Professional Documents

Culture Documents

ISO 3834 Check List

Uploaded by

sheikmoinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 3834 Check List

Uploaded by

sheikmoinCopyright:

Available Formats

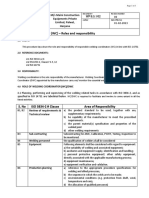

A.

Section

1. Organization chart, (copy of organization chart including Inspection supervisor and

Welding Supervisor, Designations)

2. Responsibilities: Responsibilities as referred in ISO 3824-2 for Welding supervisor and

Insp. Supervisor refer EN ISO 14731; other function may remain same as in your ISO 9001

system)

3. Welding technology qualification of the welding coordinator (supervisor) (CV,

Qualification certificate, Training Records), at least one IWE or IWT is required. It can be

subcontracted.

4. Knowledge of the welding coordinator (supervisor)(As above)

5. Further training of the welding coordinators (supervisor)(Training Calendar for the year

inclusive of any technical trainings attended like IIW training)

6. Standard department - availability of actual standards and rules (List of EN / ISO

Standards required by EN 3834-2 and 5 with system of updation)

7. Condition of workshop equipment (List of equipment and Preventative maintenance

plan)

8. Quality level of welded assembly (Required weld quality as referred in Drawing / QAP)

9. Qualification and approval of welding processes - list (List with range and copies all

approved procedure as EN 15614 series of standard & other EN standards for spot welding

etc.)

10. Production test, current process (As applicable)

11. Welding procedure specifications for manufacturing (Weld Plan, Drawing with

reference to which WPS to be referred for welding)

12. Qualification and approval of welders and welding operators - list, validity (List with

details of qualification range as per EN 287-1/ISO 9606-1 for steel, 9606-2 for

aluminum and ISO 14732 for operator qualification)

13. Safety instructions and retraining

14. NDE procedures approved as per EN standard

B. Section ISO 3834

1. Documentation of QM (QA, QC) (Supplementary Manual, Procedures, Work instructions)

2. Review of requirements and technical review (Order review form along with Technical

review check list as per EN 3834-2)

3. Sub-contracting (If any List and control)

4. Welding personnel - Welding coordination personnel / Welders and welding operators

refer point A3)

5. Inspection and testing personnel

6. Equipment - Production and testing equipment, description, maintenance,(Refer Point 7)

7. Welding and related activities

8. Production planning, welding-procedure specifications (Refer Point A11)

9. Qualification of the welding procedures (refer Point A9)

10. Welding consumables, storage and handling

(Storage procedure, and photographs of actual storage at stores)

11. Storage of parent materials (same as point 11)

12. Inspection and testing - before, during and after welding (Prepare format for inspection

covering requirements as per EN 3834-3)

13. Post-weld heat treatment (As applicable, Procedure)

14. Non-conformance and corrective actions (ISO 9001 Procedure)

15. Calibration and validation of measuring, inspection and testing equipment (ISO 9001

Procedure , list of measuring and monitoring equipment with due date)

16. Identification, marking (throughout manufacturing) and traceability, (Procedure, WI)

17. Quality records (List, retention period to be addressed in ISO 9001 procedure)

Note: The above requirement shall meet 80 % for your EN 15085-2 CL1 audit, additional

things are

1) In house ISO 9712 level II certified person for VT & DPT, for RT it can be subcontracted

2) Drawing shall clearly define the weld performance class for each welded joints and also

certification level

3) The Inspection shall be done w.r.t the weld performance classification.

You might also like

- ISO 3834-2 Compliance Check List PDFDocument1 pageISO 3834-2 Compliance Check List PDFMichael TayactacNo ratings yet

- Iso 3834 GuidelinesDocument3 pagesIso 3834 Guidelinesshabashakkim0% (1)

- Iso 3834Document52 pagesIso 3834Akshay Kumar100% (1)

- EN 1090 Checklist - Industries > Metal Fabrication > EN 1090 ComplianceDocument3 pagesEN 1090 Checklist - Industries > Metal Fabrication > EN 1090 Compliance26110100% (1)

- ISO 3834 welding certification levelsDocument9 pagesISO 3834 welding certification levelsvilukNo ratings yet

- Quest Audit 3834Document38 pagesQuest Audit 3834g33k59100% (2)

- Introduction to ISO 3834Document54 pagesIntroduction to ISO 3834amit50% (2)

- Sample of Welding Quality ManualDocument5 pagesSample of Welding Quality ManualwentropremNo ratings yet

- CE Marking GuideDocument26 pagesCE Marking GuideshaggerukNo ratings yet

- WP-8.5.1-02 Role of RWCDocument3 pagesWP-8.5.1-02 Role of RWCNitin SharmaNo ratings yet

- ISO 3834 - Checklist-2Document6 pagesISO 3834 - Checklist-2Abhishek Anand83% (6)

- EN ISO 3834-2 (2021) (E) CodifiedDocument8 pagesEN ISO 3834-2 (2021) (E) CodifiedJózsef Hegedűs100% (1)

- Welding Coordination-Tasks & ResponsibilitiesDocument14 pagesWelding Coordination-Tasks & Responsibilitieskumaraswamy.kNo ratings yet

- ISO TC 176 - N544 Guidance On Process ApproachDocument11 pagesISO TC 176 - N544 Guidance On Process Approachghafoorian_khoshgovar1488100% (1)

- ISO 3834 Welding Certification GuideDocument11 pagesISO 3834 Welding Certification GuideWeld Bro Sandeep100% (1)

- ISO 3834 Evaluation TestDocument2 pagesISO 3834 Evaluation TestSatish KeskarNo ratings yet

- Welding Process Work InstructionDocument6 pagesWelding Process Work InstructionmkcsekarNo ratings yet

- BS en Iso 3834-3 - 2021Document16 pagesBS en Iso 3834-3 - 2021jesonelite100% (2)

- ISO 3834 InterpretationDocument14 pagesISO 3834 InterpretationMako SkyNo ratings yet

- Requirements ISO 3834Document76 pagesRequirements ISO 3834mdasifkhan2013100% (7)

- Review of RequirementsDocument1 pageReview of RequirementsSatish KeskarNo ratings yet

- Need of ISO 3834 To Welding Fabrication IndustryDocument4 pagesNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- Welding Coordination Tasks ISO 14731Document1 pageWelding Coordination Tasks ISO 14731Ion Plesa100% (1)

- ISO 3834 Awareness Program OutlineDocument1 pageISO 3834 Awareness Program OutlineSatish KeskarNo ratings yet

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- Technical Review For ISO 3834Document1 pageTechnical Review For ISO 3834Satish Keskar100% (3)

- ISO 3834 - ChecklistDocument26 pagesISO 3834 - ChecklistAbhishek Anand83% (6)

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- Iso 3834 2 2021Document10 pagesIso 3834 2 2021Tuan Pham Anh50% (2)

- Welding CoordinationDocument3 pagesWelding CoordinationIon PlesaNo ratings yet

- En Iso 10675-1 2013 - RTDocument22 pagesEn Iso 10675-1 2013 - RTMohamed ZahranNo ratings yet

- Control Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFDocument11 pagesControl Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFNenad NedeljkovicNo ratings yet

- Welding Coordination Activities and ResponsibilitiesDocument7 pagesWelding Coordination Activities and ResponsibilitieseliiiiiiNo ratings yet

- Iso 3834-1-2021.09 Part 1 Criteria For The Selection of The Appropriate Level of Quality Requirements API Asme PublicationDocument14 pagesIso 3834-1-2021.09 Part 1 Criteria For The Selection of The Appropriate Level of Quality Requirements API Asme PublicationJestin Daniel James100% (3)

- Iso 3834Document2 pagesIso 3834Jaay Vel0% (1)

- FPC ManualDocument17 pagesFPC ManualCE_Wizard100% (2)

- I S Eniso3834-2-2021Document28 pagesI S Eniso3834-2-2021Ngoc Bang67% (3)

- WPQR Sample FormDocument1 pageWPQR Sample FormshwayeNo ratings yet

- Template For List of DocumentsDocument1 pageTemplate For List of DocumentsSatish KeskarNo ratings yet

- Assessment Procedure Welding Report FormDocument23 pagesAssessment Procedure Welding Report Formssierro100% (1)

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Implement ISO 3834 welding standardsDocument34 pagesImplement ISO 3834 welding standardschowhkNo ratings yet

- Filler Materials TestingDocument34 pagesFiller Materials TestingSunilNo ratings yet

- Welding Coordinator Tasks and ResponsibilitiesDocument3 pagesWelding Coordinator Tasks and ResponsibilitiesShaun Holder100% (4)

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- Duties of The RWCDocument3 pagesDuties of The RWCbluegalago100% (1)

- FPC ManualDocument15 pagesFPC ManualDavid SeeNo ratings yet

- Written PracticeDocument27 pagesWritten PracticeSefa KasapogluNo ratings yet

- FPC Manual PreviewDocument5 pagesFPC Manual PreviewIbrahim Levent AkkoyunluNo ratings yet

- Part 01 - Review of EN ISO 9606-1Document26 pagesPart 01 - Review of EN ISO 9606-1Turbo Snail RNo ratings yet

- ISO 3834 IntroDocument84 pagesISO 3834 IntroUjjawal AgrawalNo ratings yet

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- Quality StandardsDocument18 pagesQuality StandardsramausNo ratings yet

- ISO 3834 by SelvaDocument83 pagesISO 3834 by Selvaaravindan100% (11)

- IWE4-1-Introduksjon Kvalitetssystem, Ny EngelskDocument34 pagesIWE4-1-Introduksjon Kvalitetssystem, Ny EngelskIrmantas ŠakysNo ratings yet

- ASME Certification.Document1 pageASME Certification.Hoque AnamulNo ratings yet

- QP-Cutting, Crimping and Connector Assembly OperatorDocument19 pagesQP-Cutting, Crimping and Connector Assembly OperatorsheikmoinNo ratings yet

- Director's Profile (Trainer)Document5 pagesDirector's Profile (Trainer)sheikmoinNo ratings yet

- AWS Code Clinic D1 1 QuestionsDocument14 pagesAWS Code Clinic D1 1 QuestionsNian S KoNo ratings yet

- Student QuestionnaireDocument2 pagesStudent QuestionnaireLakshmi PrasannaNo ratings yet

- MagnetDocument1 pageMagnetsheikmoinNo ratings yet

- Radiography 2 ProcedureDocument9 pagesRadiography 2 ProceduresheikmoinNo ratings yet

- ASME MTC Types & Verification GuideDocument47 pagesASME MTC Types & Verification GuideSULTAN100% (1)

- Api 578-Mock 1 - KeyDocument28 pagesApi 578-Mock 1 - KeysheikmoinNo ratings yet

- Bmoned 2Document2 pagesBmoned 2sheikmoinNo ratings yet

- Bmoned 2Document2 pagesBmoned 2sheikmoinNo ratings yet

- Global Anticorruption Policy PDFDocument3 pagesGlobal Anticorruption Policy PDFsheikmoinNo ratings yet

- List of Document To Be Submitted To Germany For ISO 3834Document1 pageList of Document To Be Submitted To Germany For ISO 3834sheikmoinNo ratings yet

- Brief ProfileDocument4 pagesBrief ProfilesheikmoinNo ratings yet

- Tube-Tubesheet Mockup Test ProcedureDocument2 pagesTube-Tubesheet Mockup Test Procedurefizanlamin100% (9)

- Api 570 - 571 - Mock 1Document103 pagesApi 570 - 571 - Mock 1sheikmoin100% (5)

- Welders Continuity Log: Name Welder ID PMI Job # Gtaw SmawDocument3 pagesWelders Continuity Log: Name Welder ID PMI Job # Gtaw SmawLalit Bom MallaNo ratings yet

- Bmoned 2Document2 pagesBmoned 2sheikmoinNo ratings yet

- API 578 Mock Guide Quality AssuranceDocument27 pagesAPI 578 Mock Guide Quality Assurancesheikmoin100% (1)

- CV Trainer SKMDocument5 pagesCV Trainer SKMsheikmoinNo ratings yet

- IQRA Business PresentationDocument27 pagesIQRA Business PresentationsheikmoinNo ratings yet

- IQRA Business PresentationDocument27 pagesIQRA Business PresentationsheikmoinNo ratings yet

- Astm B576Document5 pagesAstm B576iyamNo ratings yet

- AL 4104 BAlSi-11 TDSDocument2 pagesAL 4104 BAlSi-11 TDSsheikmoin100% (1)

- IzsDocument3 pagesIzssheikmoinNo ratings yet

- CalculationsDocument5 pagesCalculationssheikmoinNo ratings yet

- Polysiloxanes: Norman R. Mowrer Ameron International Performance Coatings and FinishesDocument11 pagesPolysiloxanes: Norman R. Mowrer Ameron International Performance Coatings and FinishessheikmoinNo ratings yet

- MACE Gamma-Ray Telescope - A Status Update: Ramesh KoulDocument5 pagesMACE Gamma-Ray Telescope - A Status Update: Ramesh KoulsheikmoinNo ratings yet

- Smaw Is The Manual Metal Arc Welding ProcessDocument1 pageSmaw Is The Manual Metal Arc Welding ProcesssheikmoinNo ratings yet

- Smaw Is The Manual Metal Arc Welding ProcessDocument1 pageSmaw Is The Manual Metal Arc Welding ProcesssheikmoinNo ratings yet

- Resort PlanDocument15 pagesResort PlanVenu S100% (2)

- Mumbai Dabbawala Case Study TQM AnalysisDocument9 pagesMumbai Dabbawala Case Study TQM AnalysisananyaNo ratings yet

- Rocket Internet Fact SheetDocument4 pagesRocket Internet Fact SheetViolinAceOfSpadesNo ratings yet

- Full Download Advanced Accounting 9th Edition Hoyle Solutions ManualDocument35 pagesFull Download Advanced Accounting 9th Edition Hoyle Solutions Manualjacksongubmor100% (25)

- D FSC ProgramDocument18 pagesD FSC ProgramShirley FarraceNo ratings yet

- Hansen Aise Im Ch02Document39 pagesHansen Aise Im Ch02FirlanaSubekti100% (1)

- Portfolio SOFTWARE ENGINEERINGDocument8 pagesPortfolio SOFTWARE ENGINEERINGKaheem Koolkidz WhittinghamNo ratings yet

- Kaizen CostingDocument21 pagesKaizen CostingAustin OliverNo ratings yet

- Level of Nigerian Cadets' Satisfaction On The Services of Lyceum International Maritime AcademyDocument7 pagesLevel of Nigerian Cadets' Satisfaction On The Services of Lyceum International Maritime AcademyapjeasNo ratings yet

- Light After DarknessDocument47 pagesLight After DarknessAvinashmachadoNo ratings yet

- Contract Law Quiz QuestionsDocument4 pagesContract Law Quiz QuestionsChristina KaukareNo ratings yet

- UIC NursingDocument98 pagesUIC NursinglolaNo ratings yet

- Deed of Conditional Sale MarizDocument6 pagesDeed of Conditional Sale MarizRochen Shaira DargantesNo ratings yet

- Haldiram - Mktg. MixDocument3 pagesHaldiram - Mktg. MixManjusha100% (2)

- Rudiments of Gann TheoryDocument5 pagesRudiments of Gann Theorydilbert618No ratings yet

- Entry-Level Programmer ResumeDocument2 pagesEntry-Level Programmer ResumemohsinNo ratings yet

- PUMA V IACDocument9 pagesPUMA V IACChristopher Joselle MolatoNo ratings yet

- Rujukan Group FinalDocument4 pagesRujukan Group FinalNazliana ZakariaNo ratings yet

- Modeling and Analysis of Stochastic Systems 3rd Kulkarni Solution ManualDocument8 pagesModeling and Analysis of Stochastic Systems 3rd Kulkarni Solution ManualJamesAndersongoki94% (31)

- CFO or COO or Chief Financial Officer or Chief Operating OfficerDocument3 pagesCFO or COO or Chief Financial Officer or Chief Operating Officerapi-77544720No ratings yet

- 313738Document90 pages313738louis04No ratings yet

- Management Prerogatives CompilationDocument21 pagesManagement Prerogatives CompilationRap SantosNo ratings yet

- Sandeep Garg Microeconomics Class 12 Solutions Chapter 1Document3 pagesSandeep Garg Microeconomics Class 12 Solutions Chapter 1Avinash KumarNo ratings yet

- 2 Growth Trends in National IncomeDocument29 pages2 Growth Trends in National IncomeDheeraj Budhiraja0% (1)

- Kondal TicketDocument2 pagesKondal TicketPraveen Rs SNo ratings yet

- Coconut Oil Project with 46% ROIDocument6 pagesCoconut Oil Project with 46% ROIhunky11100% (1)

- Amazon vs Alibaba - Comparing the eCommerce GiantsDocument11 pagesAmazon vs Alibaba - Comparing the eCommerce Giantshaseeb ahmad100% (2)

- Chap 2 Tanner - The Sales Function & Multi Sales Channels 280516Document17 pagesChap 2 Tanner - The Sales Function & Multi Sales Channels 280516Shahzain RafiqNo ratings yet

- Employee Costs in Software IndustryDocument7 pagesEmployee Costs in Software Industryapi-3702531No ratings yet

- B555 RoadmapDocument7 pagesB555 Roadmapvico1982No ratings yet