Professional Documents

Culture Documents

Pompe Verder

Uploaded by

valiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pompe Verder

Uploaded by

valiCopyright:

Available Formats

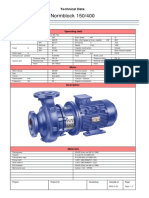

Offer No. 16401/18.06.

15

Verder Romania srl, Bucuresti

18/06/2015 Item 30

pump to handle filtrate water

qty.: 2 Progressive cavity pump

BN 10-6L

Remarks

Verderpro VPS101L

Application data

Conveyed product filtrate water

Flowability well flowable

Solids content <1%

Size of solids not specified

Concentration not specified

Specific gravity 1 kg/dm³

product temperature 5°C - 45°C

pH value 6,5 - 8,5

Kind of operation continuous

Operating hours 8h/day

Location indoor, dry atmosphere

Performance data

Capacity Pressure Speed

3 -1

6 m /h 5 bar 252 min min

3 -1

7 m /h 5 bar 288 min max

Starting torque 90 Nm

Req. power at pump shaft 1.8 kW

Inlet pressure flooded suction (up to 0,5bar)

Tolerances according to SEEPEX standards.

Materials and executions

Installation vertical, drive on top

Direction of rotation counter clockwise (left)

Lantern - Design standard

Lantern - Material EN-JL 1040 (gci-25)

Suction casing - Design standard

Suction casing - Material EN-JL 1040 (gci-25)

Pressure branch - Design standard

Pressure branch - Material EN-JL 1040 (gci-25)

Position of branch position 1

Suction connection DN 80 PN 16 DIN EN 1092-2 (DIN2501)

Pressure connection DN 65 PN 16 DIN EN 1092-2 (DIN2501)

Joint - Design pin joint with joint sleeve, grease filled

Joint - Material standard

Joint - Universal joint sleeve: material NBR - Perbunan

Coupling rod - Design standard

Coupling rod - Material 1.4021 / AISI 420

Rotor - Design standard

Rotor - Material 1.2436 / tool steel AISI D6

Stator - Design standard

Stator - Material NBR - Perbunan

Shaft sealing packing

Design standard

Casing - material EN-JL 1040 (gci-25)

Packing ring - material K41

Plug-in Shaft - Design standard

Plug-in Shaft - Material 1.4021 / AISI 420

Bolting - Design standard

Offer No. 16401/18.06.15

Verder Romania srl, Bucuresti

Painting - Color standard RAL 5013 (blue)

From the second quarter of 2015, SEEPEX will replace the material 1.4571 (AISI 316Ti ) by the similar

material 1.4404 (AISI 316L), step by step.

Depending on actual stock levels during the transition period the material delivered may differ from the

material offered.

Drive

Type Gear motor at freq. inv.

Mounting position M4

Ratio (i) 6.58

-1

Speed 220 min

Norm Min Max

-1 -1 -1

Speed 220 min 252 min 288 min

-1 -1 -1

Motor speed 1450 min 1655 min 1894 min

Frequency 50 Hz 57 Hz 65 Hz

Rated output 2.2 kW

-1

Rated speed 1450 min

Starting direct on frequency inverter

Efficiency class IE2

Terminal box position acc. to supplier 1

Cable entry position acc. to supplier I

Voltage 230/400V

Frequency 50Hz

Enclosure IP55

Thermal class F

Winding protection 3 PTC - thermistors

The frequency inverter has to follow a linear U/f characteristic curve (constant torque).

It’s essential to have a minimum overload capability of 150% for at least 3 seconds. (see technical

data sheet)

Baseplate

Design baseplate for block pump

Material steel, painted

GPU Type Code B-ST

Price composition Unit price

EUR 2280

Dry running protection device (TSE)

Design basic design included

- sensor sleeve fitted to the stator of the

pump with integrated temperature sensor

and evaluation unit (IP67)

- fixed switch off temperature 60°C

- connection with M12 sensor plug

Voltage 24V DC

Temperature coefficient Pt100

Material sensor sleeve 1.4571 / AISI 316Ti

Material connection head 1.4404 / AISI 316L

Delivery time: 8-9 weeks

Quote validity: 30 days/ Price without VAT

Delivery condition: EXW Bucharest, Verder Romania SRL

Payment condition: 15% advance, 85% at delivery

not binding drawing for offer

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Datasheet 70 24RDocument10 pagesDatasheet 70 24RCarlos VergaraNo ratings yet

- Tech Water PumpDocument2 pagesTech Water PumpRafaelNo ratings yet

- Data Sheet FA 20.97Z PDFDocument4 pagesData Sheet FA 20.97Z PDFShah Newaz KabirNo ratings yet

- Recycled Sodium 1Document4 pagesRecycled Sodium 1511231103No ratings yet

- MovitecV 004 14-B4G13Document6 pagesMovitecV 004 14-B4G13Adi MartuahNo ratings yet

- Data SheetDocument10 pagesData SheetVuk VujatovicNo ratings yet

- Commission No.: 386207 Type: BN 130-6L Application DataDocument1 pageCommission No.: 386207 Type: BN 130-6L Application DatavyshakhNo ratings yet

- WILO FA60 14mDocument4 pagesWILO FA60 14mJairo Alonso Fox RoaNo ratings yet

- Valve PagesDocument5 pagesValve PagesJoyal ThomasNo ratings yet

- PDS1 KRTK GermanyDocument5 pagesPDS1 KRTK Germanyfirman syahNo ratings yet

- Data SheetDocument5 pagesData SheetAmr IbrahimNo ratings yet

- Wetpit 3.B SA20.97M+SI44.1-04-90-PTC-15m 120 Lps @45 MDocument4 pagesWetpit 3.B SA20.97M+SI44.1-04-90-PTC-15m 120 Lps @45 MAtika RadhevaNo ratings yet

- Grundfos - CR 10 3A FJ A E HQQEDocument15 pagesGrundfos - CR 10 3A FJ A E HQQEArleene Mariano SalazarNo ratings yet

- WW Pump 900 m3Document12 pagesWW Pump 900 m3Iskandar Zulkarnain HasibuanNo ratings yet

- Grundfos CRN 1s 10 A FGJ G e HqqeDocument15 pagesGrundfos CRN 1s 10 A FGJ G e HqqeANDRESNo ratings yet

- Catalogo TsurumiDocument40 pagesCatalogo TsurumiAPOLINAR GARCÍA OTINIANONo ratings yet

- PDS Amacan PA4 800-540 UTG1 Q 1000 LPS H 6 MDocument11 pagesPDS Amacan PA4 800-540 UTG1 Q 1000 LPS H 6 MBudi SNo ratings yet

- MovitecVCI04-06-06AA14CS080B5UW Rotor 86mmDocument6 pagesMovitecVCI04-06-06AA14CS080B5UW Rotor 86mmRaphaelNo ratings yet

- PDS2 Transmisi Air Bersih Omega PumpDocument6 pagesPDS2 Transmisi Air Bersih Omega PumpBudi SNo ratings yet

- Grundfos - CRI 3 23 A P I E HQQEDocument15 pagesGrundfos - CRI 3 23 A P I E HQQEHeinium DannemannNo ratings yet

- ksb غاطسDocument5 pagesksb غاطسGhassan ABO ALINo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- PDS 1000 LPS Head 5 MDocument10 pagesPDS 1000 LPS Head 5 MBudi SNo ratings yet

- Spek PompaDocument4 pagesSpek PompaTri YuniantoNo ratings yet

- Data SheetDocument6 pagesData SheetHaroonNo ratings yet

- Data Teknis WILO 100lps @40mDocument4 pagesData Teknis WILO 100lps @40mAnonymous dr93RjfPEY100% (1)

- MovitecV 002-20-B5K13FS090D5UWDocument6 pagesMovitecV 002-20-B5K13FS090D5UWRaphaelNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Grundfos - CR 10 16 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 16 A FJ A E HQQEJafar SidiqNo ratings yet

- Boulder Stream Cascade PumpDocument3 pagesBoulder Stream Cascade PumpJawNo ratings yet

- Grundfos - CR 10 2 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 2 A FJ A E HQQEMario PatarroyoNo ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- Pneumatic Gap Frame Single Point Press JH21-125, 160 TDocument14 pagesPneumatic Gap Frame Single Point Press JH21-125, 160 TNaukowyDrpNo ratings yet

- Water ةىلارؤDocument25 pagesWater ةىلارؤnaseerlateefNo ratings yet

- 01 Data Sheet FA 30.93DDocument3 pages01 Data Sheet FA 30.93Dاحمد شوقي عمارNo ratings yet

- AbbDocument3 pagesAbbFabiano TonnNo ratings yet

- KRT-Caracteristicas TecnicasDocument41 pagesKRT-Caracteristicas TecnicasJjoseph MaquNo ratings yet

- WEG 132kW SpecificationDocument8 pagesWEG 132kW Specificationbonginkosi mathunjwaNo ratings yet

- LIW Final DatasheetDocument1 pageLIW Final Datasheetparth sapariaNo ratings yet

- Data SheetDocument7 pagesData SheetCesar TrujilloNo ratings yet

- 8038 - Data SheetDocument5 pages8038 - Data SheetJakub KjubNo ratings yet

- Offer 1 - Chilled Water Primary PumpsDocument6 pagesOffer 1 - Chilled Water Primary Pumpschukudi oguneNo ratings yet

- 6.0 - en-US - 2019-01 - TS - Flygt 3171Document48 pages6.0 - en-US - 2019-01 - TS - Flygt 3171FedeNo ratings yet

- Datasheet - TV7H 236-11z: Print Create PDF Create EXCEL FileDocument6 pagesDatasheet - TV7H 236-11z: Print Create PDF Create EXCEL Fileعالم الصيانة معدات ثقيلة ومعدات خرسانةNo ratings yet

- Grundfos CRN 3 3 A FGJ G e HqqeDocument15 pagesGrundfos CRN 3 3 A FGJ G e Hqqewmgb249529No ratings yet

- CRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965Document15 pagesCRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965PysasaIrapuatoNo ratings yet

- Iso-Kinetic Stack PM SamplerDocument3 pagesIso-Kinetic Stack PM Samplergivemore handizvihweNo ratings yet

- AGITADOR SUBMERSÍVEL ABS SULZER XRW - 210 - 60Hz - TDSDocument1 pageAGITADOR SUBMERSÍVEL ABS SULZER XRW - 210 - 60Hz - TDSVictor SouzaNo ratings yet

- Sea Water Intake PumpDocument10 pagesSea Water Intake PumpmbgprsmsNo ratings yet

- Grundfos CRI 5 3 A FGJ I E HQQE UnlockedDocument15 pagesGrundfos CRI 5 3 A FGJ I E HQQE UnlockedLEONARD CHRISTOPHER LIMANJAYANo ratings yet

- RTAF - Air-Cooled Series R (TM) Product ReportDocument2 pagesRTAF - Air-Cooled Series R (TM) Product ReportRafaelDutraNo ratings yet

- Offer 2 - HVAC Booster Pumps FCU Zone 1Document6 pagesOffer 2 - HVAC Booster Pumps FCU Zone 1chukudi oguneNo ratings yet

- Air-Cooled Series R (TM) CRTAG145 Product Report - Rev01aDocument2 pagesAir-Cooled Series R (TM) CRTAG145 Product Report - Rev01aUrsula MottaNo ratings yet

- PreviewDocument6 pagesPreviewHassan GhumroNo ratings yet

- Grundfos - CR 15 10 A F A E HQQE PDFDocument15 pagesGrundfos - CR 15 10 A F A E HQQE PDFdimasNo ratings yet

- CHLF4 603PH50HZSS 31611KWDocument2 pagesCHLF4 603PH50HZSS 31611KWKunal GadeNo ratings yet

- Catalogo de Cilindros Neumaticos FestoDocument2 pagesCatalogo de Cilindros Neumaticos FestoRuBeN cruzNo ratings yet

- Verbe NeregulateDocument8 pagesVerbe NeregulatevaliNo ratings yet

- CWL Excellent CWL GBDocument24 pagesCWL Excellent CWL GBvaliNo ratings yet

- Recuperator GV-HR110 - 01Document16 pagesRecuperator GV-HR110 - 01valiNo ratings yet

- Nibe GV HR110 Pliant 30 09 2013 enDocument4 pagesNibe GV HR110 Pliant 30 09 2013 envaliNo ratings yet