Professional Documents

Culture Documents

General BoRexMC7 BB3 Re95080 06-96

Uploaded by

Eduardo Aguero ValdezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General BoRexMC7 BB3 Re95080 06-96

Uploaded by

Eduardo Aguero ValdezCopyright:

Available Formats

RE 95080-B/06.

96

Functions of Control Panel BB-3 (VT 12321)

when used with MC Microcontroller

RE

Diagnostics, Parameterisation, Process Value Display 95080-B/06.96

Brueninghaus Hydromatik Version 1.6 Preliminary version

The control panel BB-3 is used for communication with a variety

of digital control devices from the Mannesmann Rexroth range.

If the BB-3 unit is connected to such an output device, this will

automatically be recognised and the relevant software in the BB-

3 will start up.

In addition to the general description of the BB-3 hardware in RE

29798, the special functions shown here are available when the

control panel BB-3 is connected to a Brueninghaus Hydromatik

MC microcontroller.

The individual functions are as follows:

● Diagnostics

Display of errors in clear text

● Parameterisation

Input and editing of userspecific values, MC7 and BB-3

e.g. time ramps, pilot currents

● Process value display

Display of actual values, e.g. speeds

● Teach

Store and load edited or

standard parameters

Special features

– User-friendly menu

– Easy input by means of numerical keys with edit functions

– Multi-lingual

– Online editing of parameters (while machine in operation)

– Reset to standard settings (defaults) possible at any time

Ordering code (for BB-3, VT12321 incl. software)

The functions required for a Brueninghaus Hydromatik MC

microcontroller are contained in the BB-3 software under the

following designation:

(VT12321-1X/E- VX.X/X.X/X.X/1.6)

or VT12321-20 VX.X/X.X/X.X/1.6

Brueninghaus Hydromatik BB-3 Software Version 1.6

Brueninghaus Hydromatik 1/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

Description

1. Start-up functions

After switching on the power for the Control panel BB-3 the following functions are

carried out and shown on the display (flow chart Fig. 1, page 10):

1.1 Self-test and baud rate recognition * BB - 3 / BF - 1 *

The BB-3 automatically recognises the rate of data transmission from the MC Ve r s i on :

electronics. During this time the message 'not received' may be briefly displayed. XX XX XX 16

N.B.:

As long as a key* is being activated while switching on, the software version will be

displayed. (*exception: ALT key) * R e x r o t h BB - 3 *

If the BB-3 remote control unintentionally activates the "Test mode" (these displays are V 2 . 0

not shown or described here), this mode can be cleared by pressing and holding down

( RS 4 2 2 / RS 2 3 2 )

the ALT + CLEAR keys simultaneously for a few seconds.

( XXXXX Ba u d )

* HYD - D i a g n o s e *

(C) H y d r oma t i k

V 1 . 6

1.2 Identification D e v ice :

On recognition of the MC electronics the relevant software in the BB-3 will be started MCX

up. Pr o g r am V e r s i o n :

XX X X X X X

1.3 Main menu F1 C o n f i g / Ca l

Initialisation of remote control unit BB-3 is complete. One of the four main menu items F2 D i agnostic

can be selected using the given keys. (Fig. 1, page 10) P R OC S t a t u s

T EACH S t o r a g e

2. Functions in main menu

Keys: + Language Selection

Submenu Configuration / Calibration of Parameters

Submenu Diagnostic

Submenu Status of Process Value

Submenu Storage

2.1 Language selection (Keys ALT + CLEAR)

Keys 1 and 2 are pressed to select either German or English. The user guide, as well 1 . Deu t s ch

as error messages, will then be displayed in the relevant language.

2 . Eng l i s h

3 . - - -

Keys: ... Select Language 4 . - - -

1 4

2/12 Brueninghaus Hydromatik

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

3. Submenu Config/Cal Groups (Key F1)

Key F1 is used to exit the main menu and enter the submenu to

select a parameter group. (Flow chart Fig. 2, page 11)

1 . Parameter group A

2 . Parameter group B

3 . Parameter group C

4 . Parameter group D

Example

1 . cur r en t s

2 . t ime r a mp s

3 . - - -

4 . - - -

Change to an alternative set of parameter groups. (Depending on the

Keys: + or + MC software there can be up to 3 sets, each with 8 parameter groups.)

Depending on how the MC microcontroller is programmed, a password

(? : – ) may be requested on the display when changing over to an alternative

parameter group. Only when the correct password is entered can another

parameter group be accessed.

1 ... 8 Select parameter group 1 to 8

Change from parameter groups 1...4 to parameter groups 5...8

Change from parameter groups 5...8 to parameter groups 1...4

Return to main menu

Activate storage menu (see section 6)

3.1 Submenu Select parameter (Keys 1...8) 1 Parameter a

Keys 1...8 are used to exit the submenu Config/Cal 2 Parameter b

into the relevant submenu Select parameter 3 Parameter c

4 Parameter d

Example

1 I ma x P u m p

2 Im i n Pu m p

3 I ma x Mo t o r

4 I m i n Mo t o r

Keys: 1 ... 8 Select a parameter

Change to parameters 5...8

Change to parameters 1...4

Return to submenu Config/Cal

Activate Store menu (see section 6)

Brueninghaus Hydromatik 3/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

3.1.1 Edit parameter (Keys 1...8) Example

On selecting a parameter by pressing one of the number keys 1...8 in the 1 I m a x P um p

submenu Select parameter, the display / edit function for parameters is 0 - 1 4 0 0 ± 2 mA

activated. The following text may for example be displayed: 1230

Keys for entering parameter:

Edit functions

0 ... 9 Enter number

Delete number left of cursor

Move cursor to left or right

Increase or decrease number by the given "+/-" value in steps.

The new value is accepted instantaneously by the MC without

Enter 1)

Accept instantaneously in MC 1)

Abort function and return to submenu Select parameter

1) Stored in EEPROM only by means of

Storage menu

If a value entered for a parameter lies outside the given value

range, an error message will be output and the setting will not be

accepted.

General functions

pressed + Load standard values from MC-EPROM

3.1.2 Parameter types

Different types of parameter are set in the MC software, and they

offer various editing functions.

Depending on the parameter type the following texts will be displayed:

1. Type: "Numeric" Example:

Parameter 3: No. of teeth 3 N o. o f t e e t h

Value range 0 - 510, Steps ±1 0 - 510±1

Actual value 135

Line for error messages

Keys: Editing and general functions

4/12 Brueninghaus Hydromatik

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

2. Type: "Time ramp" Example:

Parameter 1: Swivel out pump 1 Swivel out pump

Value range, steps, unit ms (milliseconds) 1 0 0 - 5 0 0 0 ± 1 0 0ms

Actual value 100

Error message

Keys: Editing and general functions

3. Type: "Current" Example:

Parameter 5: Motor - Minimum current 5 I m i n Mo t o r

Value range, steps, unit mA (milliampere) 0 - 1 4 0 0 ± 2 mA

Actual value 396

Error message

Keys: Editing and general functions

4. Type "potentiometer calibration"

To enter parameter type potentiometer calibration a program routine in the MC electronics is initiated, that reads in the

actual value at an analogue input and displays it on the BB-3 as an input voltage.

The minimum voltage Umin of a particular potentiometer setting is accepted as the 1st parameter by the ENTER command.

With the next setting of the potentiometer the maximum voltage Umax is accepted as the 2nd parameter via ENTER command.

Example:

Parameter 2: Travel lever

Maximum/Minimum setting 2 . Tr ave l lever

Actual voltage M i n i mu m s e t t i n g

Error message 0 . 0 V

Keys: Acceptance of new value

Abort function and return to submenu Select parameter

5. Type "Learning curve"

With this parameter type the MC electronics stores the relationship between two input signals, for example as a characteristic

of the relationship between Diesel engine speed and position of the injection pump in the unloaded condition.

The input values must be changed slowly, e.g. by increasing the engine speed. Press ENTER to confirm completion.

Example:

Parameter 3: Recording of a Learning curve

Actual frequency (proportional to engine speed)

Voltage at potentiometer 3 L e arning c u r v e

900 Hz

0 . 3 V

Keys: Input completed

Abort function and return to submenu Select parameter

Brueninghaus Hydromatik 5/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

6. Type "List"

There is a list of values or conditions that may be selected.

Example:

Parameter 2: Drive dynamics 2 Dr ive dynamics

The list contains e.g. hard, medium, soft etc. m e d i um

Keys: Switch between fixed values or conditions

Accept value/conditon in MC electronics

Do not accept value,

return to submenu Select parameter

7. Type "function"

With the function type a user-specific program in the MC electronics is run.

Before starting the function a parameter value can be entered or edited (cf. type "Numeric").

Example:

Parameter 2: adjustment speed 2 ad j . speed

Value range, steps 900 - 1150 ±1

Actual value 950

Name of parameter Low idling speed

Keys: Editing and general functions

St ar t?

After acceptance of the parameter value via ENTER the - - > < ENT ER>

function in the MC can be either started or aborted. Ca n c e l ?

- - > < ME NU >

Func t i on ac t i v e !

If the function is started via ENTER, the following message will be

displayed during execution. P l ease wai t . . .

Func t i on ended

If the function in the MC program is completed, the BB-3 will No e r r o r

display as a result an application-specific message (e.g. "No error").

Pressing the ENTER key will effect a return to submenu Press < ENT ER>

Select paramter.

6/12 Brueninghaus Hydromatik

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

4. Submenu Diagnostic (Key F2) Example

Key F2 is used to branch from the Main menu into the submenu 1 Ac t u a l Fau l t s

Diagnostic. (Flow chart Fig. 3, page 11) 2 Saved Fau l t s

3 De l e t e Fau l t s

4

Keys: 1 ... 3 Select menu item

Return to Main menu

4.1 Actual Faults (Key 1)

Display actual errors in clear text.

Keys: Scroll error list up or down

Return to submenu Diagnostics

4.2 Saved Faults (Key 2)

Display of errors occuring since last delete, in clear text.

It is determined in the MC software whether an error is to be stored or

only displayed as an actual error.

Keys: Scroll error list up or down

Return to submenu Diagnostics

4.3 Delete Faults (Key 3) Example

Delete?

- - > < ENT ER>

Ca n c e l ?

- - > < ME NU >

Keys: Delete stored errors

Abort and return to submenu Diagnostics

5. Submenu Status (Key PROC)

Key PROC is used to branch from the Main menu into the submenu 1 . status/value A

Status of process values. (Flow chart Fig. 4, page 12) 2 . status/value B

3 . status/value C

4 . status/value D

Example

1 . A c t. s p e e d

2 . C o m m. s p e e d

3 . C o n t r o l d e v.

4 . P ump o u t p u t

Brueninghaus Hydromatik 7/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

Switch between alternative sets of

Keys: + or +

status

1 ... 8 Select status

N.B.:

Two status must always be selected, and they are displayed

simultaneously. The selection is displayed by numbers 1 and 2

according to the process value number.

Change from status 1...4 to

status 5...8

Change from status 5...8 to

status 1...4

Return to Main menu

5.1 Display of two status (Key 1...8)

Example:

Process value 1: Actual speed 1 . A c t. s p e e d

Actual value 500

Process value 3: Control deviation 3 . C o n t r o l d e v.

Actual value - 125

Keys: Return to Submenu Status

6. Submenu Storage (Key TEACH) Example

Key TEACH is used to exit the main menu and enter

1 S a v e P a r ams

the submenu Storage. (Flow chart Fig. 5, page 12) 2 D e f a u l t P a r ams

3 G e t E E P R OM

4 S e n d E E P ROM

Keys: ... Select menu item

1 4

Return to Main menu

6.1 Save Params (Key 1)

This menu item permits storage of all edited parameters

in the EEPROM of the MC electronics. This means that Teach?

the values of all parameters will be retained even if the - - > < ENT ER>

supply voltage is switched off. Ca n c e l ?

- - > < ME NU >

Keys: Store parameters

Abort

8/12 Brueninghaus Hydromatik

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

6.2 Default Params (Key 2)

With this function all parameters can be reset to the De f a u l t s ?

standard values fixed in the EEPROM of the MC electronics. - - > < ENT ER>

Ca n c e l ?

- - > < ME NU >

Keys: Load default values

Abort

6.3 Get EEPROM (Key 3)

When this menu item is activated all parameters are transmitted from G e t i n M emo r y ?

MC-EEPROM and loaded into the selected area of the BB-3. 1 : N ame

2 : ??????????????

N.B.: Names may be displayed as well as question marks.

3 : ??????????????

This permits e.g. an optimum control setting to be stored in the BB-3 and if required to be transmitted to another system of the same

type, thus considerably shortening control setting times. Control panel BB-3 can store a max. of 3 parameter sets. The data in the

BB-3 will be retained, even if the BB-3 is separated from the MC.

Keys: 1 ... 3 Select store area

Return to Submenu Storage

After selecting the area the following message will be displayed:

The MC transmits the data, the progress being displayed as a percentage. P l e a s e wa i t !

Load i ng . . . X X%

The BB-3 will then request a name for the store area. The name N ame ?

can have a maximum of 12 characters.

1 :

Keys: Move through letters/characters forwards/backwards

Cursor to left/right

Accept name and store MC parameters

Abort

Brueninghaus Hydromatik 9/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

6.4 Send EEPROM (Key 4)

This menu item permits the transmission of the parameters stored in the BB-3 S e n d M emo r y ?

to the MC-EEPROM. 1 : N ame

2 : ??????????????

3 : ??????????????

Keys: 1 ... 3 Select store area

Return to submenu Storage

Selecting a store area (1...3) produces the following message:

P l e a s e wa i t !

Data transmission running

L o a d i n g E E P ROM !

Sav i ng

Data stored in MC

f i n i shed !

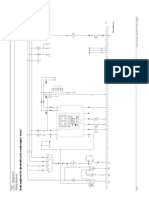

Fig. 1: BB-3 Main menu and Submenus

Start

Self test

Baud rate recognition

Program identification

Keys ALT+CLR

Main menu Language selection

Key F1 Key F2 Key PROC Key TEACH

Submenu Submenu Submenu Submenu

Config/Cal Diagnostic Status Storage

10/12 Brueninghaus Hydromatik

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

Fig. 2: BB-3 Submenu Parameter

Main menu

Key F1

Keys Keys 1)

Submenu ALT+ ← Submenu ALT+ → Submenu

Config/Cal Config/Cal Config/Cal

(Group) (Group) (Group)

Keys 1...8

1)

Submenu Submenu Submenu

Parameter ... Parameter ... Parameter

(Selection 1) (Selection 4) (Selection 8)

Keys 1...8

Parameter 1 Parameter 8

Display/ ... Display/

Edit Edit

Keys Keys

ALT+ENTER ALT+ENTER

Load Load 1) Branch into

default value default value submenu TEACH

from EEPROM from EEPROM possible

Fig. 3: BB-3 Submenu Diagnostics

Main menu

Key F2

Submenu

Diagnostic

Key 1 Key 2 Key 3

Actual Saved Delete

faults faults faults

Display actual Display stored Delete stored

errors errors errors

Brueninghaus Hydromatik 11/12

RE 95080-B/06.96

Functions of control panel BB-3 when used with the MC microcontroller

Fig. 4: BB-3 Submenu Status

Main menu

Key PROC

Keys Keys

ALT+ ← ALT+ →

Submenu Submenu Submenu

Status Status Status

Select 1st

process value

Keys 1...8

Select 2nd

process value

Keys 1...8

Display both

process values

Fig. 5: BB-3 Submenue storage

Main menu

Key TEACH

Submenu

storage

Save parameters Default parameters Get EEPROM Send EEPROM

Key 1 Key 2 Key 3 Key 4

Teach? Defaults? Input area Select storage

Cancel? Cancel? name area

Loads Sends

Store parameters Load default

EEPROM contents EEPROM

in EEPROM values

into BB-3 contents to MC

Brueninghaus Hydromatik GmbH, Plant Elchingen, Glockeraustraße 2, D–89275 Elchingen 2, Tel. (07308) 820, Fax (07308) 7274

12/12 Brueninghaus Hydromatik The specified data is for product description purposes only and may not be deemed to be

guaranteed unless expressly confirmed in the contract. All rights reserved – Subject to revision

You might also like

- A From Ø 1: Kanten GebrochenDocument1 pageA From Ø 1: Kanten GebrochenEduardo Aguero ValdezNo ratings yet

- AirConditioning enDocument21 pagesAirConditioning enEduardo Aguero ValdezNo ratings yet

- AirConditioning enDocument21 pagesAirConditioning enEduardo Aguero ValdezNo ratings yet

- Hydr MHL434Document6 pagesHydr MHL434Eduardo Aguero ValdezNo ratings yet

- GLR Linde Teach inDocument42 pagesGLR Linde Teach inEduardo Aguero Valdez100% (1)

- Hydr MHL434Document6 pagesHydr MHL434Eduardo Aguero ValdezNo ratings yet

- GLR Linde Teach inDocument42 pagesGLR Linde Teach inEduardo Aguero Valdez100% (1)

- GLR Boschrex Bb3Document16 pagesGLR Boschrex Bb3Eduardo Aguero ValdezNo ratings yet

- GLR Boschrex Bb3Document16 pagesGLR Boschrex Bb3Eduardo Aguero ValdezNo ratings yet

- General BoRexRC2 Re95310 2009-01 enDocument12 pagesGeneral BoRexRC2 Re95310 2009-01 enEduardo Aguero ValdezNo ratings yet

- A From Ø 1: Kanten GebrochenDocument1 pageA From Ø 1: Kanten GebrochenEduardo Aguero ValdezNo ratings yet

- Ops VHP90, HP60CMH 12-06Document61 pagesOps VHP90, HP60CMH 12-06Eduardo Aguero ValdezNo ratings yet

- Setting MHL460Document3 pagesSetting MHL460Eduardo Aguero ValdezNo ratings yet

- Elplan MHL460T PC 0011 0014Document8 pagesElplan MHL460T PC 0011 0014Eduardo Aguero ValdezNo ratings yet

- General BoRexMC7 BB3 Re95080 06-96Document12 pagesGeneral BoRexMC7 BB3 Re95080 06-96Eduardo Aguero ValdezNo ratings yet

- Manual de Servicio Deutz PDFDocument82 pagesManual de Servicio Deutz PDFDaniel Castillo Peña100% (1)

- AirConditioning enDocument21 pagesAirConditioning enEduardo Aguero ValdezNo ratings yet

- Elplan MHL335 PDFDocument1 pageElplan MHL335 PDFEduardo Aguero Valdez0% (1)

- Boletin de Servicio Filtros de AireDocument2 pagesBoletin de Servicio Filtros de AireEduardo Aguero ValdezNo ratings yet

- General ServiceBulletins AuroraDocument40 pagesGeneral ServiceBulletins AuroraEduardo Aguero ValdezNo ratings yet

- XHP1170WCU Parts 5-03Document58 pagesXHP1170WCU Parts 5-03Eduardo Aguero ValdezNo ratings yet

- CounterweightsDocument1 pageCounterweightsEduardo Aguero ValdezNo ratings yet

- Counterweights PDFDocument1 pageCounterweights PDFEduardo Aguero Valdez100% (1)

- Instalacion de Banda de TiempoDocument11 pagesInstalacion de Banda de TiempoEduardo Aguero ValdezNo ratings yet

- TB 60 Repair Parts PDFDocument282 pagesTB 60 Repair Parts PDFvatasa100% (2)

- Diagrama Electrico LlindeDocument6 pagesDiagrama Electrico LlindeEduardo Aguero ValdezNo ratings yet

- Diagrama Electrico Llinde PDFDocument6 pagesDiagrama Electrico Llinde PDFEduardo Aguero ValdezNo ratings yet

- Manual: Operator'SDocument84 pagesManual: Operator'SZhenya ChaicynNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)