Professional Documents

Culture Documents

rfg069179 PDF

rfg069179 PDF

Uploaded by

Juan HurtadoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

rfg069179 PDF

rfg069179 PDF

Uploaded by

Juan HurtadoCopyright:

Available Formats

TECHNICAL SERVICE BULLETIN

BULLETIN NUMBER: D194/D195/D203/D204 - 032 10/9/2015

APPLICABLE MODEL:

LANIER – Pro C7100S/Pro C7110S/Pro C7100SX/Pro C7110SX

RICOH – Pro C7100S/Pro C7110S/Pro C7100SX/Pro C7110SX

SAVIN – Pro C7100S/Pro C7110S/Pro C7100SX/Pro C7110SX

SUBJECT: TONER DETERIORATION (BANDING, GRAINY, DIRTY BACKGROUND)

SYMPTOM:

One or more of the following recurs, after a temporal improvement brought by toner refresh:

- Banding

- Grainy images

- Dirty background

CAUSE:

Deterioration of the toner.

Fresh toner supplied to the development unit deteriorates over time while agitated in the development unit,

gradually losing its transferability.

Note: The following factors promote faster toner deterioration. They commonly occur on showroom

machines.

Printing at low image coverage

Printing at low P/J

Printing with mixed paper sizes and media types

(This results in more pauses to optimize the fusing temperature, during which the development

unit continues to rotate).

Frequent usage of finishing options, especially folding

Frequent machine power OFF/ON

Intermittent use of the machine

SOLUTION:

Perform the following procedure if any of the conditions above apply:

Copyright 2015 RICOH Americas Corporation. All rights reserved. Page 1 of 2

Tech Service Bulletin No. D194/D195/D203/D204 - 032

PROCEDURE

1. Refresh the toner using the following steps.

Note: This will completely replace the toner currently inside the development unit.

1. Set SP2109-003 (Pattern Selection) to 26 (Full Dot Pattern).

2. Set SP2109-005 (Color Selection) to 1 (Full Color).

3. Set SP2109-006 (Density: K) to 15.

4. Set SP2109-007 (Density: C) to 15.

5. Set SP2109-008 (Density: M) to 0.

6. Set SP2109-009 (Density: Y) to 0.

7. Print or copy 60 duplex pages (30 sheets) onto A3.

IMPORTANT: Do not print 4C solid images (i.e., Do not set SP2109-008 or -009 to a value of 15 in

Steps 5 and 6). If you do, toner may scatter inside the machine.

8. Set SP2109-006 (Density: K) to 0.

9. Set SP2109-007 (Density: C) to 0.

10. Set SP2109-008 (Density: M) to 15.

11. Set SP2109-009 (Density: Y) to 15.

12. Print or copy 60 duplex pages (30 sheets) onto A3.

IMPORTANT: Continue with this procedure only if Step 1 (refreshing of the toner) improved the

symptom. (Doing the following steps will increase toner consumption).

2. Set SP3820-032 (Tnr Refresh Mode: Accumulated refresh length: Upper Limit)

to a value of 50000.0mm.

Note:

SP3820-011, 012, 013, 014, 015 (Tnr Refresh Mode: Amount) indicate the amount of the toner that

needs to be refreshed (i.e., how much the toner has deteriorated).

This SP change will allow the machine to continually refresh the toner even when the machine is

used under relatively severe conditions.

3. Set all of the following SP modes to a value of “0”.

SP3530-001 (Power ON ProCon:Set:Non-use Time Setting)

SP3530-002 (Power ON ProCon:Set:Temperature Range)

SP3530-003 (Power ON ProCon:Set:Relative Humidity Range)

SP3530-004 (Power ON ProCon:Set:Absolute Humidity Range)

Note:

This is done because process control can accelerate toner deterioration, especially with machines

that are turned OFF/ON frequently. This is also true of machines that are used intermittently, as

process control is also triggered after the machine is not used for over 30 minutes. These settings will

cancel process control at these times.

There are no side-effects in terms of image quality (as process control is still performed before the

next job is printed). However, this process control before the next job will take longer to complete.

4. Set the following SP modes to the values shown.

SP3820-022 (Tnr Refresh Mode:Max Job End Pattern): Set to 1000mm.

SP3820-024 (Tnr Refresh Mode:Job End Ptn Start threshold): Set to 1mm.

Note:

This will enable toner refresh at job end. By doing this, there are more opportunities for the machine

to refresh the toner.

Toner consumption will increase.

Page 2 of 2

You might also like

- Photography 101: Pocket Guide: Exposure Basics, Camera Settings, Lens Info, Composition Tips, and Shooting ScenariosFrom EverandPhotography 101: Pocket Guide: Exposure Basics, Camera Settings, Lens Info, Composition Tips, and Shooting ScenariosNo ratings yet

- Practice ProblemsDocument2 pagesPractice ProblemsAmandeep DahiyaNo ratings yet

- EVE EVE48100 User ManualDocument29 pagesEVE EVE48100 User ManualHoàng HiếuNo ratings yet

- Canon Service Mode EEPROM Info 1Document5 pagesCanon Service Mode EEPROM Info 1gomo710100% (2)

- Canon PixmaPro 9000 ManualDocument46 pagesCanon PixmaPro 9000 ManualcyberiahNo ratings yet

- Canon Pixma MP810 + MP960 Service ManualDocument82 pagesCanon Pixma MP810 + MP960 Service Manuallossie46No ratings yet

- MP 2554-6054 Series - Full-Ct - EN - 1.0.aDocument277 pagesMP 2554-6054 Series - Full-Ct - EN - 1.0.aArlindPacuku100% (1)

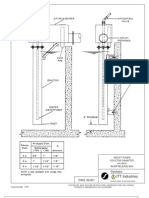

- Airlift Pump DWGDocument18 pagesAirlift Pump DWGravichandiran_a2001100% (2)

- TSB Light Images - Toner Dusting - Over ToningDocument2 pagesTSB Light Images - Toner Dusting - Over ToningTintila StefanNo ratings yet

- Technical Service BulletinDocument5 pagesTechnical Service BulletinRister ZinnNo ratings yet

- Light Images, Toner Dusting and Over Toning IssuesDocument2 pagesLight Images, Toner Dusting and Over Toning IssuesRICHARD ALBERTO NARVA ORTIZNo ratings yet

- PIXMA Ip5200 PIXMA iP5200R: Service ManualDocument64 pagesPIXMA Ip5200 PIXMA iP5200R: Service ManualmatmaricNo ratings yet

- Reguero de TonerDocument1 pageReguero de TonerescanerdocumentalljsNo ratings yet

- Ip1000 Service Manual PDFDocument20 pagesIp1000 Service Manual PDFAlexSantosNo ratings yet

- Kyocera Mita KM1505 1510 1810 Series ELITEC EssentialsDocument6 pagesKyocera Mita KM1505 1510 1810 Series ELITEC EssentialsJaime RiosNo ratings yet

- Canon Pixma-Ip1000 SMDocument31 pagesCanon Pixma-Ip1000 SMFlorin Gostian100% (1)

- SPC232SF SPmodeDocument15 pagesSPC232SF SPmodeHelder CostaNo ratings yet

- I P100 SMDocument28 pagesI P100 SMSean BurnsNo ratings yet

- Fusing Offset Image METISDocument3 pagesFusing Offset Image METISKhan FaisalNo ratings yet

- Canon Pixma IP-90 Service ManualDocument17 pagesCanon Pixma IP-90 Service ManualCatalin Banica100% (1)

- Technical Bulletin No. RTB-001Document32 pagesTechnical Bulletin No. RTB-001Long MinhNo ratings yet

- SureColor Print Quality GuideDocument6 pagesSureColor Print Quality GuideAdrian YapNo ratings yet

- F2 T01 N09 10058 05Document4 pagesF2 T01 N09 10058 05MatijaNo ratings yet

- Pixma Mp520: Service ManualDocument37 pagesPixma Mp520: Service ManualLeticia Barcenas SalidoNo ratings yet

- ProductSupportGuide SPC242SFDocument25 pagesProductSupportGuide SPC242SFRicoh Company LtdNo ratings yet

- 3035-4035-5035 Firmware Bulletin R22Document50 pages3035-4035-5035 Firmware Bulletin R22Tiago Rebelo100% (1)

- Canon Pixma Ix5000 Ix4000 Service ManualDocument44 pagesCanon Pixma Ix5000 Ix4000 Service ManuallftrevNo ratings yet

- Canon PIXMA IP1500 Service ManualDocument21 pagesCanon PIXMA IP1500 Service Manualnetinho2000No ratings yet

- Canon MP 160Document13 pagesCanon MP 160Derla Corina0% (1)

- Technical Bulletion AF200Document198 pagesTechnical Bulletion AF200Amer RafiqueNo ratings yet

- Bizhub: Troubleshooting GuideDocument50 pagesBizhub: Troubleshooting GuideRaheelNo ratings yet

- E Studio 160200250 GBDocument180 pagesE Studio 160200250 GBHettiarachchi JayasingheNo ratings yet

- Features of The RISOGRAPH FRDocument1 pageFeatures of The RISOGRAPH FRRheana DomingoNo ratings yet

- 7075Document156 pages7075petrasNo ratings yet

- Service Bulletin: Subject ModelDocument1 pageService Bulletin: Subject ModelAlexNo ratings yet

- Echnical Ulletin: PAGE: 1/4Document14 pagesEchnical Ulletin: PAGE: 1/4schlitztechNo ratings yet

- NTV-T1 Viscometer Operation ManualDocument16 pagesNTV-T1 Viscometer Operation ManualAlfian Firdaus DarmawanNo ratings yet

- Canon Pixma Mp610Document45 pagesCanon Pixma Mp610promatis5746100% (2)

- Canon Ip4600Document21 pagesCanon Ip4600pcboygr100% (1)

- Kyocera FS-1035MFP-1135MFP FW Release Notes R4Document5 pagesKyocera FS-1035MFP-1135MFP FW Release Notes R4AlNo ratings yet

- Printer Sublim Epson SureColor SC F10030H 76Document8 pagesPrinter Sublim Epson SureColor SC F10030H 76Khelvin WongNo ratings yet

- Ricoh 6000Document2 pagesRicoh 6000Dương Minh PhụngNo ratings yet

- Black Background Bizhub 600Document1 pageBlack Background Bizhub 600saito36100% (1)

- Canon Pixma I80 Service Manual PDFDocument12 pagesCanon Pixma I80 Service Manual PDFkev2310No ratings yet

- Instruction ManualDocument16 pagesInstruction Manualshirley_toNo ratings yet

- D Copia - 12sm (Y101700 5) PDFDocument78 pagesD Copia - 12sm (Y101700 5) PDFTonyandAnthonyNo ratings yet

- c352 Troubleshooting GuideDocument54 pagesc352 Troubleshooting Guideroosterman4everNo ratings yet

- SECTION 03 InstallationDocument14 pagesSECTION 03 InstallationRFamDamily100% (1)

- TP12 384 PDFDocument7 pagesTP12 384 PDFgentoaliNo ratings yet

- CD1116-20-25 TechnicalBulletin 20101018Document123 pagesCD1116-20-25 TechnicalBulletin 20101018dtolind smtpNo ratings yet

- Fujifilm X-T3: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T3: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Fujifilm X100VI: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X100VI: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- The Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesFrom EverandThe Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesNo ratings yet

- Fujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- 3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!From Everand3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!No ratings yet

- Chapter 3 Formulas, Equations and MolesDocument23 pagesChapter 3 Formulas, Equations and MolesVrundanNo ratings yet

- Orb SampleDocument2 pagesOrb SampleChong Ching ShyanNo ratings yet

- Build A Variable High Voltage Power Supply PDFDocument17 pagesBuild A Variable High Voltage Power Supply PDFsynkybabyNo ratings yet

- Nupetiet Golgranzs DreadnoughtDocument7 pagesNupetiet Golgranzs DreadnoughtJesse WilliamsNo ratings yet

- Cembre Zeta ConnectorDocument10 pagesCembre Zeta ConnectorAbdul Majeed SurmawalaNo ratings yet

- Machinists Tools by Williams 1944Document32 pagesMachinists Tools by Williams 1944OSEAS GOMEZNo ratings yet

- Flowcharts and PseudocodeDocument6 pagesFlowcharts and PseudocodeBrody MNo ratings yet

- Elastopor H 2130-38 Material CertificateDocument3 pagesElastopor H 2130-38 Material Certificatejithinjose860% (2)

- Mounting Instructions For The '123ignition': ImportantDocument4 pagesMounting Instructions For The '123ignition': ImportantclmarinNo ratings yet

- Tetracycline ADocument15 pagesTetracycline APapaindoNo ratings yet

- Programming ESP8266 - ESP-201 Stand Alone With Arduino IDE - 6 StepsDocument6 pagesProgramming ESP8266 - ESP-201 Stand Alone With Arduino IDE - 6 StepsZenón Martínez CruzNo ratings yet

- Injectomat Tiva AgiliaDocument2 pagesInjectomat Tiva AgiliaswamyNo ratings yet

- SapsdmaterialDocument367 pagesSapsdmaterialNaresh BitlaNo ratings yet

- Industrial Training Final ReportDocument28 pagesIndustrial Training Final ReportMuhammad Harith Hilmi Zen AzharNo ratings yet

- Manin6300m01 A PDFDocument58 pagesManin6300m01 A PDFMIGUELNo ratings yet

- JKR - Soil InvestigationDocument49 pagesJKR - Soil InvestigationIr Fid100% (3)

- 10128688-400-EnG-MKT41-02 - Coiled Tubing Tools Catalog - Distribution FileDocument100 pages10128688-400-EnG-MKT41-02 - Coiled Tubing Tools Catalog - Distribution Filetao.han100% (1)

- PhyML-3.1 - Manual BioinformaticsDocument39 pagesPhyML-3.1 - Manual BioinformaticsRogelio PrietoNo ratings yet

- Universal Serial Bus (USB)Document15 pagesUniversal Serial Bus (USB)rajkumar_jain4855100% (2)

- Pent Shed PlansDocument11 pagesPent Shed PlansRonney GuerraNo ratings yet

- 006 Blasting TechnologyDocument5 pages006 Blasting TechnologyKenny CasillaNo ratings yet

- C45T OM ManualDocument30 pagesC45T OM Manualfrancescoli80100% (1)

- 2002 Trans TOCDocument5 pages2002 Trans TOCparand92No ratings yet

- XL1500Document2 pagesXL1500arianebelenNo ratings yet

- ES - 1NZ-FXE Engine Control SystemDocument480 pagesES - 1NZ-FXE Engine Control SystemHari Prasad Ambaripeta84% (19)

- Tensile Testing Mild Steel As Received Sample: Experiment 1 Group1Document9 pagesTensile Testing Mild Steel As Received Sample: Experiment 1 Group1Adarsh BujadeNo ratings yet

- Instrumental Analysis Lecture Notes IIDocument56 pagesInstrumental Analysis Lecture Notes IIcoolhemakumar100% (3)