Professional Documents

Culture Documents

Hot Work

Uploaded by

yadu kumar singhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work

Uploaded by

yadu kumar singhCopyright:

Available Formats

MOHINDER

A G E N C I E S

Hot Work Tool Steels Product Specifications

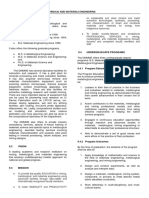

MATERIAL CHEMISTRY HEAT TREATMENT DETAILS

AISI/ Annealing Quenchent Tempering Annealed Quenched &

EN DIN JIS C Si Mn P S Cr W Mo Ni V Quenching

ASTM (Slow Cooling) (Hot Bath) (Air Cooling) (HB)-max (Hrc) Tempered

H11 X38CrMoV5-1 1.2343 0.38 1.1 0.4 0.03 0.01 5 1.25 0.45 750-800 OIL/AIR 1000-1040 500-600 240 48

H13 X40CrMoV5-1 1.2344 SKD61 0.39 1.1 0.4 0.03 0.01 5.2 1.4 0.95 800-850 OIL/AIR 1000-1085 500-600 230 52

H12 1.2606 SKD62 0.39 1.1 0.4 0.03 0.01 5.2 1.25 1.4 0.35 800-870 OIL/AIR 1000-1050 500-600 230 52

L6 56NiCrMoV7 1.2714 SKT4 0.55 0.25 0.8 0.03 0.02 1.2 0.4 1.7 0.15 750-800 OIL 830-850 400-650 240 50

H21 X30WCrV9-3 1.2581 0.35 0.25 0.3 0.03 0.03 2.7 9 0.35 750-800 OIL/AIR 1070-1150 500-600 240 51

Hot Work Tool Steels Size Range

AISI DIN Supply condition Rounds Square Flat Application

Dies for pressure casting of light alloys, dies for presses for

H11 1.2343 Annealed 4 500 100x20 1000x300 hot forming steels, brass, aluminium and its alloys, hot work

shear blades.

Dies for pressure casting of light alloys, dies for aluminium

H13 1.2344 Annealed 4 500 20 300 100x20 1000x300 extrusion dies for hot forming of steels, extractors.

HOT WORK H12 1.2606 Annealed 300x65 500x150 Cast moulds for aluminium and zinc alloy

Blocks for dies, hammers and pile drivers, rams for power

L6 1.2714 Hardened & Tempered 90 700 200 600 300x155 1000x600 hammers , hot mill rolls, very hard, cold work dies and punches.

Extrusion moulds and cast moulds for copper, aluminium

H21 1.2581 Annealed 30 200 and zinc alloy

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Duplex SteelsDocument231 pagesDuplex SteelsDavindRa SoniNo ratings yet

- Heat Treatment of Metals: An OverviewDocument36 pagesHeat Treatment of Metals: An OverviewRex SabersonNo ratings yet

- Steel Making PresentationDocument80 pagesSteel Making PresentationAlvin Garcia PalancaNo ratings yet

- Works Instructions For Cutting MachineDocument2 pagesWorks Instructions For Cutting Machineyadu kumar singhNo ratings yet

- Isasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessDocument18 pagesIsasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessHunNo ratings yet

- Corrosion On WeldmentDocument5 pagesCorrosion On Weldmentprabuharan89100% (1)

- Iron Making by TupkaryDocument494 pagesIron Making by Tupkarygfgfgf100% (1)

- The Bessemer ProcessDocument3 pagesThe Bessemer ProcessSaurabh PatelNo ratings yet

- Works Instructions For Preparing The SampleDocument2 pagesWorks Instructions For Preparing The Sampleyadu kumar singhNo ratings yet

- Modern Metals India Pvt. LTD: Corrective and Preventive Action ReportDocument1 pageModern Metals India Pvt. LTD: Corrective and Preventive Action Reportyadu kumar singhNo ratings yet

- Works Instructions Micro Hardness TesterDocument2 pagesWorks Instructions Micro Hardness Testeryadu kumar singhNo ratings yet

- Works Instructionsfor Belt GrinderDocument2 pagesWorks Instructionsfor Belt Grinderyadu kumar singhNo ratings yet

- Specialty Steels FM Alloy: Material's General CatalogDocument16 pagesSpecialty Steels FM Alloy: Material's General Catalogyadu kumar singhNo ratings yet

- HP 1 SteelDocument4 pagesHP 1 Steelyadu kumar singhNo ratings yet

- Plasma Ion NitridingDocument2 pagesPlasma Ion Nitridingyadu kumar singhNo ratings yet

- Plasma Nitriding Process - DataDocument11 pagesPlasma Nitriding Process - Datayadu kumar singhNo ratings yet

- Chapter 11: Transformation in AlloysDocument48 pagesChapter 11: Transformation in AlloysbadaboyNo ratings yet

- NopanDocument3 pagesNopanM.Dwi CahyaNo ratings yet

- Metal Coating - Marine CorossionDocument16 pagesMetal Coating - Marine CorossionSARANG saNo ratings yet

- Alloy Steel Grade and Specs Aerovacalloyforge ComDocument3 pagesAlloy Steel Grade and Specs Aerovacalloyforge ComSteve BraunNo ratings yet

- Tempering Behavior of The Fusion Boundary Region of Anf22 - 625 Weld OverlayDocument14 pagesTempering Behavior of The Fusion Boundary Region of Anf22 - 625 Weld OverlayAnonymous GhPzn1xNo ratings yet

- Department of Mining, Metallurgical and Materials EngineeringDocument24 pagesDepartment of Mining, Metallurgical and Materials EngineeringDrakeNo ratings yet

- Material Data Sheet Mds D55 Rev. 5: TYPE OF MATERIAL: Ferritic/Austenitic Stainless Steel, Type 25Cr DuplexDocument1 pageMaterial Data Sheet Mds D55 Rev. 5: TYPE OF MATERIAL: Ferritic/Austenitic Stainless Steel, Type 25Cr Duplex1380miniNo ratings yet

- Isothermal Transformation DiagramsDocument6 pagesIsothermal Transformation DiagramsSalem GarrabNo ratings yet

- 13HMFDocument9 pages13HMFAnonymous 1Mk09KeNo ratings yet

- Lab 7 Cold Work Annealing Sp2011Document10 pagesLab 7 Cold Work Annealing Sp2011Rob Carter50% (4)

- Rock Characterization at El Teniente Mine PDFDocument15 pagesRock Characterization at El Teniente Mine PDFEmanuel NicolásNo ratings yet

- X17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IdDocument2 pagesX17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IddabarcinaNo ratings yet

- Ferrous MaterialsDocument151 pagesFerrous MaterialsAli RayyaNo ratings yet

- Fastener Academy Basics PDFDocument94 pagesFastener Academy Basics PDFKiran BathiniNo ratings yet

- High-Alloy Steels Are Defined by A High Percentage of Alloying Elements. The Most CommonDocument3 pagesHigh-Alloy Steels Are Defined by A High Percentage of Alloying Elements. The Most CommonKent Clark VillaNo ratings yet

- Anodic ProtectionDocument18 pagesAnodic Protectiongalati12345No ratings yet

- Physical Metallurgy of Modern High Strenght Steel Sheets PDFDocument13 pagesPhysical Metallurgy of Modern High Strenght Steel Sheets PDFJose Merced Martinez VazquezNo ratings yet

- Assignment 1Document9 pagesAssignment 1Muhammad AliNo ratings yet

- Corrosion PDFDocument46 pagesCorrosion PDFNixon RamsaranNo ratings yet

- Disclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Document15 pagesDisclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Selvaraji Muthu50% (2)

- Steel Making Using Open Hearth Furnace-1Document9 pagesSteel Making Using Open Hearth Furnace-1victorymusa45No ratings yet

- Some Guidelines To The Design of A Diagnostic Leaching ExperimentDocument10 pagesSome Guidelines To The Design of A Diagnostic Leaching ExperimentAldoNo ratings yet

- TempleDocument17 pagesTemplesan moedanoNo ratings yet