Professional Documents

Culture Documents

Uploaded by

sergioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploaded by

sergioCopyright:

Available Formats

Model/Series: 54, 55 & 57

O P E R ATI N GOperating

MA NUA L

Manual Number:

Version:

040-550GB

2009-11

Rotating Unions

Series

54 55 57

Model

54 55 57

154 155 157

254 255 257

354 355 357

524 525 527

554 555 557

655 657

755 857

Exception: The present Operating Manual is not applicable for the following models 555-413-xxx,

655-905-xxx, 655-921-xxx and 655-952-xxx. Those are described in the Operating Manual 040-550-1.

Rev. E Page 1 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

Content

1 For your Safety ________________________________________________________________ 3

1.1 Intended Use __________________________________________________________________ 3

1.1.1 Application one-way version (Mono) ______________________________________________ 4

1.1.2 Application two-way version (Duo) ________________________________________________ 5

1.2 Misuse ________________________________________________________________________ 5

1.3 Safety Instructions______________________________________________________________ 6

1.3.1 Hazards due to hot surfaces _____________________________________________________ 6

1.3.2 Hazards by improper hoses ______________________________________________________ 6

1.3.3 Hazards due to the flow medium _________________________________________________ 6

1.3.4 Hazards by faulty installation _____________________________________________________ 6

1.4 Structure of Pictograms _________________________________________________________ 7

2 Information as to this Manual ___________________________________________________ 7

3 Information on the Name Plate __________________________________________________ 7

4 Information on the Design ______________________________________________________ 8

4.1 Filtering of the Flow Medium _____________________________________________________ 8

4.2 Connecting Options of the Rotating Union at the Machine Shaft ______________________ 8

4.3 Options of Hose Installation _____________________________________________________ 8

4.3.1 Connection of hose to the rotating union __________________________________________ 9

4.3.2 Hose connection in case of additional axial movement of the machine shaft ___________ 9

4.3.3 Hose connection for hoses with SAE flange _______________________________________ 10

4.3.4 Optional: Connection of a leakage line ___________________________________________ 10

5 Installation ___________________________________________________________________ 11

6 Information on the Operation ___________________________________________________ 11

7 Storage _____________________________________________________________________ 11

8 Maintenance _________________________________________________________________ 11

8.1 Maintenance Intervals __________________________________________________________ 11

8.2 Daily Inspection _______________________________________________________________ 12

8.3 Maintenance after Operating Hours ______________________________________________ 12

8.3.1 Allowed lubricants _____________________________________________________________ 13

8.3.2 Volume of grease for lubrication _________________________________________________ 13

8.3.3 Relubrication intervals for series 55 _____________________________________________ 13

8.3.4 Relubrication intervals for 55 Hot Package series __________________________________ 15

8.3.5 Lubricate the rotating union _____________________________________________________ 15

9 Trouble Shooting _____________________________________________________________ 15

9.1 Potential Causes for Errors and their Elimination___________________________________ 15

9.2 Pack Rotating Union for Transport _______________________________________________ 16

10 Disposal_____________________________________________________________________ 17

10.1 Dispose of Packaging __________________________________________________________ 17

10.2 Dispose of Rotating Union ______________________________________________________ 17

11 Spare Parts __________________________________________________________________ 17

Rev. E Page 2 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

1 For your Safety

This chapter provides information on the safe handling of DEUBLIN rotating unions.

❑ For your own safety and the safety of other people read this operating manual carefully and

completely prior to working on or with DEUBLIN rotating unions.

❑ This operating manual exclusively describes the rotating unions of the manufacturer DEUBLIN.

In the further description/explanation the name “DEUBLIN” is left out for a better readability.

❑ This operating manual is a material part of the specified rotating unions. The operator is re-

sponsible for the personnel to take note of this manual.

❑ Always use the latest version of the operating manual, available under www.deublin.com.

❑ The operator of the rotating unions shall not make any modifications or attachments to and

retrofitting of the rotating union without the manufacturer’s consent.

❑ Please follow the additional instruction „Installation“ for a secure and corrrect installation of the

rotating union. The installation instruction is included with the delivered union.

1.1 Intended Use

The rotating unions of the series 54, 55 and 57 supply the feeding of the following flow media: Water,

steam (not for series 55 Hot Package), thermal oil

Flow medium

Temperature

Series Model Steam (short-term

range (°C) Water Thermal oil

saturated steam)

54 up to 90° •

55 55 up to 655 up to 120° • • •

1)

55 Hot Package 55 up to 655 up to 160° • •

55 755 up to 120° • •

1)

55 Hot Package 755 up to 160° •

57 up to 90° •

57 857 up to 120° •

1)

Hot Package models are suitable either for hot water or thermal oil.

The rotating unions referred to are designed for non-potentially explosive environments and non-com-

bustible flow media. Details on the operating range of the rotating unions are provided in the catalogue

and/or the model-specific installation drawing.

The rotating unions of the series 54, 55 and 57 can be used as one-way or two-way version depending

on the type of connection.

Please note: Several special models are available for the use of other media (e.g. air), but the present

operating manual does not apply to these models. Please contact DEUBLIN if you want to use other

media.

Rev. E Page 3 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

1.1.1 Application one-way version (Mono)

For the one-way version, models are available which can be installed at the machine shaft from the

outside or in the machine shaft.

Rotating union externally mounted

B A

Fig. 1: Schematic diagram one-way version (Mono – externally mounted)

One one-way version of the rotating union is mounted at each of the two ends of the roller. The rotating

union (A) conveys the flow medium into the roller. The rotating union (B) conveys the flow medium into

the piping system of the machine.

Rotating union in-the-shaft-mounted

B A

Fig. 2: Schematic diagram one-way version (Mono – in-the-shaft mounted)

One one-way version of the rotating union is mounted in each of the two ends of the roller. The rotating

union (A) conveys the flow medium into the roller. The rotating union (B) conveys the flow medium into

the piping system of the machine.

Rev. E Page 4 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

1.1.2 Application two-way version (Duo)

The rotating unions of the 54, 55 and 57

series are also available as two-way

model (Duo).

The two-way rotating union is fitted

with an axial connection at the elbow.

Through this elbow the flow medium

is conveyed into the machine shaft

through a supply tube.

The return flow medium is absorbed by

Fig. 3: Schematic diagram two-way version (Duo) the same rotating union and conveyed

into the piping system of the machine

through the radial connection.

1.2 Misuse

This chapter provides information on known misuse of rotating unions of the 54, 55 and 57 series.

The rotating unions are not suitable for the areas and applications described herein. Use in such ar-

eas or for such applications constitutes a misuse endangering people and machines and is therefore

prohibited.

Prohibition for the following areas:

❑ Potentially explosive areas

The rotating unions of the 54, 55 and 57 series shall not be used in potentially explosive areas,

as they are not approved for the requirements in potentially explosive areas. Operation in such

areas may cause explosions.

❑ Food

Food, cleaning and disinfectant residues cannot be removed from the rotating unions. People

may suffer poisoning.

Prohibition for the following applications:

❑ Conveying of combustible flow media or hydrocarbons

Combustible flow media or hydrocarbons may ignite or cause explosions.

Exception: Thermal oil within the admissible temperature range. Please observe the safety

data sheet of the used thermal oil.

❑ Connection to a piping system with excessive pressure

If excessive pressure is applied to the rotating unions, supply pipes can come off and cause

personal injury or property damage.

❑ Operation without lubrication

Dry operation (without flow medium) of the rotating union causes damage to the axial face

seals.

❑ Connection to fixed pipes

In case of connection to fixed pipes, the rotating unions may leak and the ball bearing may be

damaged.

❑ Conveying of flow media which are too hot

If the flow media exceed the maximum admissible temperature for the rotating union, the

static seals (elastomer seals) can be damaged which may result in leaky rotating unions and

personal injury or property damage.

❑ For series 55 only: Conveying continuous saturated steam

Escaping steam may injure people seriously.

❑ For series 54 and 57 only: Conveying saturated steam

Escaping steam may injure people seriously.

Rev. E Page 5 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

This list is not comprehensive and will be updated with results from product observation.

1.3 Safety Instructions

This chapter provides information on the hazards through rotating unions.

1.3.1 Hazards due to hot surfaces

The rotating unions are heated by the temperature of the flow medium. Skin contact with heated rotat-

ing unions can cause injuries.

❑ Use safety gloves and PPE (Personal Protective Equipment) protecting against heat when han-

dling the rotating union.

❑ Attach a clearly visible danger sign visibly on/next to the rotating union in order to warn of

danger.

1.3.2 Hazards by improper hoses

For the connection of the rotating union to the machine, you have to choose appropriate hoses for the

respective flow media the specification of which meets the application.

If you use improper hoses, the latter may become porous or burst. This can cause personal injury and/

or property damage to components of the machine.

❑ In case of the flow media water, steam and thermal oil, use hoses which are suitable for the

maximum system pressure of the machine and the maximum temperature of the flow media.

1.3.3 Hazards due to the flow medium

When working on the rotating union, injuries can be caused by skin or eye contact with the flow me-

dium.

❑ Observe the security instructions for the flow medium.

1.3.4 Hazards by faulty installation

If the rotating unions are installed incorrectly, hoses and connections may become leaky. The flow

medium can escape. Depending on the flow medium, personal injury or property damage to the com-

ponents of the machine may occur.

❑ Before installing the rotating union ensure that no feed pressure and no residual pressure is

applied to the pipeline system of the machine.

❑ Install the rotating union on the machine using hoses only, in order to avoid stress on the rotat-

ing union.

❑ Install the hoses free from stress.

❑ Install the rotating union in a way that the leaking medium can be carried away securely down-

ward at the lowest point and that the drain line shows a fall (min. 15°).

❑ Install the hoses to the rotating union prior to mounting it at the machine shaft.

Rev. E Page 6 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

1.4 Structure of Pictograms

This chapter provides information on the meaning of the pictograms used in the manual.

Warning

Potentially dangerous situation which may result in death or serious bodily injuries.

Warning

Note

Potentially harmful situation in which the product or an object in its surroundings can

be damaged.

Note

Application notes

and other useful information.

Info

2 Information as to this Manual

The copyright as to this manual remains with DEUBLIN. Subject to changes!

❑ You can download the latest version of this manual under www.deublin.com.

❑ Always use the latest version of the operating manual.

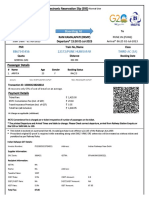

3 Information on the Name Plate

Model number

DEUBLIN‘s internal identification / date of manufacture

MADE IN <<country of manufacture>>

Fig. 4: Name plate

The coding of the model number is described in the catalogue.

Rev. E Page 7 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

4 Information on the Design

This chapter provides information as to which items have to be observed in the design in order to have

a positive effect on the service life of the rotating union.

You can obtain the drawings of the rotating unions from DEUBLIN in order to integrate

the rotating union in your drawing.

Info

4.1 Filtering of the Flow Medium

Unfiltered flow media with a particle size of more than 60 μm result in increased wear of the rotating

union.

The larger the particles in the flow medium, the higher the wear of the rotating union is.

The higher the total of all particles (polluting load), the higher the wear is.

Info

❑ Insert a filter in front of the rotating union which filters particles with a size of 60 μm and larger

from the flow medium.

4.2 Connecting Options of the Rotating Union at the Machine Shaft

A B

Fig. 5: Options for the installation on the machine shaft

The rotating unions can be fastened on the machine shaft by screwing (A) or by means of a flange (B)

depending on the rotating union.

4.3 Options of Hose Installation

The following examples show how to install the hoses at the rotating unions.

These connecting options ensure that the hoses do not transfer stress to the rotating unions when the

machine shaft moves.

❑ Please pay attention to the chapter “Security Advices” regarding the design.

Rev. E Page 8 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

4.3.1 Connection of hose to the rotating union

The hoses must be installed without stress and bends so that they do not apply any forces to the rotat-

ing union. The following figures show examples of installation.

If the rotating unions are installed with connections posi-

tioned horizontally, connect the hoses as shown.

Fig. 6: Connect hoses horizontally

If the hoses are to be guided away from the rotating unions

vertically and bent by 90°, connect the hoses as shown.

Fig. 7: Hoses bent by 90°

4.3.2 Hose connection in case of additional axial movement of the machine shaft

If the rotating unions are installed at machine shafts with an

oscillating (axial) movement, the hoses must be stress-free in

both extreme positions.

Fig. 8: Hoses laid in a curve

Rev. E Page 9 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

4.3.3 Hose connection for hoses with SAE flange

Only possible, if the rotating union is ordered with SAE connections.

Info

The hoses are fastened at the rotating union by means of its

SAE flanges using four screws.

Fig. 9: Flange connection

4.3.4 Optional: Connection of a leakage line

Only possible, if the rotating union is externally mounted.

Info

In order to prevent surrounding components from being damaged by escaping flow medium, you can

connect a leakage line to the rotating union, if required.

The rotating unions are equipped with leakage holes.

❑ When used in dirty environment, we recommend to pro-

tect the leakage holes against penetrating dirt. You can

order sealing plugs at DEUBLIN. If you close the leakage

holes, you have to provide the rotating union with ventila-

tion, if applicable by means of a second leakage connec-

tion. Without ventilation the leaking medium cannot drain

off.

❑ Position the rotating union in a way that you can always

connect the leakage line in 6 o’clock position (at the lowest

point) to a leakage hole.

Fig. 10: Schedule connection of leakage line

Rev. E Page 10 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

5 Installation

The union installation is described in an additional manual which is supplied with each rotating union.

Enclosed you will also find the manual “Installation”.

Please follow the additional instruction “Installation” for a secure and correct installation of the rotating

union. The instruction “Installation” is available online under www.deublin.com.

❑ Ensure that the person installing the rotating union receives the following information:

- Position and location of the rotating union in the machine

- Plan for connection of hoses

- Position of leakage line

- Information on the flow medium

6 Information on the Operation

Damage to components due to missing lubrication (Dry run)

The axial face seals of the rotating unions are lubricated by the flow medium. If the

rotating unions are operated without medium present they are not lubricated and will

Note thus be damaged.

❑ Ensure that the rotating unions are operated with a flow medium.

❑ Switch off the plant/machine, if the rotating unions are operated without flow me-

dium.

7 Storage

Damage of component due to incorrect storage

If you store the rotating unions incorrectly, they become leaky or are damaged.

❑ Store the rotating unions in a dry space between 3 °C and 40 °C.

Note ❑ Store rotating unions for two years at the most.

8 Maintenance

This chapter provides information on how to extend the service life of the rotating unions by means of

maintenance.

8.1 Maintenance Intervals

You can avoid early wear of the rotating unions, if you adhere to the maintenance intervals described

herein.

Risk of injury due to hot or cold surfaces

The rotating unions are heated or cooled by the temperature of the flow medium.

Skin contact with these heated or cooled rotating unions can cause severe injuries.

Warning

❑ Before starting to work on the rotating union, allow the machine to cool down.

❑ Use safety gloves and PPE (Personal Protective Equipment) protecting against heat

or cold depending on the application of the rotating unions.

Rev. E Page 11 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

8.2 Daily Inspection

Check the rotating unions for tightness.

Risk of injuries due to applied line pressure

If you have to work on the rotating union and feed pressure of the flow medium is ap-

plied or there is residual pressure in the piping system of the machine, the flow medium

Warning can escape under pressure when releasing the connections. You and other people

may suffer severe injuries.

❑ Ensure that no feed pressure is applied.

❑ Ensure that there is no residual pressure in the piping system.

During operation of the machine, leakages may occur at the

connections and hoses depending on the requirements to

the rotating unions.

1. Carry out daily visual inspections in order to check wheth-

er leakages occurred at the connections (see arrows).

If you detect leakage:

1. Stop the machine.

2. Replace the defective hoses with new ones.

3. Seal leaking connections.

Fig. 11: Inspect visually 4. If the rotating union is worn and leaks, replace it with a

new one. Repair kits for various models can be obtained

from DEUBLIN.

8.3 Maintenance after Operating Hours

This chapter describes how to relubricate the rotating unions.

The maintenance operations described below have to be executed in case of series 55

and 55 Hot Package only. Rotating unions of the series 54 and 57 are lubricated in the

factory for the entire service life.

Info The rotating unions are already lubricated in the factory and delivered ready-to-be-

installed.

The indicated volumes of grease and intervals for relubrication are based on experi-

ence resulting from the information of the manufacturer of the lubricant and the operat-

ing parameters of the rotating unions. The information given herein refers to operating

Info hours depending on the respective speed.

❑ In case of doubt, consult DEUBLIN.

Lubricate the ball bearings of the rotating unions at the stated lubricating intervals using the listed

volume of grease suitable for the operating conditions. If you do not adhere to these instructions, the

service life of the ball bearings is reduced.

Rev. E Page 12 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

8.3.1 Allowed lubricants

Series allowed lubricants Series allowed lubricants

54 / 55 / 57 TEXACO CHEVRON SRI 2 55 Hot Package DUPONT KRYTOX XHTRUF

GREASE NLGI 2 KLÜBER BARRIERTA L55/0, L55/2

LUBCON TURMOTEMP II/400

8.3.2 Volume of grease for lubrication

Damage to the component due to excessive grease

If you put too much grease in the ball bearings, the latter can be damaged.

❑ Adhere to the stated volumes of grease for lubrication.

Note

Damage of part by loss of grease quality

If e.g. the grease for relubrication is supplied by a central lubrication system to the

rotating unions, the grease may loose its essential characteristics. The bearings of the

Note rotating unions will be damaged.

❑ Make sure only fresh grease as good as new is fed to the bearings.

❑ Comply with the specifications for sevice life of the grease manufacturer.

Series Model Volume of grease (g) Series Model Volume of grease (g)

55 55 3.5 55 Hot Package 55 7

155 5.5 155 12

255 10 255 19

355 10 355 24

525 12 525 29

555 18 555 40

655 18 655 47

755 42

8.3.3 Relubrication intervals for series 55

The intervals for relubrication depend on the operating conditions of the rotating unions.

Rev. E Page 13 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

Relubrication intervals for light duty operating conditions

Light duty operating conditions are:

❑ Flow medium with a temperature of max. 75 °C

❑ Few vibrations

❑ Little humidity

❑ Hardly polluted environment

Model

Operating hours

Speed

Relubrication intervals for medium-heavy duty operating conditions

Medium-heavy duty operating conditions are:

❑ Flow medium with a temperature of 75 ° to 120 °C

❑ many vibrations

❑ much humidity

❑ extremely polluted environment

Model

Operating hours

Speed

Relubrication intervals for extreme operating conditions

If the operating conditions exceed the easy and medium-heavy operating conditions, the lubrication

interval, volume of grease and grease type have to be adapted to the application.

❑ Please consult your lubricant supplier.

Rev. E Page 14 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

8.3.4 Relubrication intervals for 55 Hot Package series

Lubrication interval after commissioning

Lubricate the rotating union with the stated volume of grease and grease type after 1,000 operating

hours for the first time.

Subsequent lubrication interval

If you convey flow media with a temperature below 100 °C through the rotating union,

you do not have to relubricate the rotating union.

Info

Operating Conditions Subsequent lubrication intervals

from 100 ° to 150 °C after 6,000 operating hours

from 150 ° to 160 °C after 3,000 operating hours

8.3.5 Lubricate the rotating union

The following paragraphs describe how to place the grease

gun and inject the stated volume of grease into the ball bear-

ing.

1. Attach the grease gun to the lubricating nipple (see arrow).

2. Ensure that the connector of the grease gun is placed cor-

rectly on the lubricating nipple.

3. Actuate the grease gun in order to inject the stated volume

of grease into the ball bearing.

4. Count the operating hours for the following lubrication in-

terval.

Fig. 12: Attach grease gun for relubrica-

tion

9 Trouble Shooting

This chapter provides the following information:

1. Which problem may occur?

2. What can be the cause of the problem?

3. How can you eliminate this problem?

9.1 Potential Causes for Errors and their Elimination

Risk of injuries due to applied line pressure

If you have to work on the rotating union and feed pressure of the flow medium is ap-

plied or there is residual pressure in the piping system of the machine, the flow medium

Warning can escape under pressure when releasing the connections. You and other people

may suffer serious injuries.

❑ Ensure that no feed pressure is applied.

❑ Ensure that there is no residual pressure in the piping system.

Rev. E Page 15 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

Error Potential causes Elimination

Rotating union is Incorrect installation 1. Stop the machine.

leaky after installation 2. Ensure that the connections are sealed ac-

cording to the manual “Installation”.

3. Ensure that all hoses are installed without

stress.

4. Ensure that all seal faces are clean.

Seal faces of the rotating 1. Pack rotating union (see Pack rotating un-

union are damaged ion for transport, page 16).

2. Send rotating union to DEUBLIN for over-

Rotating union is defec-

haul/service.

tive

Rotating union leaks Flow medium is contami- 1. Stop the machine.

before the end of the nated 2. Drain flow medium.

expected service life 3. Send rotating union to DEUBLIN for over-

haul/service, if required.

4. Mount new filter.

5. Flush the piping system of the machine.

6. Fill in new flow medium.

Rotating union is not de- 1. Ensure that the correct DEUBLIN Rotating

signed for the respective Union is used.

application 2. Contact DEUBLIN if required.

Rotating union runs Thread and/or concen- 1. Stop the machine.

untrue or wobbles tricity outside the admis- 2. Remove rotating union.

sible tolerance. 3. Manufacture new thread or flange.

4. Install rotating union.

Rotating union is mount-

ed incorrectly.

9.2 Pack Rotating Union for Transport

The rotating union has to be protected against mechanical impact and humidity during transport to

ensure that the rotating union will arrive at DEUBLIN without being damaged.

1. Dismount the rotating union in reverse order of the installation (see Installation).

2. Ensure that the rotating union is free from the respective flow medium.

3. Use a cardboard box which is suitable for the weight of the rotating union.

4. Cushion the base of the cardboard box with a soft material, e.g. air bubble film.

5. Wrap the rotating union with a soft material, e.g. air bubble film.

6. Ensure that no packing material or dirt can penetrate the opening of the rotating union.

7. Position the rotating union in the middle of the cardboard box.

8. Fill the free space around the rotating union with newspaper or another suitable material.

9. Close the cardboard box by means of tape.

Rev. E Page 16 of 18 ©DEUBLIN

Model/Series: 54, 55 & 57

Operating Manual Number: 040-550GB

Version: 2009-11

10 Disposal

10.1 Dispose of Packaging

❑ Dispose of the packaging (cardboard box and plastics) according to the national standards,

regulations and directives.

10.2 Dispose of Rotating Union

Basically, the rotating unions consist of metals (steel, brass, bronze, copper) which can be reused

within the reclamation of scrap. Dispose of materials in a way that the disposal is compatible regarding

humans, nature and environment. In doing so, ensure that rotating unions to be disposed of are free

from the respective flow media.

❑ Dismount the rotating union in reverse order of the installation (see Installation).

❑ Flush the rotating union.

❑ Collect the dirty flushing media.

❑ Dispose of the collected flushing media according to the national standards, regulations and

directives.

❑ If you use thermal oil, please observe the instructions of the thermal oil manufacturer.

❑ Dispose of the rotating union according to the national standards, regulations and directives.

In case of repair, DEUBLIN disposes of all used parts.

11 Spare Parts

The rotating unions have a limited service life and include wearing parts. Wearing parts are excluded

from the warranty. All static and dynamic sealing elements of a component are considered wearing

parts.

Repair kits are available for several models of the rotating unions and can be obtained from DEUBLIN.

Please ask your DEUBLIN Service.

You need special tools and repair instructions for repair of the rotating unions which can be obtained

from DEUBLIN as well.

Note

If you do not want to repair your rotating union on your own, DEUBLIN will be pleased

to help you. If requested, DEUBLIN will exchange all wearing parts and clean all com-

Info ponents of the rotating union. Before repaired rotating unions leave the premises, they

will be subjected to an operational check. You will receive a rotating union with war-

ranty.

Rev. E Page 17 of 18 ©DEUBLIN

Reliability

Many years’ experience, ongoing liaison with customers, innovations sourced

inhouse and from suppliers place DEUBLIN in a position providing

reliable Rotating Unions at the highest level.

When it comes to concrete applications, maximum service life is guaranteed

by matching the sealing to the respective medium.

The service life is also equally maximized by maintaining cleanliness when

storing and handling the Rotating Union and by adhering to the guidelines issued

by DEUBLIN in respect of the conditions on the customer’s premises.

DEUBLIN Company DEUBLIN Ibérica, S.L. DEUBLIN de Mexico S. De R.L. de C.V.

2050 Norman Drive, West Avda. Bogatell 23 Norte 79-A No. 77

Waukegan, IL 60085-6747, U.S.A. 08005 Barcelona, Spain Col. Claveria

++1-847-689-8600 ++34-93-2211223 02080 Mexico, D.F.

++1-847-689-8690 ++34-93-2212093 ++52-55-5342-0362

customerservice@deublin.com serviciocliente@deublin.es ++52-55-5342-0157

deublin@prodigy.net.mx

DEUBLIN Austria GmbH

CANADIAN OFFICE Trazerberggasse 1/2 DEUBLIN Korea Co., Ltd

9454 Route Trans-Canadienne 1130 Wien, Austria 104-11, Ssang-Ryung-Dong

St-Laurent, Quebec H4S 1R7, Canada ++43-1-8768450 Kwang-Ju-Si, Kyung-Gi-Do, Korea

++1-514-745-4100 ++43-1-876845030 ++82-31-763-3311

++1-514-745-8612 info@deublin.at ++82-31-763-3309

customerservice@deublin.com customerservice@deublin.co.kr

DEUBLIN Polska Sp. z o.o

ul. Kamieńskiego 201-219 DEUBLIN Brasil

DEUBLIN GmbH 51-126 Wrocław, Poland Juntas Rotativas de Precisão Ltda.

Nassaustraße 10 ++48-71-3528152 Rua Santo Antonio, 1458 Vila Galvão

65719 Hofheim, Germany ++48-71-3207306 Guarulhos São Paulo Brazil 07071-000

++49-6122-80020 info@deublin.pl ++55-11-2455-3245

++49-6122-15888 ++55-11-2455-2358

info@deublin.de DEUBLIN Finland Oy deublinbrasil@deublinbrasil.com.br

Kivääritehtaankatu 8

40100 Jyväskylä, Finland DEUBLIN (Dalian)

DEUBLIN Italiana S.r.l. ++358 207 290 210 Precision Rotating Unions Co. Ltd

Via Giovanni Falcone 36 ++358 207 290 219 No. 2, 6th DD street

20010 Bareggio (MI), Italy info@deublin.fi DD Port Dalian

++39-02-90312711 Liaoning Province, 116620 P.R. China

++39-02-90278189 DEUBLIN Italiana S.r.l. - Swedish Filial ++86-411-87549678

info@deublin.it Cylindervägen 18, Box 1113 ++86-411-87549679

13 126 Nacka Strand, Sweden info@deublin.cn

++46 8 716 2033

DEUBLIN Ltd. ++46 8 601 3033 DEUBLIN Asia Pacific Pte Ltd

6 Sopwith Park, info@deublin.se 51 Goldhill Plaza, #11-11/12

Royce Close, West Portway Singapore 308900

Andover SP10 3TS, U.K. DEUBLIN Japan Limited ++65-6259-9225

++44-1264-333355 2-13-1, Minamihanayashiki ++65-6259-9723

++44-1264-333304 Kawanishi City 666-0026, Japan deublin@singnet.com.sg

deublin@deublin.co.uk ++81-72-757-0099

©2009 DEUBLIN GmbH | Nassaustr. 10 | 65179 Hofheim

++81-72-757-0120 DEUBLIN Asia Pacific Pte Ltd

customerservice@deublin-japan.co.jp Shanghai Representative Sales Office

DEUBLIN Sarl China Merchants Plaza 12th Floor,

61 bis, Avenue de l'Europe 2-4-10-3F Ryogoku Suite (East) 1208

Z.A.C de la Malnoue Sumida-Ku, Tokyo 130-0026, Japan 333 Chengdubei Road

77184 Emerainville, France ++81-35-625-0777 Shanghai, 200041 China

++33-1-64616161 ++81-35-625-0888 ++86-21-52980791

++33-1-64616364 customerservice@deublin-japan.co.jp ++86-21-52980790

service.client@deublin.fr service@deublin.cn

Alle Rechte vorbehalten.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 5th Grade English Activity 1 PDFDocument4 pages5th Grade English Activity 1 PDFsergioNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- NTZ 238252Document3 pagesNTZ 238252sergioNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 5 - Operating Instruction - Reel Station WS With DC Actuator AG 2571 AG 2671 AG 4571 AG 4671 - BEADocument8 pages5 - Operating Instruction - Reel Station WS With DC Actuator AG 2571 AG 2671 AG 4571 AG 4671 - BEAjose mondacaNo ratings yet

- PDFDocument3 pagesPDFsergioNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PDFDocument5 pagesPDFsergioNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- PDFDocument6 pagesPDFsergioNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PDFDocument6 pagesPDFsergioNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PDFDocument14 pagesPDFsergioNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- PDFDocument5 pagesPDFsergioNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- PDFDocument18 pagesPDFsergioNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- PDFDocument6 pagesPDFsergioNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Trabajo de Investigación y Divulgación CientíficaDocument3 pagesTrabajo de Investigación y Divulgación CientíficasergioNo ratings yet

- PDFDocument6 pagesPDFsergioNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PDFDocument14 pagesPDFsergioNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- PDFDocument3 pagesPDFsergioNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 5th Grade English Activity 1 PDFDocument4 pages5th Grade English Activity 1 PDFsergioNo ratings yet

- 5th Grade English Activity 2 PDFDocument2 pages5th Grade English Activity 2 PDFsergioNo ratings yet

- Interactive Catalog Supplements Catalog PdfsDocument3 pagesInteractive Catalog Supplements Catalog PdfssergioNo ratings yet

- 5th Grade English Activity 2Document2 pages5th Grade English Activity 2sergioNo ratings yet

- Human BodyDocument55 pagesHuman BodysergioNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2 Quarter Examination in Tle 8 (Electrical Installation and Maintenance)Document3 pages2 Quarter Examination in Tle 8 (Electrical Installation and Maintenance)jameswisdom javier100% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CoaseDocument20 pagesCoasepwalker_25100% (1)

- What Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingDocument26 pagesWhat Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingVeeraperumal ArumugamNo ratings yet

- Constitutional Law Digest PDFDocument212 pagesConstitutional Law Digest PDFJoram WambuguNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Organizational Citizenship Behavior (OCB) andDocument10 pagesOrganizational Citizenship Behavior (OCB) andInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SD WanDocument32 pagesSD WanAbdalrawoof AlsherifNo ratings yet

- Community Service ProposalDocument3 pagesCommunity Service ProposalAbdurahman AbdulhakimNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Managerial Eco and Accounting FinalDocument16 pagesManagerial Eco and Accounting FinalMichael Paul GabrielNo ratings yet

- Simplex 4081-0002Document2 pagesSimplex 4081-0002vlaya1984No ratings yet

- 5.1.2.8 Lab - Viewing Network Device MAC AddressesDocument5 pages5.1.2.8 Lab - Viewing Network Device MAC Addresseschristian hallNo ratings yet

- Arid Agriculture University, Rawalpindi: MultimediaDocument22 pagesArid Agriculture University, Rawalpindi: MultimediaAshh Ishh100% (1)

- IBM Informix 4GL V7.50 - Quick Start GuideDocument2 pagesIBM Informix 4GL V7.50 - Quick Start GuideMohamed AfeilalNo ratings yet

- Module Code & Module Title CC6051NI Ethical Hacking Assessment Weightage & Type Weekly AssignmentDocument7 pagesModule Code & Module Title CC6051NI Ethical Hacking Assessment Weightage & Type Weekly AssignmentBipin BhandariNo ratings yet

- Application of Power Electronic Converters in Electric Vehicles andDocument22 pagesApplication of Power Electronic Converters in Electric Vehicles andfekadu gebeyNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Installing Wilson Yagi Antenna 301124Document4 pagesInstalling Wilson Yagi Antenna 301124SentaNo ratings yet

- FINANCE CASES AND TOPICSDocument7 pagesFINANCE CASES AND TOPICSFuzael AminNo ratings yet

- Related Lit For ArDocument30 pagesRelated Lit For ArBey Bi NingNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 22172/pune Humsafar Third Ac (3A)Document2 pages22172/pune Humsafar Third Ac (3A)VISHAL SARSWATNo ratings yet

- Wiccan - The Basics of Herbs and Herbal Magic and Spells and MagickDocument5 pagesWiccan - The Basics of Herbs and Herbal Magic and Spells and Magickkhalilgib67% (3)

- BSBDIV501 Assignment Activity: This Study Resource WasDocument6 pagesBSBDIV501 Assignment Activity: This Study Resource WasRajeev AdhikariNo ratings yet

- Service Manual: Washing Machine Toploader AWT 2287/3Document14 pagesService Manual: Washing Machine Toploader AWT 2287/3panda3362No ratings yet

- ICO LetterDocument3 pagesICO LetterLola HeaveyNo ratings yet

- ICE Export Catalog 2011Document72 pagesICE Export Catalog 2011Thien BinhNo ratings yet

- Safe Operating Area Testing Without A Heat SinkDocument4 pagesSafe Operating Area Testing Without A Heat SinkCarlos MeloNo ratings yet

- Preamble 2023Document94 pagesPreamble 2023SAIGAL TANKERNo ratings yet

- BS 3921-1985 Specification For Clay Bricks PDFDocument31 pagesBS 3921-1985 Specification For Clay Bricks PDFLici001100% (4)

- STP-135-130 TB PDFDocument2 pagesSTP-135-130 TB PDFasif iqbalNo ratings yet

- iC60L Circuit Breakers (Curve B, C, K, Z)Document1 pageiC60L Circuit Breakers (Curve B, C, K, Z)Diego PeñaNo ratings yet

- Income Tax Raids: Procedures and RightsDocument4 pagesIncome Tax Raids: Procedures and RightsshanikaNo ratings yet