Professional Documents

Culture Documents

Micropile Design Calculations for Kenny Hill Formation

Uploaded by

matt nOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micropile Design Calculations for Kenny Hill Formation

Uploaded by

matt nCopyright:

Available Formats

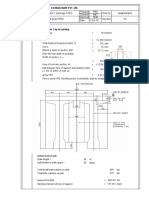

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Sample Design Calculations

For Micropiles in Kenny

Hill Formation

Generalized Subsoil Profile

- Generally flat terrain

- Subsoil profile:

0-3m, silty SAND, SPT=1- 5

3-6m, silty SAND, SPT= 15 - 50

6-20m, highly weathered sandstone

Schematic Detail

Mild Steel Capping Plate

L = 350mm

B = 350mm

Soil becoming Thickness = 1 0m m

weathered rock

Mild Steel Stiffeners

Thickness = 10mm

Pile Boring

Diameter = 200mm

API Pipe

O. D. = 127.0mm

Thickness = 9.2mm

fy (min) = 552 Mpa

L = 20.0m Grade = N-80

Cementitious Grout

W/c = 0.45

Fcu = 2 5 M pa

Safe Working Load

Pa = 80 tonnes

Lsocket = 20m

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 1

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Subject : Micropile Design

1.0 Material Pr

Properties

1.1 Basic Di

Dimensions an

and Properties

1.1.1 Micropile Diameter, D = 200mm

1.1.2 Pile Composite Modulus Ep = 41 GPa

1.1.3 Moment of Inertia, Ip = 7.85E+07 mm^4

1.2 Cementitious Grout

1.2.1 Max. water/cement ratio = 0.45

1.2.2 Anti-shrink / Additives = Adogroud 100g 150kg bag

1.2.3 Grout Area. Ac = 45686 mm"2

1.2.4 28 day Comp. Strength, Fcu' = 25 MPa

1.2.5 Density = 2000 kg /M^3

1.2.6 Elastic Modulus. Ec = 28 GPa

1.3 API Pipe Reinforcement

1.3.1 Source =

1.3.2 Outer Diameter, OD = 127 mm

1.3.3 Wall Thickness. t = 9.19 mm

1.3.4 Inner Diameter. ID = 108.62 mm

1.3.5 Cross Sectional Area, As = 3401 mm^2

1.3.6 API Specification = 5A-80

1.3.7 Grade Designation = N-80

1.3.8 Mm. Yield Strength, fy = 552 MPa

1.3.9 Elastic Modulus. Es = 210 GPa

1.4 Compliance with British Standards Designed Req. Min. Source

(Max)

1.4.1 Working Grout/API Pipe Bond (MPa) 0.8 12 BS8110

1.4.2 Grout Characteristic Strength, fcu (MPa) 25 20 BS8004

1.4.3 Cement content (kg/m"3) 400 00 BS8004

1.4.4 Grout working compressive stress,0.4fcu/FoS 0.2 x fcu 0.25 x fcu BS8004

1.5 Minimum Fa

Factors of

of Sa

Safety

1.5.1 Against Structural Failure = 2.00

1.5.2 Against Buckling Failure = 1.60

1.5.3 Against Geotech. Failure = 2.00 Skin Friction

1.5.4 Against Geotech. Failure = 2.50 End Bearing

2.0 Structural Design

Assuming that the applied vertical load is carried by the API Pipe alone.

2.1 Ultimate Load Capacity Pu = 0.87 x fy x As

= 1633450 N

= 1633.5 kN

= 163.3 tonnes

Use the Factor of Safety prescribed in Section 1.5 on Plate 2

2.2 Allowable Load Capacity Pa = 82 tonnes

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 2

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

2.3 Design Safe Working Load SWL = 80 tonnes

3.0 Geotechnical De

Design

Refer Piler Analysis for derivation of Geotechnical Safe Wo

Working

rking Load -Appendix ......

3.1 Design Length

3.1.1 Safe Working Load per Pile P = 800 kN

3.1.2 Nominal Diameter D = 200 mm

3.1.3 Embedment Ls = 20.0 m

3.2 Grout l API Pipe Bond

3.2.1 Ultimate Grout Pipe - Bond Stress, t (u) = 2.0 MPa

3.2.2 Factor of Safety = 2.5

3.2.3 Working Bond Stress, t (w) = 0.8 MPa

3.2.4 Req'd API Pipe Embedment in Grout = 2.5 m

< 20.0 m

Therefore, adopted socket length is OK

4.0 Buckling (P

(Pile Sl

Slenderness) Analysis no

not ap

appropriate

for Kenny Hill Formation

4.1

4.1 Pile

Pile End Conditio

ition

ns (Un

(Unfille

illed

d Cavi

Caviti

ties

es))

4.1.1 Pile Top (at Pilecap Level) = Fixed

4.1.2 Pile Base (at Rock Head Level) = Fixed

4.1.3 Ass. length in unfilled cavity L assumed = 1m

4.1.4 Effective Length - 0.7 x L L efeff. = 0.7 m

4.2

4.2 Eucl

Eucler

er''s Bu

Buckl

ckling

ing Lo

Load (Un

(Unfille

illed

d Cav

Caviities

ties))

4.2.1 Effective radius r = 41.8

4.2.2 Euler Critical Load Pe = @pi^2 - Ep l(Lelr)^2 = 1428 kN

FOS available = 9.78 OK

4.3

4.3 Elas

Elasti

tic

c Buck

Buckli

ling

ng Load

Load of

of Pil

Pile

e embe

embedd

dded

ed in

in Ove

Overb

rbur

urde

den

n (ie

(ie Win

Winkl

kler

er Med

Mediu

ium)

m)

4.3.1 Average SPT inin Overburden soils, N = 50

4.3.2 Est. Und. Cohesion Overburden soils, Cu = 6'N kPa 300 kPa

4.3.3 Modulus of Horiz. Subgrade Reaction, kh'c = 67*Cu

20100 kPa = 20.1 MPa

4.3.4 Elastic Buckling Load, Pcr = 2 x @sgrt (Ep x Ip x kh x d)

= 16014 kN

4.3.5 FOS available = 20.02 OK

5.0 Rate of Corrosion of Reinforcement

5.1 Ex Oil Drill API Pipe Reinforcement

5.1.1 Outer Diameter O.D. = 127.0 mm

5.1.2 Wall Thickness t = 9.2 mm

5.1.3 Internal Diameter I.D. = 108.6 mm

5.1.4 Cross sectional Area As = 3401 mm^2

5.1.5 API Specification = 5A-80

5.1.6 Grade Designation = N-80

5.1.7 Min Yield Strength fy = 552 MPa

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 3

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

5.1.8 Elastic Modulus Es = 210 GPa

5.1.

5.1.9

9 Allo

Allowa

wablblee Axi

Axial

al Wor

Worki

king

ng Str

Stres

esss (Clau

(Clause

se 7.4

7.4.6

.6.3

.3.1

.1 BS80

BS8004

04))

Fa = 50% of Yield Strength

= 276 MPa

5.2

5.2 Desi

Design

gn for

for allo

allowa

wabl

ble

e corr

corros

osio

ion

n as

as for

for shee

sheetp

tpil

iles

es w/o

w/o grou

grout/

t/

concrete protection

5.2.1 Allowable corrosion rate = 0.01 mm/year

5.2.2 Max. pile axial load Pa = 800 kN

5.2.3 Req'd Steel Area Asc = 2899 mm^2

5.2.4 Min. OD of API Pipe O.D. = 124.5 mm

5.2.5 Allowable Corrosion Period Tc = 255 years

Summary

No addi

additio

tional

nal reinfo

reinforce

rcemen

mentt requi

required

red,, Tc

Tc > Desi

Design

gn Life

Life of 50

50 years

years..

6.0 Pilehead Capping Details

Safe Working Load = 800 kN

6.1 Capping Plate Size

6.1.1 Assume characteristic strength of pileca f cu = 25 MPa

6.1.2 Permissible direct compressive stress fcu13.65 = 6.85 MPa

6.1 3 Req'd bearing area of capping plate = 116800 mm^2

Adopt plate of dimmensions (mm) 350 x 350 OK

6.2 Thickness of Stiffners

6.2.1 Allowable Axial Compressive Stress = 155 MPa

(Table 17 (a). BS449 : Part 2: 1969)

6.2.2 Contact Area of API Pipe on Capping Plate = 3401 mm^2

6.2.3 Stiffener projection beyond API pipe OD = 184 mm

6.2.4 Required thickness of MS Stiffeners t(s) = 2.4 mm

Adopt 10 mm

(4No. MS Stiffeners)

6.3 Thickness of Capping Plate

6.3.1 Allow Shear Stress on Capping Plate = 125 MPa

(Table

(Table 10. BS449:Part 2:1969)

6.3.2 Effect. Punching Shear Shear Perimeter = OD of API Pipe + Perimeter

- 8 x thickness of stiffeners

= 1599 mm

6.3.3 Required Thickness of Capping Plate = 4.0 mm

Adopt 10 mm

6.4

6.4 Allo

Allow

wabl

able Bea

Beari

rin

ng Stress

ress on Capp

apping

ing Plat

late

6.4.1 Allow. Bearing Stress on Capping Plate = 210 MPa

(Table

(Table 9. BS449:Part 2:1969)

6.4.2 Proj. Bearing Area (API + Stiffeners) = 10761 mm^2

6.4.3 Actual Bearing Stress = 74 MPa

< All. Bearing Stress, OK

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 4

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

6.5 Check Stiffeners for Buckling

6.5.1 Bearing Area of API Pile = 3401 mm^2

6.5.2 Bearing Area of 4No. Stiffeners = 7359 mm^2

Assume uniform distribution of Pile Axial Load,

6.5.3 Compressive Load per Stiffener = 136.8 kN

6.5.4 Pile head Embedment into Pilecap = 150 mm

6.5.5 Assume Stiffener Depth, d = 140 mm

(Conservative Estimate)

6.5

6.5.6 Slen

Slende

dern

rnes

esss Rat

Ratio

io of Stiffe

iffene

ner

r

d ' @sgrt(3)1 thickness of stiffener = 24.2

6.5.7 Allow. Compressive Stress = 146 MPa

(Table 17(a). BS449)

6.5.8 Allow. Buckling Load on Stiffener = 268.6 kN '

> Compressive Load of Stiffener,

Stiffener, OK

6.6 Check Bearing on API Pipe

Moment equilibrium about intersection of Capping Plate and API Pipe,

6.6.1 Bearing Force on API Pipe = 180 kN

6.6.

6.6.2

2 Assu

Assume

me mat

mater

eria

iall for

for API

API Pipe

Pipe to

to be equi

equiva

vale

lent

nt to G55

G55 stee

steel,

l,

6.6.3 Allow. Bearing Stress = 320 MPa

6.6.4 Allow Bearing Load = 448 kN

> Actual Bearing Force, OK

6.7

6.7 Fille

illett Wel

Weld

d Desig

esign

n (St

(Stiffe

iffen

ner to API Pip

Pipe)

e)

6.7.1 Weld Length per Stiffener = 2xd

= 280 mm per stiffener

6.7.2 Req'd Shear Load Capacity for weld = 0.49 kN/mm

Adopt 7 mm Fillet Weld

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 5

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Design Report

1. Introduction

This report presents the design criteria and design calculations for pile foundation for

Interchange 3 of Project B 15 Road Upgrading Works.

Works.

Interchange 3 is a cloverleaf interchange with arch shaped R.C bridge as shown below

From structural analysis the compression load coming over the piles from one half of the

bridge

bridge is 1260

12600

0 ton

ton while

while the other

other half

half is 2800

2800 ton in tens

tension

ion..

2. Site Condition

The topograph of the site is rolling to undulating. The subsoil condition is generalized as

shown above.

The top 12m to

to 16m from the OGL of the residual soil is clayey

clayey silt with SPT 6-39 (aver

age SPT=20): This is underlain by hard clayey silt sith

sith SPT exceeding 50 up to 28m bgi.

3. Analysis

Shallow foundation is not suitable because part of the formation is on filled ground and also

part

part of the founda

foundatio

tion

n is in tens

tension

ion or high

high compre

compressi

ssion.

on.

Driven spun piles cannot or not practical to provide adequate tension required. Large diam

eter bored piles are suitable for high compression and tension required.

4. Design Calculations

4.1 Compression pi

piles

The allowable compression load carrying capacity of the single pile has been cal

culated based on the SPT 'N" values, using the following

following formula.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 6

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Allowable load : Ab, af + As,fs

3 2

Ab = base area (m2)

qf = unit base resistance

= 400

400 Nb (in

(in SI-u

SI-uni

nit)

t),, Meye

Meyerh

rhof

of's

's Emp

Empir

iric

ical

al For

Formu

mula

la

Nb = averag

averagee 'N'

'N' over

over 5m

5m above

above and 3m belo

below

w depth

depth

being

being cons

conside

idered

red (< 50)

50)

As = Pile circumference area (m2)

fs = unit skin friction

= 2 Nave (in SI-unit)

Nave

Nave = Average

verage SPT value

value with

with depth

depth

Fact

Factor

or of

of safe

safety

ty of bas

basee resi

resist

stan

ance

ce = 3 to

to cont

contro

roll set

settl

tlem

emen

entt

Fact

Factor

or of

of safe

safety

ty of

of fric

fricti

tion

on res

resis

ista

tanc

ncee = 2

The detailed pile calculations are given in Appendix B.

4.2 Tension piles

The allowable tension load carrying capacity of single pile has been calculated

based

based on

on SPT

SPT 'N' values

values,, using

using follow

following

ing formul

formulaa

Allowable load = As . fs 2

As = Pile circumference area

fs = Unit skin friction

= 2 Nave (in SI-unit)

Nave

Nave = Average

verage SPT 'N' value

value with

with depth

depth

Factory of safety against friction resistance = 2

The detailed pile calculations are given in Appendix B.

5. Design Calculations

5.1 General

Diameter of Compression pile : 1500 mm with design load of 900 ton

Diameter of Tension piles : 1200m with design load of 400 ton

Estimated pile length = 19m socketing 3 times diameter into hard stratum of SPT> 50

5.2

5.2 Prel

Prelim

imin

inar

ary

y Loa

Load

d Tes

Tests

ts Anal

Analys

ysis

is

Compression load tests and pull out tests were carried out at the Interchange bridge site to

assess the performance of the piles installed to the design lengths.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 7

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

(a) West Abutment

The tension Test

Test Piles (No.81) located on the west abutments satisfied the per

formance criteria. Based on Prof Chin's Stability Plot:

Ultimate load : 1141 tonne

Average Unit Shaft Friction : 16 tonne/m 2

The compression Test

Test Pile No. 15 located ont the west abutments satisfied crite

ria at work load and 2 x work load but just failed to satisfy the recovery criteria.

Based on stability plot.

Ultimate capacity : 2,490 tonne

Ultimate Shaft capacity : 1,945 tonne

Mobilised Toe capacity : 548 tonne

Ultim

ltimat

atee Uni

Unitt Shaf

Shaftt Resi

Resist

stan

ance

ce : onne//m 2

39 tonne

Mobi

Mobili

lise

sed

d Uni

Unitt Toe Resi

Resist

stan

ancce : 310

310 to

tonne/m2

nne/m

Based on these assessment, piles were constructed to following toe elevations:

Compression Piles : RL 33.00

(5m longer than Test Piles)

Tension Piles : RL 31.00

(same length as Test Pile)

(b) East Abutment

Tension Pile No. 71 was tested. Pile satisfy the deflection criteria at working load

but howeve

howeverr failed

failed to atta

attain

in the

the 2 x worki

working

ng load

load withou

withoutt exces

excessiv

sivee movem

movement

ent..

Based on Stability Plot, the following capacitities can be estimated:

Ultimate Shaft capacity : 624 tonne

Unit Shaft Resistance : 9 tonne/m 2

This is much less than the 16.0 tonne/m2 value of tension pile No. 81. Based on

the evaluated value of 9.0 tonne/m2, all remaining working tension

piles

piles are

are inst

install

alled

ed to

to RL 21.00

21.00 toe

toe leve

level,

l, l O.Om

O.Om longe

longerr than

than the

the test

test pile.

pile.

Compression pile No. 65 was first tested. It failed to satisfy the performance cri

teria. Estimated capacities are:

Ultimate capacity : 1600 tonne

Ultimate Shaft capacity : 625 tonne

Ultimate Toe capacity : 1041 tonne

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 8

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Unit Shaft Resistance : 12 tonne/m 2

Mobilised Unit Toe

Toe Resistance 589 tonne/m2 Based on above results, Test Pile

No. 2 (Pile

(Pile No.66)

No.66) locate

located

d 4.50m

4.50m from

from P65

P65 was

was insta

installe

lled

d to toe level

level RL

RL 33.00

33.00

(5.Om longer). Theoretical ultimate capacity should be of the order of 1,900

tonnes. The test showed the following:

Ultimate capacity : 1520 tonne

Ultimate Shaft capacity : 730 tonne

Mobilised Toe capacity : 790 tonne

Ultimate Unit Shaft Resistance : 10 tonne/m 2

Mobilised Unit Shaft Resistance : 447 tonne/m 2

These are less than values obtained from P65, indicating significant variation in the sub

soil strength. Concreting procedures are satisfactory and concrete batch records

and test indicate supplied concrete complied with the requirements of the specification.

Concreting volume of pile does not indicate occurrence of collapse of borehole or neck

ing. Since the pile was concrete immediately after boring, strength relaxation due to

aging should not occured.

Based on above, all remaining piles are to be installed to toe levels 23. Pile No. P52 will

be test

test to asse

assess

ss amou

amount

nt of

of pile

pile head

head mov

moveme

ement

nt at

at worki

working

ng load

load and 2 x work

working

ing load.

load.

Estimated ultimate capacity of piles to toe level RL 23.00 is order 2,100 tonnes.

(c) Result

Resultss of loads

loads test

testss carrie

carried

d out at

at Interc

Interchan

hange

ge No.

No. 3 are show

shown

n in Figur

Figuree T1 to

to

T.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 9

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 13

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 14

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 15

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 16

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

5) Check fo

for bu

buckling lo

load

Qub = λ√Cu El

Where = λ = 10

CU = 15 kPa

E = 210 kN/mm2

I = 1/64 B (d 14 - d 24)

Qub = 10 √15 x 210 x B (101.64 - 85.444)

64 106

= 907 kN

Allowable Q b = 907

___

2

= 454 kN > 300 kN

OK

6) Check

Check for elasti

elasticc ccomp

ompres

ressio

sion

n

e = PL P = 300 kN

L = 10m

EP A = 31416 mm2

Ep = 35.3 kN/mm2

= 300 x10 x103

31416 x 35.3

= 3 mm

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 17

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

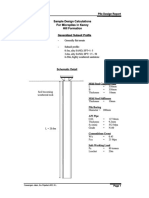

Sample Pile Design Calculations

1. Project : KKS Road Project

Piled Embankment for the approaches to Sg. Likas

Bridge.

2. Genera

nerallize

ized su

subso

bsoil prof

profiile.

le.

C

L

Piled embankment

Bridge

V.soft to soft clay

Sand Lenses

Stiff to hard

Sandstone/shale

* Flat alluvial formation

* Top 24m

24m cons

consist

istss of soft

soft to very

very soft

soft allu

alluviu

vium

m with

with few

few loca

localiz

lized

ed sand

sandy

y lense

lensess (Cu

(Cu =

10-20 kPa with an average of about 15 kPa except at lenses of sand). Stiff to hard

strata of about 2 - 4m thick overlying on highly to moderately weathered

sandstone/shale

sandstone/shale bedrock. WT is near the ground surface.

3. Analysis

Stability and settlement analysis have concluded that simple ground treatments by partial

sand replacement with high strength woven polyester geotextile reinforcement or vertical

drains are not possible to achieve FOS = 1.5 and or post construction settlement to be less

than 200mm for the first 5 years of service if height of embankment exceeds 4.2m.

Piled raft embankment is adopted in preference to EPS, elevated structure and stone column

treatment because:

a) EPS emba

embankm

nkmentent is

is techni

technical

cally

ly not

not accept

acceptabl

ablee becaus

becausee the site

site is

is subjec

subjectt to flood

flooding

ing

& the cost is high.

b) Elevat

Elevated

ed stru

structu

cture

re is

is about

about 30% more

more expen

expensiv

sivee (sepa

(separat

ratee analy

analysis

sis))

c) Though

Though trea

treatme

tment

nt by stone

stone colum

columns

ns is chea

cheaper

per,, it requi

requires

res long

longer

er time

time to cons

consoli

olidat

datee

and technically less superior

4. Design calculation

Analysis has shown that driven R.C piles will be the most cost effective.

The site has no vibration or noise or ground heave constraints. Pile capacity of about

600 kN is chosen to get optimum pile spacing of 2 to 3m and raft thickness of 350 -

450mm for pile depth of about 30m.

Use 250X250 R.C piles at spacing "x" bothways Max design capacity - 625 kN.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 18

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Load on each pile = x2.d.h, where x = spacing

d = soil density

= 20kN/m3 h

h = embankment height

625 = x2.20.h

x = (31.25/h)1/2

For

For h = 6.5m

6.5m,, x = 2.1

2.19m

9m,, say

say 2.0m

2.0m

For h = 6.0m,

6.0m, x = 2.2m,

2.2m, say 2.0m

2.0m

For h = 5.5m,

5.5m, x = 2.38m,

2.38m, say 2.25m

2.25m

For h = 5.0m,

5.0m, x = 2.50m,

2.50m, say 2.25m

2.25m

For h = 4.5m, x = 2.64m,

2.64m, say 2.25m

2.25m (allo

(allow

w some

some traffic

traffic load

load of 10 kPa)

kPa)

Conclusion:

Use 250x250 R.C x 30m long at 2.0m spacing for h=6.5 - 6.0m & 2.25m spacing for h = 4-6m

(Pile capacity calculations enclosed).

R.C piles (MS 1314, Class 1) are designed as end bearing piles driven to set.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 19

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 20

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Design of Micropile

a) Design load per pile = 800kN

b) Diamet

Diameter

er of

of micro

micropil

pilee = 200

200mm

mm

c) Main reinforcement = 3 Nos of 50mm diam. deformed bars of yield

stress fy = 410N/mm2.

d) Factor of safety = 2.5 (min)

e) Grou

Groutt cha

chara

ract

cter

eris

isti

ticc str

stren

engt

gth,

h, fcu

fcu = 20N/ mm2.

20N/mm

Check Structural Capacity

Area of reinf, Asc = x 502 x 3

B/4

= 5892mm2

fcu = 20N/mm2

Area of grout, Ag = B/4 x 2002

= 31,416mm2

..Area of net grout = 31,416 - 5892

= 25,524mm2

According to BS 8110, clause 3.8. 4.3

Ultimate axial load, Pu = 0.4 fcu Ac + 0.75Asc fy

= 0.4x20x25,524 + 0.75x5892x410

0.75x5892x410

= 2,016kN.

.. Factor of safety = Pu/800

= 2.53

> 2.5 O.K.

Check Bond Length Required

- Dept

epth of

of mi

microp

cropil

ilee = 20m

20m

At least l0m will be embedded in very hard decomposed granite SPT, N > 50.

- Bond

Bond bet

betwe

ween

en gro

grout

ut & har

hard

d form

format

atio

ion

n = 0.4N

0.4N/mm2

/mm

.. Min

Min req

requi

uire

redd bon

bond

d len

lengt

gth

h in

in har

hard

d

formation, I b = 800 800 x 2.5

2.5 x l 000N

000N

B x 200 x 0.4

= 7958mm

= 8.0m.

< 10m

10m pro

provi

vide

ded

d O.K

O.K..

Design of M.S. Plate for Pile Head

Use 250mm x 250mm x 20mm M.S. plate

Stre

Stress

ss on plat

platee 800 x l03 N

= 800

250 x 250

= 12.8N/mm2

< 155N/mm2 O.K.

(allowable stress BS449)

Details of Micropiles & works specification are encl

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 21

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Works Specification for Design and Installation of

200mm Diameter Micropiles

1. Scope

Scope of work

work shal

shalll incl

include

ude design

design & inst

install

allati

ation

on of 200

200mmmm diam

diam micr

micropi

opiles

les of 20m provi

provi

sional length. The micropiles shall be reinforced with 3 Nos. of 50mm diam deformed bars

(fy = 410N/mm2) The workin workingg load

load of

of the

the micro

micropil

pilee is 800

800KN.

KN.

2. Drilling

Initial drilling involves installation

installation of 242mm diam conductor casing through loose soil

(about 1.5m) by means of rotary boring or equivalent. Upon reaching hard/stiff formation

down the hole hammer will be used to advance the borehole till a minimum penetration of

10m in very hard decomposed granite. The drilled hole will be flush clean by compressed

air before the reinforcement bars are inserted into the hole. Suitable coupling device will be

used. During drilling, a complete record of soil strata will, be taken for Engineer's inspec

tion.

3. Grout Mix

Ordinary Postland cement with water cement ratio of 0.5 will be used Non-shrink cement

admixture will be added to improve bonding.

4. Grouting Pr

Procedure

A high speed Koken grout mixer is used for the mixing of the cement grout. The capacity

of the grout mixer is about 25-0 litres.

For grout mixing, 100 litres of water with some non shrink admixture is poured into the

mixer follow by 4 bags of 50 kg. ordinary Portland cement then allow to mix throughly,

normally a few minutes. After mixing, the cement grout, a pressure hose is connected to the

grouting pipe which acts as tremie pipe for grouting. The other end of the pressure hose is

connected to a diesel engine high pressure pump.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 22

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 23

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Micropile Design Calculations

Micropile design for underpinning works for an old building is shown as follows. The subsoil con-

sists of about 3m of very soft clay,

clay, 5m to 8m of stiff to hard sandy clay with gravels (SPT = 11 to

42). The bedrock generally consists of highly weathered and fractured sandstone/shale (RQD = 0 -

25%, UCS = 7.5 Mpa).

1) Micropile de

details

Diameter of micropile = 200 mm

Des

Design

ign load

load of micr

microp

opil

ilee = 300

300 kN

Pipe diameter = 101.6 mm

Pipe wall thickness = 8.08 mm

Steel grade (API pipe) = N80

Yield strength = 500 N/mm2

(a)

(a) Chec

Check

k for

for str

struc

uctu

tura

rall capa

capaci

city

ty

Ultimate structural capacity

PU = B (101.62 -85.44 2) X 500 kN

4 1000

= 1187 kN

Applying factor of safety of 2.5.

Allowable structural capacity.

PA = 1187

2.5

= 475 kN > 300 kN

OK

(b)

(b) Chec

Check

k for

for geot

geotec

echn

hnic

ical

al capa

capaci

city

ty

Based on boreholes BH1 and BI-12, the depth of bedrock (sandstone/shale) varies

from 8.7 m to 11.0 m b.g.l. Since the overburden soil consists of about 3.0 m of very

soft soil, the shaft friction on the remaining overburden soil (5 to 8 m) with N value

of 11 to 42 should be ignored and the micropiles are designed to be socketed into the

bedroc

bedrock.

k.

The socketing length in rock, L, is worked out as follows:

FS Qa = 0.05 qa B D x L + 0.5q

0.5q a B D2

4

where FS is the factor

factor of safety

safety

= 2.5

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 24

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Qa = Allowa

Allowable

ble geot

geotech

echnic

nical

al capac

capacity

ity

q a = Unconfined

Unconfined compressiv

compressivee streng

strength

th of rock

= 7.5 Mpa for sandst

sandstone

one/sh

/shale

ale

Bond stress = 5% of UCS of rock

D = Diameter of micropile hole

2.5 x 300 = 0.05 x 7.5 x 103 x B x0.2

x0.2 L +

0.5 x 7.5 x 103 x B x 0.22

4

750 = 235.6 L + 117.8

L = 2.68 m

Designed socketing length of pile = 3.0 m

2) Chec

Check

k ove

overa

rall

ll unde

underp

rpin

inni

ning

ng pile

pile supp

suppor

ortt

Estimated total load of the whole building (3 storey).

= 2,000 tons

No. of micr

micropi

opile

le poin

points

ts = 95

Load on each pile = 2,000

95

= 21 tons

Working load for each micropile provided = 30 tons

OK

3) Check

Check for

for anchor

anchorage

age bon

bond

d betwe

between

en unde

underpi

rpinni

nning

ng pile

pile and the existi

existing

ng foun

foundat

datic

ic

Since epoxy grout is used to fill the hole formed by the micropile in the existir foundation

and the strength of epoxy grout is much higher than the concrete strength, it can be consid

ered as monolithic for the whole foundation.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 25

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Critical section

for shear check

Existing

Column Proposed 200mm

Stump Ø micropile

650mm

100

mm

1900mm

4) Chec

Check

k for

for shea

shearr fai

failu

lure

re of exis

existi

ting

ng foun

founda

dati

tion

on..

Perime

Perimeter

ter for shear

shear check,

check, p = 190

1900

0 mm

Effe

Effect

ctiv

ivee dept

depth

h of foun

founda

dati

tion

on,, d = 1050

1050-5

-50-

0-10

10

= 990 mm

Maximum reaction load, V = 300 kN

Shear stress, V = V

Pd

= 300 x 103

1900 x 990

= 0.16 N/mm2

From Table 3.9, BS 8110 for d > 400 mm and

100As/bd = 0.25 (nominal reinforcement), allowable shear stress V c = 0.40 N/mm2

V<Vc OK

In grouting operation, the cement grout is pumped into the borehole through the pipe by

tremie method. All loose material, cuttings and water in the borehole are displaced by the

cement grout. Pressure applied should be just adequate to displace the cutting and water

from the borehole. Temporary casings should be withdrawn where cement grout overflow

from the casing and top up cement grout if necessary.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 26

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Item

De s cription Quantity Unit Rate $ ¢

No.

A. Design

Design and install

install cast in-situ

in-situ 800k

800kN N worki

working

ng

capacity

capa city micropiles

micropiles complete

c omplete with

with

reinforcem

reinforcement

ent as sh own on the d rawings

rawings in

provisional

prov isional lengths

lengt hs 20.0m

20.0m and pres su re-

grouted with and including

including app roved grout ing

material, drill

drilling

ing in all type s o f so ils

ils a nd

rock and all coring

coring casings , linings,

linings, p lugs,

etc. and disposal of all excavated material

and debris from site.

Design information:-

information:-

a) Diam

Diameter

eter of piles: 200m

200mm m

b) Main bars : 3Y

3Y50

c) Links

Links : R05

R05 helical link

link @ 100m

100mmm c/c

c/ c

d) Steel cas ings : 292m

292mmm O.D

O.D x 9mm

9mm thick

e) Grout:

rout : Cem

Cement

ent grout,

grou t, w/c = 0.5, 20N/m2

0.5, fcu = 20N/m

f) Grout add itives

itives : Non

Non s hrink admix

admixture

ture

g) Factor of safety : 2.5

2.5

h) Bond s trength: 0.9

0.9N/mm2

N/mm

i) Bond length:

length: 10m

10m

j) Ultim

Ultimate

ate load:

load : 2016

2016kN

kN

k) Capacity: 800

800kN

kN

l) Working

Working load: 800k

800kNN

m) etc

Design and install all

all capping plates and

sta rter bars

bars

Design information:-

information:-

Plate size: 250 x 250mm

Plate thickness

th ickness : 25m

25mm

B. Star

tarter

ter bar

bar siz

size: 3Y50 or 8Y25

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 27

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Proje

ojek : Cadangan BlBlok Tam

Tamb bahan pada Ho

Hospi

spital

Bersalin di Hospital Besar, K.Lumpur.

1.0 Tujuan

Laporan ini bertujuan untuk menyampaikan laporan penyiasatan tanah dan syor-syor

asas yang sesuai bagi:Projek blok tambahan pada hospital bersalin, Kuala Lumpur.

Lumpur.

2.0 Skop Projek

Perlaksanaan projek ini melibatkan pembinaan blok tambahan 2 tingkat di Hospital

Bersalin. Blok yang dicadangkan ini dikelilingi oleh bangunan sedia ada.

3.0 Keadaan Tanah

3.1 Sebanyak

Sebanyak 3 ujian

ujian gerekan

gerekan dalam

dalam telah dijalanka

dijalankan.

n. Hasil

Hasil ujian

ujian menunj

menunjukkan

ukkan

keadaan lapisan tanah seperti berikut :-

Ukurdalam(m) Jenis Tanah SPT (b

(blows/ft.)

0 - 4.5 Very soft CLAY 0-4

4.5 - 9/10.5 Loose SAND 1-7

9/10.5-13.5/16.0 Stiff silt or CLAY 1-9

13.5/16.0 Limestone RQD = 73 - 100%.

>16.0 Limestone -

3.2

3.2 Kedu

Kedudu

duka

kan

n aras

aras air

air baw

bawah

ah tan

tanah

ah ial

ialah

ah 1.4

1.45m

5m..

4.0 syor-syor Asas

4.1 Penapak

Penapak konkr

konkrit

it tetula

tetulang

ng adalah

adalah tidak

tidak sesuai

sesuai kerana

kerana keupayaa

keupayaan

n galas

galas yang

yang rendah

rendah

dan jugs paras air bawah-tanah adalah tinggi.

"Driven R.C. or steel piles" adalah juga tidak sesuai kerana masalah "noise &

vibration" dikawasan Hospital sukar diterima. "Inclined bedrock" juga mungkin

mengakibat "excessive pile deviations".

Syor-syor asas yang dicadangkan adalah seperti berikut :-

Jenis Bangunan Jenis Asas Saiz Panjang Keupayaan Geseran Beba

(mm) (m) galas yg Kulit Ujian

dibenarkan negatif

Blok Tambahan Cerucuk 200Ø 16.5-19 200kN - 400kN

mikro with 102

(micropile) API paip

(4ӯ)

4.2 Cerucuk

Cerucuk mikro hendaklah

hendaklah digerudi

digerudi sehingga

sehingga ke paras

paras batukapur

batukapur dan dikunci

dikunci

(key) minima 3m ke dalam batukapur.

4.3 Sekura

Sekurang-

ng-kur

kurang

angnya

nya 2 bilan

bilangan

gan ceruc

cerucuk

uk digun

digunaka

akan

n untuk

untuk setiap

setiap tiang.

tiang.

4.4 Jack

Jack pile

pile (200x20

(200x200xl

0xl5m)

5m) juga

juga boleh

boleh diteri

diterima

ma sebaga

sebagaii cerucuk

cerucuk ganti

gantian.

an.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 28

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

5.0 Syor-syor Tambahan

5.1 Jika

Jika rongga

rongga (cav

(cavity

ity)) ditemu

ditemui,

i, ceruc

cerucuk

uk henda

hendakla

klah

h dipanj

dipanjang

angkan

kan

melebihi rongga dan dikunci (keyed) minima 3m ke dalam batukapur

tanpa rongga. (rujuk Fig. 1).

5.2 Untuk

Untuk mengatasi

mengatasi masalah

masalah penanaman

penanaman micropile

micropile dirongga,

dirongga, penender

penender mestilah

mestilah

diarah mengemukakan cadangan sistem 'micropile installation' dan teknik-teknik

'grouting' dirongga semasa tawaran dibuat.

6.0 Hal-hal lain

Satu set rekod penanaman cerucuk-cerucuk yang diuji berserta ujian beban hendaklah

dihantar ke Unit Makmal bagi tujuan dokumentasi.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 29

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Lampiran ‘A’

Micropile Specfication

1. General

The work involves the construction of 200mm (8") diameter micropile. The micropile shall

be fabr

fabrica

icated

ted using

using stee

steell tube

tube and

and the

the bond

bond length

length of micr

micropi

opile

le shal

shalll be 16m or dire

directe

cted

d

by the

the S.O.

S.O. The workin

working g load

load of

of micro

micropil

pilee is 200 kN and

and fact

factor

or of

of safet

safety

y used

used in

in desig

designn is

2.0. The whole of work and materials shall be in, accordance with curreht Malaysian or

British Standard or other National Standards approved by the S.O.

2. Reinforcement

Steel

Steel grade

grade - HFS 16

16 (BS: 1775 - 1964)

1964)

External diameter 139mm (51/2”)

Thic

Thickn

knes

esss - 9.5m

9.5mmm (3/

(3/8"

8")) 2

Yield strength - 250 N/mm (16 Tsi)

3. Grout

The grout shall be thcFoughly mixed with Ordinary Portland Cement (MS522) and water

(MS28). The grout shall be Antishrink cement grout. The water cement ratio shall be 0245 -

0.50. The 28 days. Strength for cement grout shall be 25N/mm (3570 psi). The representa

tive cubes shall be collected on each day of grouting works for testing on the 28th days.

Details of admixture shall be submitted to the S.O. for approval before commencement of

works. The use of the admixture shall comply with instruction by the manufacturer & MS

922. The grout shall be free from segregation, slumping, & bleeding of water and fine

materials during and after placing.

4. Installation

a) Drilling

The drilling for installation of micropile shall guarantee the absence of Vibration

Vibration

which may cause damage to the existing building. Adequate precaution must be

taken to ensure boreholes for micropile do not collapse during drilling.

If necessary, temporary casing shall be used. During drilling of borehole, the con

tractor shall maintain complete record of soil profile. The logging shall include

depth of soil and water table. This drilled hole Viand! soil bore log shall be

signed by contractor's site representative and a copy of which shall be deposited

with the S.O. The contractor shall be required to keep representative sample of

soil for each soil profil in plastic bag for inspection by.the S.O. Sample may only

be disp

dispose

osedd after

after the S.O.

S.O. is satisf

satisfied

ied that

that the

the loggi

logging

ng has

has been

been proper

properly

ly done

done..

The type-of drilling equipment shall be approved by the S.O. The drilled hole

shall be flushed ckean.with air or water.

b) Fabrication of micro pile

Method of splicing of bars or pipes shall be approved by the S.O. Centralisers at

about 3m centre must be used to ensure a minimum cover of 25mm or directed

by the

the S.O.

S.O.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 30

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

c) Grouting

The contractor shall also provide details on method and equipment used in grout

mixing. Further information such as grouting pressure, grouting procedure, grout

ing equipment and techniques employed in grouting under water shall also be

furnished and approved by the S.O.

'To

'To prevent deterioration of strength of soil, soil coring, installation of reinforce

ment and cement grouting shall be carried out in one continous operation.

5. Load Testing

Micro-pile shall be load tested to 2 times design load using the Maintain Load Test.

Minimum of one (1) load test shall be carried out. The contractor shall also specify and pro

vide details of the method of load testing. Micropile shall be constructed only after the pre

liminary pile pass the load test requirements of JKR standard specification for building

Works.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 31

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Contoh

Contoh Jadual Sebut Harga

Bi l . Description Un i t Q u anti ty Rate $

1 MI CROP I LE S

(ALL PROVISIONAL)

A. Allo w f o r P r elim in ar ies I t em

B. P r ov

ov id

ide al

all n ec

ece ssssa ry

ry pi

pilin g

equipment on site, maintain on site,

dismantle and remove from site on

complet ion, allow for all standing

or idling time and cost of operation

f o r t h e wh o le o f p ilin g wo r k s. I t em

C. I ns

nst al

alla ti

tio n o f 2 00

00 mm

mm di

dia m

mee te

te r

Micropiles in soil, including coring,

4" diameter pipe, steel plate head,

joint ing and ext ension and grouting MR

in cement , all as specified

specified (50

posit ions)

D. Provi

Provid

de all

all nece

necesssary

ary pi

pile testin

testing

g

equipment

equipment on site, dismantle and

remove from site on completion.

Test 200mm diameter Micropiles in soil

as sp ecif ied. NO

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 32

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Lampiran E1

Pile Design

for

SMK (Perempuan Raja Zarina)

Kelang

1. This

This proje

project

ct consi

consists

sts of cons

constru

tructi

ction

on of

of one

one addit

addition

ional

al 3-st

3-store

orey

y schoo

schooll block

block..

2. Max column load = 57 ton

3. This

This is a typic

typical

al coast

coastal

al alluv

alluvium

ium site

site wher

wheree first

first 60ft

60ft to 100

100 ft cons

consist

istss of very

very soft

soft clay

clay

4. Deep

Deep Soundi

Sounding

ng is very

very suit

suitabl

ablee and 4 nos

nos of

of D/S resu

results

lts give

give cons

consist

istent

ent resu

results

lts as shown

shown in

in

Lampiran E-1

5. The site

site is

is a flat

flat land

land and the

the first

first 4 ft

ft is impo

importe

rted

d fill

fill (about

(about 5 years

years ago)

ago) Negat

Negative

ive fric

frictio

tion

n

has to be checked.

6. Sele

Select

ctio

ion

n of

of pil

piles

es (Ref

(Refer

er to Fig.

Fig. 1)

6.1 Non displaceme

displacementnt piles

piles not suitable

suitable because

because of

of low column

column load

load and

and very

very soft

soft clay

clay

near the first 100 ft.

6.2 Timber

Timber pile also not suitable

suitable bacause

bacause its

its max

max length

length is about

about 40 ft.

ft. only

only..

6.3 Use 12" x 12"

12" x 100

100 ft R.C.

R.C. pile

piless Desig

Design

n load

load = 30

30 Ton/

Ton/pil

pilee (max)

(max)

7. Chec

Check

k Pil

Pilee Cap

Capac

acit

ity

y (Re

(Refe

ferr to

to Lam

Lampi

pira

ran

n E-1

E-1))

From D/S results

Qu = Qs + Q p

where Qu = ulti

ultima

mate

te capa

capaci

city

ty

Qs = skin

kin fri

frict

ctio

ion

n

Q p = end resistance

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 33

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

7.1 Skin friction, Qs

Based on total friction (remoulded)

At 30m (100ft), total friction = 3,000 kg.

Qs = tube

tube fricti

friction

on x-pi

x-pile

le peri

perimet

meter

er

tube perimeter

= 3,00

3,000

0 x (12"

(12" x 2.5

2.54

4 x 4)

11.3

= 32,300 kg

kg

= 30 Ton.

Based on local friction (undisturbed)

Qs = (8.5 x 0.05 + 7.5 x 0.13

0.13 + 13

13 x 0.27

0.27 + 0.9)

0.9) x 3.28

3.28 x 4 x 0.92

0.92

= 70 Ton

Sensitivity = Q s (undisturbed)

Qs (remoulded)

= 70

30

= 2.3,

2.3, wit

withi

hin

n usua

usuall rang

rangee

Q's = " Qs, where " = 0.7 (Bjerrum)

= 0.7 x 70

= 49 Ton

7.2 End Re

Resistance, Q p,

Q p = 80 (kg/cm2) x 1 ft2 x 0.92

= 73.6 Ton

Qu = 49 + 73.6

= 122.6 Ton

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 34

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

7.3 Negative friction

Negati

Negative

ve fric

frictio

tion

n for

for piles

piles at spac

spacing

ing more

more than

than 3 x diame

diameter

terss is

f n = 0.2 Po (Bjerrum)

where Po = effe

effect

ctiv

ivee ove

overb

rbur

urde

den

n

= γ h

= 100'

100' (10

(100p

0psf

sf - 62.

62.4

4 psf)

psf)

= 3760 psf

Max. f n = 0.2 Po

= 0.2 x 3760

= 752 psf

Average f n = (0 + 752)/2

= 376 psf

Total negative friction = f n x As

= 376 x (10

(100

0 x 4)

= 150,400 lb

lb

= 67 Ton

7.4 Allowable lo

load, Qs

The negative skin friction, Q N should only considered in combination with dead

load because QN acts mainly at the lower portion of the pile and would only affect

the settlement.

2.5 QD.L = Qu - Q N

QD.L = 70% Qa

2.5 x 0.7Qa = Qu - Q N

Qa = (Qu - Q N) /1.75

= (122

(122.6

.6 - 67)/

67)/1.

1.75

75

= 31 Ton

say 30 Ton/pile

Notes

Notes : The fillin

filling

g is don

donee about

about 5 years

years ago.

ago. At leas

leastt 60 - 70%

70% conso

consolid

lidati

ation

on com

com

pleted

pleted..

f n used is about the same as the undrained shear strength. Hence QN estimated is on the

light side.

To prevent tensile stress and buckling during driving, free drop hammers is preferred.

8. Recommendation

Use 12" x 12" x 100 ft R.C. piles

Friction piles, driven to the required pene:,tration and load test to verify the capacity. (No

"set" required).# Load tests after 4 weeks of driving.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 35

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 36

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Memo

Daripada:

Daripada: Penolong

Penolong Pengarah

Pengarah Makmal,Caw

Makmal,Caw.. Rekaben

Rekabentuk

tuk & Penyel

Penyelidik

idikan,

an, IP.

IP. JKR

JKR

Kepa

Kepada

da:: Peno

Penolo

long

ng Peng

Pengar

arah

ah(B

(Bin

inaa

aan)

n),, Ibu

Ibu Peja

Pejaba

batt JKR

JKR,, K.L

K.L..

Bil surat: (X) dlm. PKR.RB 4112 Tarikh : 26.3.1983

Per: Cadangan

Cadangan Masjid

Masjid Baru

Baru di Batu 31/2,

31/2, Jalan

Jalan Cheras,

Cheras, K.L.

Berhubung dengan perkara yang tersebut di atas, sukacita dimaklumkan bahawa cadan

gan asas yang disyorkan adalah seperti berikut:-

1. Kep

Keputus

utusan

an pen

penyi

yias

asat

atan

an tan

tanah

ah

Sebanyak 28 Nos. Proba JKR dan 5 Nos. “Deep Boring” telah dijalankan ditapak projek

itu. Keputusan

Keputusan - keputusan

keputusan yang diterima menunjukkan bahawa kawasan projek ini

adalah terdiri daripada batu kapur. Paras batu kapur adalah daripada 2.5m hingga 14m

daripada paras permukaan tanah sedia ada. Oleh kerana keadaan batu dasar yang susah

untuk diramalkan, langkah-langkah pengawasan dan faktor keselamatan yang lebih

tinggi perlu diambil di dalam rekabentuk asas.

2. Syor-syor asas

2.1 Jenis - jenis

jenis asas

asas yang

yang disyorkan

disyorkan adalah

adalah sepert

sepertii dicatitkan

dicatitkan di dalam

dalam Lampiran

Lampiran A.

Sebelum kerja - kerja ‘piling’ dimulakan sekurang - kurangnya satu ujian Proba Proba JKR

perlu

perlu dija

dijalan

lankan

kan di seti

setiap

ap kedu

keduduk

dukan

an tian

tiang

g untuk

untuk menent

menentuka

ukann paras

paras batu

batu dasar

dasar (>400

(>400

blows/

blows/kakkaki).

i). Sekira

Sekiranya

nya paras

paras batu

batu dasar

dasar dida

didapat

patii kuran

kurang

g darip

daripada

ada 4.5m

4.5m dibaw

dibawah

ah per

per

mukaan bumi, adalah dicadangkan

dicadangkan supaya menggunakan “R.C.cylinder

“R.C.cylinder foundation”

(sila lihat Lampiran

Lampiran A & B)

2.2 Sekurang

Sekurang - kurangnya

kurangnya 2 cerucuk

cerucuk perlulah

perlulah digunakan

digunakan ditiap-ti

ditiap-tiap

ap kedudu

kedudukan

kan tiang

kecuali jika ‘R.C.cylinder foundation’ digunakan. Tiap

Tiap - tiap tiang hendaklah diikat den

gan rasak bawah dikedua - dua arah. Ini adalah sebagai langkah awas oleh kerana terda

pat rongga

rongga - rongg

ronggaa dan

dan kemun

kemungki

gkinan

nan masala

masalah

h surut

surutan.

an.

2.3 Untuk

Untuk memperoleh

memperolehii pengawasa

pengawasan n yang lebih

lebih baik semasa

semasa memacu

memacu cerucuk

cerucuk tukul

tukul jatuh

jatuh

bebas(

bebas(fre

freee drop

drop hamm

hammer)

er) dicada

dicadangk

ngkan

an supa

supaya

ya digu

digunak

nakan.

an. Ini ialah

ialah supa

supaya

ya ceru

cerucuk

cuk tidak

tidak

menerima hentaman dan menyimpang berlebihan (overdriving and excessive deviation)

oleh kerana keadaan batu dasar yang mencerun (inclined bedrock surfaces).

2.4 Hujung

Hujung cerucuk

cerucuk keluli

keluli hendakla

hendaklah

h dikeluli

dikelulikan

kan dengan

dengan plat

plat yang lebih.

lebih. Ini

Ini adalah

adalah perlu

perlu

untuk menahan tegasan yang berlebihan (withstand overstressing) apabila cerucuk sam

pai ke para

parass batu

batu dasa

dasarr.

2.5 Sekurang

Sekurang - kurangnya

kurangnya 2 nos.

nos. kumpulan

kumpulan cerucuk

cerucuk (pile

(pile group,

group, NCT single

single pile)

pile) perlul

perlulah

ah

dipilih untuk ujian beban. Satu set “driving records” dan keputusan ujian beban hendak

lah dihantar kepada Unit Makmal ini untuk analisa dan sebagai rekod di Unit Makmal.

2.6 Perhatian

Perhatian hendakl

hendaklah

ah diberi

diberi kepada

kepada pengalam

pengalaman

an yang

yang lepas iaitu

iaitu cerucuk

cerucuk - cerucu

cerucuk

k tam

bahan

bahan mung

mungkin

kin diperl

diperluka

ukan

n untuk

untuk mengga

mengganti

ntikan

kan cerucu

cerucuk

k - ceru

cerucuk

cuk yang

yang menyi

menyimpa

mpangng

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 37

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

berleb

berlebiha

ihan

n dan

dan ceruc

cerucuk

uk - cerucu

cerucuk

k yang

yang masih

masih tidak

tidak ‘set

‘set’’ dipara

diparass yang

yang dala

dalam

m (>10m

(>10m).

).

Adalah dicadangan supaya tambahan sebanyak 25m disertakan didalam “B.Q.”

2.7 Oleh kerana

kerana keadaan

keadaan tanah

tanah yang

yang rumit

rumit (tricky)

(tricky) juruter

juruteraa tapak bina

bina hendakl

hendaklah

ah selalu

selalu

rujuk kepada keputusan penyelidikan tapak semasa menyelia kerja - kerja pembinaan

asas. Apabila cerucuk dijangka sampai paras batu dasar, kejatuhan pemukul (drop of

hammer) hendaklah dikurangkan. Tujuan langkah ini ialah untuk “better keying & bed

ding effect on rock surface”. Langkah ini juga akan mengurangkan cerucuk daripada

menyimpang berlebihan.

Sekian disampaikan ulasan kami untuk tindakan tuan selanjutnya.

‘Berkhidmat Untuk Negara’

......................................................

(Ir. Neoh Cheng Aik),

Jurutera Kerja Kanan (R1),

bp. Penolo

Penolong ng Peng

Pengara arah h (Makm

(Makmal) al),,

Ibu Pejabat JKR, K.L.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 38

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Lampiran A

Cadangan Asas Untuk Pro jek

Mas jid Batu 31/2, Jalan Cheras,K.L.

1. Bangunan Masjid (13T - 105T)

Sila gunakan cerucul; keluli 203mm x 203mm x 45kg/m (Grade 43A9 BS 4360) den

gan beban keupayaan

keupayaan 210 0/eerucuk.

0/eerucuk. Untuk tujuan tawaran, panjang cerucuk

cerucuk ialah 8.5m

(27ft) AT

ATAU "R-C- cylinder foundation".Sila

foundation". Sila lihat Para 2.1

2. Bangunan Quarters Kelas G(9T - 16T)

Sila gunakan eerucuk I-,yu berubat (treated timber pile) 125m x 125m dengan beban

keupayaan 5W/oerucuk. Untuk tujuan taviarany panjang cerucuk ialah 8.5m (27 ft).

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 39

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 40

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Lampiran E 5

Extension of Terminal Building, Subang Airport

1. General

The project consists of extension of International and Domestic Transper Corridor for

Subang International Airport.

Airport. The proposed-site is situated approximately 13 miles west of

Kuala Lumpur.

Due to the close proximity of the proposed site to the existing terminal building v where the

Control Tower for the airport is located, severe vibration such as driving piles is unaccept

abldo Bored and Cast-in-situ piles were considered most suitable.

2. Soil Condition

The site consists of residual soils of granite.

Lampiran E5-1 represents the generalised poil profile. The top layer of the soil consists of

brown

brown firm

firm sandy

sandy silt

silty

y clay

clay with

with som

somee organ

organic

ic matt

matters

ers.. The

The depth

depth of this

this top soil

soil varie

variess

from 6" to 2ft. Beneath this top soil underlies the yellowish with patches of grey medium

sandy clayey silt with some gravelse This medium sandy clayey silt extend to a depth of 40

to 85 ft. below R.L. 86.00'. Between these layers of medium sandy sandy clayey silt and th

thee frac

tured or slightly weathered granite bedrocksq lies the greyish very stiff decomposed granite

residual soil. The thickness of this decomposed granite residual soil varies. Water table is

about Oft. b.g.l.

3. Load Se

Settlement Cr

Criteria

The system of piling to be designed shall meet the followings:-

a) Safe

Safety

ty Fac

Facto

tor

r

The factor of safety for the purpose of computing the working load shall be taken

as 2.5.

b) Worki

Working

ng Load

Load

The working load adopted for single pile shall not be greater than the ultimate

load divided by the safety factor of 2.5 and the ultimate load is defined as:

(i) Load

Load at which

which the

the gross

gross sett

settlem

lement

ent cont

continu

inues

es to incr

increas

easee withou

withoutt any furt

further

her

increase in load.

(ii)

(ii) Load

Load at whic

which

h gross

gross settle

settlemen

mentt is 10%

10% of

of the

the pile

pile diam

diamete

eterr.

c) Settle

Settlemen

mentt Criter

Criteria

ia

(i) Gross

Gross sett

settlem

lement

ent of the

the pile

pile at workin

working

g load

load duri

during

ng the

the first

first cycle

cycle of

of load

load

ing, loading to one time working load, shall not exceed 0.5".

(ii) The residual

residual settle

settlement

ment of the

the pile

pile at

at the

the end of the

the first

first cycle

cycle of loadi

loading

ng

shall not exceed 0.10".

(iii) The gross

gross settlement

settlement of the

the pile

pile at twice

twice the

the workin

working

g load

load shall

shall not

not exceed

exceed

1.5"

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 41

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

d) Grou

Group

p Effec

Effectt

Neglig

Negligibl

iblee becau

because

se of

of small

small group

group (2

(2 or 3 pile

pile per

per grou

group)

p) & large

large spac

spacing

ing 2.5 Ø.

4. Stru

tructur

tural Ca

Capaci

acity of Piles

iles

Since piles are not fully reinforced, the structural capacity of the piles will be solely depend

on the concrete

concrete sectio

section

n of the piles*

piles* In this case,

case, the pile

pile is reinforce

reinforced

d for the top 40ft.

40ft.

only for the dispersion of the possible slight bending moment elperienced at the pile top.

The piles will be designed as short columns. According to CP 2004, the structural carrying

capacity of Cast-in-situ concrete pile, that is, the safe working load per pile, W

W - 1/4

1/4 (Acc.Uw

(Acc.Uw))

Wher

Wheree Acc

Acc = Gros

Grosss cros

crosss sect

sectio

ion

n of the

the area

area of conc

concre

rete

te

Uw = Specified cube crushing strength at 28 days.

= 3000 psi.

For d = 18ӯ, max. structural load = 80 Ton.

d = 24ӯ, max. structural

structural load = 150 Ton

d = 30ӯ, max structura

structurall load = 230 Ton.

5. Check Pile Capacity

Use 18" Ø bored piles x85 ft max. Meyerhofs’ formula (modified) is applicable for bored

piles

piles in

in resid

residual

ual soil

soil

Qu = Qs + Q p

= f s As.+ O p A p

= N As + N. A p

50

where

where N = averag

averagee SPT along

along pile

pile shaft

shaft

N = averag

averagee SPT

SPT near

near pile

pile base

base (4Ø above

above pile

pile base

base & 2Ø

2Ø below

below pile

pile base)

base)..

As = pile shaft area (ft2)

As = pile base area (ft2)

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 42

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Based on DB12

18"Ø x 75'

N = 16 f s = N = 0.32

0.32 TSF

TSF

50

N = 50 q

p = 50 TSB

Qs = f s As

= 0.32 x (1.5' x 3.1416 x 75) = 113 Ton

Q p = 50 x (1/4 x 1.52 x 3.1416) = 88 Ton

Qa = Qs/20 + Q p/3.0

= 56.5 + 29.3

= 85.8 Ton

say 80 Ton

Based on DB 10

18"Ø x 55

55ft

N = 20 f s = 0.4 TSF

N = 80 q

p = 80 TSF

= 0-4 x (1o5 x 301416 x 55) = 104 Ton

Q p = 80 x (1/4 x 1o5 x 1o5 x 3o1416) = 141 Ton

Qa = Qs/2.0 + Op/3.0 = 52 + 47 = 99 Ton

say 80 Ton.

Based on DB 13

18ӯ x 80ft.

N = 23 f s = 0.46 TSF

N = 35 q

p = 35 TSF

Qs = 0.46

.46 x (1.5 x 3.14

.1416 x 80) =173

=173 Ton

Q p = 35 x (1/4

(1/4 x 3o1

3o1416

416 x 1o5 x 145

145)) = 62 Ton

Qa = Qs / 2.0 + Q p / 3.0 = 173/2 + 62/3.0

= 86 + 31

= 117 Ton

> 80 Ton.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 43

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

6. Founding Level

Founding level should be determined by observing the soil type from the boring. Suitable

founding soil should be weathered granite bedrock or oompacted/cemented clayey silt with

gravels,

gravels, or up to

to a max depth

depth of eft'.

eft'. In case of

of dou7gt,

dou7gt, SPT shou

should

ld be carried

carried in

in the bored

bored

base.

base.

7. Recommendation

Use 18ӯ bored pile Vrith max capacity 80 Ton per pile. Site engineer should use the DB

results

results to determine

determine the

the foundi

founding

ng level.

level. Para 6 above

above can be used

used as a guide.

guide. 4 Nos load

tests should be carried out to verify the capacity.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 44

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

1

B

D

2

B

D

3

B

D

4

B

D

5

B

D

6

B

D

”

0

’

8

4

e

l o

f t

i

o ”

r 6

1

/

P 3

l l

a

i t

o n

o

z

S i

1 r

o

7 . H

B g :

e

i l

D F a

c

S

8

B

D

s

l

9 e

v e

B s a

l r t

i

D e g n

a

v

a h

t r

r i g

g w d

h d e

t r

i n e d

0 w a

s h

t n

t y a

1 c

a

l t

i

s l e a

s

B i

s W y

t

D m y l

, i

e y d

r

a y y s

t a

l a e

l y e ,

r y

e

c c u e

a t

c l

y

a t

f y c c y

a

l

r i d t a

r l

n c c

1

1 s s

u

y a a F

s p d e

,

d d f m r s

B r

a n i o a o

f

D a t o

H S S C H L

2

1

B

D

3

1

B

D

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 45

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Lampiran E 6

1. Objective

To design the foundation system for the proposed Dewan Orang Ramai in Kampung

Cheras Baru

2. Introduction

2.1 The proposed.

proposed.struc

structure

ture is a one-sto

one-storey

rey assembly-h

assembly-hall's

all'situat

ituated

ed on

on Lot

Lot 405 in

Kampung Ceras Baru, M11rim Ampang, Daerah Hulu Langat

2.2 Column loads

Maximum - 68T

Minimum - 30T

3. Site Condition

3.1 Surface Con

Condition

The terrain is generally flat. It was formerly an old building site that has been

cleared. Springs of water are visible which suggest the ground water table is

very near the ground surface. The only visible form of undergrowth are bushes

and shrubs.

3.2

3.2 Subsurf

surfac

ace

e Con

Conditio

tion

3.2.

3.2.1

1 Refe

Referr

rrin

ing

g to the

the geol

geolog

ogic

ical

al map

map of

of Kual

Kualaa Lump

Lumpurur Dist

Distri

rict

ct (af

(afte

terr Tin

Ting

g

and Ooi 1972)2, Kampung Cheras Baru is located

located in the Granite

Granite

region. Hence the soil is residual Gradite soil.

3.2.2

.2.2 Scop

Scopee of Sit

Site Inv

Invest

estigat

igatiion.

on.

Initially 6 Nos of JKR Probes were performed by the district office of

JKR Hulu Langat. Due to the inconsistency of the probe results, a

more elaborate method of sub-soil exploration in the form of 3 Nos.

Deep Boring was done by the Unit Makmal Ibu Pejabat JKR.

Borehole positions are as indicated in Appendix B. From the borelog

results (APPENDIX C) the soil profile is not consistent along the three

boreho

boreholes

les.. Gener

Generall

ally)

y) thou

though,

gh, the sub

sub-so

-soil

il eons

eonsist

istss of interl

interlaye

ayerr

betwee

between n sand,

sand, clay

clay and

and stilt

stilt.. The

The first

first 9 metre

metress Appear

Appearss to be comcom

prised

prised of loos

loosee to medium

medium dense

dense sand

sand and very

very soft-

soft-to

to firm

firm clays

clays (the

(the

variation occuring with depth). Below 9m the soil seems to improve

from medium dense to very dense silts and sands as well as stiff to

very hard clays. The groundwater is very near to the surface and the

subsoil is assumed to be fully saturated.

3.2.3

.2.3 Othe

Otherr Rel

Relevan

evantt Info

Inform

rmat

atio

ion.

n.

Near

Near to the propos

proposeded site

site of the

the hall

hall,, in a north

north,, easte

easterly

rly direct

direction

ion is sit

sit

uated a quarry. There is an access-road leading to the intended site but

it is in a bad state.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 46

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

4. Foun

Founda

dati

tion

on Anal

Analys

ysis

is and

and Reco

Recomm

mmen

enda

dati

tion

on

4.1 Selection of type of foundation

With reference-to the results obtained from the S.I. done the first 5 metres com

prises

prises of comp

compres

ressib

sible

le mate

materia

riall which

which is of

of insuf

insuffic

ficien

ientt stren

strength

gth to sust

sustain

ain the

intended imposed loads. Hence an ordinary shallow foundation in the form of a

pad footin

footing

g would

would not suffic

suffice.

e. A piled

piled foun

foundat

dation

ion sys

system

tem is warr

warrant

anted

ed here

here in

order to transfer the loads to the stronger material found below 15m of the

ground-level. In selecting the particular type of pile'to be used, particular consid

eration has been made to

(a) Cost.

(b) Driving lengths

(c)

(c) Res

Resista

istan

nce to har

hard

d dri

drivi

ving

ng..

(d)

(d) Stre

Streng

ngth

th mf pile

pile as stru

struct

ctur

ural

al memb

member

er

(e) Effec

Effectiv

tivene

eness

ss in mob

mobili

ilisin

sing

g fric

frictio

tion

n and

and end-be

end-beari

aring

ng

(see Table 1)

Table 1 : Selection of Pile Type

Type Max. length Resistance Structural Merit as Merit as Cost

of of to Hard Capacity frictional end (per m run)

pile Driving possible Driving pile bearing

(18m) pile

R.C.

v 2 v 2 v 2 v 1 v 2 v 2

Steel

v 1 v 1 v 1 v 2 v 1 X 3

T im

im be

ber X 3 X 3 X 3 X 3 X 3 v 1

Figures

Figures in box represent s order of choise

e.g. 3 third choice

From Table 1, the most apparent' choice would be to use steel piles. However,

based

based on

on the

the soil

soil vari

variati

ation

on (pro

(profil

file)

e) and

and the

the inten

intended

ded loadin

loading

g syste

system

m which

which is rel

rel

atively small, the .use of steel' piles is overly conservative. Furthermore hard

driving is not expected.RC piles would be more appropriate in this case because;

(a) it is more economical

(b) RC piles

piles woul

would

d be able

able to mobili

mobilise

se suff

suffici

icient

ent safe

safe end-b

end-bear

earing

ing resi

resista

stance

nce

at a much shallower depth than would be necessary fdv its steel counter

part.

part.

(c) Due to

to its

its roughe

rougherr surfac

surfacee textur

texturee RC piles

piles can

can mobil

mobilise

ise fric

frictio

tional

nal resi

resist

st

ance better than steel piles

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 47

FOR INTERNAL

INTERNAL USE ONLY

ONLY Pile Design Report

Hence RC Piles would serve better and cheaper than-steel piles as both a friction

al and end-bearing pile in this particular sub-soil condition.

4.2 Estimation of

of Ul

Ultimate Lo

Loads

4.2.1 Design Assumptions

(a) The soil

soil is fully

fully satur

saturate

ated.

d. In calcul

calculati

ating

ng the

the effecti

effective

ve overbu

overburde

rden

n pressur

pressure,

e,

Pd, the values of X sat for the various soil categories are obtained from

Appendix B in Ref. 1 (Pg. 397).

(b)

(b) For

For an SPT valu

valuee of

of N 11p the

the und

undra

rain

ined

ed cohe

cohesi

sion

on Cu,

Cu, is

is ass

assum

umed

ed

approximately to be 125 lbs/ft ,

(c) Due toto the

the incons

inconsist

istenc

encyy in the

the soil

soil variat

variation

ion for

for the

the three

three boreh

borehole

oles,

s, the

the

piles

piles were

were design

designed

ed base

based

d on each

each indiv

individu

idual

al bore

borehol

holee resul

resultt and

and the

the worst

worst

(or lowest)' calculated working load per pile was adopted for use.

(d) The crit

criteri

eriaa for desi

design

gn was

was only

only to cons

conside

iderr both

both fricti

frictiona

onall and end-

end-bea

bear

r

ing piles. Totally

Totally frictional or totally end-bearing-piles were not consid

ered.

(e) Assumed

Assume d that

that piles

piles woul

would

d achiev

achievee safe

safe and bear

bearing

ing resi

resista

stance

nce in

in soil

soil lay

ers with SPT values of N-~ 15 i.e. in medium dense

dense coesionless soils

soils or

stiff cohesive layers.

(f) Factor

Factor of safety

safety adopte

adopted

d is

is 2

2.5

.5 (para

(para 4.6 pg. 149 of. ref.