Professional Documents

Culture Documents

Agco PTM Vis 4

Uploaded by

sitaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agco PTM Vis 4

Uploaded by

sitaCopyright:

Available Formats

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

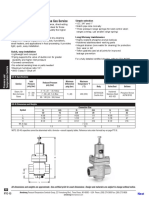

Static Pressure Manifolds – PTM and PT7 2-Valve

Manifolds

PT7

PTM

Product Overview Features and Benefits

The PT Two-Valve Calibration Manifolds • Cost savings when manifolding the

are used on static pressure transmitters, instruments. This eliminates several

switches or gauges. The shutoff valve, parts used in conventional methods of

tee, calibration valve, and all immediate ‘piping up’ resulting in cost reduction

tubing/fittings are available in one simple of 20-30 percent.

manifold. The PT manifolds are available

with either metal seats or replaceable soft • Compact design requires minimum

seat inserts. space for operation and installation.

The PTM manifold features a unique • Rolled threads, stem and bonnet

valve seat that can be converted from soft threads are rolled for increased

to hard by simply removing two insert strength. This prevents galling and

washers. No other parts are required. adds years to the useful life of the

valve.

The PT7 manifold is available for elevated

temperatures and features an integral • Fewer leak points reduce leakage by

metal seat. having fewer parts to assemble.

• Teflon® and GRAFOIL® adjustable

packing is easily adjusted for leak-

proof and long service life.

• Stem threads are isolated from

process fluid (O-ring stem seal). This

prevents galling and corrosion of the

stem threads. The O-ring isolates the

stem threads from the process.

• Backseat stem prevents stem

blowout.

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 15

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

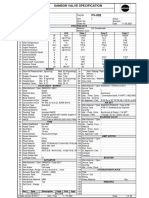

Static Pressure Manifolds – PTM Specifications

Dimensions, inches [mm]

Instrument

B Max. Open Instrument

1.25 Vent/Test

[31.8] Vent/Test

Block/Isolate

Block/Isolate

1/2- 14 NPT

3 Places

A Max. Process

Open Process

Vent/Test Valve

2.50 [63.5]

1/2- 14 NPT 1/2- 14 NPT

Vent/Test Port 0.63 [16.0] Instrument Port

0.68 [17.3] Flow Washer

Optional Soft Seat

2.38

[60.5]

1.00 [25.4]

Block/Isolate

Valve

1/2- 14 NPT

0.25 [6.4] 1.00

[25.4] Process Port

ø 0.28 [7.1] Mounting Holes, 2 Places

Dimensions, inches [mm] Note

Packing A B 1. Approximate valve weight: 2.0 lb [0.9 kg].

0.136-inch [3.5 mm] diameter orifice.

2.50 3.75 Valve CV Hard Seat 0.25 maximum.

O-ring

[63.5] [95.3] Valve CV Soft Seat 0.24 maximum.

3.10 4.35

Teflon®

[78.7] [110.5]

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 16

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PTMV ( ) – ( ) – PM

(Panel Mount) Specifications

Dimensions, inches [mm]

NPT TYP. 3 Places

Instrument PTMV( )-2-PM 1/4 - 18

PTMV( )-4-PM 1/2 - 14

Panel Hole 1/2- 14 NPT

ø 0.469 [11.9] Instrument Port

0.188 [4.76] Max. 0.68 [17.3]

Thick Panel 0.63

Vent/Test Vent/Test Valve Vent/Test Port 1.25 [16.0]

[31.8]

Block/Isolate

1.38

[35.1]

3.25

[82.6]

Process

0.75 1.25

[19.1] [31.8]

Block/Isolate

Valve

1.00

Panel Nut [25.4]

1.25 0.63 [16.0] 2.50 [63.5]

[31.8]

ø 0.28 [7.1] Thru 1/2- 14 NPT

3.10 [78.7] Max. Open Mounting Holes Process Port

2 Places

Standard Materials

Valve Body Bonnet Stem Flow Washer4

CS2 A108 A108 A581-303 316

SS A479-316 A479-316 A276-316 316

SG3 A476-316 A479-316 Monel® R405 316

Monel® Monel® 400 Monel® R405 Monel® R405 Monel® 400

Notes

1. Approximate valve weight: 2.7 lb [1.2 kg].

0.136-inch [3.5 mm] diameter orifice.

Valve CV Hard Seat 0.25 maximum.

Valve CV Soft Seat 0.24 maximum.

2. CS is zinc cobalt plated to prevent corrosion.

3. SG (Sour Gas) – all SS wetted parts are

RC22 or less to meet requirements of

NACE MR0175-latest revision.

4. Soft seated valves only.

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 17

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PT7 Specifications

Dimensions, inches [mm]

B Max. Open Instrument

2.73

0.63 [16.0] [69.3]

Vent/Test

1.25 [31.8]

Vent/Test Port Block/Isolate

Block/Isolate

A Valve

Max.

Open

Process

Vent/Test Valve

Instrument Port 1 /2 - 14 NPT TYP. 3 Places

Dimensions, inches [mm]

1.25 [31.8]

Packing A B

1.88

[47.8] 3.85 5.33

Teflon®

2.88 [97.8] [135.4]

[73.2]

4.50 5.98

0.75 [19.1]

GRAFOIL®

[114.3] [151.9]

ø 0.28 [7.1]

Mounting Holes

1.00 [25.4] 2 Places

1.90 [48.3] Process Port

Standard Materials Notes

Valve1 Body Bonnet Stem Ball Packing 1. Approximate valve weight: 3.0 lb [1.4 kg].

0.187-inch [4.8 mm] diameter orifice.

Valve Cv 0.52 maximum.

CS2 A105 A108 A581-303 17-4 PH Teflon®

2. CS is zinc cobalt plated to prevent corrosion.

GRAFOIL®/ 3. SG (Sour Gas) meets the requirements of

CS2 A105 A105 A581-303 17-4 PH

Low Emissions Graphite NACE MR0175-latest revision.

SS SS, A479-316 SS, A479-316 A276-316 316 Teflon®

GRAFOIL®/

SS SS, A479-316 SS, A479-316 A276-316 316

Low Emissions Graphite

SG3 SS, A479-316 SS, A479-316 Monel® 400 Monel® K500 Teflon®

GRAFOIL®/

SG3 SS, A479-316 SS, A479-316 Monel® 400 Monel® K500

Low Emissions Graphite

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 18

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PTM and PT7

Specifications

Pressure and Temperature Ratings - PTM

Packing PCTFE/Delrin® Seat PEEK Seat Metal Seat

6000 psig @ 200°F 6000 psig @ 200°F

3000 psig @ 200°F 3000 psig @ 300°F 4000 psig @ 500°F

Teflon® [207 barg @ 93°C] [414 barg @ 93°C] [414 barg @ 93°C]

[207 barg @ 149°C] [276 barg @ 260°C]

3000 psig @ 200°F 6000 psig @ 200°F 6000 psig @ 200°F

O-ring

[207 barg @ 93°C] [414 barg @ 93°C] [414 barg @ 93°C]

Pressure and Temperature Ratings - PT7

Valve Packing Ratings

6000 psig @ 200°F 4000 psig @ 500°F

CS Teflon®

[414 barg @ 93°C] [276 barg @ 260°C]

GRAFOIL®/Low 6000 psig @ 200°F 1500 psig @ 850°F

CS

Emissions Graphite [414 barg @ 93°C] [103 barg @ 454°C]

6000 psig @ 200°F 4000 psig @ 500°F

SS Teflon®

[414 barg @ 93°C] [276 barg @ 260°C]

GRAFOIL®/Low 6000 psig @ 200°F 1500 psig @ 1000°F

SS

Emissions Graphite [414 barg @ 93°C] [103 barg @ 538°C]

6000 psig @ 200°F 4000 psig @ 500°F

SG Teflon®

[414 barg @ 93°C] [276 barg @ 260°C]

GRAFOIL®/Low 6000 psig @ 200°F 1500 psig @ 1000°F

SG

Emissions Graphite [414 barg @ 93°C] [103 barg @ 538°C]

PTM Pressure vs. Temperature

Delrin®/PCTFE

PEEK (O-ring Packed)

Metal Seat (O-ring Packed)

6000 PEEK (Teflon® Packed)

[414]

Metal Seat (Teflon® Packed)

5000 Denotes intersecting data

[345]

4000

Pressure psig [barg]

[276]

3000

[207]

2000

[138]

1000

[69]

0 100 200 300 400 500

[-18] [38] [93] [149] [204] [260]

Temperature °F [°C]

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 19

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PTM and PT7

Specifications

PT7 Pressure vs. Temperature

PT7VIC/PT7VIS

6000 PT7HIC/PT7EIC

[414] PT7HIS/PT7EIS

Denotes

5000

intersecting data

[345]

Pressure psig [barg]

4000

[276]

3000

[207]

2000

[138]

1500

[103]

1000

[69]

0

0 100 200 300 400 500 600 700 800 900 1000

[-18] [38] [93] [149] [204] [260] [316] [371] [427] [482] [538]

850

Temperature °F [°C] [454]

PTM – Ordering Information

PTM V D S –4 – SG

Bonnet Packing

V – Teflon®

R – O-ring (SS - Viton®, CS - BUNA-N) (Soft Seat Only)

Seat Material

D – Delrin® (standard)

K – PCTFE

E – PEEK

I – Integral (body material)

Body Material

C – A108

S – A479-316 SS

M – Monel® 400

Connections

4 – 1/2-inch FNPT

Options

–AL Arctic Lubricant (low temperature –HD Hydrostatic Testing (100 percent) –SG Sour Gas meets the requirements

service). Not available for CS (MSS-SP-61) of NACE MR0175-latest revision.

valves. –ST Stellite Ball Ended Stem (PT7 only) (SS valves only) (Not available for

–AM AGCO Mount Kit for 2-inch pipe –MS Monel® Stem O-ring packed valves)

mounting of manifold (page 38). –PHB Phenolic Black Handle (PTM only) –SP Special options or requirements not

–CL Cleaned for Chlorine Service. –PHG Phenolic Green Handle (PTM only) otherwise noted by descriptive

–OC Cleaned for Oxygen Service. –PHR Phenolic Red Handle (PTM only) codes.

–PM Panel Mount (PTM only, page 17)

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 20

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PTM and PT7

Specifications

PT7 – Ordering Information

PT7 V I S –4 – SG

Bonnet Packing

V – Teflon®

H – GRAFOIL®

E – Low Emissions Graphite

Seat Material

I – Integral (body material)

Body Material

C – A105

S – A479-316 SS

Connections

4 – 1/2-inch FNPT

Options

–AL Arctic Lubricant (low temperature service). Not available for CS valves.

–AM AGCO Mount Kit for 2-inch pipe mounting of manifold (page 38).

–CL Cleaned for Chlorine Service.

–OC Cleaned for Oxygen Service.

–HD Hydrostatic Testing (100 percent) (MSS-SP-61)

–ST Stellite Ball Ended Stem (PT7 only)

–MS Monel® Stem

–PHB Phenolic Black Handle (PTM only)

–PHG Phenolic Green Handle (PTM only)

–PHR Phenolic Red Handle (PTM only)

–PM Panel Mount (PTM only, page 17)

–SG Sour Gas meets the requirements of NACE MR0175-latest revision.

(SS valves only) (not available for O-ring packed valves)

–SP Special options or requirements not otherwise noted by descriptive codes.

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 21

Anderson Greenwood Manifolds Catalog

Flow, Static Pressure, and Liquid Level Manifolds

Static Pressure Manifolds – PT7M ASME B31.1

Specifications

PT7MHP – Ordering Information Power Industry Applications1

PT7MHP S –4 –XP SG

Body Material

C – A105

S – A479-316 SS

Connections (Process x Instrument x Vent)

3 – 3/8-inch FNPT x 3/8-inch FNPT x 3/8-inch FNPT

3TC – 3/8-inch Tube Stub (6” x 0.065”) - All Connections

3TC4 – 3/8-inch Tube Stub (6” x 0.065”) x 3/8-inch Tube Stub x 1/2-inch FNPT

3TC44 – 3/8-inch Tube Stub (6” x 0.065”) x 1/2-inch FNPT x 1/2-inch FNPT

4 – 1/2-inch FNPT x 1/2-inch FNPT x 1/2-inch FNPT

422 – 1/2-inch FNPT x 1/4-inch FNPT x 1/4-inch FNPT

442 – 1/2-inch FNPT x 1/2-inch FNPT x 1/4-inch FNPT

4B2 – 1/2-inch PSW x 1/4-inch FNPT x 1/4-inch FNPT

4TC4 – 1/2-inch Tube Stub (6” x 0.095”) x 1/2-inch Tube Stub x 1/2-inch FNPT

4TC44 – 1/2-inch Tube Stub (6” x 0.095”) x 1/2-inch FNPT x 1/2-inch FNPT

Options

–AM AGCO Mount Kit for 2-inch pipe mounting of manifold (page 38).

–SP Special options or requirements not otherwise noted by descriptive codes.

Notes

1. All Manifolds come standard with

GRAFOIL® packing, integral seats, bonnet

locks, and are subjected to hydrostatic

testing.

2. Manifold ratings:

SST 6000 psig @ 100°F

2915 psig @ 1000°F

[414 barg @ 38°C]

[201 barg @ 538°C]

STL 6170 psig @ 100°F

3430 psig @ 800°F

[425 barg @ 38°C]

[236 barg @ 427°C]

3. See page 148 for Code Requirements.

© 1998, Rev. 1999 Anderson Greenwood Instrumentation Products reserves the

right to change product designs and specifications without notice. 22

You might also like

- Manifold Anderson - GreenDocument5 pagesManifold Anderson - GreenkicsnerNo ratings yet

- Anderson Greenwood AGCO MM1 AEDocument4 pagesAnderson Greenwood AGCO MM1 AEMuhammad Moeed AlamNo ratings yet

- Instruments Valve ManifoldDocument7 pagesInstruments Valve ManifoldkicsnerNo ratings yet

- Norgren - MufflersDocument14 pagesNorgren - Mufflerssh4kzyNo ratings yet

- 115NZ NZCDocument4 pages115NZ NZCOdicoNo ratings yet

- Diaphragm Valve Metal Construction GuideDocument12 pagesDiaphragm Valve Metal Construction GuidealbetoNo ratings yet

- Technical Features: Medium: Mounting: MaterialsDocument10 pagesTechnical Features: Medium: Mounting: MaterialsValourdos LukasNo ratings yet

- K-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederDocument2 pagesK-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederARK MurpheyNo ratings yet

- Pgi M 675 M 775 M 678 GS 3Document6 pagesPgi M 675 M 775 M 678 GS 3Juan Carlos Enríquez BarragánNo ratings yet

- Ball Valve, Stainless Steel: ConstructionDocument19 pagesBall Valve, Stainless Steel: ConstructionSanjay MaheshNo ratings yet

- Regulators S100KDocument16 pagesRegulators S100KAlberto CastellanosNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- DP Series Wafer Check Valve CiDocument2 pagesDP Series Wafer Check Valve CiAerox neoNo ratings yet

- SLC 1 Spec SheetDocument2 pagesSLC 1 Spec SheetArstNo ratings yet

- Specs of Ducted UnitsDocument2 pagesSpecs of Ducted UnitsAdil MohdNo ratings yet

- High Pressure UCV Catalog 2020Document10 pagesHigh Pressure UCV Catalog 2020МаксимNo ratings yet

- 29.5in-500psi Diverter Operation ManualDocument16 pages29.5in-500psi Diverter Operation ManualIskander KasimovNo ratings yet

- Type R122H First-Stage RegulatorDocument2 pagesType R122H First-Stage RegulatorJVMNo ratings yet

- Block and Bleed Gauge Valves - M25 and M251: Product OverviewDocument5 pagesBlock and Bleed Gauge Valves - M25 and M251: Product OverviewFercomil S.A.SNo ratings yet

- PDF Actuator Datasheet - CompressDocument1 pagePDF Actuator Datasheet - Compresshellraizer1978No ratings yet

- Samson 24-03-20 - 001 - IQ24-0082 - Typ 3241-7 - Ciadana Raya Chemicals - ISASheetDocument2 pagesSamson 24-03-20 - 001 - IQ24-0082 - Typ 3241-7 - Ciadana Raya Chemicals - ISASheetdeath noteNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- Durable Design For Survivability in Harsh Environments: Qualitrol 050Document2 pagesDurable Design For Survivability in Harsh Environments: Qualitrol 050Rafael Cruz VazquezNo ratings yet

- Micro FiltrationDocument7 pagesMicro FiltrationEdwin CaleñoNo ratings yet

- Shut Off Valve: Series GS3Document1 pageShut Off Valve: Series GS3beemasundarNo ratings yet

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosNo ratings yet

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Standard Pilot, Steel Seat, Pilot-To-Open Check Valve Ckeb: 30 GPM (120 L/min.)Document4 pagesStandard Pilot, Steel Seat, Pilot-To-Open Check Valve Ckeb: 30 GPM (120 L/min.)Alex RamirezNo ratings yet

- Asco Quick Exhaust CatalogDocument4 pagesAsco Quick Exhaust CatalogAlan GarciaNo ratings yet

- Rociador de Gas de Sistema FM-200Document9 pagesRociador de Gas de Sistema FM-200Eduardo QuirozNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- V44/V45, 2 X 3/2, 5/2 & 5/3 Mini ISO Valves: Medium: Flow: Operating Pressure: Media/Ambient Temperature: MaterialsDocument13 pagesV44/V45, 2 X 3/2, 5/2 & 5/3 Mini ISO Valves: Medium: Flow: Operating Pressure: Media/Ambient Temperature: MaterialsNguyễn TríNo ratings yet

- DB - c50 - 51 - 57hpw - GB - GEMU Diaphragm Globe ValveDocument8 pagesDB - c50 - 51 - 57hpw - GB - GEMU Diaphragm Globe ValveKrisNo ratings yet

- Check-Trol: Isolation Flow Control FlangeDocument2 pagesCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eNo ratings yet

- Rotary Plug Valve Data SheetDocument12 pagesRotary Plug Valve Data SheetAnderson SiqueiraNo ratings yet

- B38 Filter/regulator (Stainless Steel) : Medium: Maximum Inlet Pressure: Port Sizes: Ambient/Media Temperature: MaterialsDocument3 pagesB38 Filter/regulator (Stainless Steel) : Medium: Maximum Inlet Pressure: Port Sizes: Ambient/Media Temperature: Materialsarif fadhillahNo ratings yet

- SOV - 97300 Namur PDFDocument7 pagesSOV - 97300 Namur PDFNani TamizhaNo ratings yet

- Etp Ticknical Data ReportDocument18 pagesEtp Ticknical Data Reportshaik abidNo ratings yet

- Pipe Valves and Fittings - 15000Document11 pagesPipe Valves and Fittings - 15000willianNo ratings yet

- CKEB_full_en_metric_letterDocument2 pagesCKEB_full_en_metric_letterRafalNo ratings yet

- Valvula en Linea Norgren x30Document6 pagesValvula en Linea Norgren x30Base SistemasNo ratings yet

- Valvula en Linea Norgren 030Document6 pagesValvula en Linea Norgren 030Base SistemasNo ratings yet

- Down Hole Assembly PDFDocument13 pagesDown Hole Assembly PDFOvRrj AhmedNo ratings yet

- XL16i Performance DataDocument12 pagesXL16i Performance Dataexodustwentyfifteen.613No ratings yet

- IR 43Q-R Product-Page EnglishDocument2 pagesIR 43Q-R Product-Page EnglishJesus Vargas JimenezNo ratings yet

- Vanne Série 400Document2 pagesVanne Série 400RitouiNo ratings yet

- Ham-Let Metal Seat UCV Valves Catalog 2020Document6 pagesHam-Let Metal Seat UCV Valves Catalog 2020XavierNo ratings yet

- Square Profile Cylinders DNC - Inch SeriesDocument26 pagesSquare Profile Cylinders DNC - Inch SeriesAkmal ZuhriNo ratings yet

- Uflow Make Angle Seat ValveDocument3 pagesUflow Make Angle Seat ValveMurtaza BarwaniwalaNo ratings yet

- Series GD45Document2 pagesSeries GD45JJMEDINA REUNIONESNo ratings yet

- Weir Control & Choke Valves Technical Specification Sheet for Produced Water ServiceDocument1 pageWeir Control & Choke Valves Technical Specification Sheet for Produced Water ServiceKo Aung KoNo ratings yet

- LIT Sullair Air Tools Brochure PAPTOOLS202012-5 enDocument8 pagesLIT Sullair Air Tools Brochure PAPTOOLS202012-5 enJonathan Campos SanchezNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Speed control valve guideDocument4 pagesSpeed control valve guideTrantan CdtNo ratings yet

- Relief Valves FlyerDocument1 pageRelief Valves FlyerAkhil JoseNo ratings yet

- Conductivity sensor-SC4Document12 pagesConductivity sensor-SC4Ziyaur RahmanNo ratings yet

- Valvula Diafragma Buschjost 82630Document2 pagesValvula Diafragma Buschjost 82630Base SistemasNo ratings yet

- Dodge Quantis Gear Box BrochureDocument12 pagesDodge Quantis Gear Box BrochuresitaNo ratings yet

- C236385 WithakerDocument2 pagesC236385 WithakersitaNo ratings yet

- FLEXICHEVRON-Mist-Eliminators Type VIIIDocument12 pagesFLEXICHEVRON-Mist-Eliminators Type VIIIsitaNo ratings yet

- DetronicDocument217 pagesDetronicsitaNo ratings yet

- Flexteral HoseDocument56 pagesFlexteral HosesitaNo ratings yet

- HXA FilterDocument1 pageHXA FiltersitaNo ratings yet

- Forged check valves for flow controlDocument1 pageForged check valves for flow controlsitaNo ratings yet

- 178 SeriesDocument1 page178 SeriessitaNo ratings yet

- Red SkinDocument1 pageRed SkinsitaNo ratings yet

- CAm TECH AgentDocument1 pageCAm TECH AgentsitaNo ratings yet

- WFT06272 Sucker RodDocument12 pagesWFT06272 Sucker RodsitaNo ratings yet

- BOTIL Cement RetainerDocument1 pageBOTIL Cement RetainersitaNo ratings yet

- N BridgingDocument1 pageN BridgingsitaNo ratings yet

- Advanced Rock Properties (Core Lab)Document3 pagesAdvanced Rock Properties (Core Lab)sitaNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- Edited CatalogDocument8 pagesEdited CatalogsitaNo ratings yet

- Vogt BrochureDocument1 pageVogt BrochuresitaNo ratings yet

- Part and Lists Drawing Page 5Document1 pagePart and Lists Drawing Page 5sitaNo ratings yet

- For KevinDocument6 pagesFor KevinsitaNo ratings yet

- ABB AMD Motor BrochureDocument4 pagesABB AMD Motor BrochuresitaNo ratings yet

- NC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75Document1 pageNC3M 4 1-16 3K X 4 600 Ansi RF 3 Trim Spec Dims 11.31 X 10.75sitaNo ratings yet

- Westco Thortle Cylinder AssyDocument1 pageWestco Thortle Cylinder AssysitaNo ratings yet

- General Product Catalogue SmallDocument88 pagesGeneral Product Catalogue SmallsitaNo ratings yet

- Sling ShackelDocument1 pageSling ShackelsitaNo ratings yet

- Spareparts ListDocument5 pagesSpareparts ListsitaNo ratings yet

- Linetroll 110 EURDocument2 pagesLinetroll 110 EURsitaNo ratings yet

- VictorDocument136 pagesVictorsitaNo ratings yet

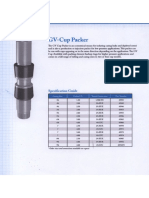

- Watson PackerDocument2 pagesWatson PackersitaNo ratings yet

- RFQ 9747: Part number change notification with attached manualDocument1 pageRFQ 9747: Part number change notification with attached manualsitaNo ratings yet

- MSDS Lead Acetate TapeDocument9 pagesMSDS Lead Acetate TapesitaNo ratings yet