0% found this document useful (0 votes)

217 views7 pagesHandrails and Railings for Marassi Park

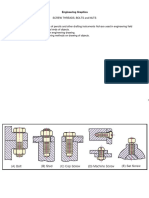

This document outlines specifications for handrails and railings to be installed at the proposed Marassi Park in Bahrain. It includes requirements for glass railings, balustrades, and handrails made of materials like stainless steel, brass, bronze and aluminum. Load and strength testing requirements are specified to ensure the railings can withstand the required loads without failure.

Uploaded by

shajbabyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

217 views7 pagesHandrails and Railings for Marassi Park

This document outlines specifications for handrails and railings to be installed at the proposed Marassi Park in Bahrain. It includes requirements for glass railings, balustrades, and handrails made of materials like stainless steel, brass, bronze and aluminum. Load and strength testing requirements are specified to ensure the railings can withstand the required loads without failure.

Uploaded by

shajbabyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd