Professional Documents

Culture Documents

Nelson n4s 60 A Main Fuse Stud Welder System PDF

Uploaded by

Francisco R. SouffleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nelson n4s 60 A Main Fuse Stud Welder System PDF

Uploaded by

Francisco R. SouffleCopyright:

Available Formats

N4S System

N4s

Stud Welder

Perfect for Short-Cycle / Drawn-Arc Stud Welding!

universal · flexible

Compatible with

Suited for all Customizable Nelson® FSE Networking

short-cycle to your specific feeders and stud & Monitoring

drawn arc studs. requirements. welding tools. 1 Power Source. resources.

The unit can be used Interfaces with Combine up to Use only 1 source for Supervise quality

with a variety of robots and 5 feeders and stud welding, TARC and operation from

studs for whatever transferlines using welding tools to welding and TARC a PC throughout the

your application parallel interface, your specifications nut welding. corporate network.

InterBusS, DeviceNet, (standard or reverse

EtherNet/IP, ProfiBus, polarity).

ProfiNet and

numerous others.

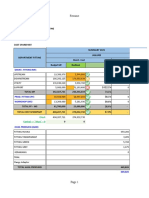

Specifications

Power Supply Inverter

Weld Current 250A-1800A

Main Fuse 60A (32)

Power Plug CCE 60A (32)

· 100Mb / sec. Fast Ethernet Degree of Protection IP 21

· Large Program Storage Capacity Protection Class 1

· Service-Friendly Unit Enclosure Cooling AF (fan, temperature-controlled)

Connection Possibilities Manual Handguns: P-NS 40SL

· Digitally-Controlled Personnel Access Function Automatic Welding Guns: PSE 1000s/PFL901

· S-Mark, Crane Eyelets, (4) Wheels Welding Heads: KSE 1000s

Feeders: FSE 1000s/FSE100

· Removable Graphic Control Panel

Dimensions Width 24 in. (610mm)

· Power-Safe Mode

Height 39 in. (981mm)

· Weld Impedance Control Warning Depth 27 in. (684mm)

· Steady Power even with Long Cables Weight 265 lbs. (120kg)

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

Speedport Feeding

SpeedPort Fast Even Faster

Feed Studs 50% Faster!

· Produces faster feed times as the Speed Port is

located less than 3 ft. (1 m) to the weld head

· 50+ Studs/min. is possible.

· The weld cycle is reduced from

2.1 seconds to 1 second.

A Stud is fed to the Speed Port during the prior weld sequence. As the weld head retracts,

the stud at the Speed Port is released allowing for a fast stud load to be ready to fire again.

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

KSE 1000 and PSE 1000 Welding Tools

Probeless Weld Head: Handheld: When Automation or

Better Access to Confined Spaces Robotics Are Not Possible

KSE 1000 Welding Gun PSE 1000 Welding Gun

Modular, robust construction. Autofeed stud welding.

Interchangeable nose to accomodate various stud configurations.

A gooseneck option is available for welding tight spaces. Compatable with all automotive studs.

Simplified modular design.

Pluggable feed hose with quick connect/disconnect & safety

switch. Stud welding without a supporting base.

Integrated compressed air & protective gas. Servo-Electric Drive.

Integrated connection for tool balancer.

Stud welding without a foot for improved access.

Easy lift adjustment by digital control.

Servo-Electric Drive with encoder for precision movement.

No slag build-up means less maintenance Adjustable lift-off dimensions with constant control even on

convex or concave surfaces.

SpeedPort connection to accelerate the feeding process. LED indicators monitor angularity and suspect welds.

Easy lift adjustment by digital control. Gun allows operator to select from 9 programs.

Optional inert gas welding.

17.2 lbs. (7.8 kg)

7 lbs. (3.2 kg)

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

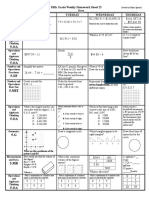

FSE 1000 / ECO Escapement

FSE 1000

Stud Feeder

60% Air Savings!

ECO Feeder.

· Suited for all automotive studs

· Easily changes stud sizes

· 60% air consumption savings with ECO Escapement design

· Quietest feeding system on the market! Sound level under 70 dB

Versatile Design.

· Can be used as a control box for other welding tools

· Up to 5 feeders and bunker units can be operated from 1 control box

· Provides flexibility and is easily serviced

· Able to serve as a central control unit for a group of feeders

Production Monitoring. The complete feed system uses up to 6 sensors to monitor production and consistency

Specifications

Feeder Type FSE1000s Storage Temperature 0°F to 185°F (-20°C to 85°C)

Position of Use horizontal ± 3% Noise Emission < 70 dB

Operatin Modes automatic / manual Air Consumption approx. 19 I / feeding settings

Control Voltages 24 Vdc ± 10% Mains Pressure max. 116 psi (8 bar)

Power Supply Voltage 90 Vdc ± 10% Work Pressure 65 to 80 psi (4.5 to 5.5 bar)

Protection Type IP 20 Weight 163 lbs. (74 kg)

120 lbs. (54 kg) w/o inner components

Protection Class I, according to DIN 40 100 Capacity 7500 for AXC 5 x 14.2 (SC-Z 5x14.2 mm)

Operating Temperature 40°F to 100°F (5°C to 40°C) Conveyance Performance max. 45 / min. depending on stud type

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

AC Aluminum Welding

Developed for the High-Tech Automotive Industry

N4s Inverter + FSE 1000 + AC Module + KSE 1000 = Flawless Aluminum Welding!

· Allows Weld to Change Polarity. · Higher Quality Aluminum Weld.

· High Speed Switching Device. · Even Heating of Aluminum Stud.

· Shielding Gas for Aluminum. · Optional Module can be added to any N4/N4s System.

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

Arc Charger™ Portability

N 550 c

Powerful 550A arc welder from a 120V outlet!

Weld the full range of drawn arc studs, up to 3/8” pitch (M8)

diameter from a standard household 120V wall outlet!

Share a Single Wall Outlet with Other Devices.

Input energy is efficiently drawn from a standard 120V wall outlet, and stored in a durable, high-capacity, electrical storage system adjustable by the user.

Advanced, High-Performance, Drawn Arc Welding.

Stored energy is precisely delivered to the weld by an advanced digitally-controlled, switch-mode welding power supply. Drawn arc, gas arc, and short cycle processes with all

weldable metals are consistent and smooth.

Sophisticated Microprocessor Control.

The Arc Charger’s 32-bit microprocessor monitors both charging current input from the wall, it’s smooth welding arc, and provides a long list of helpful setup and diagnostic

features.

Stud Expert™.

Quick & easy. Input your stud diameter and metal, and Stud Expert automatically selects the right settings for you.

Multifunction Key Pad / Display.

Preset buttons provided to save favorite settings. Display shows settings, actual weld results, as well as diagnostic error codes to help with troubleshooting.

Safe, Low Cost Input Power.

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

Pinnacle™ Battery Powered Welding

& ma x

High performance battery-powered design

delivers 1000’s of welds from a single charge!

Cordless = Unparalleled Flexibility.

Weld nearly anywhere, with no need for a power cord to limit worksite access or power generator.

Ultra-Portable.

18 lbs! Easy to carry with the padded shoulder strap to weld while carrying the unit. 2 orientations: tabletop (horizontal) and user-carried (vertical).

Advanced Battery Management System (BMS).

Rechargeable lithium ion battery with internal monitoring system protects the battery from high temperature, input overcharging, and output overload.

Integrated Cable Cleat & Gun Holster.

Very easy to manage both at the jobsite and in between jobsites.

Multifunction Display

Clear, multi-color viuals with Nelson’s familiar graphical gun display.

Advanced Microprocessor Control

Provides control, diagnostic and safety features not found in any other pin welder.

Safe

No comparable CD stud welder can run continuously without an input power cord. No cord means less risk of electric shock, arc flash injury, or tripping on the power cord.. A

dedicated ground conductor assures that the welder case is grounded to the weld work piece.

External Battery Charger.

Iincluded 120V, 6A input

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

FACS Weld Systems

Forward-Thinking Designs

Integrated

Cutting edge technology makes set-up, operation and maintenance a breeze with a

common circuit board platform.

Flexible

Easy upgrades allow customers to add features they value.

User-Enhancing Options

· LCD touch screen display provides easy troubleshooting videos and intuitive feel.

· Wireless communications.

· Weld monitoring & data storage.

NELSON® STUD WELDING

NELSON® STUD WELDING

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

7900 W. Ridge Rd. · Elyria, OH 44035 · PH: +1(440) 329-0400 · Fax: +1 (440) 329-0526 · www.NelsonStud.com

USA • Canada • Mexico • Germany • China • France • Italy • UK • India

©2017, Nelson Stud Welding A Nelson Fastener Systems Company

You might also like

- Welding Engineering - FALL2021-22 - Module 1Document44 pagesWelding Engineering - FALL2021-22 - Module 1dhaya nidhiNo ratings yet

- Certification Manual For Welding Inspectors 2000, 4th EditionDocument24 pagesCertification Manual For Welding Inspectors 2000, 4th EditionCak NhassNo ratings yet

- Failure Analysis Report: Open Filament Due to High VSWRDocument2 pagesFailure Analysis Report: Open Filament Due to High VSWRSathiyaPrakash50% (2)

- QC10 2017 Final WebDocument34 pagesQC10 2017 Final WebJose nuñez100% (1)

- AWS D16.1M D16.1 - 2004 Specification For Robotic Arc Weldinf SafetyDocument27 pagesAWS D16.1M D16.1 - 2004 Specification For Robotic Arc Weldinf Safetymasv792512100% (2)

- Iso 544-2011Document14 pagesIso 544-2011Vũ Đình PhongNo ratings yet

- d8 9mPVDocument9 pagesd8 9mPVFarid HasannudinNo ratings yet

- Aws Nema d16 2d16 2mDocument6 pagesAws Nema d16 2d16 2mjessy eghNo ratings yet

- Stud WeldingDocument40 pagesStud WeldingKirandeep GandhamNo ratings yet

- Definition of Resistance WeldingDocument16 pagesDefinition of Resistance WeldingMitul patelNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

- STTDocument11 pagesSTTamr kouranyNo ratings yet

- Specification For Carbon and Low-Alloy Steel Flux Cored Electrodes For Flux Cored Arc Welding and Metal Cored Electrodes For Gas Metal Arc WeldingDocument9 pagesSpecification For Carbon and Low-Alloy Steel Flux Cored Electrodes For Flux Cored Arc Welding and Metal Cored Electrodes For Gas Metal Arc Weldinghetpin100% (1)

- E0900048-V4 LIGO UHV Welding SpecDocument7 pagesE0900048-V4 LIGO UHV Welding SpecBenjamin BrownNo ratings yet

- Lesson Plan SETS 2 PDFDocument10 pagesLesson Plan SETS 2 PDFHelmi Tarmizi83% (6)

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- RSW Lab Guide: Resistance Spot Welding Process ParametersDocument11 pagesRSW Lab Guide: Resistance Spot Welding Process ParametersAli Raza JuttNo ratings yet

- Metallography EtchantsDocument9 pagesMetallography EtchantsMaulik SavaliaNo ratings yet

- Arclog X Manual 1.19Document55 pagesArclog X Manual 1.19davmac79No ratings yet

- The Role of Tip DressingDocument4 pagesThe Role of Tip DressingLutfi Ismail100% (1)

- SST (GMAW) Welding Process PDFDocument4 pagesSST (GMAW) Welding Process PDFmudrijasm100% (1)

- ProgManual - DXF (EZ Trak Programming and Operating Manual-March 2001)Document289 pagesProgManual - DXF (EZ Trak Programming and Operating Manual-March 2001)Mike Ham100% (1)

- NASA-TM-110843 Standard Threaded Fasteners Torque LimitsDocument44 pagesNASA-TM-110843 Standard Threaded Fasteners Torque LimitsJenner Volnney Quispe ChataNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- The Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..Document4 pagesThe Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..OnderNo ratings yet

- WeldPulse - Welding Software BrochureDocument13 pagesWeldPulse - Welding Software BrochureWeldPulse100% (1)

- AWS C7.3-2016 - Process Specification For Electron Beam WeldingDocument36 pagesAWS C7.3-2016 - Process Specification For Electron Beam Weldingarnoldbatista55100% (1)

- Spot Weld Mech PropDocument57 pagesSpot Weld Mech PropWeld Bro SandeepNo ratings yet

- d14 3-d14 3m-2005PVDocument8 pagesd14 3-d14 3m-2005PVweldingchileNo ratings yet

- Weld Tech TrainingDocument44 pagesWeld Tech TrainingEduardo ContrerasNo ratings yet

- Tungsten Selection and Preparation: Tungsten Electrode Selector ChartDocument1 pageTungsten Selection and Preparation: Tungsten Electrode Selector ChartBilfred JoseNo ratings yet

- IRB 580 DatasheetDocument2 pagesIRB 580 DatasheetCircusNo ratings yet

- Aws A5.8-A5.8m-2004Document47 pagesAws A5.8-A5.8m-2004HenryNo ratings yet

- Fuel Equivalent Factor - Marine Services PDFDocument9 pagesFuel Equivalent Factor - Marine Services PDFMax Kolonko100% (1)

- ABB - Profibus ControllerDocument62 pagesABB - Profibus ControllerAbraham Cisneros GarcíaNo ratings yet

- New StandardsWELDING STANDARDS - VOLVODocument22 pagesNew StandardsWELDING STANDARDS - VOLVORadivojJovanovNo ratings yet

- Pulsed MIG WeldingDocument68 pagesPulsed MIG Weldingcentaury2013No ratings yet

- AWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringDocument33 pagesAWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringJairo ContrerasNo ratings yet

- Duties of Welding ManagerDocument3 pagesDuties of Welding ManagerBalkishan DyavanapellyNo ratings yet

- SEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding RodDocument2 pagesSEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding Rodsoft4gsmNo ratings yet

- WP07 WeldPRO Setting Angles Sept 2013Document16 pagesWP07 WeldPRO Setting Angles Sept 2013Clecio de PaulaNo ratings yet

- Gen - Importance of Welding in L & T PDFDocument30 pagesGen - Importance of Welding in L & T PDFSivaNo ratings yet

- Fronius Cold Metal TransferDocument16 pagesFronius Cold Metal Transferbonmarche28No ratings yet

- Transamerican Manufacturing Group: Document Title: Weld Standards, SteelDocument16 pagesTransamerican Manufacturing Group: Document Title: Weld Standards, SteelQuoc VinhNo ratings yet

- Gmaw FcawDocument80 pagesGmaw FcawmarboledtNo ratings yet

- WeldDecayTesting TechSheet Sfs PDFDocument0 pagesWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNo ratings yet

- Laser Beam Welding Under Vacuum Achieves High Penetration DepthsDocument11 pagesLaser Beam Welding Under Vacuum Achieves High Penetration DepthsSudhakar LavuriNo ratings yet

- Pulse Mig WeldingDocument7 pagesPulse Mig WeldingajayNo ratings yet

- Asme Ix - : ProcedureDocument11 pagesAsme Ix - : ProcedureMohammed Elmodathir Ali100% (1)

- Aotai Welding EquipmentDocument16 pagesAotai Welding EquipmentSutanAMariNo ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- WJ 2013 05Document128 pagesWJ 2013 05Matija BušićNo ratings yet

- Welding Procedure Data SheetDocument2 pagesWelding Procedure Data SheetAmanSharmaNo ratings yet

- CMT Welding: Spatter-Free MIG/MAG for Thin SheetsDocument8 pagesCMT Welding: Spatter-Free MIG/MAG for Thin SheetsFlorin GadeaNo ratings yet

- CMT Short Circuit Metal TransferDocument3 pagesCMT Short Circuit Metal Transferkarthick32mechNo ratings yet

- SF-2012AH-QG User' S ManualDocument61 pagesSF-2012AH-QG User' S Manualkamal hasan0% (1)

- Soudokay Strip Cladding - PrincipesDocument31 pagesSoudokay Strip Cladding - PrincipesRenny DevassyNo ratings yet

- Bitumastic 300 MDocument2 pagesBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Spot Welding ParametersDocument3 pagesSpot Welding ParametersDeepak PathakNo ratings yet

- Sfa-5.7Document10 pagesSfa-5.7vannie_yundaNo ratings yet

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Stud Range: 3/16" To 3/4" (5mm - 19mm) : Warranty!Document1 pageStud Range: 3/16" To 3/4" (5mm - 19mm) : Warranty!Fher GVNo ratings yet

- Six Sigma Statistical Methods Using Minitab 13 Manual4754Document95 pagesSix Sigma Statistical Methods Using Minitab 13 Manual4754vinaytoshchoudharyNo ratings yet

- Operations Management (Zheng) SU2016 PDFDocument9 pagesOperations Management (Zheng) SU2016 PDFdarwin12No ratings yet

- User Manual: Smart Alarm System & AppDocument41 pagesUser Manual: Smart Alarm System & AppEduardo Jose Fernandez PedrozaNo ratings yet

- Quadratic SDocument22 pagesQuadratic SShawn ShibuNo ratings yet

- Sleep Hygiene Sleep QualityandDocument8 pagesSleep Hygiene Sleep QualityandVriddhi AgrawalNo ratings yet

- Oc Curve BasicsDocument25 pagesOc Curve BasicsRohit SoniNo ratings yet

- Nucleus ERPDocument3 pagesNucleus ERPdimensionone1No ratings yet

- E-Ship Assignment 2 Utkarsh Surjey MBA-FT-EDocument3 pagesE-Ship Assignment 2 Utkarsh Surjey MBA-FT-Eutkarsh surjeyNo ratings yet

- TMF1014 System Analysis & Design Semester 1, 2020/2021 APPENDIX C: Group Assignment Assessment RubricDocument4 pagesTMF1014 System Analysis & Design Semester 1, 2020/2021 APPENDIX C: Group Assignment Assessment RubricWe XaNo ratings yet

- L. M. Greenberg - Architects of The New Sorbonne. Liard's Purpose and Durkheim's RoleDocument19 pagesL. M. Greenberg - Architects of The New Sorbonne. Liard's Purpose and Durkheim's Rolepitert90No ratings yet

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDocument7 pagesCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNo ratings yet

- Cover Letter and Resume for Electrical Engineer PositionDocument4 pagesCover Letter and Resume for Electrical Engineer Positiongrabani77No ratings yet

- Work Readiness Integrated Competence Model Conceptualisation and ScaleDocument23 pagesWork Readiness Integrated Competence Model Conceptualisation and ScaleMelly NadiaNo ratings yet

- STAUFF Catalogue 1 STAUFF Clamps English TERBARU RemovedDocument5 pagesSTAUFF Catalogue 1 STAUFF Clamps English TERBARU RemovedBayuAnggaraNo ratings yet

- Brochure PILA Lamps and LuminairesDocument42 pagesBrochure PILA Lamps and Luminairesaldtol21No ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- BrochureDocument2 pagesBrochureNarayanaNo ratings yet

- This Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCDocument81 pagesThis Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCabcdNo ratings yet

- Writing Visual Basic ProjectsDocument1 pageWriting Visual Basic ProjectsAmmuKuttyNo ratings yet

- Efficiently Transfer Stock Between PlantsDocument6 pagesEfficiently Transfer Stock Between PlantsSantosh KumarNo ratings yet

- RallinAneil 2019 CHAPTER2TamingQueer DreadsAndOpenMouthsLiDocument10 pagesRallinAneil 2019 CHAPTER2TamingQueer DreadsAndOpenMouthsLiyulianseguraNo ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- I - Refracted EnergyDocument6 pagesI - Refracted EnergyAmmad Ali QureshiNo ratings yet

- R7 Injection CheatSheet.v1Document1 pageR7 Injection CheatSheet.v1qweNo ratings yet

- 3 6 17weekly Homework Sheet Week 23 - 5th Grade - CcssDocument3 pages3 6 17weekly Homework Sheet Week 23 - 5th Grade - Ccssapi-328344919No ratings yet

- Elm-490-Clinical Practice Evaluation 2 - Single Placement EncryptedDocument17 pagesElm-490-Clinical Practice Evaluation 2 - Single Placement Encryptedapi-439334022No ratings yet