Professional Documents

Culture Documents

Implementation of Brushless DC Motor Speed Control PDF

Uploaded by

Dane DaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Implementation of Brushless DC Motor Speed Control PDF

Uploaded by

Dane DaneCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/323592210

Implementation of Brushless DC motor speed control on STM32F407 Cortex

M4

Article · November 2017

DOI: 10.14445/22315381/IJETT-V53P221

CITATIONS READS

0 195

2 authors, including:

Yogesh Parmar

Parul Universiy

7 PUBLICATIONS 2 CITATIONS

SEE PROFILE

All content following this page was uploaded by Yogesh Parmar on 07 January 2020.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

Implementation of Brushless DC motor speed

control on STM32F407 Cortex M4

Mr. Kanaiya G Bhatt1, Mr. Yogesh Parmar2

Assistant Professor, Assistant Professor, Dept. of Electrical & Electronics,

ITM Vocational University, Vadodara, Gujarat, India

Abstract — Brushless Direct Current (BLDC) 1. Introduction

motors, also known as permanent magnet motors This paper describes how to implement a

find wide applications in many industries due to brushless DC motor control in sensor mode using the

their higher performance, reliability and ease of STM32STM32F407 Cortex M-4 microcontroller. In

control. A new generation of microcontrollers and this document, we will give a description of

advanced electronics has overcome the challenge of brushless DC motor theory of operations, we give

implementing required control factions, making details about how to control a brushless DC motor in

BLDC motor more practical for a wide range of uses. sensor mode and we will also give a short

In this project, BLDC motor circuitry is designed, description of the STM32STM32F407 Cortex M-4

and develops using 120- degree control with a boards used in this application report. Simulink

sensor. In the present project, 3- phase BLDC motor model is also discussed with output waveform using

control solution using STM32F407 Cortex M4 as the a PI algorithm. This application report deals only

motor controller, Hall sensors are used to detect the with BLDC motor speed control application using

rotor position and close the commutation loop. The Hall effect position sensors using commutation

main objective of this project is controlling speed of sequence.

BLDC motor and displays its speed. The speed

1.1 BASIC OF BRUSHLESS DC MOTOR:

control of the BLDC motors is very essential. This

proposed system provides a very precise and Brushless Direct Current (BLDC) motors

effective speed control system. The user can increase are one of the motor types rapidly gaining popularity.

or decrease the speed as per the requirement and the BLDC motors are used in industries such as

motor will run at that exact speed. Topics discussed Appliances, Automotive, Aerospace, Consumer,

include interrupt handling for pulse width Medical, Industrial Automation Equipment and

modulation (PWM) generation and sensor Instrumentation. As the name implies, BLDC motors

processing with performance measurement for do not use brushes for commutation; instead, they

STM32F407 Cortex M4 microcontroller usage. are electronically commutated

Implementation of a speed profile (speed Vs. time).

The project is divided into three stages:

input, processing and output stage. The input stage

consists of entering the required speed through

switches. The processing stage provides RPM

reference of the motor, by feedback of Hall signal

interrupt to the microcontroller in the circuit. The

microcontroller develops PWM pulses which are

varied with switches to regulate the DC power to the

motor such that the desired speed is achieved. The 1.2 BLDC Motor Hall Sensor:

output stage uses a MOSFET being driven by the Unlike a brushed DC motor, the

microcontroller output. A STM32F407 Cortex M4 commutation of a BLDC motor is controlled

microcontroller is used with a set of switches to electronically. To rotate the BLDC motor, the stator

increase or decrease the speed of the BLDC motor. windings should be energized in a sequence. It is

This speed is sensed by the hall sensors and is given important to know the rotor position in order to

to microcontroller which in turn displays it on a understand which winding will be energized

LCD display. The above operation is carried out by following the energizing sequence. Rotor position is

using PI algorithm and a MOSFET for driving the sensed using Hall effect sensors embedded into the

BLDC motor. This work is aimed at get precise stator. Most BLDC motors have three Hall sensors

output for speed control using STM32F407 Cortex embedded into the stator on the non-drying end of

M4 microcontroller with lower system cost. the motor. Whenever the rotor magnetic poles pass

Keywords - STM32F407 Cortex M4; Brushless DC near the Hall sensors, they give a high or low signal,

motor speed control in open and closed loop. indicating the N or S pole is passing near the sensors.

Based on the combination of these three Hall sensor

ISSN: 2231-5381 http://www.ijettjournal.org Page 118

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

signals, the exact sequence of commutation can be energized condition. Torque is produced because of

determined. For the estimation of the rotor position, the interaction between the magnetic field generated

the motor is equipped with three hall sensors. These by the stator coils and the permanent magnets of the

hall sensors are placed every 120°. With these rotor. In order to keep the motor running, the

sensors, 6 different commutations are possible. magnetic field produced by the windings should

Phase commutation depends on hall sensor values. shift position, as the rotor moves to catch up with the

Power supply to the coils changes when hall sensor stator field. What is known as “Six-Step

values change. With right synchronized Commutation” defines the sequence of energizing

commutations, the torque remains nearly constant the windings. In six-step commutation, only two out

and high. of the three Brushless DC Motor windings are used

at a time. Steps are equivalent to 60 electrical

degrees, so six steps make a full, 360 degree rotation.

One full 360 degree loop is able to control the

current, due to the fact that there is only one current

path. Six-step commutation is typically useful in

applications requiring high speed and commutation

frequencies. A six-step Brushless DC Motor usually

has lower torque efficiency than a sine-wave

commutated motor.

1.3 Phase Commutations: 2.0 IMPLEMENTATION:

To simplify the explanation of how to System Block Diagram:

operate a three phase BLDC motor, a typical BLDC

motor with only three coils is considered. As

previously shown, phases commutation depends on

the hall sensor values. . When motor coils are

correctly supplied, a magnetic field is created and

the rotor moves. The most elementary commutation

driving method used for BLDC motors is an on-off

scheme: a coil is either conducting or not conducting.

Only two windings are supplied at the same time and

the third winding is floating. Connecting the coils to

the power and neutral bus induces the current flow.

This is referred to as trapezoidal commutation or

block commutation. To command brushless DC

motors, a power stage made of 3 half bridges is used.

Figure: Basic Block Diagram of Typical Speed control

system

2.1 Explanation of Block Diagram

2.1.1 Power Supply:

We have to use two power supply for run

the project. First power supply is 5v DC which used

to give supply for STM32F407 Cortex M-4. Second

power supply is 24V DC which used to give supply

Figure : Half Bridge schematic for MOSFET driver kit.

Reading hall sensor values indicates which switch

should be closed. 2.1.2 Front Level Control :

Mode Selection Switch is used for selecting

mode. Here we have used two mode. a) Open loop

mode b) Closed loop mode. Speed Up switch is used

for increasing duty cycle and speed of BLDC motor.

If selection is in Open lopp mode then second switch

is used for increasing duty cycle. And if selection is

Table: Switches commutation for rotation in Close loop mode then second switch is used for

1.4 Operation of Brushless DC motor: increasing speed in rpm. We can see increasing

Each commutation sequence has one of the changes of the duty cycle and speed of BLDC motor

windings energized to positive power (current enters in LCD display which is interface with our project.

into the winding), the second winding is negative

(current exits the winding) and the third is in a non-

ISSN: 2231-5381 http://www.ijettjournal.org Page 119

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

Speed Down switch is used for decreasing duty 2.1.4 MOSFET Driver Board:

cycle and speed of BLDC motor. If selection is in MOSFET driver board consist of 6 N-

Open lopp mode then third switch is used for channel power MOSFET (IC IRF840) which is used

decreasing duty cycle. And if selection is in Close as 3- phase bridge which is used for rotation 3-

loop mode then third switch is used for decreasing phase BLDC motor. There 6 N-channel power

speed in rpm. We can see decreasing changes of the MOSFET are connected with 3-phase wire of BLDC

duty cycle and speed of BLDC motor in LCD motor for given a phase voltage. And MOSFET

display which is interface with our project. driver board is controlling by STM32f407 Cortex

Speed-Ref. Set Switch is used to lock the set switch. M-4. STM32f407 Cortex M-4 is given 6 PWM

Which gives command to STM32F407 to consider pulses to MOSFET driver board with commutation

mode which we have selected by operate switch first. sequences. From those commutation sequences

Start/Stop Switch is used for ON\OFF operation: MOSFET drive motor. MOSFET Driver board I/P

When we have to start BLDC motor then we have to comes from STM32f407 Cortex M-4 in the form of

press switch fifth after selection of Open loop mode pulse and MOSFET driver board O/P is connected

or Closed loop mode. with phase wire of BLDC motor.

2.1.3 STM32F407 Cortex M-4 controller: 2.1.5 BLDC Motor (57BLS94):

It is used for controlling speed for BLDC It is 4 poles, 3-phase Brushless DC motor.

motor with generating PWM pulse using hall sensor It has 3000 rmp maximum speed. Which have

feedback signal by commutation method. There are interface between MOSFET driver board and

power supply, 5 switches, LCD, MOSFET driver STM32f407 Cortex M-4. Motor rotate in respect of

and hall sensor feedback signal interface with MOSFET driver commutation sequence. BLDC

STM32f407 Cortex M-4. These power supply, 5 motor has internally 3 Hall sensor wire which is

switches, Hall sensor feedback signal are input of connected with STM32f407 Cortex M-4 and 3-

STM32f407 Cortex M-4 and these LCD, MOSFET phase are connected with 6- N channel power

driver are output of STM32f407 Cortex M-4. When MOSFET which is used for energized 2 coils

we choose Open loop mode and press SET button simultaneously. In BLDC motor Blue, Green and

for select open loop mode then we see 50% duty White wire are indicate Hall sensor H1, H2 & H3

cycle in LCD display and press start button then respectively. Red and Black wire are indicate +VCC

motor will rotate as 1500 rpm per 50 % duty cycle (+5v to +24v DC) and GND. Yellow, Red and Black

because of maximum speed of BLDC have 3000 wires are Phase U, V & W respectively.

rpm. And if we increase duty cycle from 50% using

press switch second then speed of the BLDC motor 3.SYSTEM SCHEMATICS AND CONTROL:

increasing rotation per minute. And if we decrease

duty cycle from 50% using press switch third then 3.1 Circuit Diagram of Our Project:

speed of the BLDC motor decreasing rotation per

minute. If we increasing torque on BLDC shaft then

motor speed will reducing their speed because of

Open loop configuration. When we choose Closed

loop mode and press SET button for select closed

loop mode then we see Set speed and Actual speed

in LCD display and press start button then motor

will rotate as set speed. And if we increase Set speed

using press switch second then speed of the BLDC

motor increasing rotation per minute. And if we

decrease Set speed using press switch third then

speed of the BLDC motor decreasing rotation per

minute. If Set speed is 1500 rpm same speed rotation

of BLDC motor 1500 rpm. If we increasing torque

on BLDC shaft then motor speed will remains

constant because of closed loop configuration.

STM32f407 Cortex M-4 generating six Pulse Width

Modulation signals (PWM) and given to MOSFET

driver. STM32f407 Cortex M-4 is received 3 hall

sensor signal from BLDC motor output. From that 3

hall sensor signal STM32f407 Cortex M-4 know

about motor speed and used for controlling constant

motor speed.

ISSN: 2231-5381 http://www.ijettjournal.org Page 120

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

3.2 Pin diagram STM32F407 Cortex M4:

Core: Cortex-M4F

Microcontroller: STM32F407VGT6

1MB Flash

192KB SRAM

Package: LQFP100

I/O pins: 82

Timers(16-bit): 12

Advanced Control Timers: 2

General Purpose Timers: 10

Basic Timers: 2

PWM Channels: 6

ADC(12-bit): 3 (16 channels)

I2C(TWI): 3

USART: 4

SPI: 3 full duplex

DMA: 2 (8 channels each)

USB: 1 (2.0 full speed)

3.3 BLDC 57BLS94 motor specification:

FIG: Circuit Diagram of STM32F407 Cortex M-4

Kit and Driver circuit

Figure: Picture of BLDC 57BLS94 Motor

Motor Specification:

Fig: Six steps changes for 120 deg. input Hall

sensor

ISSN: 2231-5381 http://www.ijettjournal.org Page 121

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

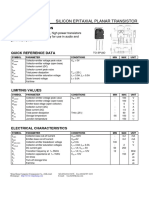

3.5 IC IRF840: [N-CHANNEL MOSFET]

3.3.1 Motor wiring details:

FEATURES:

8A, 500V

Single Pulse Avalanche Energy Rated

Nanosecond Switching Speeds

Linear Transfer Characteristics

High Input Impedance

3.6 IR2130 [3-PHASE BRIDGE DRIVER]

DISCRIPTION:

The IR2130/IR2132(J)(S) is a high voltage, high

speed power MOSFET and IGBT driver with three

independent high and low side referenced output

channels.

The floating channels can be used to drive N-

channel power MOSFETs or IGBTs in the high side

configuration which operate up to 600 volts

3.4 MC74HCT573AN: [Non inverting

transparent Latch] 3.7 HIGH SPEED OPTOCOUPLER 6N137:

Octal 3-state non- inverting transparent Latch

with LSTTL compatible inputs. High–Performance

Silicon–Gate CMOS the MC74HCT573A is

identical in pinout to the LS573. This device may be

used as a level converter for interfacing TTL or

NMOS outputs to High–Speed CMOS inputs. These

latches appear transparent to data (i.e., the outputs FEATURES

change asynchronously) when Latch Enable is high. • High speed: 10 MBd typical

When Latch Enable goes low, data meeting the setup • + 5 V CMOS compatibility

and hold times becomes latched. The Output Enable • Guaranteed AC and DC performance over

input does not affect the state of the latches, but temperature: - 40 °C to + 100 °C

when Output Enable is high, all device outputs are • Meets IEC 60068-2-42 (SO2) and IEC 60068-2-

forced to the high–impedance state. 43 (H2S) requirements

• Low input current capability: 5 mA

ISSN: 2231-5381 http://www.ijettjournal.org Page 122

International Journal of Engineering Trends and Technology (IJETT) – Volume 53 Number 3 November 2017

4.1 Connection of BLDC motor with STM32f4 Topics discussed include interrupt handling for

Discovery Development Board: pulse width modulation (PWM) generation and

sensor processing with performance measurement

for STM32F407 Cortex M4 microcontroller usage.

REFERENCES:

[1] “Implementing Embedded Speed Control for Brushless DC

Motors”,Yashvant Jani, Renesas Technology

America,Inc.,408-383-7716, yashvant.jani@renesas.com

[2] “Power Electronics and Variable Frequency Drives

Technology and Applications”, Edited by Bimal K. Bose,

IEEE Press, ISBN 0-7803-1084-5,1997

[3] “Motor Control Electronics” Handbook, By Richard

Valentine, McGraw-Hill, ISBN 0-07-066810-8, 1998

[4] “FIRST Course On Power Electronics and Drives”, By Ned

Mohan, MNPERE, ISBN 0-9715292-2-1, 2003

[5] “Electric Drives”, By Ned Mohan, MNPERE, ISBN 0-

9715292-5-6, 2003

[6] “Advanced Electric Drives, Analysis, Control and Modeling

using Simulink”, By Ned Mohan, MNPERE, ISBN 0-

9715292-0-5, 2001

4.2: Result: [7] “DC Motors Speed Controls Servo Systems including Optical

4.2.1: 6 Switch change-over mechanism using Encoders, The Electro-craft Engineering” Handbook by

Reliance Motion Control, Inc.

Hall Sensor Feedback: [8] “Modern Control System Theory and Application”, By

Observation: Stanley M. Shinners, Addison-Wesley, ISBN 0-201-07494-

Our calculations will be based on the following X, 1978

formulas: Where , We [9] “The Industrial Electronics” Handbook, Editor-in-Chief J.

David Irwin, CRC Press and IEEE Press, ISBN 0-8493-

consider 3600 RPM and 20-Mhz clock frequency. 8343-9, 1997

Speed (Hz) = Speed (RPM) / 60 = mechanical Hz [10] B.K. Lee and M. Ehsani, “Advanced Simulation Model for

Mechanical Hz = 60 Brushless DC Motor Drives”, 31, 841–868, 2003

Electrical Hz = pole pairs * mechanical Hz [11] “Microcontroller based control of tree phase BLDC motor”

Research Article, Journal of Engineering Research and

Electrical Hz = 120 Studies, E-ISSN-0976-7916.

Electrical time period or period = 1/electrical Hz; [12] “Modeling simulation and analysis of a permanent magnet

Period = 1/120 = 8.3333 ms = 8333.3 µs brushless dc motor drive,” presented at the IEEE IAS

Time tH between two Hall signals = electrical Hz / 6; Annual Meeting, Atlanta, 1987.

[13] R. Krishna, “Electric motor drives” (modeling, analysis and

tH = 8333.3 /6 = 1388.9 microseconds. control), low price Edition.

Counts between two Hall signals = Count Frequency [14] P.Pillay ad R.Krishnan, “Modeling, Simulation and Analysis

in MHz * time between two Hall signals of a Permanent Magnet Brushless DC motor drive part II:

Counts = 20 * 1388.9 = 27,778 counts in our The brushless DC motor drive,” IEEE Transactions on

Industry application, Vol.25, May/Apr 1989.

example.

When we fix the counting frequency at 20 MHz WEB SITE:

and the pole-pair equal to 2, the formula can be [1] “3-Phase BLDC Motor Control with Hall Sensors Using the

simplified to give Counts = 100,000,000 / RPM MC56F8013” Targeting User Guide (http://

freescale.com) 56F8013BLDCUG, Rev. 1, 11/2005

[2] “Speed Control of Brushless DC Motors-Block Commutation

5. Conclusion: with Hall Sensors” User’s

In this paper it is shown that BLDC motor is a Guide,(www.microsemi.com/soc/support/search/default.asp

good choice for various applications due to higher x).

[3] “Motor control and

efficiency, higher power density and higher speed Drive”http://www.microchip.com/pagehandler/en-

ranges compare to other motor types. BLDC motor us/technology/motorcontrol/motor-types/bldc.html

circuitry is designed and develop using 120-degree [4]http://www.mathworks.in/help/physmod/elec/examples/brushle

trapezoidal control with a sensor. In the present ss-dc-motor.html

[5]http://www.youtube.com/watch?v=5GTQI9aG8U0

project, 3- phase BLDC motor control solution using [6]http://ctms.engin.umich.edu.php=MotorSpeed§ion=Simuli

STM32F407 Cortex M4 as the motor controller, Hall nkModeling

sensors are used to detect the rotor position and [7]http://www.en.pudn.com/downloads161/doc/detail727719_en.

close the commutation loop. The main objective of htm

[8]http://eprints.uitm.edu.my/3602/1/MOHAMADFAUZI_BIN_

this project is controlling speed of BLDC motor and OMAR_07_24.pdf

displays its speed. The speed control of the DC [9]http://www.mathworks.in/help/robot-axis-control-brushless-

motors is very essential. This proposed system dc-motor-drive.html

provides a very precise and effective speed control [10] http://www.liveieeeprojects.com/bldc-motor-speed-control-

with-rpm-display

system. The user can increase or decrease the speed [11] http://karthikpatnaik.blogspot.in/bldc-speed-control-matlab-

as per the requirement and the motor will run at that simulink.html

exact speed.

ISSN: 2231-5381 http://www.ijettjournal.org Page 123

View publication stats

You might also like

- Best Transformer - O&m - Manual PDFDocument803 pagesBest Transformer - O&m - Manual PDFIulian0% (1)

- Using The MOSFET As A SwitchDocument4 pagesUsing The MOSFET As A Switchadrian665100% (2)

- Building Your Own PC Guide: Assembly Step-by-StepDocument18 pagesBuilding Your Own PC Guide: Assembly Step-by-StepWahab TemitayoNo ratings yet

- DC Circuits 1st Edition by Chad DavisDocument136 pagesDC Circuits 1st Edition by Chad DavisHippong NiswantoroNo ratings yet

- Geyssel: Elevator Spare PartsDocument352 pagesGeyssel: Elevator Spare PartsErick CL100% (1)

- Pic PWMDocument9 pagesPic PWMAditya Gannamaraju100% (1)

- PG42CB00E Rev 001Document191 pagesPG42CB00E Rev 001al100% (1)

- Control Electrical Cabinet Problems in 10 StepsDocument5 pagesControl Electrical Cabinet Problems in 10 StepsOsaid AladdasiNo ratings yet

- The Definitive Guide to How Computers Do Math: Featuring the Virtual DIY CalculatorFrom EverandThe Definitive Guide to How Computers Do Math: Featuring the Virtual DIY CalculatorNo ratings yet

- Advantages of Valve Regulated Lead Acid (VRLA) BatteriesDocument1 pageAdvantages of Valve Regulated Lead Acid (VRLA) BatteriessuhailfarhaanNo ratings yet

- EEE 471: BLDC Motor GuideDocument19 pagesEEE 471: BLDC Motor GuideKhalid MahmudNo ratings yet

- HBT BMS 31 00478 BACnet Integration Guide TC500ADocument142 pagesHBT BMS 31 00478 BACnet Integration Guide TC500ACesar BarqueroNo ratings yet

- Sensorless PMSM Vector Control With A SM Observer USING MC56F8013Document110 pagesSensorless PMSM Vector Control With A SM Observer USING MC56F8013Chiheb Ben RegayaNo ratings yet

- TM1600 ManualDocument28 pagesTM1600 ManualedgarcooNo ratings yet

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsFrom EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsNo ratings yet

- ICT Testing Electronic ComponentsDocument7 pagesICT Testing Electronic ComponentsCristine Santos100% (1)

- En CD00201961 PDFDocument39 pagesEn CD00201961 PDFIrini Fountouli - LadopoulouNo ratings yet

- Position and Speed Control of Brushless DC Motors Using Sensorless Techniques and Application TrendsDocument67 pagesPosition and Speed Control of Brushless DC Motors Using Sensorless Techniques and Application TrendsTri Wahono100% (1)

- Substation EquipmentsDocument106 pagesSubstation EquipmentsChetansharma2048100% (1)

- Tip Speed RatioDocument4 pagesTip Speed Ratiomaantom3No ratings yet

- HMI Connecting Guide PDFDocument382 pagesHMI Connecting Guide PDFRonald Borda SalinasNo ratings yet

- ABB DisconnectorDocument8 pagesABB DisconnectoridundoviNo ratings yet

- Gallagher - HBUS ModulesDocument2 pagesGallagher - HBUS ModulesNikitaNo ratings yet

- Generador MagnaplusDocument24 pagesGenerador MagnaplusLuis Sandi Rivera100% (1)

- Automatic Plant Irrigation SystemDocument32 pagesAutomatic Plant Irrigation SystemKishore Naidu75% (8)

- BLDC Motor Open Loop ControlDocument20 pagesBLDC Motor Open Loop ControlShiva SuryaNo ratings yet

- Construction and Working of Brushless DC PDFDocument12 pagesConstruction and Working of Brushless DC PDFaswardi8756No ratings yet

- Velocity and Position Control of The Burshless DC Motor.Document112 pagesVelocity and Position Control of The Burshless DC Motor.Diego MVNo ratings yet

- Modbus Gateway: Installation and Operation ManualDocument122 pagesModbus Gateway: Installation and Operation ManualNacho V' ZaletaNo ratings yet

- BACnetIP Functional Specifications (CB07A004B)Document61 pagesBACnetIP Functional Specifications (CB07A004B)JeffersonNo ratings yet

- BrushlessDocument141 pagesBrushlessalysonmicheaalaNo ratings yet

- Scilab textbook companion for digital principals and applicationsDocument217 pagesScilab textbook companion for digital principals and applicationsRadhika Agarwal50% (2)

- Design of Three Phase Inverter Fed Induction Motor Drive Using Neural Network Predictive ControlDocument5 pagesDesign of Three Phase Inverter Fed Induction Motor Drive Using Neural Network Predictive Controlesatjournals100% (1)

- Sensorless Foc of PMSM Chu YDocument42 pagesSensorless Foc of PMSM Chu Yhieuhuech1No ratings yet

- Speed Control of BLDC MotorDocument5 pagesSpeed Control of BLDC Motorgourav kakhaniNo ratings yet

- STM32 for Motor Control Applications FeaturesDocument61 pagesSTM32 for Motor Control Applications FeaturestraineeNo ratings yet

- DOMINO PPT FINAL AnkitDocument32 pagesDOMINO PPT FINAL Ankitsurbhi98No ratings yet

- Design and Development of Three Phase Permanent Magnet BrushlessDocument11 pagesDesign and Development of Three Phase Permanent Magnet BrushlessteomondoNo ratings yet

- Mo at Source PDFDocument2 pagesMo at Source PDFcavcicNo ratings yet

- MODBUS TCP and PROFINET Can Live With Each OtherDocument6 pagesMODBUS TCP and PROFINET Can Live With Each OtheranyayadhishNo ratings yet

- Brushless Sensor ConfigDocument11 pagesBrushless Sensor ConfigAlexandru TimofteNo ratings yet

- Electrical Machine Design Question Bank - As Per VTU SyllabusDocument20 pagesElectrical Machine Design Question Bank - As Per VTU SyllabusManjunathNo ratings yet

- Powering electric vehicles with dynamosDocument14 pagesPowering electric vehicles with dynamosBhaktiJadhavNo ratings yet

- Battery ChargerDocument117 pagesBattery ChargerAnup PravinNo ratings yet

- Exam 03 SolutionDocument13 pagesExam 03 Solutiondummy1957jNo ratings yet

- Exam 4 Solutions PDFDocument5 pagesExam 4 Solutions PDFdannyNo ratings yet

- Capacitor Start Induction Motor - Its Phasor Diagram Characteristic & Applications - Circuit GlobeDocument9 pagesCapacitor Start Induction Motor - Its Phasor Diagram Characteristic & Applications - Circuit Globejeet kumarNo ratings yet

- Reduction of Power MOSFET Losses in Hard-Switched ConvertersDocument2 pagesReduction of Power MOSFET Losses in Hard-Switched ConvertersWesley de PaulaNo ratings yet

- Speed Control Brushless DCDocument27 pagesSpeed Control Brushless DCstanley FNo ratings yet

- Application of Brushless DC Motor in MilitaryDocument10 pagesApplication of Brushless DC Motor in Militarymighty_heart100% (1)

- Selecting X-Rated Capacitors for Transformerless AC Power SupplyDocument8 pagesSelecting X-Rated Capacitors for Transformerless AC Power SupplyIvez StrausseNo ratings yet

- Omnidirectional Planar Dipole-Array Antenna For 2.4/5.2-Ghz Wlan Access PointsDocument4 pagesOmnidirectional Planar Dipole-Array Antenna For 2.4/5.2-Ghz Wlan Access PointsMuhammad Rizwan WaliNo ratings yet

- BACnetDocument24 pagesBACnetmdalt9180No ratings yet

- Design 1.5kVA PWM InverterDocument13 pagesDesign 1.5kVA PWM Invertershah pallav pankaj kumarNo ratings yet

- BLDCDocument4 pagesBLDCmechtex Pvt LtdNo ratings yet

- Fundamentals of Electrical Drives - G. K. Dubey PDFDocument121 pagesFundamentals of Electrical Drives - G. K. Dubey PDFAnonymous l7YZBdNo ratings yet

- R11um0146eu0100 FSP v100 PDFDocument1,444 pagesR11um0146eu0100 FSP v100 PDFChử HoàngNo ratings yet

- DBWS - Controlling DC Motors With The L298N Dual H-Bridge and An Arduino PDFDocument46 pagesDBWS - Controlling DC Motors With The L298N Dual H-Bridge and An Arduino PDFsam etcNo ratings yet

- Manual Axpert KING PYLONDocument59 pagesManual Axpert KING PYLONEllis BergmanNo ratings yet

- Advanced Speed Control Techniques of Brushless DC MotorDocument17 pagesAdvanced Speed Control Techniques of Brushless DC Motorsrinupid100% (1)

- Power Saving Street LightDocument79 pagesPower Saving Street LightEmilsonu Sam50% (2)

- Psimbook Exercises PreviewDocument28 pagesPsimbook Exercises PreviewLaura Garcia Mateo0% (1)

- Ata 24Document9 pagesAta 24Prince AbbasNo ratings yet

- UL 1564 SUN Rev 8 25 2020 ED 8 25 2022Document3 pagesUL 1564 SUN Rev 8 25 2020 ED 8 25 2022Joshua JonesNo ratings yet

- SchneiderDocument68 pagesSchneiderTu NguyenNo ratings yet

- Load Cell (UTM)Document1 pageLoad Cell (UTM)José Rubén Ramos GarzaNo ratings yet

- 2 SD 716Document1 page2 SD 716Bawantha Prasad MihirangaNo ratings yet

- BB-BC Series Service Manual - BBBC V0.0Document73 pagesBB-BC Series Service Manual - BBBC V0.0a.elwahabNo ratings yet

- Know The Major Difference Between BJT and FETDocument11 pagesKnow The Major Difference Between BJT and FETabraham kaseyaNo ratings yet

- Product Data Sheet: iPRD40r Modular Surge Arrester - 1P - 350V - With Remote TransfertDocument3 pagesProduct Data Sheet: iPRD40r Modular Surge Arrester - 1P - 350V - With Remote TransfertLeonel Jesus Pareja MorenoNo ratings yet

- Changhong Batteries CatalogueDocument22 pagesChanghong Batteries CatalogueHoracio BerniNo ratings yet

- Insulation Testing and Maintenance ProgramDocument35 pagesInsulation Testing and Maintenance ProgramRafiqul kuddusNo ratings yet

- Irtccstd 04Document13 pagesIrtccstd 04Bilal Ahmad100% (3)

- Resistance and Reactance of Copper and Aluminium CablesDocument2 pagesResistance and Reactance of Copper and Aluminium CablesTheophilus AmaraNo ratings yet

- Power Systems GroundingDocument3 pagesPower Systems GroundingSayed NagyNo ratings yet

- Surgical Light v1350dDocument114 pagesSurgical Light v1350dFélix Adilson ElíasNo ratings yet

- White Paper AVRDocument1 pageWhite Paper AVRstmeuNo ratings yet

- RMS voltage ratings and core lossesDocument1 pageRMS voltage ratings and core lossesTosikur RahmanNo ratings yet

- VC8036Document5 pagesVC8036harmlesdragonNo ratings yet

- Mid 20-25KW KTL3XDocument2 pagesMid 20-25KW KTL3XwaqasNo ratings yet

- DTS Drip Tray Sensor With Output Relay 1Document2 pagesDTS Drip Tray Sensor With Output Relay 1joNo ratings yet

- Characteristics of PN Junction Diode and Zener DiodeDocument7 pagesCharacteristics of PN Junction Diode and Zener DiodeMegha UmeshaNo ratings yet

- Lab #2 - Phase SequenceDocument6 pagesLab #2 - Phase SequenceJorge GuerreroNo ratings yet

- Week3Document11 pagesWeek3T GUNA gunaNo ratings yet

- HE Series Selectable Candela Evacuation Signals: Standard FeaturesDocument2 pagesHE Series Selectable Candela Evacuation Signals: Standard FeaturesRdb HaxorNo ratings yet

- Motor Bridge Controller: 1 Features Figure 1. PackageDocument17 pagesMotor Bridge Controller: 1 Features Figure 1. PackageNoelNo ratings yet

- 3VL CatalogueDocument6 pages3VL CatalogueKevin DucusinNo ratings yet