Professional Documents

Culture Documents

API BB1 vs BB2: Radially split pumps better for H2S, high pressure

Uploaded by

bomthanhphuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API BB1 vs BB2: Radially split pumps better for H2S, high pressure

Uploaded by

bomthanhphuCopyright:

Available Formats

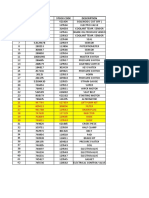

COMPARISON OF API BB1 vs BB2

Axially Split Pump Radially Split Pump

API 610 Designation Comments

API Type BB1 API Type BB2

Volute casing Axially Split Radially Split BB2 is barrel case and therefore more robust design, originally

designed for Hydrocarbon Applications as per API 610 compared to

BB1 pumps which were historically designed as water pumps and

have been converted to comply where possble with API 610

Casing MAWP 16 or 24 bar.g 40 or 50 bar.g BB2 designed as per API (min 40 barg)

The case and cover design is suitable for higher BB1 is limited to lower working pressure due to the difficulty in bolting

working pressure than an axial split case pump due with a flat, unconfined, and irregular case gasket, and due to the non-

to its smaller bolting area, symmetrical bolting symmetrical volute and suction areas between the upper half and

pattern, and confined gasket design lower half casing.

Operating conditions Temperature - No more than 200 °C (400 °F) Temperature - No restriction It is typically limited to 400 °F operating temperature due to thermal

Density - No less than 0.7 Density - No restriction expansion consideration as there is significant differences in the case

Disch. Pr - No restriction metal thickness between the upper half and lower half of the pump

resulting in differences in thermal expansion;

H2S Service & Sealing Flat gasket Viton O-rings BB1 uses compression gasket or liquid gasket and is more dependent

Not preferred by end-user for H2S application Allows for better sealing and is better suited for on correct bolt torque sequence to prevent leakage.

H2S service for avoiding any leaks BB1 pumps require careful cleaning of top and bottom half casing

faces before every assembly (to remove old gasket material)

Mounting Foot mounted or Near centreline Centreline mounted Pump cannot be supported at the shaft centerline where the pump

casing is split in half (at best, it can be supported at near-centerline

only). This results in asymmetrical thermal expansion between the

upper half and lower half casing.

Pump Maintenance without Yes Yes Both BB1 and BB2 allow for rotor removal / maintenance without

disturbing disturbing pipework

Suction/Discharge Pipework

Sulzer BB2 pump rotor removal is achieved in a similar manner to that

for a BB1 pump - using eye-bolt for lifting the NDE end-cover (as

opposed to lifting the top-cover) and slings for the rotor. No special

tools are required

You might also like

- TURBINESDocument44 pagesTURBINESESWARANM91No ratings yet

- Vertical PumpsDocument16 pagesVertical PumpsAdel ShatlaNo ratings yet

- GEA Grasso Company ProfileDocument28 pagesGEA Grasso Company ProfileLuis Fernando Lopez PalaciosNo ratings yet

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- Hotspot Repair Report SummaryDocument14 pagesHotspot Repair Report SummaryRajabuddin AhmedNo ratings yet

- Vertical pumps-II PDFDocument8 pagesVertical pumps-II PDFjagadeesanNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- PumpLab Book 1 PreviewDocument11 pagesPumpLab Book 1 Previewcorey6No ratings yet

- Monitoreo de BombasDocument6 pagesMonitoreo de Bombasroberdani12No ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Steam Separator and Steam Trap Are Almost Same in FunctionDocument7 pagesSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNo ratings yet

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийNo ratings yet

- Low NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFDocument12 pagesLow NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFMuhammad ImranNo ratings yet

- Steam TrapDocument8 pagesSteam TrapSanket BandekarNo ratings yet

- Pumps ChecklistDocument3 pagesPumps ChecklistRaouf AbdelmonemNo ratings yet

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Gas Jet Pump Paper Oct03 Ipa03 e 059Document11 pagesGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Equipment and Materials Unit Tag Number Qty NameDocument2 pagesEquipment and Materials Unit Tag Number Qty NameIshwar AltNo ratings yet

- AgitatorsDocument9 pagesAgitatorsB Santosh Kumar DoddalaNo ratings yet

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNo ratings yet

- 4 Reciprocating Compressor IIDocument41 pages4 Reciprocating Compressor IIBassam AmirNo ratings yet

- Engineering Tips-Cooling TowerDocument6 pagesEngineering Tips-Cooling TowerSharon LambertNo ratings yet

- Determine if Existing Pump Suitable for New SystemDocument3 pagesDetermine if Existing Pump Suitable for New SystemDhamotharan ChinnaduraiNo ratings yet

- Static and Rotating Equipment PDFDocument4 pagesStatic and Rotating Equipment PDFjpr220022No ratings yet

- Steps For The Procurement of Piping / Mechanical ItemsDocument2 pagesSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarNo ratings yet

- 5 SMPV RulesDocument16 pages5 SMPV Rulesvimalk017No ratings yet

- TRU Waste Processing Center PBVS Design DescriptionDocument37 pagesTRU Waste Processing Center PBVS Design DescriptionShaimaa SaadNo ratings yet

- YAMADA Engineering Handbook 2014Document141 pagesYAMADA Engineering Handbook 2014ToyinNo ratings yet

- Gost 12821-80Document19 pagesGost 12821-80Mile NikolcicNo ratings yet

- Gas Turbine Power Plant PresentationDocument49 pagesGas Turbine Power Plant PresentationM Hamza Nadeem100% (1)

- Compressors: Basic Classification and Design OverviewDocument35 pagesCompressors: Basic Classification and Design Overviewfilmon abebe100% (1)

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDocument42 pagesPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplNo ratings yet

- SEALDocument6 pagesSEALkishorsinghNo ratings yet

- LNG Centrifugal Compressors BrochureDocument12 pagesLNG Centrifugal Compressors BrochurehacenescribdNo ratings yet

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 pageCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiNo ratings yet

- Pumps StudentsDocument62 pagesPumps StudentsAKHIL JOSEPH100% (1)

- Tanky 53 KL Rev.1Document187 pagesTanky 53 KL Rev.1Priyo Jati WahyonoNo ratings yet

- System OneDocument4 pagesSystem OnerasottoNo ratings yet

- Data Teknis WILO 100lps @40mDocument4 pagesData Teknis WILO 100lps @40mAnonymous dr93RjfPEY100% (1)

- Vertical Sump Pump SpecificationsDocument2 pagesVertical Sump Pump SpecificationsHongwei GuanNo ratings yet

- Delayed Coking Technology: Residue Conversion: Naphtha KeroDocument2 pagesDelayed Coking Technology: Residue Conversion: Naphtha KeroDikul BrahmbhattNo ratings yet

- Automatic Recirculation ValveDocument3 pagesAutomatic Recirculation ValveIsares PodkohNo ratings yet

- Lavalin Bomba SumergibleDocument3 pagesLavalin Bomba SumergibleEyffer Cabrera PalominoNo ratings yet

- Lesson Learnt From SNC On Stress AnalysisDocument3 pagesLesson Learnt From SNC On Stress AnalysiszahoorNo ratings yet

- AutoPIPE QuickStart - Model Modification - WorkbookDocument63 pagesAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Booster PumpDocument28 pagesBooster PumpCollin PhelpsNo ratings yet

- Eagle Burgmann API PlanDocument43 pagesEagle Burgmann API PlanONURNo ratings yet

- Explanation API 610 Pump ConfigurationsDocument11 pagesExplanation API 610 Pump ConfigurationsWandri Bojan Hidayat100% (1)

- 10 Steps To Pump ReliabilityDocument15 pages10 Steps To Pump ReliabilityaqhammamNo ratings yet

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPDocument17 pagesDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandNo ratings yet

- Comparing API BB1 and BB2 axial and radial split pumpsDocument1 pageComparing API BB1 and BB2 axial and radial split pumpsasbuasbu100% (1)

- Parameters For Pump Selection - Part 1 PDFDocument5 pagesParameters For Pump Selection - Part 1 PDFpalluraviNo ratings yet

- API Verses Non APIDocument19 pagesAPI Verses Non APIsandeshNo ratings yet

- PNGRB Regulations General Concepts Followed Up in CGDsDocument59 pagesPNGRB Regulations General Concepts Followed Up in CGDsYogesh SainiNo ratings yet

- Hydraulic Tube Bender: Series HTB & HTB-A Operation and Maintenance ManualDocument4 pagesHydraulic Tube Bender: Series HTB & HTB-A Operation and Maintenance ManualLord KrsnikNo ratings yet

- AM8 Printer: A Metal Frame For Your Anet A8Document28 pagesAM8 Printer: A Metal Frame For Your Anet A8polococo6No ratings yet

- Kyocera FS-600 Parts Manual PDFDocument19 pagesKyocera FS-600 Parts Manual PDFliviumaraNo ratings yet

- Frame Generator PDFDocument13 pagesFrame Generator PDFWilly PeralesNo ratings yet

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Packing List: Sportrak Tire Group LimitedDocument1 pagePacking List: Sportrak Tire Group Limitedissa lamarNo ratings yet

- Daily production report for 17-JUN-19 highlights units, targets, actualsDocument1 pageDaily production report for 17-JUN-19 highlights units, targets, actualsSergio Quisbert P.100% (1)

- LED TV Service ManualDocument54 pagesLED TV Service ManualJuan Jose100% (1)

- Tilt Cylinders PDFDocument12 pagesTilt Cylinders PDFamineNo ratings yet

- Release GuideDocument74 pagesRelease Guidelcalvo50No ratings yet

- Xt1100-2a-Eec-Standard Einzelteile Kunstoff OrangeDocument21 pagesXt1100-2a-Eec-Standard Einzelteile Kunstoff Orangeapi-26422514No ratings yet

- Media Cloud: An Open Cloud Computing Middleware For Content ManagementDocument6 pagesMedia Cloud: An Open Cloud Computing Middleware For Content Managementmr_harisskumarNo ratings yet

- ASTM D747 Overview PDFDocument41 pagesASTM D747 Overview PDFtangogll11No ratings yet

- Gerontis Constantinos ResumeDocument1 pageGerontis Constantinos Resumeapi-402481422No ratings yet

- Dam PluggingDocument104 pagesDam PluggingMpho Vince MatlouNo ratings yet

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- Project Management Assignment 2 - Soichiro HondaDocument7 pagesProject Management Assignment 2 - Soichiro HondaGladwin SamuelNo ratings yet

- Structural Geology CompiledDocument381 pagesStructural Geology CompiledLen-Len Cobsilen100% (2)

- Co2 Extinguihsers Ul ListedDocument2 pagesCo2 Extinguihsers Ul ListedAmeen Hamed AlwseyNo ratings yet

- Manage Your ODI Development Cycle with Versioning and PromotionDocument146 pagesManage Your ODI Development Cycle with Versioning and PromotionLilantha Lakmal GallabaNo ratings yet

- Unified Schedule of Rates Iw DeptDocument96 pagesUnified Schedule of Rates Iw Deptanirbanpwd76No ratings yet

- Verification Manual COMPRESS 2021Document149 pagesVerification Manual COMPRESS 2021Unidos Con PuerresNo ratings yet

- Energy and Chemistry Chapter on CalorimetryDocument93 pagesEnergy and Chemistry Chapter on CalorimetryKaye Reies100% (1)

- Racing Boy Catalog - 2014Document117 pagesRacing Boy Catalog - 2014Eddie BoyzNo ratings yet

- Physics Cambridge Igcse Year 10 Paper 1Document18 pagesPhysics Cambridge Igcse Year 10 Paper 1Adibah AliasNo ratings yet

- Kodak X-Omat Multiloader 300 Film Feeder - User ManualDocument10 pagesKodak X-Omat Multiloader 300 Film Feeder - User ManualNikolay PenevNo ratings yet

- 02 Control System FAT TestDocument12 pages02 Control System FAT TestHashemAliHashemNo ratings yet

- VOIP On Packet Tracer PDFDocument10 pagesVOIP On Packet Tracer PDFHead Bang100% (2)

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Yogesh Kumar Garg Resume Mechanical EngineerDocument3 pagesYogesh Kumar Garg Resume Mechanical EngineerYogeshGargNo ratings yet

- An Automatic Tool For Generating Test Cases From The System's RequirementsDocument6 pagesAn Automatic Tool For Generating Test Cases From The System's RequirementsSaba Vijay KumarNo ratings yet