklist30 Dan 31 Jan2024Yusoff Sya JajaNo ratings yet

- Your Accounts at A Glance: Your Balances On 22 Feb 2022Document4 pagesYour Accounts at A Glance: Your Balances On 22 Feb 2022mohamed elmakhzniNo ratings yet

- Entrepreneurship Y4Document223 pagesEntrepreneurship Y4Ronina De Guzman AngelesNo ratings yet