Professional Documents

Culture Documents

TDS-PARALINK Rev11-07072015 en

Uploaded by

jitendraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS-PARALINK Rev11-07072015 en

Uploaded by

jitendraCopyright:

Available Formats

TECHNICAL DATA SHEET

Rev. 11, Issue Date 07.07.2015

PARALINKTM

STRIP BONDED GEOGRIDS WITH HIGH TENACITY POLYESTER CORE

100x10 100x10 100x10 100x10

ParaLink geogrids are pla-

1100 1200 1300 1350

1390

PET

0.53

135

900

-33

91

4.5

PE

12

50

nar structure consisting of a

monoaxial array of compos-

ite geosynthetics strips.

1339

PET

0.52

130

860

-32

91

4.5

PE

12

50

Each single longitudinal

strip has a core of high te-

nacity polyester yarns ten-

1236

PET

0.50

790

120

-30

91

4.5

PE

12

50

dons encased in a polyeth-

ylene sheath; the single

strips are connected by

1133

PET

0.50

110

710

-27

4.5

PE

12

91

50

non-resisting cross laid

polyethylene strip that

100x12. 100x12.

gives a grid like shape to

1000

1038

PET

0.50

4.5

126

660

-25

91

PE

12

50

the composite.

5

* Short-term tests in

112.5

PET

0.50

accordance with EN ISO

900

4.5

927

600

-22

91

PE

12

50

5

10319:2008. The values

cm 100x18 100x18 100x18 100x18 100x18 100x18 100x18 100x18 100x15 given are mean values of

ultimate strength and

0.50

PET

800

120

826

550

-22

4.5

PE

12

91

50 tolerance values

correspond to the 95%

0.50

c o n fi d en ce l e ve l to

PET

700

126

721

480

-17

4.5

PE

12

91

50

establish the characteristic

short-term tensile strength

0.70 in accordance with EN

PET

600

108

612

100

750

4.5

PE

12

90

-9

13251:2001. Tolerance for

strain values is ± 2.

0.75

PET

500

515

130

780

-13

4.5

PE

90

12

90

Intermediate grades are

available on request.

0.75

PET

400

412

150

750

-10

4.5

PE

72

12

90

0.70

PET

300

309

200

770

4.5

PE

54

12

88

-8

0.70

PET

200

206

200

590

4.5

PE

36

12

85

-5

0.51

PET

100

103

200

410

4.5

PE

18

12

82

-2

PET

200

370

4.5

0.5

PE

50

51

12

82

-1

For the optimisation and improvement

kN/m

mm

kN

kg

%

process of the technical characteristics

m

of the products, the producer reserves

the right to modify standard characteris-

Polymer of the reinforcement strip

tics of the product without any notice.

Physical properties (typical values)

The information contained herein is

Single strip longidudinal tensile

accurate to the best of our knowledge,

Roll diameter (nominal value)

Strain at UTS - Longitudinal*

Polymer coating of the strips

but since the circumstances and condi-

Roll weight (nominal value)

tions in which it may be used are be-

yond our control, we do not accept any

liability for any loss or damage, whatso-

Mechanical properties

UTS - Longitudinal *

ever, which results directly or indirectly

Pitch (weft x warp)

from the use of such information nor do

Single strip width

we offer any warranty or immunity

against patent infringement.

PARALINK

Tolerance *

Roll length

Roll width

ParalinkTM is a registered

strength

element

trademark of Linear

Composite Ltd.

Maccaferri Environmental Solutions Pvt. Ltd. LRQA certified Quality management system with

14th Floor, Vatika Professional Point, Golf Course Ext. Road ,Gurgaon – 122001 UKAS accreditation.

Tel: +91- 0124– 4398400 , Fax: +91– 0124– 4398444 .

E-mail: technical@maccaferri-india.com - Web site: www.maccaferri.com/in

MI/WDC/QF/23-25

R00 - 01/07/08

You might also like

- Ticket 20232212677-3Document1 pageTicket 20232212677-3Multani KanwarNo ratings yet

- 2C-M002 - Rev 0Document1 page2C-M002 - Rev 0Marco Andres Ortiz TitoNo ratings yet

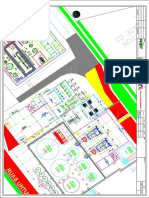

- Wal0079 101 0 PDFDocument1 pageWal0079 101 0 PDFyassir dafallaNo ratings yet

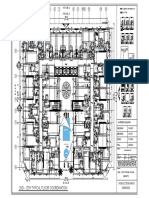

- Ground Tiling Layout-Model333Document1 pageGround Tiling Layout-Model333SIDHARTH SNo ratings yet

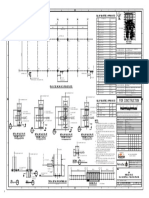

- HS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary PlatformsDocument1 pageHS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary PlatformsFatih ÜnlüNo ratings yet

- Compound Waal-ModelDocument1 pageCompound Waal-Modelsri projectssNo ratings yet

- Plan - J04 - Restaurant Table: Legends & FinishesDocument1 pagePlan - J04 - Restaurant Table: Legends & FinishesHoward RoarkNo ratings yet

- Moraine State Park MapDocument1 pageMoraine State Park Mapinvading_jam7582No ratings yet

- TochiDocument1 pageTochiRommeoNo ratings yet

- Undertale - MegalovaniaDocument7 pagesUndertale - MegalovaniaEnder Lion100% (1)

- Outils - 6 Sigma Project GuidelineDocument1 pageOutils - 6 Sigma Project GuidelineCar YamooNo ratings yet

- Al Amra Coordnation 20-6-2020-ModelDocument1 pageAl Amra Coordnation 20-6-2020-ModelNagy FaragNo ratings yet

- A-206-Mosque Entrance Porch ElevationDocument1 pageA-206-Mosque Entrance Porch ElevationEmmanuel InfanteNo ratings yet

- C-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelDocument1 pageC-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelHUSSEIN FNEISHNo ratings yet

- Lampiran PFD ParaxyleneDocument1 pageLampiran PFD ParaxyleneAviv AL FarisNo ratings yet

- Boq DrawingDocument1 pageBoq DrawingPrince Phill DziruniNo ratings yet

- Alba (Live Version For Cercle) - Sofiane PamartDocument6 pagesAlba (Live Version For Cercle) - Sofiane PamartJulien Gasser100% (1)

- Carnegie: State Vehicular Recreation AreaDocument1 pageCarnegie: State Vehicular Recreation AreabradalbiNo ratings yet

- Rds Ormoc-2f Reflected Ceiling PlanDocument1 pageRds Ormoc-2f Reflected Ceiling PlanAaron JabasNo ratings yet

- Gambar 2222Document1 pageGambar 2222Bagas HilmiNo ratings yet

- New PlanDocument1 pageNew Plani putu riki darmawanNo ratings yet

- asset-v1-TUMx QPLS1x 2T2018 Type@asset block@SixSigma - Project-GuidelineDocument2 pagesasset-v1-TUMx QPLS1x 2T2018 Type@asset block@SixSigma - Project-Guidelineravapu345No ratings yet

- Code Geass - StoriesDocument5 pagesCode Geass - Stories1234chocoNo ratings yet

- 02 Estructural Vivienda CF001Document1 page02 Estructural Vivienda CF001GERARDO PINCAY BRAWNNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- Game of Thrones: Arr.: Simon CsokanDocument5 pagesGame of Thrones: Arr.: Simon CsokanRaymond TranNo ratings yet

- Game of Thrones - Difficult Piano Version PDFDocument5 pagesGame of Thrones - Difficult Piano Version PDFΔημητρης ΚαλουμενοςNo ratings yet

- Game of Thrones - Difficult Piano Version PDFDocument5 pagesGame of Thrones - Difficult Piano Version PDFggNo ratings yet

- Atlas Copco Compressor DrawingDocument1 pageAtlas Copco Compressor DrawingKumar Gaurav100% (8)

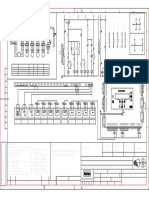

- Schematic Diagrams (1/13) Input / Volume BoardDocument13 pagesSchematic Diagrams (1/13) Input / Volume BoardWinger ZsNo ratings yet

- DENON AVR-1905 SchematicDocument13 pagesDENON AVR-1905 SchematicGuillaume HubertNo ratings yet

- Produced by An Autodesk Educational Product: Female W.C Fire Exit Assistant Manager 1Document1 pageProduced by An Autodesk Educational Product: Female W.C Fire Exit Assistant Manager 1haiderdbNo ratings yet

- 640-0762 (Inversora) - SURT7500,8000,10000Document7 pages640-0762 (Inversora) - SURT7500,8000,10000Helder RizziNo ratings yet

- Villa Los AromosDocument1 pageVilla Los AromosMiguel Zuñiga YañezNo ratings yet

- Song PDFDocument4 pagesSong PDFNikita HolubNo ratings yet

- Passacaglia: G. F. Handel 120Document7 pagesPassacaglia: G. F. Handel 120marlete duraesNo ratings yet

- The Big Bang Theory Theme by Barenaked Ladies Piano CoverDocument1 pageThe Big Bang Theory Theme by Barenaked Ladies Piano CoverliviancabralNo ratings yet

- Pastime FlûteDocument1 pagePastime FlûteMeliodas SamaNo ratings yet

- Pastime FlûteDocument1 pagePastime FlûteMeliodas SamaNo ratings yet

- SCALE 1: 400: Denah Rencana Ac Basement Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)Document1 pageSCALE 1: 400: Denah Rencana Ac Basement Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)najiha salsabilaNo ratings yet

- Cinderella: Komi-San Can't Communicate OPDocument3 pagesCinderella: Komi-San Can't Communicate OPVader JorgeNo ratings yet

- A - Hisa - Magic Logic LabyrinthDocument6 pagesA - Hisa - Magic Logic LabyrinthNewPlayNo ratings yet

- (AqareCover) Bereaved and Those Left Behind v2Document4 pages(AqareCover) Bereaved and Those Left Behind v2nartiishartiiNo ratings yet

- CJP (TYP.) : Sample TextDocument1 pageCJP (TYP.) : Sample TextGHULAM NABINo ratings yet

- Front Rear: 584 and 584HD Forwarder Hydraulic SystemDocument2 pagesFront Rear: 584 and 584HD Forwarder Hydraulic Systemcjl08No ratings yet

- Chaconne J. S. Bach Partita No 2 in D MenorDocument2 pagesChaconne J. S. Bach Partita No 2 in D MenoriiVxrceNo ratings yet

- Contratempo: JoropoDocument4 pagesContratempo: JoropoAlexandra OwensNo ratings yet

- South Province (Pokémon Scarlet & Violet)Document2 pagesSouth Province (Pokémon Scarlet & Violet)Ethan LaiNo ratings yet

- Denah PDF KeseluruhanDocument13 pagesDenah PDF KeseluruhanpoladwipaNo ratings yet

- Sas D Arc 1304 Hdimensionf v00 r01Document1 pageSas D Arc 1304 Hdimensionf v00 r01Maguedwathah AlzayadeeNo ratings yet

- Bảng Thống Kê ThépDocument1 pageBảng Thống Kê ThépChâu Thư NguyễnNo ratings yet

- Bảng Thống Kê ThépDocument1 pageBảng Thống Kê ThépChâu Thư NguyễnNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 16Document1 pageEpcc05 MDR 421 STR DWG 000 0072 16RANJEET PRATAP SINGHNo ratings yet

- 535 (Fá) - Tu És Fiel, SenhorDocument1 page535 (Fá) - Tu És Fiel, SenhorSérgioNo ratings yet

- Produced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Document1 pageProduced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Sang TrầnNo ratings yet

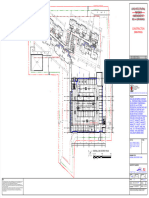

- Architectural Tender Amendment No. 4 Drawing: Construction DrawingsDocument1 pageArchitectural Tender Amendment No. 4 Drawing: Construction Drawingsme kwc36No ratings yet

- P Ple Als 220 30002 0Document1 pageP Ple Als 220 30002 0BadiNo ratings yet

- Birou Individual de ARHITECTURÃ RÃDUCANU Samuel: Plan ParterDocument1 pageBirou Individual de ARHITECTURÃ RÃDUCANU Samuel: Plan ParterIldiko MihaiNo ratings yet

- Game of Thrones - Difficult Piano Version PDFDocument5 pagesGame of Thrones - Difficult Piano Version PDFDavide MontagnanaNo ratings yet

- Construction MethodologyDocument102 pagesConstruction MethodologyjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- TCS PDFDocument2 pagesTCS PDFjitendraNo ratings yet

- Bitumen SpecDocument1 pageBitumen SpecvikasbadhanNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet