Professional Documents

Culture Documents

J14 - The Effects of ZrO2 Nanopowders On Compressive Damage and Pore Structure Properties of Concrete Specimens PDF

Uploaded by

KarnalPreethOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J14 - The Effects of ZrO2 Nanopowders On Compressive Damage and Pore Structure Properties of Concrete Specimens PDF

Uploaded by

KarnalPreethCopyright:

Available Formats

Journal of American Science, 2012;8(3) Farzad Soleymani

The effects of ZrO2 nanopowders on compressive damage and pore structure properties of concrete specimens

Farzad Soleymani

Department of Metallurgical Engineering, Payame Noor University, P.O. 19395-4697, Tehran, Iran.

E-mail: farzad.soleymani52@yahoo.com

Abstract: Flexural of concrete containing ZrO2 nanoparticles which were cured in saturated limewater have been optimized.

ZrO2 nanoparticles with partial replacement of Portland cement by 0.5, 1.0, 1.5 and 2.0 weight percent have been used as

nano-fillers. The specimens were cured in water and saturated limewater for 7, 28 and 90 days after casting and then their

strength was evaluated by flexural strength test. The results showed that replacement of Portland cement with ZrO2

nanoparticles up to 1.0 weight percent for the specimens cured in water and 2.0% for the specimens cured in saturated

limewater produces concrete with the best strength. It has been obtained that curing the specimens in saturated limewater for

28 days and then in water until 90 days, produces more strengthened concrete than those cured only in saturated limewater

for 90 days. Excess Ca(OH)2 crystals which forms after 28 days, when the specimens cured in limewater, reduces the effect

of strengthening gels which form until the 90 days hence reduces the mechanical properties of the specimens. On the other

hand, curing the specimens in water after 28 days produces more strengthening gel results in a concrete with higher strength.

The pore structure of different mixtures was studied. The addition of nanoparticles improves the pore structure of concretes,

the refined extent of pore structure increase with decreasing nanoparticles’ content. The pore structure of concretes which

were cured in saturated limewater is better than that of concretes cured in water.

[Farzad Soleymani. The effects of ZrO2 nanopowders on compressive damage and pore structure properties of

concrete specimens. Journal of American Science 2012;8(3):738-744]. (ISSN: 1545-1003). http://www.americanscience.org. 99

Key words: ZrO2 nanoparticles; flexural strength; optimized properties; pore structure; concrete.

There are few reports on incorporation of pastes has been considered and it has been shown that the

nanoparticles in cement-based composites. Li et al. [1] flowability of the cementitious composite decreases by

investigated the properties of cement mortars blended with increasing the nanoparticle amount. Lin and Tsai [7]

nanoparticles to explore their super mechanical and smart investigated the influences of nano-materials on the

(temperature and strain sensing) potentials. Also useful microstructures of sludge ash cement paste. They noticed

applications of nano-SiO2 are addressed by the Fuji that the amount of crystallization in the hydrates increased

Chimera Research Institute (2002). However, until now, with the increased quantities of nano-material added.

research performed over the years has been mainly aimed Furthermore, denser crystallizations, smaller pore sizes,

at achieving high mechanical performance with cement and a decreased number of pores were observed with the

replacement materials in micro level. Several researchers addition of nano-material results in decreasing water

have demonstrated that the finer the SiO2 particle sizes in permeability.

micron level, the higher the compressive strength [2,3]. There are few works about incorporating other

But there are few works on the effects of ultra fine and nanoparticles in cementitious composites. For example,

nano-size particles on cementitious composite’s properties. For example, Li et al. [9, 10] have investigated the

Lu and Young [3] achieved high strengths on compressive strength and aberration resistance of cement

compressed samples which contain SiO2 nanoparticles. paste composites incorporating nano-Fe2O3 and nano-TiO2

Richard and Cheyrezy [4] developed Reactive Power particles, respectively. Incorporation of zinc-iron oxide

Concretes (RPCs) by SiO2 nano-fillers. The development nanoparticles as a replacement of cement have been

of an ultrahigh strength cementitious composite was made investigated by Flores-Velez and Dominguez [11].

possible by the application of DSP (Densified System The other nanoparticles (such as ZrO2 nanoparticles

containing homogeneously arranged ultra-fine Particles) in this work) have rarely investigated and some of

with super plasticizer and silica fume content [5]. researchers do not agree that the other nanoparticles could

Kuo et al. [6] investigated the properties of be pozzolans. It seems that several works are needed to

waterworks sludge ash cement paste incorporating SiO2 introduce these new materials as cement replacement.

nanoparticles. In their work, the flowability of the cement

Table 1. Chemical and physical properties of Portland cement (Wt. %)

Material SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O Loss on ignition

Cement 21.89 5.3 3.34 53.27 6.45 3.67 0.18 0.98 3.21

Specific gravity: 1.7 g/cm3

http://www.americanscience.org 738 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

Table 2. The properties of nano-ZrO2

Diameter (nm) Surface Volume ratio (m2/g) Density (g/cm3) Purity (%)

15 ± 3 160 ± 12 < 0.14 >99.9

Table 3. Mixture proportion of nano-ZrO2 particles blended concretes

Sample designation nano-ZrO2 particles Quantities (kg/m3)

Cement ZrO2 nanoparticles

C0 (control) 0 450 0

N1 0.5 447.75 2.25

N2 1.0 445.50 4.50

N3 1.5 443.25 6.75

N4 2.0 441.00 9.00

Water to binder [cement + nano-ZrO2] ratio of 0.40, sand 492 kg/m3, and aggregate 1148 kg/m3

Previously, a series of works [12-19] has been laboratory trials. Series C0 mixtures were prepared as

conducted on cementitious composites containing different control specimens. The control mixtures were made of

nanoparticles evaluating the mechanical properties of the natural aggregates, cement and water. Series N were

composites. In this work, the influence of nano-ZrO2 on prepared with different contents of nano-ZrO2 particles

flexural strength of binary blended cementitious composite with average particle size of 15 nm. The mixtures were

cured in water and saturated limewater for different ages prepared with the cement replacement of 0.5%, 1.0%,

has been investigated. The optimum replacement level of 1.5% and 2.0% by weight. The water to binder ratio for all

ZrO2 nanoparticles has been determined in different curing mixtures was set at 0.40 [21]. The aggregates for the

media has been obtained and the method for achieving the mixtures consisted of a combination of crushed basalt and

optimum strength using a combination of two curing of fine sand, with the sand percentage of 30% by weight.

media has been discussed. The binder content of all mixtures was 450 kg/m3. The

proportions of the mixtures are presented in Table 3.

2. Materials and Methods Series N mixtures were prepared by mixing the

Ordinary Portland Cement (OPC) obtained from course aggregates, fine aggregates and powder materials

Holcim Cement Manufacturing Company of Malaysia (cement and nano-ZrO2 particles) in a laboratory concrete

conforming to ASTM C150 [20] standard was used as drum mixer. The powder material in the series C0 mixtures

received. The chemical and physical properties of the was only cement. They were mixed in dry condition for

cement are shown in Table 1. Also, the distribution pattern two minutes, and for another three minutes after adding the

of cement obtained from BET method has been illustrated water. Cubes with 200 mm × 50 mm × 50 mm edges for

in Fig. 1. flexural strength tests were cast and compacted in two

layers on a vibrating table, where each layer was vibrated

120

for 10 s [22]. The moulds were covered with polyethylene

100

sheets and moistened for 24 h. Then the specimens were

Percentage finer than

demoulded and cured in water (N-W series) and saturated

80

limewater (N-LW series) at a temperature of 20o C prior to

60

test days. The strength tests of the concrete samples were

40

determined at 7, 28 and 90 days. A series of the specimens

20 were cured in saturated limewater for 28 days and then

0 cured in water until 90 days (N-LW-W series) after casting

0 20 40 60 80 100 120 140 160

and then were tested.

Particle size (μm)

Flexural test were done in accordance to the ASTM

Fig. 1. Illustration of cement particles’ distribution. C293 [23] Standard. Again, flexural tests were carried out

on triplicate specimens and average flexural strength

Nano–ZrO2 with average particle size of 15 nm values were obtained.

prepared from Suzhou Fuer Import & Export Trade Co., There are several methods generally used to measure

Ltd was used as received. The properties of nano-ZrO2 the pore structure, such as optics method, mercury

particles are shown in Table 2. intrusion porosimetry (MIP), helium flow and gas

Locally available natural sand with particles smaller adsorption [24]. MIP technique is extensively used to

than 0.5 mm and fineness modulus of 2.25 and specific characterize the pore structure in porous material as a

gravity of 2.58 g/cm3 was used as fine aggregate. Crushed result of its simplicity, quickness and wide measuring

basalt stored in the laboratory with maximum size of 15 range of pore diameter [24, 25]. MIP provides information

mm and specific gravity of 2.96 g/cm³ was used as coarse about the connectivity of pores [24]. In this study, the pore

aggregate. structure of concrete is evaluated by using MIP.

Two series of mixtures were prepared in the To prepare the samples for MIP measurement, the

http://www.americanscience.org 739 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

concrete specimens after 28 days of curing are first broken particle packing density of the blended cement, directing to

into smaller pieces, and then the cement paste fragments a reduced volume of larger pores in the cement paste.

selected from the center of prisms are used to measure Table 4 also shows the flexural strength of C0-LW

pore structure. The samples are immersed in acetone to and N-LW series. The results show that the replacement of

stop hydration as fast as possible. Before mercury intrusion cement by ZrO2 nanoparticles up to 2.0 Wt% (N4-LW) in

test, the samples are dried in an oven at about 110°C until N-LW series produces concrete with high strength with

constant weight to remove moisture in the pores. respect to N-LW concrete. By comparison the flexural

MIP is based on the assumption that the non-wetting strength results of C0-W and C0-LW series, it shows that

liquid mercury (the contact angle between mercury and after 7, 28 and 90 days of curing the concrete in the

solid is greater than 90o) will only intrude in the pores of saturated limewater, the flexural strength of the C0-LW

porous material under pressure [24, 25]. Each pore size is series is smaller than the corresponding strength of C0-W

quantitatively determined from the relationship between series. This may be due to more formation of crystalline

the volume of intruded mercury and the applied pressure Ca(OH)2 in the presence of limewater which reduces the

[25]. The relationship between the pore diameter and flexural strength in C0-LW series with respect to C0-W

applied pressure is generally described by Washburn series. On the other hand, the flexural strength of the N-

equation as follows [24, 25]: LW series is more than those of N-W series. Lime reacts

D 4 cos / P (1) with water and produces Ca(OH)2 which needs to form

where, D is the pore diameter (nm), γ is the surface strengthening gel. When ZrO2 nanoparticles react with

tension of mercury (dyne/cm), θ is the contact angle Ca(OH)2 produced from saturated limewater, the content

between mercury and solid (o) and P is the applied of strengthening gel is increased because of high free

pressure (MPa). energy of nanoparticles which reduces significantly when

The test apparatus used for pore structure reacts by Ca(OH)2. The flexural strength of N-W and N-

measurement is AutoPore III mercury porosimeter. LW series should be compared from two viewpoints. The

Mercury density is 13.5335 g/ml. The surface tension of first viewpoint is that the flexural strength of N-LW series

mercury is taken as 485 dynes/cm, and the contact angle increases by partial replacement of cement with ZrO2

selected is 130o. The maximum measuring pressure nanoparticles up to 2.0 wt% (N4-LW) while for N-W

applied is 200 MPa (30000 psi), which means that the series it increases by partial replacement of cement with

smallest pore diameter that can be measured reaches about ZrO2 nanoparticles up to 1.0 wt% (N2-W) and then

6 nm (on the assumption that all pores have cylindrical decreases. Once more this confirm the more strengthening

shape). gel formation in the presence of saturated limewater in

which the quantity of nano-ZrO2 particles (pozzolan)

3. Results and discussion present in the mix is close to the amount required to

3.1. Flexural strength combine with the liberated lime during the process of

The flexural strength results of series C0-W and N-W hydration thus leading to lesser silica leaching out with

mixtures are shown in Table 4. Comparison of the results respect to the specimens cured in water. Second viewpoint

from the 7, 28 and 90 days samples shows that the flexural is that the difference between flexural strengths of the N-

strength increases with nano-ZrO2 particles up to 1.0% W and N-LW series after 28 days of curing is relatively

replacement (N2-W) and then it decreases, although the high while this difference in flexural strength after 90 days

results of 2.0% replacement (N4-W) is still higher than of curing is not high. This may be due to formation of

those of the plain cement concrete (C0-W). It was shown crystalline Ca(OH)2 in N-LW series after the 28 day causes

that the use of 2.0% nano-ZrO2 particles in N-W series reduction in flexural strength. In the other words, curing of

decreases the flexural strength to a value which is near to the ZrO2 nanoparticles blended concrete in saturated

the control concrete. This may be due to the fact that the limewater after 28 days is completely suitable to achieve

quantity of nano-ZrO2 particles (pozzolan) present in the high strength especially with high weight percent of

mix is higher than the amount required to combine with nanoparticles.

the liberated lime during the process of hydration thus

leading to excess silica leaching out and causing a 3.2. Pore structure of concrete

deficiency in strength as it replaces part of the The pore structure of concrete is the general

cementitious material but does not contribute to strength embodiment of porosity, pore size distribution, pore scale

[26]. Also, it may be due to the defects generated in and pore geometry. The test results of MIP in this study

dispersion of nanoparticles that causes weak zones. The include the pore structure parameters such as total specific

high enhancement of flexural strength in the N series pore volume, most probable pore diameter, pore size

blended concrete are due to the rapid consuming of distribution, porosity, average diameter, and median

Ca(OH)2 which was formed during hydration of Portland diameter (volume).

cement specially at early ages related to the high reactivity In terms of the different effect of pore size on

of nano-ZrO2 particles. As a consequence, the hydration of concrete performance, the pore in concrete is classified as

cement is accelerated and larger volumes of reaction harmless pore (<20 nm), few-harm pore (20~50 nm),

products are formed. Also nano-ZrO2 particles recover the harmful pore (50~200 nm) and multi-harm pore (>200 nm)

http://www.americanscience.org 740 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

[27]. In order to analyze and compare conveniently, the according to this sort method in this work.

pore structure of concrete is divided into four ranges

Table 4. Flexural strength of nano-ZrO2 particle blended cement mortars

Flexural strength (MPa)

Sample designation nano-ZrO2 particle (%) 7 days 28 days 90 days

C0-W (control) 0 4.2 4.4 4.7

N1-W 0.5 4.7 5.0 5.2

N2-W 1.0 5.2 5.5 5.8

N3-W 1.5 4.9 5.3 5.6

N4-W 2.0 4.5 4.7 4.9

C0-LW (control) 0 4 4.1 4.2

N1-LW 0.5 5.0 5.6 5.7

N2-LW 1.0 5.7 6.1 6.2

N3-LW 1.5 6.0 6.4 6.4

N4-LW 2.0 6.5 6.8 6.9

C0-LW-W (control) 0 4 4.1 4.3

N1-LW-W 0.5 5.0 5.6 6.0

N2-LW-W 1.0 5.7 6.1 6.5

N3-LW-W 1.5 6.0 6.4 7.1

N4-LW-W 2.0 6.5 6.8 7.6

Water to binder [cement + nano-ZrO2] ratio of 0.40

W denotes the specimens cured in water and LW denotes to those cured in saturated limewater

Table 5. Total specific pore volumes and most probable pore diameters of concretes.

Mixture Total specific pore volume Most probable pore diameter

type Value (mL/g) Reduced extent (%) Value (mL/g) Reduced extent (%)

C0-W (control) 0.0481 0 42 0

N1-W 0.0446 +7.12 34 +19.05

N2-W 0.0451 +6.18 35 +16.67

N3-W 0.0455 +5.24 36 +14.29

N4-W 0.0460 +4.31 39 +7.14

C0-LW (control) 0.0466 0 40 0

N1-LW 0.0426 +8.69 30 +25

N2-LW 0.0431 +7.53 31 +22.5

N3-LW 0.0437 +6.18 34 +15

N4-LW 0.0442 +5.21 36 +10

Water to binder [cement + nano-ZrO2] ratio of 0.40

W denotes the specimens cured in water and LW denotes to those cured in saturated limewater

Table 6. Prosities, average diameters and median diameters (volume) of concretes.

Mixture Prosity Average diameter Median diameter (volume)

type Value Reduced Value Reduced Value Reduced extent

(%) extent (%) (nm) extent (%) (nm) (%)

C0-W (control) 9.99 0 37.53 0 51.4 0

N1-W 9.01 +8.84 31.9 +13.60 42.5 +15.60

N2-W 9.30 +6.24 34.0 +8.42 44.8 +11.51

N3-W 9.46 +4.78 35.6 +4.75 47.9 +6.15

N4-W 9.56 +3.89 37.1 +1.08 50.4 +1.73

C0-LW (control) 9.66 0 34.2 0 48.7 0

N1-LW 8.20 +13.59 30.1 +10.89 40.1 +15.97

N2-LW 8.42 +11.49 32.3 +4.97 42.4 +11.65

N3-LW 8.70 +8.89 33.0 +3.08 44.3 +8.15

N4-LW 8.90 +7.046 35.4 -3.08 47.9 +1.50

Water to binder [cement + nano-ZrO2] ratio of 0.40

W denotes the specimens cured in water and LW denotes to those cured in saturated limewater

http://www.americanscience.org 741 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

Table 7. Pore size distribution of concretes

Mixture Pore size distribution (mL/g(%)) Total

type Harmless Few-harm pores Harmful Multi-harm specific

pores (<20 (20~50 nm) pores pores (>200 pore

nm) (50~200 nm) nm) volume

(mL/g)

C0-W

(control) 0.0065 0.0147 0.0169 0.0099 0.0481

N1-W 0.0066 0.0166 0.0141 0.0076 0.0446

N2-W 0.0067 0.0161 0.0148 0.0080 0.0451

N3-W 0.0068 0.0156 0.0154 0.0085 0.0455

N4-W 0.0068 0.0151 0.0158 0.0089 0.0460

C0-LW

(control) 0.0067 0.0157 0.0148 0.0091 0.0466

N1-LW 0.0069 0.0175 0.0122 0.0064 0.0426

N2-LW 0.0069 0.0170 0.0128 0.0068 0.0431

N3-LW 0.0069 0.0166 0.0140 0.0071 0.0437

N4-LW 0.0070 0.0160 0.0142 0.0075 0.0442

Water to binder [cement + nano-ZrO2] ratio of 0.40

W denotes the specimens cured in water and LW denotes to those cured in saturated limewater

3.2.1 Total specific pore volume and most probable LW<N2-LW<N1-LW, and the similar results can be

pore diameter of concrete observed for the concretes containing nano-ZrO2 which

Table 5 shows that with the addition of nanoparticles, were cured in water; i.e. N4-W<N3-W<N2-W<N1-W.

the total specific pore volumes of concretes is decreased, The harmless and few-harm pores in N1-Lw and N1-W

and the most probable pore diameters of concretes shift to series increase by the largest extent, while its harmful and

smaller pores and fall in the range of few-harm pore, multi-harm pores decrease by the largest extent, which

which indicates that the addition of nanoparticles refines indicates that the pore structure of N1-Lw and N1-W is

the pore structure of concretes. most significantly improved. With increasing of

The effectiveness of nano-ZrO2 in reducing the total nanoparticles’ content, the enhanced extent of harmless

specific pore volumes and most probable pore diameters of and few-harm pores and the reduced extent of harmful and

concretes increases in the order: N4-LW<N3-LW<N2- multi-harm pores in concretes are all decreased, and the

LW<N1-LW, and the similar results can be observed for improvement on the pore structure of concretes is

the concretes containing nano-ZrO2 which were cured in weakening.

water; i.e. N4-W<N3-W<N2-W<N1-W. The mechanism that the nanoparticles improve the

With increasing content of nanoparticles, the reduced pore structure of concrete can be interpreted as follows.

extent of total specific pore volume and most probable Supposed that nanoparticles are uniformly dispersed in

pore diameter decreases, and the refinement on the pore concrete and each particle is contained in a cube pattern,

structure of concretes is weakening. the distance between nanoparticles can be determined.

Table 6 gives the porosities, average diameters and After hydration begins, hydrate products diffuse and

median diameters (volume) of various concretes. The envelop nanoparticles as kernel. If the content of

regularity of porosity is similar to that of total specific pore nanoparticles and the distance between them are

volume. The regularity of average diameter and median appropriate, the crystallization will be controlled to be a

diameter (volume) is similar to that of most probable pore suitable state through restricting the growth of Ca(OH)2

diameter. Therefore, it is no longer necessary to analyze crystal by nanoparticles. Moreover, the nanoparticles

one by one herein. located in cement paste as kernel can further promote

cement hydration due to their high activity. This makes the

3.2.2 Pore size distribution of concrete cement matrix more homogeneous and compact.

The pore size distribution of concretes is shown in Consequently, the pore structure of concrete is improved

Table 7. Fig. 2 shows the percent of specific pore volume evidently such as the concrete containing nano-ZrO2 in the

of various grade pore size accounting for total specific amount of 1% by weight of binder.

pore volume. It can be seen that by the addition of nano- With increasing content of nanoparticles, the

particles, the amounts of harmless and few-harm pores in improvement on the pore structure of concrete is

concretes increase, and the amounts of harmful and multi- weakening. This can be attributed to that the distance

harm pores decrease, which shows that the density of between nanoparticles decreases with increasing content of

concretes is increased and the pore structure is improved. nanoparticles, and Ca(OH)2 crystal cannot grow up enough

The effectiveness of nano-ZrO2 in improving the pore due to limited space and the crystal quantity is decreased,

structure of concretes increases in the order: N4-LW<N3- which leads to the ratio of crystal to strengthening gel

http://www.americanscience.org 742 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

small and the shrinkage and creep of cement matrix 2.0 wt% cement with ZrO2 nanoparticles which was cured

increased [28], thus the pore structure of cement matrix is for 28 days in saturated limewater and then in water until

looser relatively. 90 days.

On the whole, the addition of nanoparticles improves

the pore structure of concrete. On the one hand, References

nanoparticles can act as a filler to enhance the density of [1] Li H, Xiao HG, Yuan J, Ou J. Microstructure of cement

concrete, which leads to the porosity of concrete reduced mortar with nano-particles. Composites Part B:

significantly. On the other hand, nanoparticles can not only Engineering 2003; 35(March).

act as an activator to accelerate cement hydration due to [2] Erdogdu K, Tucker P. E.ects of .y ash particle size on

their high activity, but also act as a kernel in cement paste strength of Portland cement fly ash mortars. Cem

which makes the size of Ca(OH)2 crystal smaller and the Concr Res 1998;28:1217–22.

tropism more stochastic. [3] Lee SH, Sakai E, Diamond M, Bang WK.

Characterization of fly ash directly from electrostatic

45

precipitator. Cem Concr Res 1999;29:1791–7.

40

[4] Lu P, Young JF. Hot pressed DSP cement paste,

specific pore volume/total

specific por volume (%)

C0-W

35 Material Research Society Symposium Proceedings,

N1-W

30 N2-W

1992; 245.

25 N3-W [5] Richard P, Cheyrezy M. Reactive powder concretes

20 N4-W with high ductility and 200- 800 MPa compressive

15 C0-LW strength, San Francisco: ACI Spring Convention, SP

10 N1-LW 144–24, 1994.

5 N2-LW

[6] Jo BW, Kim CH, Tae G, Park JB. Characteristics of

0 N3-LW

N4-LW

cement mortar with nano-SiO2 particles. Const Build

1 2 3 4

Pore size distribution

Mater 2007; 21(6): 1351-1355.

[7] Kuo WT, Lin KL, Chang WC, Luo HL, Effects of

Fig. 2. Percent of specific pore volume of various grade Nano-Materials on Properties of Waterworks Sludge

pore size accounting for total specific pore volume. Ash Cement Paste. Journal of Indian Engineering

Chemistry 200; 12(5): 702-709.

3.4. Optimized Strength [8] Lin DF, Tsai MC. Journal of Air Waste

Table 4 shows the flexural strength of N-LW-W series ManagementAssoc:2006; 56: 1146.

blended concretes. The strength of the N-LW-W series is [9] Li H., Xiao H. and Ou J. A study on mechanical and

more than that of N-LW series after 90 days of curing. As pressure-sensitive properties of cement mortar with

it mentioned above, this may be due to formation of nanophase materials, Cement and Concrete Research

crystalline Ca(OH)2 in N-LW series after the 28 day. After 34 (2004) 435–438.

curing for 28 days in saturated limewater, curing the [10] Li H., Zhang M. and Ou J. Abrasion resistance of

specimens in water prevents from crystalline Ca(OH)2 concrete containing nano-particles for pavement,

formation hence produces concrete with higher strength. In Wear 260 (2006) 1262–1266.

the other words, after 28 days of curing in saturated [11] Flores-Velez and Dominguez. Characterization and

limewater, only strengthening gel forms by curing the properties of Portland cement composites

specimens until the day 90 in water. incorporating zinc-iron oxide nanoparticles, J Mater

Therefore, the optimized strength of nanoparticles Sci 37 (2002) 983– 988.

blended concrete was achieved by partial replacement of [12] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF,

2.0 wt% cement with ZrO2 nanoparticles which was cured Khademno A., Mechanical properties of cement

for 28 days in saturated limewater and then in water until mortar with Al2O3 nanoparticles. Journal of

90 days. American Science, 2010; 6(4): 94-97.

[13] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF,

Conclusions Khademno A., The effects of incorporation Fe2O3

The results show that the nano-ZrO2 particles blended nanoparticles on tensile and flexural strength of

concrete had significantly higher strength with respect to concrete. Journal of American Science, 2010; 6(4):

that of the concrete without nano-ZrO2 particles. It is 90-93.

found that the Portland cement could be advantageously [14] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF,

replaced with nano-ZrO2 particles up to maximum limit of Khademno A., Improvement the mechanical

2.0% with average particle sizes of 15 nm when the properties of the concrete by using TiO2

specimens cured at saturated limewater for 28 days. The nanoparticles. Journal of American Science, 2010;

optimal level of nano-ZrO2 particles content was achieved 6(4): 98-101.

with 1.0% replacement for the specimens cured in water 7, [15] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF,

28 and 90 days. The optimized strength of nanoparticles Khademno A., Embedded TiO2 nanoparticles

blended concrete was achieved by partial replacement of mechanical properties monitoring in cementitious

http://www.americanscience.org 743 editor@americanscience.org

Journal of American Science, 2012;8(3) Farzad Soleymani

composites. Journal of American Science, 2010; 6(4): strength of rice husk ash blended gap-graded

86-89. Portland cement concrete. Cem Concr Compos 2005;

[16] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF, 27(3): 357–366.

Khademno A., Benefits of Fe2O3 nanoparticles in [23] ASTM C293, Standard Test Method for Flexural

concrete mixing matrix. Journal of American Strength of Concrete (Using Simple Beam With

Science, 2010; 6(4): 102-106. Center-Point Loading), ASTM, Philadelphia, PA;

[17] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF, 2001.

Khademno A., Assessment of the effects of the [24] Tanaka K, Kurumisawa K.. Development of

cement paste composite in presence TiO2 technique for observing pores in hardened cement

nanoparticles. Journal of American Science, 2010; paste. Cement and Concrete Research 2002; 32:

6(4): 43-46. 1435-41.

[18] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF, [25] Abell AB, Willis KL, Lange DA. Mercury Intrusion

Khademno A., An investigation on the Strength and Porosimetry and Image nalysis of Cement-Based

workability of cement based concrete performance by Materials. Journal of Colloid and Interface Science

using TiO2 nanoparticles. Journal of American 1999; 211: 39-44.

Science, 2010; 6(4): 29-33. [26] AI-Khalaf MN, Yousift HA. Use of rice husk ash in

[19] Nazari A, Riahi Sh, Riahi Sh, Shamekhi SF, concrete. Int J Cem Compos Lightweight Concr

Khademno A., Influence of Al2O3 nanoparticles on 1984; 6(4): 241-248.

the compressive strength and workability of blended [27] Wu ZW, Lian HZ. High performance concrete.

concrete. Journal of American Science, 2010; 6(5): 6- Beijing: Railway Press of China; 1999, p43. (in

9. Chinese).

[20] ASTM C150, Standard Specification for Portland [28] Ye Q. The study and development of the nano-

Cement, annual book of ASTM standards, ASTM, composite cement structure materials. New building

Philadelphia, PA; 2001. materials 2001; (1): 4-6. (in Chinese).

[21] Zivica V. Effects of the very low water/cement ratio.

Const Build Mater 2009; 23(8): 2846-2850.

[22] Bui DD, Hu J, Stroeven P. Particle size effect on the

2/2/2012

http://www.americanscience.org 744 editor@americanscience.org

You might also like

- J2 - Assessments of The Effects of ZrO 2 Nanopowders On Porosimetry and Mechanical Properties of ConcreteDocument7 pagesJ2 - Assessments of The Effects of ZrO 2 Nanopowders On Porosimetry and Mechanical Properties of ConcreteKarnalPreethNo ratings yet

- 2.5. - Assessment of The Effects of The Cement Paste Composite in Presence TiO2 NanoparticlesDocument4 pages2.5. - Assessment of The Effects of The Cement Paste Composite in Presence TiO2 NanoparticlesCARLOS ALEJANDRO CABALLA OLIVARESNo ratings yet

- 2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteDocument4 pages2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteCARLOS ALEJANDRO CABALLA OLIVARESNo ratings yet

- Effect of Zinc Oxide Nanoparticle On Pro PDFDocument4 pagesEffect of Zinc Oxide Nanoparticle On Pro PDFJoseph EspinozaNo ratings yet

- Benefits of Fe2O3 Nanoparticles in Concrete MixingDocument6 pagesBenefits of Fe2O3 Nanoparticles in Concrete MixingyousifNo ratings yet

- Transport Properties and Strength Development of Blended Cement MDocument9 pagesTransport Properties and Strength Development of Blended Cement MMeenu KalraNo ratings yet

- Effect of silica fume on mechanical properties of fly ash-based geopolymer concreteDocument7 pagesEffect of silica fume on mechanical properties of fly ash-based geopolymer concreteNeeraj VarmaNo ratings yet

- Mechanical Properties of Cement Mortar With Al O NanoparticlesDocument4 pagesMechanical Properties of Cement Mortar With Al O NanoparticlesSridhar DineshNo ratings yet

- 1 s2.0 S2214509522006258 MainDocument10 pages1 s2.0 S2214509522006258 MainFarjallah Al-AssãadNo ratings yet

- Manuscript ZnODocument22 pagesManuscript ZnOMARIA JOSE MORAIS ABRANTES FERREIRANo ratings yet

- Experimental Study On Strength and Durability Characteristics of Concrete With Partial Replacement of Nano-Silica, Nano-Vanadium MixtureDocument4 pagesExperimental Study On Strength and Durability Characteristics of Concrete With Partial Replacement of Nano-Silica, Nano-Vanadium MixtureInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Experimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDocument7 pagesExperimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDas TadankiNo ratings yet

- Chloride Intrusion and Freeze-Thaw Resistance of Self-Compacting Concrete With Two Different Nano-SioDocument14 pagesChloride Intrusion and Freeze-Thaw Resistance of Self-Compacting Concrete With Two Different Nano-SioJhon CardenasNo ratings yet

- AUEJ - Volume 12 - Issue 45 - Pages 1417-1426Document14 pagesAUEJ - Volume 12 - Issue 45 - Pages 1417-1426jaafar abdullahNo ratings yet

- Corrosion Resistance of Geopolymer ConcretesDocument10 pagesCorrosion Resistance of Geopolymer ConcretesJHON WILMAR CARDENAS PULIDONo ratings yet

- Influence of Fly Ash On The Compressive Strength and Young'S Modulus of ConcreteDocument5 pagesInfluence of Fly Ash On The Compressive Strength and Young'S Modulus of ConcreteSamsouma BkNo ratings yet

- Effect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteDocument9 pagesEffect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteRameshNayakaNo ratings yet

- Properties of Concrete Modified by Amorphous Alumina SilicateDocument6 pagesProperties of Concrete Modified by Amorphous Alumina SilicateYen Ling NgNo ratings yet

- Geo Polymer Mix DesignDocument12 pagesGeo Polymer Mix DesignpulendralkNo ratings yet

- 42 JMES Belmokhtar 2016 PDFDocument7 pages42 JMES Belmokhtar 2016 PDFJesha LibreaNo ratings yet

- Geopolymer Concrete With Fly Ash: NalloydandbvranganDocument12 pagesGeopolymer Concrete With Fly Ash: NalloydandbvranganJoel ulrich Ndengue mballaNo ratings yet

- Behaviour of Different Nanomaterials in Geopolymer Concrete: M. Manoj Kumar, S. YuvarajDocument7 pagesBehaviour of Different Nanomaterials in Geopolymer Concrete: M. Manoj Kumar, S. YuvarajMd zakirNo ratings yet

- (IJETA-V8I6P3) :mehtab Alam, Hemant Kumar SainDocument7 pages(IJETA-V8I6P3) :mehtab Alam, Hemant Kumar SainIJETA - EighthSenseGroupNo ratings yet

- 2021 IOP Conf. Ser. Mater. Sci. Eng. 1144 012095Document9 pages2021 IOP Conf. Ser. Mater. Sci. Eng. 1144 012095Achmad MaulanaNo ratings yet

- Effect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of ConcreteDocument5 pagesEffect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of Concretesruthi jayadeepNo ratings yet

- 2) Hongen ZhangDocument18 pages2) Hongen ZhangArti KarnukeNo ratings yet

- IJETR042328Document7 pagesIJETR042328erpublicationNo ratings yet

- Effect of Admixture On The Compressive Strength of Composite Cement MortarDocument9 pagesEffect of Admixture On The Compressive Strength of Composite Cement MortarNam HuynhNo ratings yet

- 1 s2.0 S1877705811062990 Main - 3Document8 pages1 s2.0 S1877705811062990 Main - 3Ephrem MelakuNo ratings yet

- Foundry Sand Concrete StrengthDocument4 pagesFoundry Sand Concrete Strengthshivanand hippargaNo ratings yet

- Sample TemplateDocument3 pagesSample TemplatepraveenNo ratings yet

- Effects of Fly Ash on Strength and Ultrasound Velocity of Concrete Exposed to High TemperaturesDocument12 pagesEffects of Fly Ash on Strength and Ultrasound Velocity of Concrete Exposed to High TemperaturesMohd NasimNo ratings yet

- Effect of Cement Types On Carbonation Depth of ConcreteDocument8 pagesEffect of Cement Types On Carbonation Depth of ConcreteEliott ThommesNo ratings yet

- 28 Day PDFDocument4 pages28 Day PDFBEN NARENDRANNo ratings yet

- Effect of Metakaolin on Concrete Strength and Durability Using Treated Waste WaterDocument11 pagesEffect of Metakaolin on Concrete Strength and Durability Using Treated Waste WaterIsrael VenkatNo ratings yet

- Matecconf Krynica2018 06002Document7 pagesMatecconf Krynica2018 06002shivanand hippargaNo ratings yet

- RigidDocument23 pagesRigidMadhu MadhuNo ratings yet

- The Effect of Exposition Conditions On The Durability of Cement Concrete With Dolomite Aggregate Sourced Near Kraków, PolandDocument8 pagesThe Effect of Exposition Conditions On The Durability of Cement Concrete With Dolomite Aggregate Sourced Near Kraków, PolandSiddhesh Kamat MhamaiNo ratings yet

- Kandungan Semen OPCDocument9 pagesKandungan Semen OPCtheodore stanleyNo ratings yet

- Tociej 10 782Document12 pagesTociej 10 782Jimianta S.S.TNo ratings yet

- Use of Steel Slag in Pervious ConcreteDocument11 pagesUse of Steel Slag in Pervious ConcretemargarethsmNo ratings yet

- Foundry Sand Utilisation As A Partial Re PDFDocument4 pagesFoundry Sand Utilisation As A Partial Re PDFHarshit KumarNo ratings yet

- Reuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsDocument10 pagesReuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsfoufouNo ratings yet

- Mini Project Final ReviewDocument19 pagesMini Project Final Reviewjagandas chouhanNo ratings yet

- A Study On Water Absorption and Sorptivity of Geopolymer ConcreteDocument9 pagesA Study On Water Absorption and Sorptivity of Geopolymer ConcreteSajjad AhmadNo ratings yet

- Jitchaiyaphum2011 PDFDocument8 pagesJitchaiyaphum2011 PDFmekalaNo ratings yet

- Ceramics International: Mahmood Hunar Dheyaaldin, Mohammad Ali Mosaberpanah, Radhwan AlzeebareeDocument13 pagesCeramics International: Mahmood Hunar Dheyaaldin, Mohammad Ali Mosaberpanah, Radhwan Alzeebareemahmood hunarNo ratings yet

- Treatment of Soft Soil With Nano-Magnesium Oxide: Mohd Raihan Taha, Ibtehaj Taha Jawad, and Zaid Hameed MajeedDocument9 pagesTreatment of Soft Soil With Nano-Magnesium Oxide: Mohd Raihan Taha, Ibtehaj Taha Jawad, and Zaid Hameed MajeedVILCAPAZA11No ratings yet

- JETIRC006007Document5 pagesJETIRC006007vyshnavkumarNo ratings yet

- Investigation Into The Possibility of Partial Replacement of Cement With Bone Powder in Concrete ProductionDocument6 pagesInvestigation Into The Possibility of Partial Replacement of Cement With Bone Powder in Concrete ProductionManuNo ratings yet

- The Effect of Zinc Water To Binder Ratio and SilicDocument9 pagesThe Effect of Zinc Water To Binder Ratio and SilicFrancisco GarayoNo ratings yet

- Engineering Properties of Inorganic Polymer Concretes (Ipcs)Document7 pagesEngineering Properties of Inorganic Polymer Concretes (Ipcs)joNo ratings yet

- Durability Study of Low Calcium Fly Ash Geopolymer ConcreteDocument7 pagesDurability Study of Low Calcium Fly Ash Geopolymer Concretethisisatest402003No ratings yet

- PREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Document5 pagesPREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Nagaraja M LNo ratings yet

- GLASSDocument6 pagesGLASSMR. ESHAN GHARPURENo ratings yet

- Compressive Strength of Cement & Fly Ash MortarDocument9 pagesCompressive Strength of Cement & Fly Ash MortarOudhai VONGKEONo ratings yet

- International Journal of Chemtech Research: Baskara Sundararaj J, Dhinesh M, Revathi.T, Rajamane N.PDocument11 pagesInternational Journal of Chemtech Research: Baskara Sundararaj J, Dhinesh M, Revathi.T, Rajamane N.PheminNo ratings yet

- 4-DEVELOPMENT OF PAVER BLOCK BY USING RICEDocument9 pages4-DEVELOPMENT OF PAVER BLOCK BY USING RICElafryNo ratings yet

- Microstructural Geochronology: Planetary Records Down to Atom ScaleFrom EverandMicrostructural Geochronology: Planetary Records Down to Atom ScaleDesmond E. MoserNo ratings yet

- A19 - Performance On The Study of Nano Materials For The Development of Sustainable ConcreteDocument7 pagesA19 - Performance On The Study of Nano Materials For The Development of Sustainable ConcreteKarnalPreethNo ratings yet

- A14 - Influence of Nano Particles On Durability and Mechanical Properties of High Performance ConcreteDocument6 pagesA14 - Influence of Nano Particles On Durability and Mechanical Properties of High Performance ConcreteKarnalPreethNo ratings yet

- A2 - An Experimental Investigation On Nano Al2O3 Based Self Compacting MortarDocument5 pagesA2 - An Experimental Investigation On Nano Al2O3 Based Self Compacting MortarKarnalPreethNo ratings yet

- Pervious ConcreteDocument2 pagesPervious ConcreteaaNo ratings yet

- A45Document5 pagesA45KarnalPreethNo ratings yet

- A34 - Investigations On The Preparation and Mechanical Properties of The Nano-Alumina Reinforced Cement CompositeDocument4 pagesA34 - Investigations On The Preparation and Mechanical Properties of The Nano-Alumina Reinforced Cement CompositeKarnalPreethNo ratings yet

- A26 - The Effects of Nano-Silica and Nano-Alumina On Frost Resistance of Normal ConcreteDocument5 pagesA26 - The Effects of Nano-Silica and Nano-Alumina On Frost Resistance of Normal ConcreteKarnalPreethNo ratings yet

- A7 - Effect of Nano Alumina On Pore Structure and Durability of Class F Fly Ash Self Compacting MortarDocument11 pagesA7 - Effect of Nano Alumina On Pore Structure and Durability of Class F Fly Ash Self Compacting MortarKarnalPreethNo ratings yet

- A22 - Properties of High Strength Concrete Incorporating Colloidal Nanoal2o3Document5 pagesA22 - Properties of High Strength Concrete Incorporating Colloidal Nanoal2o3KarnalPreethNo ratings yet

- Effect of Nanoparticles On Frost Durability If ConcreteDocument10 pagesEffect of Nanoparticles On Frost Durability If ConcreteKarnalPreethNo ratings yet

- A4 - Behavior of Magnetic Concrete Incorporated With Egyptian Nano AluminaDocument5 pagesA4 - Behavior of Magnetic Concrete Incorporated With Egyptian Nano AluminaKarnalPreethNo ratings yet

- A40 - Characteristics of Cement Concrete With Nano Alumina ParticlesDocument11 pagesA40 - Characteristics of Cement Concrete With Nano Alumina ParticlesKarnalPreethNo ratings yet

- An Investigation On The Effects of Al2O3 Nano Particles On Durability and Mechanical Properties of High Performance ConcreteDocument11 pagesAn Investigation On The Effects of Al2O3 Nano Particles On Durability and Mechanical Properties of High Performance ConcreteKarnalPreethNo ratings yet

- To Study The Effect of Adding Al2O3 Nanoparticles On The Mechanical Properties and Microstructure of Cement MortarDocument5 pagesTo Study The Effect of Adding Al2O3 Nanoparticles On The Mechanical Properties and Microstructure of Cement MortarKarnalPreethNo ratings yet

- A37 - Improvement Compressive Strength of Concrete in Different Curing Media by Al2O3 NanoparticlesDocument9 pagesA37 - Improvement Compressive Strength of Concrete in Different Curing Media by Al2O3 NanoparticlesKarnalPreethNo ratings yet

- A48Document7 pagesA48KarnalPreethNo ratings yet

- Role of Nano Oxides For Improving Cementitious Building MaterialsDocument7 pagesRole of Nano Oxides For Improving Cementitious Building MaterialsKarnalPreethNo ratings yet

- A8 - Effect of Nano Particles On Durability of Fiber-Reinforced Concrete PavementDocument8 pagesA8 - Effect of Nano Particles On Durability of Fiber-Reinforced Concrete PavementKarnalPreethNo ratings yet

- The Effects of Limewater On Flexural Strength and Water Permeability of Al2O3 Nanoparticles Binary Blended ConcreteDocument8 pagesThe Effects of Limewater On Flexural Strength and Water Permeability of Al2O3 Nanoparticles Binary Blended ConcreteKarnalPreethNo ratings yet

- The Effects of Limewater On Split Tensile Strength and Workability of Al2O3 Nanoparticles Binary Blended ConcreteDocument6 pagesThe Effects of Limewater On Split Tensile Strength and Workability of Al2O3 Nanoparticles Binary Blended ConcreteKarnalPreethNo ratings yet

- Mechanical Properties of Cement Mortar With Al2O3 NanoparticlesDocument4 pagesMechanical Properties of Cement Mortar With Al2O3 NanoparticlesKarnalPreethNo ratings yet

- Influence of Al2O3 Nanoparticles On The Compressive Strength and Workability of Blended ConcreteDocument4 pagesInfluence of Al2O3 Nanoparticles On The Compressive Strength and Workability of Blended ConcreteKarnalPreethNo ratings yet

- A50Document12 pagesA50KarnalPreethNo ratings yet

- Influence of RGO, N-Al2O3 and N-SiO2 Nanomaterials On The Microstructure of OPC Paste Immersed in 0.5 M HNO3 SolutionDocument9 pagesInfluence of RGO, N-Al2O3 and N-SiO2 Nanomaterials On The Microstructure of OPC Paste Immersed in 0.5 M HNO3 SolutionKarnalPreethNo ratings yet

- A1-Abrasion Resistance of Concrete Containing SiO2 and Al2O3 Nanoparticles in Different Curing MediaDocument8 pagesA1-Abrasion Resistance of Concrete Containing SiO2 and Al2O3 Nanoparticles in Different Curing MediaKarnalPreethNo ratings yet

- A18 - Modified Properties of Cementitious Materials With Cr2o3 and Al2o3 NanoparticlesDocument10 pagesA18 - Modified Properties of Cementitious Materials With Cr2o3 and Al2o3 NanoparticlesKarnalPreethNo ratings yet

- A47Document10 pagesA47KarnalPreethNo ratings yet

- A17 - Micro Observations of Different Types of Nano Al2O3 On The Hydration of Cement Paste With Sludge Ash ReplacementDocument10 pagesA17 - Micro Observations of Different Types of Nano Al2O3 On The Hydration of Cement Paste With Sludge Ash ReplacementKarnalPreethNo ratings yet

- J8 - Limewater Effects On Properties of ZrO 2 Nanoparticle Blended Cementitious CompositeDocument6 pagesJ8 - Limewater Effects On Properties of ZrO 2 Nanoparticle Blended Cementitious CompositeKarnalPreethNo ratings yet

- Nano Particles in HighDocument5 pagesNano Particles in Highapi-297121029No ratings yet

- Stereo Isomerism - (Eng)Document32 pagesStereo Isomerism - (Eng)Atharva WatekarNo ratings yet

- How Atoms and Molecules Support LifeDocument6 pagesHow Atoms and Molecules Support Lifemelan pNo ratings yet

- CHEM 241 SyllabusDocument2 pagesCHEM 241 SyllabusBob MillerNo ratings yet

- Cambridge IGCSE (9-1) : Physics 0972/21Document16 pagesCambridge IGCSE (9-1) : Physics 0972/21Tristan GrahamNo ratings yet

- METALSDocument62 pagesMETALSEstefany MarilagNo ratings yet

- Concepts To RememberDocument13 pagesConcepts To RememberShresha DasNo ratings yet

- Drag EquationDocument4 pagesDrag EquationMspamNo ratings yet

- Waterex ThickenersDocument2 pagesWaterex ThickenerssaravananNo ratings yet

- Photosynthesis HSBDocument5 pagesPhotosynthesis HSBMs. ButeNo ratings yet

- The Measurement of The Crystallinity of Polymer by DSCDocument6 pagesThe Measurement of The Crystallinity of Polymer by DSCJack CheeNo ratings yet

- Unit 4 ClimateDocument14 pagesUnit 4 Climatebego docenciaNo ratings yet

- Storage and Use of Liquefied Petroleum Gases (LPG) in Sample Cylinders For LPG Test MethodsDocument4 pagesStorage and Use of Liquefied Petroleum Gases (LPG) in Sample Cylinders For LPG Test MethodsNguyễn Bằng NộiNo ratings yet

- Friction Conduction and InductionDocument18 pagesFriction Conduction and InductionRuqaiyah PatwaNo ratings yet

- Formulation of Water-Based Drilling Fluid Using Local MaterialsDocument8 pagesFormulation of Water-Based Drilling Fluid Using Local MaterialsDavid IsuNo ratings yet

- Physics concepts and principlesDocument16 pagesPhysics concepts and principlesKalana GamageNo ratings yet

- Exp 5 Gas ChromatographyDocument8 pagesExp 5 Gas Chromatographylebogang75% (4)

- State of Libya University Al-Mergib Faculty Engineering Department Engineering Chemical & PetroleumDocument12 pagesState of Libya University Al-Mergib Faculty Engineering Department Engineering Chemical & PetroleumSiraj AL sharif100% (1)

- Wacker Process Slides 2008Document5 pagesWacker Process Slides 2008Zakariya AdamNo ratings yet

- Merck Catalog For Analytical LabDocument138 pagesMerck Catalog For Analytical LabSalman AshfaqNo ratings yet

- KCC - DATASHEET - Komarine Anti-Rust Oil RV490 - EngDocument2 pagesKCC - DATASHEET - Komarine Anti-Rust Oil RV490 - EngNguyen1987 TrungNo ratings yet

- Floquetlecture - Konrad ViebahnDocument12 pagesFloquetlecture - Konrad ViebahnMarc de MiguelNo ratings yet

- Mc1091 Recrushed SlagDocument4 pagesMc1091 Recrushed Slagtoxicity23No ratings yet

- MY HT Espring Brochure en USDocument12 pagesMY HT Espring Brochure en USZat ZakariaNo ratings yet

- 50 General Knowledge Questions On EarthDocument2 pages50 General Knowledge Questions On EarthHariprasad SugurthiNo ratings yet

- Widmanstätten StructuresDocument3 pagesWidmanstätten StructuresdantegimenezNo ratings yet

- Daftar STandard MethodDocument33 pagesDaftar STandard Methodleni evayantiNo ratings yet

- Guide To Astm Test Methods For The Analysis of Coal and CokeDocument7 pagesGuide To Astm Test Methods For The Analysis of Coal and Cokeecsuperal50% (2)

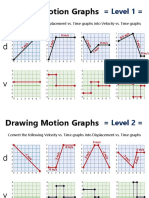

- Motion Graphs Practice SolutionsDocument6 pagesMotion Graphs Practice SolutionsVenumadhav TangiralaNo ratings yet

- A Simple HPLC Method For The Simultaneous Analysis of Phosphatidylcholine and Its Partial Hydrolysis Products 1-And 2-Acyl LysophosphatidylcholineDocument5 pagesA Simple HPLC Method For The Simultaneous Analysis of Phosphatidylcholine and Its Partial Hydrolysis Products 1-And 2-Acyl LysophosphatidylcholineChang Woo JongNo ratings yet

- GG General - Guidelines - Glass - Embedding - v1 - 10-11Document16 pagesGG General - Guidelines - Glass - Embedding - v1 - 10-11Manuel GallardoNo ratings yet