Professional Documents

Culture Documents

Howarth Bow Saw Taper Reaming

Uploaded by

StevenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Howarth Bow Saw Taper Reaming

Uploaded by

StevenCopyright:

Available Formats

EDWARDS MOUNTAIN WOODWORKS, LLC

fine handtool woodworking: creating and teaching in wood

Bill Anderson

57 Woodside Trail

Chapel Hill, NC

27517-6077

919.932.6050

bill@edwardsmountainwoodworks.com

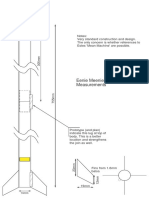

Taper Reaming for Bow Saw Pins

Taper Reamer. The hand reamer I have used is a 6 flute, straight taper reamer made by Brown and Sharp. You will

need a No. 2 taper for the Howarth bowsaw or a No. 1 taper reamer for the Melhuish bowsaw (both 1/2” per foot).

The cheapest source I have identified is at www.aircraft-tool.com, phone 800-248-0638. The cost is about $38. For

the handles of each bowsaw, the taper reamer is too long. Cut the reamer to length, where the final reamer diameter

is just a bit less than the smallest diameter of the short end of the pins, and then grind it sharp and square on the cut

end. This shortened reamer will thus ream both the handle holes and the arm holes. Note: this is hardened steel, so

a hacksaw and file will not work here. Cut-off wheel from any big-box hardware store will work well. Install this in a

6” grinder, for example.

General Procedure for Using a Reamer. You will need to use the reamer with a tap wrench. These are available

in any tap and die set or can be purchased from stores like Harbor Freight or Northern Tool or online from MSC Tools

or McMaster-Carr. Do not use the reamer in a drill press, only ream by hand. The best technique to use a reamer is

to hold the wrench handles with both hands, applying equal pressure straight down with moderate but not excessive

force. Turn the handles ½ turn at each iteration, reposition your hands and turn again. As you get close to the final

reamed dimensions, check your progress with a bowsaw pin with each ½ or even ¼ turn.

Making and Reaming the Bow Saw Handles. Any tight straight grained wood would be suitable for handles, but

boxwood is very often used. Some options might include dogwood or Osage orange. Walnut, maple and ebony are

also good choices. Cut your blanks to a length suitable for turning on the lathe (i.e., at least 1” longer than the final

length), but leave the blank square or rough at this point. Mark the centers of the blank as well as possible, and on

the lathe, drill the blanks to 9/32” (the small diameter of the brass pins). Drill both handles to a depth that is about ½”

longer than the short end of the bow saw pin (e.g., drill to about 2 ¼” for the Howarth bowsaw). Fix the blank straight

up in a shoulder vise on your bench. Ream the holes using a hand reamer until the pin is just shy of seating

completely (a skinny 1/8” or so). Return to the lathe and turn the handle to final dimensions, using a cone center for

the hole. You may want to square up the hole end of the blank so that the face is square to the hole. The handle is

then reamed carefully to fit the pin so that the flange seats against the end of the handle with a light tapping. Coat

the pin with hide glue or epoxy and tap it into place. Additionally, you can drill a cross pin hole through the minor

diameter of the handle and tap in a small brad cut to length to lock the pin and handle together. I would do this on the

drill press with a specially made vee-block to hold the handle securely. Choose a bit and a brad so that the brad fits

in tightly. You may need to carefully file the brad after it is tapped in for a smooth fit.

Drilling and Reaming the Bow Saw Arms. The goal is to seat the handle so that it is locked in by the taper and not

by abutting the pin flange against the arm. This is a “trial and error” process until the gap between the arm and the

handle flange is 1/8” to 1/4”. If you taper too deeply and the flange makes contact with the arm, take a few plane

shavings from the outside face of the arm until the handle seats properly. You will correct for this when you make the

stretcher. To begin, layout the points for drilling square around both faces of the bow saw arm, and center these

points across the thickness of the arm. Ideally, use a marking gauge set first to scribe the distance up from the

bottom edge of the arm. Reset the gauge to scribe down the centerline, and reference the marking gauge from the

same face of the arm to make both marks. In this way, both marks on the arm will be in a straight, square line. With

a brace and bit, drill a 7/64” or as much as a 9/32” hole halfway in from both faces of the arm to meet in the middle.

Use a square to aid in sighting and keeping the drill square. Ream from the outside face towards the inner face of

each arm. Carefully check the fit of the pin as you come close to the final fit. This will happen very quickly, so

caution is the word here. Make sure that the bowsaw arms are sized in width so that the pins will protrude enough to

allow a blade to be attached. With the blade attached to each arm at the pins, measure the distance between the

opposing bow saw arm faces. This is the shoulder-to-shoulder length of the stretcher. If you intend to have a curved

shoulder mortise and tenon for the stretcher, be sure to allow for the extra length accounted for by the curvature, as

well as for the two tenon lengths.

You might also like

- Tip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesDocument4 pagesTip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesAntonio Alberto Fonseca FilhoNo ratings yet

- Build A BowsawDocument4 pagesBuild A Bowsawjon789100% (1)

- Basic Box MakingDocument18 pagesBasic Box MakingSandro Braga100% (1)

- Shaker FurnitureDocument25 pagesShaker Furniturevictor100% (1)

- Starting A Business Candle Making 2009Document2 pagesStarting A Business Candle Making 2009Carlo Fabros Junio100% (4)

- Hone Your Hand-Tool Skills: A Handful of Exercises Develops Competence and Confidence With Chisels, Planes, and SawsDocument8 pagesHone Your Hand-Tool Skills: A Handful of Exercises Develops Competence and Confidence With Chisels, Planes, and SawsAdrian Cocis100% (1)

- Dovetail Guide User ManualDocument9 pagesDovetail Guide User ManualAnonymous 9zL9MblM3HNo ratings yet

- Carpenter ToolsDocument12 pagesCarpenter ToolsRavi Prakash Eranki100% (4)

- Woodworking TipsDocument13 pagesWoodworking TipsjahemscbdNo ratings yet

- Easy Resawing: The Fence. The FenceDocument2 pagesEasy Resawing: The Fence. The FenceBilAndersenNo ratings yet

- Basic Box MakingDocument16 pagesBasic Box Makingcerberus3385100% (3)

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopFrom EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopNo ratings yet

- 2011LureMakingFeature PDFDocument6 pages2011LureMakingFeature PDFJose M. Castillo50% (2)

- 1990 1 JanFebDocument25 pages1990 1 JanFebRocio Mtz100% (1)

- Manual For Building A Traditional English LongbowDocument6 pagesManual For Building A Traditional English LongbowZvonimirMalbašaNo ratings yet

- Hand Cut DovetailsFINALDocument6 pagesHand Cut DovetailsFINALMuhammet OfluoğluNo ratings yet

- Build Your Own Router Plane for Less Than $5Document4 pagesBuild Your Own Router Plane for Less Than $5jucassabao75% (4)

- Philippine LiteratureDocument82 pagesPhilippine LiteratureLovelene Chrizze100% (5)

- Tools & Techniques for Building a Classic Garden Table & BenchDocument2 pagesTools & Techniques for Building a Classic Garden Table & BenchmarianrkwNo ratings yet

- Manual For Building A C. 40 Lbs. LongbowDocument7 pagesManual For Building A C. 40 Lbs. LongbowO/JNo ratings yet

- AirTrails Classic Flying Models Fall1979Document90 pagesAirTrails Classic Flying Models Fall1979mendper100% (1)

- BASKETRY MATERIALS AND TOOLSDocument43 pagesBASKETRY MATERIALS AND TOOLSCharish Monarca Rosaldes100% (2)

- Bow SawDocument6 pagesBow Sawkhunchaiyai100% (2)

- The Hand-Cut Mortise and Tenon: HandworkDocument4 pagesThe Hand-Cut Mortise and Tenon: HandworkwitwatersrandNo ratings yet

- Scythe Peening ManualDocument16 pagesScythe Peening ManualBotan Anderson100% (1)

- Shop Made Saw ViseDocument2 pagesShop Made Saw VisesergiaocunhaNo ratings yet

- Potassium Nitrate Rocket Engine RatiosDocument15 pagesPotassium Nitrate Rocket Engine RatiosKhoa Vũ100% (1)

- MU8063 - FW Best TipsDocument13 pagesMU8063 - FW Best TipsJonas Rosa TerezaNo ratings yet

- Carpentry Workshop Practices Assignment: Clamps Are the Busiest ToolsDocument6 pagesCarpentry Workshop Practices Assignment: Clamps Are the Busiest ToolsTemesgen YohannesNo ratings yet

- Condor TailsDocument6 pagesCondor TailsEnrique CoronelNo ratings yet

- Make - Compressed Air Rockets KitDocument23 pagesMake - Compressed Air Rockets KitStevenNo ratings yet

- Hajj A Practical Guide-Imam TahirDocument86 pagesHajj A Practical Guide-Imam TahirMateen YousufNo ratings yet

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- 9781861088789Document11 pages9781861088789davidrobles269% (11)

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- Matchbox Rockets Template PDFDocument1 pageMatchbox Rockets Template PDFStevenNo ratings yet

- Peteward-Com MAKING A BOWDocument5 pagesPeteward-Com MAKING A BOWdescaraoNo ratings yet

- Classic Craftsman-Style Queen Bed: ModerateDocument11 pagesClassic Craftsman-Style Queen Bed: ModerateluisNo ratings yet

- Indigenous Basketry TechniquesDocument43 pagesIndigenous Basketry TechniquesCons Aquino ÜNo ratings yet

- Selección de Los Mejores Dispositivos y Trucos para La Sierra CircularDocument24 pagesSelección de Los Mejores Dispositivos y Trucos para La Sierra CircularPierre799es100% (6)

- Evolution Packet FinalDocument24 pagesEvolution Packet FinalJoaquinNo ratings yet

- Cut X-shaped legs with power miterboxDocument2 pagesCut X-shaped legs with power miterboxAvi KarmonNo ratings yet

- Your First Carving by LS IrishDocument22 pagesYour First Carving by LS IrishHaylton Bomfim100% (1)

- 12 Spoons, 2 Bowls, and a Knife: 15 Step-by-Step Projects for the KitchenFrom Everand12 Spoons, 2 Bowls, and a Knife: 15 Step-by-Step Projects for the KitchenRating: 5 out of 5 stars5/5 (1)

- (OM) Sharpening A Crooked, Hook or Bent KnifeDocument5 pages(OM) Sharpening A Crooked, Hook or Bent KnifeDavid UribeNo ratings yet

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolFrom EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolNo ratings yet

- Baseball Cap Rack: Woodworks: Beginner ProjectDocument7 pagesBaseball Cap Rack: Woodworks: Beginner ProjectEucap MdzNo ratings yet

- Build A Bowsaw: This Classic Tool Still Has A Place in The ShopDocument4 pagesBuild A Bowsaw: This Classic Tool Still Has A Place in The ShopBenjamin BeckerNo ratings yet

- Lesson 3: Ripping Wood: Instructables ClassesDocument12 pagesLesson 3: Ripping Wood: Instructables ClassesDian Pires100% (1)

- Glossary of Woodworking Hand ToolsDocument25 pagesGlossary of Woodworking Hand ToolsBojanNo ratings yet

- Tirfor: Lifting and Pulling Machines With Unlimited Wire RopeDocument26 pagesTirfor: Lifting and Pulling Machines With Unlimited Wire RopeGreg ArabazNo ratings yet

- Home Building TipsDocument245 pagesHome Building TipsoltaiyrxNo ratings yet

- Five tips for better bandsawingDocument6 pagesFive tips for better bandsawingAndrea Novella100% (1)

- First LongbowDocument3 pagesFirst LongbowGinshun Ray SpedowskiNo ratings yet

- Carving An Ash Flat BowDocument15 pagesCarving An Ash Flat Bowanon_3839218100% (1)

- Prof. Ed - Assessment and Evaluation of Learning Part 1-4Document8 pagesProf. Ed - Assessment and Evaluation of Learning Part 1-4Marisol Altobar PalatinoNo ratings yet

- Giant Wooden Clothes Pegs: InstructablesDocument19 pagesGiant Wooden Clothes Pegs: InstructablesToeNo ratings yet

- Sweeping Grind TipsDocument3 pagesSweeping Grind TipskayraNo ratings yet

- How To CutDocument23 pagesHow To CutAnxi NurhudaNo ratings yet

- Re SawDocument2 pagesRe Sawdogo70No ratings yet

- Marking GaugeDocument4 pagesMarking Gaugegustavoo.moura3No ratings yet

- Sawing: Tools Tools ToolsDocument38 pagesSawing: Tools Tools Toolsメルヴリッ クズルエタNo ratings yet

- Making Plastic PC ReedsDocument6 pagesMaking Plastic PC ReedsJayNo ratings yet

- Compass Rose Hand Router FinalDocument10 pagesCompass Rose Hand Router FinalJohnNo ratings yet

- Karpentiro PrintDocument22 pagesKarpentiro PrintErick MonteNo ratings yet

- Peachey: Knives and Bookbinding ToolsDocument30 pagesPeachey: Knives and Bookbinding ToolsRodrigo_La_Ros_1525No ratings yet

- Pattern Collection: Home: Knit, Relax, Smile, Repeat!Document2 pagesPattern Collection: Home: Knit, Relax, Smile, Repeat!Patricia VargasNo ratings yet

- Tip #115 Make Your Own Cam Clamps: Plan of ProcedureDocument2 pagesTip #115 Make Your Own Cam Clamps: Plan of Procedureski964No ratings yet

- Starship AntaresDocument13 pagesStarship AntaresStevenNo ratings yet

- RR KR2 Manual Pt1-6 PDFDocument25 pagesRR KR2 Manual Pt1-6 PDFSteven100% (1)

- Ecee Thunder TemplatesDocument13 pagesEcee Thunder TemplatesStevenNo ratings yet

- As5046 36inch Outline PDFDocument1 pageAs5046 36inch Outline PDFStevenNo ratings yet

- Design Card Stock AirplanesDocument35 pagesDesign Card Stock AirplanesStevenNo ratings yet

- Build a stealth delta wing gliderDocument1 pageBuild a stealth delta wing gliderStevenNo ratings yet

- Starfighter ScorpionDocument19 pagesStarfighter ScorpionStevenNo ratings yet

- Updated Version of SPOOLER PrototypeDocument8 pagesUpdated Version of SPOOLER PrototypeStevenNo ratings yet

- NikeZeusStomp Rocket-LauncherDocument4 pagesNikeZeusStomp Rocket-LauncherStevenNo ratings yet

- Designed by Greg K. Poehlein © 2005 Greg K. Poehlein: Parts ListDocument3 pagesDesigned by Greg K. Poehlein © 2005 Greg K. Poehlein: Parts ListStevenNo ratings yet

- Build and launch a soda-straw rocketDocument3 pagesBuild and launch a soda-straw rocketMichael ThelenNo ratings yet

- Build a Compressed Air Rocket TemplateDocument1 pageBuild a Compressed Air Rocket Templatesensitro9No ratings yet

- Newsletter 330Document8 pagesNewsletter 330julesvlcNo ratings yet

- Canaroc: Parts Conversions For CloningDocument1 pageCanaroc: Parts Conversions For CloningStevenNo ratings yet

- Octagon SkyrunnerDocument11 pagesOctagon SkyrunnerStevenNo ratings yet

- Design Card Stock AirplanesDocument35 pagesDesign Card Stock AirplanesStevenNo ratings yet

- NikeZeusStomp Rocket-LauncherDocument4 pagesNikeZeusStomp Rocket-LauncherStevenNo ratings yet

- Canaroc: Parts Conversions For CloningDocument1 pageCanaroc: Parts Conversions For CloningStevenNo ratings yet

- Standard rocket design and construction notesDocument1 pageStandard rocket design and construction notesStevenNo ratings yet

- Convert Gasoline Engine To Run On Alcohol 2008Document4 pagesConvert Gasoline Engine To Run On Alcohol 2008david2325100% (1)

- Octagon SkyrunnerDocument11 pagesOctagon SkyrunnerStevenNo ratings yet

- ch801 1-60 InstructionsDocument10 pagesch801 1-60 InstructionsStevenNo ratings yet

- Airborne All Stars Paper Flying Models of Famous A PDFDocument66 pagesAirborne All Stars Paper Flying Models of Famous A PDFStevenNo ratings yet

- Zenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerDocument16 pagesZenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerSteven100% (1)

- 2nd Chrispo Wind GeneratorDocument9 pages2nd Chrispo Wind GeneratorStevenNo ratings yet

- The Great International Paper Airplane Construction KitDocument88 pagesThe Great International Paper Airplane Construction Kitkarina2227No ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- Digital Water Monitoring and Turbidity Quality System Using MicrocontrollerDocument8 pagesDigital Water Monitoring and Turbidity Quality System Using MicrocontrollerIrin DwiNo ratings yet

- Appliance Saver Prevents OverheatingDocument2 pagesAppliance Saver Prevents OverheatingphilipNo ratings yet

- Kltdensito2 PDFDocument6 pagesKltdensito2 PDFPutuWijayaKusumaNo ratings yet

- LogDocument119 pagesLogcild MonintjaNo ratings yet

- A Summer Internship Project ON " To Study The Supply Chain Management On Amul Fresh Products" AT GCMMF, AmulDocument19 pagesA Summer Internship Project ON " To Study The Supply Chain Management On Amul Fresh Products" AT GCMMF, AmulweetrydhNo ratings yet

- Ringkasan LaguDocument4 pagesRingkasan LaguJoe PyNo ratings yet

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- spl400 Stereo Power Amplifier ManualDocument4 pagesspl400 Stereo Power Amplifier ManualRichter SiegfriedNo ratings yet

- English Extra Conversation Club International Women's DayDocument2 pagesEnglish Extra Conversation Club International Women's Dayevagloria11No ratings yet

- Best Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellDocument1 pageBest Home Oxygen Concentrators-Lowest Prices & Fast Shipping (Oxygen Machines) - 2021 - YuwellPelayanan ResusitasiNo ratings yet

- Vincent Ira B. Perez: Barangay Gulod, Calatagan, BatangasDocument3 pagesVincent Ira B. Perez: Barangay Gulod, Calatagan, BatangasJohn Ramsel Boter IINo ratings yet

- Ktu Students: Principles of ManagementDocument22 pagesKtu Students: Principles of ManagementNidaNo ratings yet

- Admission Procedure For International StudentsDocument8 pagesAdmission Procedure For International StudentsAndreea Anghel-DissanayakaNo ratings yet

- Polygenic InheritanceDocument13 pagesPolygenic InheritanceSandeep Kumar RaghuvanshiNo ratings yet

- Operating Manual: Please Read These Operating Instructions Before Using Your FreedomchairDocument24 pagesOperating Manual: Please Read These Operating Instructions Before Using Your FreedomchairNETHYA SHARMANo ratings yet

- Admisibility To Object EvidenceDocument168 pagesAdmisibility To Object EvidenceAnonymous 4WA9UcnU2XNo ratings yet

- More Than Moore: by M. Mitchell WaldropDocument4 pagesMore Than Moore: by M. Mitchell WaldropJuanjo ThepresisNo ratings yet

- Tuberculin Skin Test: Facilitator GuideDocument31 pagesTuberculin Skin Test: Facilitator GuideTiwi NaloleNo ratings yet

- Strategic Flexibility: The Evolving Paradigm of Strategic ManagementDocument3 pagesStrategic Flexibility: The Evolving Paradigm of Strategic Managementnanthini kanasanNo ratings yet

- Translation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Document20 pagesTranslation of Japanese Onomatopoeia Into Swedish (With Focus On Lexicalization)Aldandy OckadeyaNo ratings yet

- 1491559890CL 0417 PDFDocument48 pages1491559890CL 0417 PDFCoolerAdsNo ratings yet

- Guillermo Estrella TolentinoDocument15 pagesGuillermo Estrella TolentinoJessale JoieNo ratings yet