Professional Documents

Culture Documents

Material Data Sheet - Flexline: Description

Uploaded by

Raj RajeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Data Sheet - Flexline: Description

Uploaded by

Raj RajeshCopyright:

Available Formats

Material data sheet - FlexLine

EOS NickelAlloy IN718

EOS NickelAlloy IN718 is a heat and corrosion resistant nickel alloy powder intended for pro-

cessing on EOS DMLS systems.

This document provides information and data for parts built using EOS NickelAlloy powder (EOS

art.-no. 9011-0020) on the following specifications:

- EOS DMLS system: M400 SF

- EOSYSTEM: EOSPRINT v.1.2/HCS v.2.2.40

- EOS Parameter set IN718_040_FlexM400_1.11

Description

Parts built from EOS NickelAlloy IN718 have chemical composition corresponding to UNS

N07718, AMS 5662, AMS 5664, W.Nr 2.4668, DIN NiCr19Fe19NbMo3. This kind of precipita-

tion-hardening nickel-chromium alloy is characterized by having good tensile, fatigue, creep

and rupture strength at temperatures up to 700 °C (1290 °F).

This material is ideal for many high temperature applications such as gas turbine parts, instru-

mentation parts, power and process industry parts etc. It also has excellent potential for

cryogenic applications.

Parts built from EOS NickelAlloy IN718 can be easily post-hardened by precipitation-hardening

heat treatments. In both as-built and age-hardened states the parts can be machined, spark

eroded, welded, micro shot-peened, polished and coated if required. Due to the layerwise build-

ing method, the parts have a certain anisotropy.

Electro Optical Systems Finland Oy EOS GmbH - Electro Optical Systems

Lemminkäisenkatu 36 Robert-Stirling-Ring 1

FIN-20520 Turku D-82152 Krailling / München

EOS NickelAlloy IN718 Telephone: +358 20 765 9144 Telephone: +49 (0)89 / 893 36-0

Owner: TMS / Approved: SPU Telefax: +358 20 765 9141 Telefax: +49 (0)89 / 893 36-285

CR275 v01 / 04.03.2016 1/4 Internet: www.eos.info

Material data sheet - FlexLine

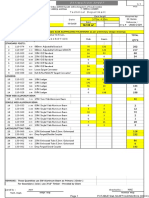

Technical Data

Powder properties

Material composition

Element Min Max

Ni 50 55

Cr 17.0 21.0

Nb 4.75 5.5

Mo 2.8 3.3

Ti 0.65 1.15

Al 0.20 0.80

Co - 1.0

Cu - 0.3

C - 0.08

Si, Mn - 0.35

P, S - 0.015

B - 0.006

Fe - Balance

Max. particle size

Particles > 63µm [1] max. 0.3 wt.-%

[1] Sieve analysis according to DIN ISO 4497 or ASTM B214.

Electro Optical Systems Finland Oy EOS GmbH - Electro Optical Systems

Lemminkäisenkatu 36 Robert-Stirling-Ring 1

FIN-20520 Turku D-82152 Krailling / München

EOS NickelAlloy IN718 Telephone: +358 20 765 9144 Telephone: +49 (0)89 / 893 36-0

Owner: TMS / Approved: SPU Telefax: +358 20 765 9141 Telefax: +49 (0)89 / 893 36-285

CR275 v01 / 04.03.2016 2/4 Internet: www.eos.info

Material data sheet - FlexLine

General process data

Layer thickness 40 µm

Volume rate [2] 4.2 mm³/s (15.2 cm³/h)

[2] The volume rate is a measure of build speed during laser exposure of the skin area. The total build speed de-

pends on this volume rate and many other factors such as exposure parameters of contours, supports, up and

downskin, recoating time, Home-In or LPM settings.

Physical and chemical properties of parts

Part density [3] min. 8.15 g/cm3

Surface roughness after shot peening [4] Ra < 6.5 µm; Rz < 50.0 µm

[3] Weighing in air and water according to ISO 3369.

[4] Measurement according to ISO 4287. The numbers were measured at the horizontal (up-facing) and all verti-

cal surfaces of test cubes. Due to the layerwise building the roughness strongly depends on the orientation of

the surface, for example sloping and curved surfaces exhibit a stair-step effect.

Tensile data at room temperature [5, 6]

As built Heat treated [7]

Ultimate tensile strength, Rm 1040 MPa 1470 MPa

Yield strength, Rp0.2 710 MPa 1200 MPa

Elongation at break A 26 % 15 %

[5] The numbers are average values and are determined from samples with horizontal and vertical orientation.

[6] Tensile testing according to ISO 6892-1:2009 (B) Annex D, proportional test pieces, diameter of the neck area

5 mm (0.2 inch), original gauge length 25 mm (1 inch).

[7] Heat treatment procedure conform to Aerospace Material Specification AMS 2774D and AMS 5662:

1. Solution Anneal at 954 °C (1750 °F ) for 1 hour per 25mm (0.98 inch) of thickness, air (/argon) cool.

2. Ageing treatment; hold at 718 °C (1325 °F ) 8 hours, furnace cool to 621 °C (1150 °F ) and hold at 621 °C

(1150 °F ) for total precipitation time of 18 hours., air (/argon) cool.

Electro Optical Systems Finland Oy EOS GmbH - Electro Optical Systems

Lemminkäisenkatu 36 Robert-Stirling-Ring 1

FIN-20520 Turku D-82152 Krailling / München

EOS NickelAlloy IN718 Telephone: +358 20 765 9144 Telephone: +49 (0)89 / 893 36-0

Owner: TMS / Approved: SPU Telefax: +358 20 765 9141 Telefax: +49 (0)89 / 893 36-285

CR275 v01 / 04.03.2016 3/4 Internet: www.eos.info

Material data sheet - FlexLine

Abbreviations

min. minimum

max. maximum

wt. weight

Legal notes

The quoted values refer to the use of this material with above specified EOS DMLS system,

EOSYSTEM software version, parameter set and operation in compliance with parameter sheet

and operating instructions. All measured values are average numbers. Part properties are meas-

ured with specified measurement methods using defined test geometries and procedures.

Further details of the test procedures used by EOS are available on request. Any deviation from

these standard settings may affect the measured properties.

The data correspond to EOS knowledge and experience at the time of publication and they are

subject to change without notice as part of EOS' continuous development and improvement

processes.

EOS does not warrant any properties or fitness for a specific purpose, unless explicitly agreed

upon. This also applies regarding any rights of protection as well as laws and regulations.

EOS, EOSINT, DMLS, DirectTool and DirectPart are registered trademarks of EOS GmbH.

2016 EOS GmbH – Electro Optical Systems. All rights reserved.

Electro Optical Systems Finland Oy EOS GmbH - Electro Optical Systems

Lemminkäisenkatu 36 Robert-Stirling-Ring 1

FIN-20520 Turku D-82152 Krailling / München

EOS NickelAlloy IN718 Telephone: +358 20 765 9144 Telephone: +49 (0)89 / 893 36-0

Owner: TMS / Approved: SPU Telefax: +358 20 765 9141 Telefax: +49 (0)89 / 893 36-285

CR275 v01 / 04.03.2016 4/4 Internet: www.eos.info

You might also like

- EOS Titanium TiCP Grade 2 - M290 - Material - Data - Sheet - 05-16 - FlexLine - en PDFDocument4 pagesEOS Titanium TiCP Grade 2 - M290 - Material - Data - Sheet - 05-16 - FlexLine - en PDFrajatNo ratings yet

- Material Data Sheet: Eos Maragingsteel Ms1Document5 pagesMaterial Data Sheet: Eos Maragingsteel Ms1Raj RajeshNo ratings yet

- EOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFDocument4 pagesEOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFRaj RajeshNo ratings yet

- Material Data Sheet - Flexline: DescriptionDocument4 pagesMaterial Data Sheet - Flexline: DescriptionRaj RajeshNo ratings yet

- Eos Ti64 9011-0014 9011-0039 m290 Mds 06-22 enDocument10 pagesEos Ti64 9011-0014 9011-0039 m290 Mds 06-22 ennicoleta.popa2093No ratings yet

- Material Data Sheet: DescriptionDocument6 pagesMaterial Data Sheet: DescriptionRaj RajeshNo ratings yet

- Material Data Sheet - Flexline: Eos Stainlesssteel CXDocument4 pagesMaterial Data Sheet - Flexline: Eos Stainlesssteel CXRaj RajeshNo ratings yet

- Material Data Sheet - Flexline: DescriptionDocument4 pagesMaterial Data Sheet - Flexline: DescriptionRaj RajeshNo ratings yet

- NiAll-HX-M290-400W Material Data Sheet 10-15 enDocument5 pagesNiAll-HX-M290-400W Material Data Sheet 10-15 enAmit PowarNo ratings yet

- Mineral-Insulated Thermocouples To DIN 43 710 and EN 60 584: Technical DataDocument7 pagesMineral-Insulated Thermocouples To DIN 43 710 and EN 60 584: Technical Datasnow69yNo ratings yet

- Material Data Sheet: Description, ApplicationDocument5 pagesMaterial Data Sheet: Description, ApplicationCharles SedilloNo ratings yet

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDDocument12 pagesS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehNo ratings yet

- Material Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Charles SedilloNo ratings yet

- WSN 104 2018 462 472Document11 pagesWSN 104 2018 462 472曹大伟No ratings yet

- SOIC-8 CaseDocument3 pagesSOIC-8 CaseFabian CabreraNo ratings yet

- Soic 8pdDocument3 pagesSoic 8pdPurple HazeNo ratings yet

- AISTech 2005 FoctDocument10 pagesAISTech 2005 Focts9hxzbgdb4No ratings yet

- Package Details: SOT-26 CaseDocument3 pagesPackage Details: SOT-26 CasedneprashNo ratings yet

- Aerospace Material Specification: AMS 5663MDocument11 pagesAerospace Material Specification: AMS 5663MAnonymous T6GllLl0No ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- BF Runner Mix 20 MT VesuviusDocument3 pagesBF Runner Mix 20 MT VesuviusSaumit PalNo ratings yet

- Rfoui-250v 2014Document5 pagesRfoui-250v 2014VENITHA KNo ratings yet

- Penta Band W1910 - W1911Document4 pagesPenta Band W1910 - W1911Miguel Andres VanegasNo ratings yet

- Ams 5662M PDFDocument11 pagesAms 5662M PDFadiNo ratings yet

- Conarc49c EngDocument2 pagesConarc49c EngtNo ratings yet

- s543b - Electrozi Basic 7018 Info ENGDocument2 pagess543b - Electrozi Basic 7018 Info ENGVlad AdrianNo ratings yet

- Mechanical Properties and MicrostruDocument11 pagesMechanical Properties and MicrostrubeyzkrkNo ratings yet

- Hetero-Dielectric Oxide Engineering On Dopingless Gate All Around NanowireDocument16 pagesHetero-Dielectric Oxide Engineering On Dopingless Gate All Around NanowireHung Lung ChienNo ratings yet

- CoCr MP1 M270 Material Data SheetDocument6 pagesCoCr MP1 M270 Material Data Sheetgpiprototype.comNo ratings yet

- Aerospace Material Specification: AMS5709 REV. HDocument6 pagesAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- Offer For SPECTROMAXx Advanced - Amit MetaliksDocument5 pagesOffer For SPECTROMAXx Advanced - Amit MetaliksSuman MukherjeeNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabNo ratings yet

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 pagePOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- lnt26 EngDocument1 pagelnt26 EngVVan TanNo ratings yet

- Material Data Sheet: Eos Maragingsteel Ms1Document6 pagesMaterial Data Sheet: Eos Maragingsteel Ms1qualityfreekNo ratings yet

- Assembly Technologies For Piezoelectric Sensors Up To 1000 °CDocument20 pagesAssembly Technologies For Piezoelectric Sensors Up To 1000 °CkashmiraNo ratings yet

- Spec LFM-57W TM-HP (S) 12 EDocument5 pagesSpec LFM-57W TM-HP (S) 12 EluismcmcNo ratings yet

- Eos Stainless Steel 316 LDocument5 pagesEos Stainless Steel 316 LsameeraNo ratings yet

- Material Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Charles SedilloNo ratings yet

- Poster Solar Cell ProjectDocument1 pagePoster Solar Cell ProjectWanichanokNo ratings yet

- Aug 08Document61 pagesAug 08lucilla.genoveseNo ratings yet

- Luckylight: 0805 Package Blue Chip LED Technical Data SheetDocument9 pagesLuckylight: 0805 Package Blue Chip LED Technical Data SheetWaltencirNo ratings yet

- As1548 Pt46onrlo l20 August2010bDocument3 pagesAs1548 Pt46onrlo l20 August2010bchoopoNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradeNo ratings yet

- 13 High Quality NitiDocument14 pages13 High Quality NitikushNo ratings yet

- Intoval T62Document1 pageIntoval T62Calvin CooksonNo ratings yet

- 20NiMo9-7 - Liga MetálicaDocument4 pages20NiMo9-7 - Liga MetálicalutherblackNo ratings yet

- Bfou C Nek 606 s4 s8 CableDocument3 pagesBfou C Nek 606 s4 s8 CableSantosh KumarNo ratings yet

- Nanofluids For Enhanced Economics and Safety of Nuclear ReactorsDocument25 pagesNanofluids For Enhanced Economics and Safety of Nuclear ReactorsManoj SaralayaNo ratings yet

- Techalloy 718: Conformances Key FeaturesDocument2 pagesTechalloy 718: Conformances Key FeaturesvishuNo ratings yet

- Tenax 35S (E 42 5 B 32 H5)Document1 pageTenax 35S (E 42 5 B 32 H5)brunizzaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Ansi/I - 75.16 - 4: Face-to-Face Dimensions For Flanged Globe-Style Control Valve Bodies (ANSI Classes 900, 1500, and 2500)Document12 pagesAnsi/I - 75.16 - 4: Face-to-Face Dimensions For Flanged Globe-Style Control Valve Bodies (ANSI Classes 900, 1500, and 2500)Raj RajeshNo ratings yet

- CL#16 0646Document15 pagesCL#16 0646Raj RajeshNo ratings yet

- F3055 14aDocument8 pagesF3055 14asenthilNo ratings yet

- ASTM F2924-14 Additive Manufactured Ti 6al 4V With Powder Bed FusionDocument9 pagesASTM F2924-14 Additive Manufactured Ti 6al 4V With Powder Bed FusionSteve Jones100% (1)

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDocument9 pagesAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionRaj Rajesh100% (1)

- Ansi/I - 75. 17 - 89: Control Valve Aerodynamic Noise PredictionDocument32 pagesAnsi/I - 75. 17 - 89: Control Valve Aerodynamic Noise PredictionRaj RajeshNo ratings yet

- Face-to-Face Dimensions For Integral Flanged Globe-Style Control Valve Bodies (ANSI Classes 125, 150, 250, 300, and 600)Document14 pagesFace-to-Face Dimensions For Integral Flanged Globe-Style Control Valve Bodies (ANSI Classes 125, 150, 250, 300, and 600)Raj RajeshNo ratings yet

- Astm E1820 PDFDocument65 pagesAstm E1820 PDFSebastián Cáceres Burgos100% (1)

- Comparison Study 316, 316L & 316Lvm Stainless Steel: Additional Requirements in ASTM F 138Document1 pageComparison Study 316, 316L & 316Lvm Stainless Steel: Additional Requirements in ASTM F 138Raj RajeshNo ratings yet

- J. Platl, H. Leitner, C. Turk, R. SchnitzerDocument20 pagesJ. Platl, H. Leitner, C. Turk, R. SchnitzerRaj RajeshNo ratings yet

- E23 5489Document26 pagesE23 5489Juanes Garcia OspinaNo ratings yet

- F3055 14aDocument8 pagesF3055 14asenthilNo ratings yet

- Learning Process of The Steel Use in Building Engineering StudentsDocument6 pagesLearning Process of The Steel Use in Building Engineering StudentsRaj RajeshNo ratings yet

- Simufact Additive - SimulationDocument6 pagesSimufact Additive - SimulationRaj RajeshNo ratings yet

- Sensors 20 03459Document20 pagesSensors 20 03459djNo ratings yet

- Feature Article Can You Build AM Parts Without SupportsDocument7 pagesFeature Article Can You Build AM Parts Without SupportsRaj RajeshNo ratings yet

- Ensayos de Impacto E23Document28 pagesEnsayos de Impacto E23Juan LeonNo ratings yet

- Preparation Method EN Magnesium AlloysDocument1 pagePreparation Method EN Magnesium AlloysRaj RajeshNo ratings yet

- Proceedings 47 00020 PDFDocument4 pagesProceedings 47 00020 PDFRaj RajeshNo ratings yet

- GD&T Symbols and Guidelines Cheat SheetDocument1 pageGD&T Symbols and Guidelines Cheat SheetViraj ShiroleNo ratings yet

- Preparation Method EN Titanium AlloyDocument1 pagePreparation Method EN Titanium AlloyRaj RajeshNo ratings yet

- Proceedings 47 00020 PDFDocument4 pagesProceedings 47 00020 PDFRaj RajeshNo ratings yet

- Portfolio Overview: EOS Materials MetalDocument3 pagesPortfolio Overview: EOS Materials MetalRaj RajeshNo ratings yet

- Proceedings 47 00020 PDFDocument4 pagesProceedings 47 00020 PDFRaj RajeshNo ratings yet

- Padamata Suryodayam PDFDocument82 pagesPadamata Suryodayam PDFRaj Rajesh75% (4)

- Koumudi CitylightsDocument50 pagesKoumudi Citylightsaryac4No ratings yet

- Metallography of Superalloys: Materials CharacterizationDocument4 pagesMetallography of Superalloys: Materials CharacterizationRaj RajeshNo ratings yet

- Metallography of Superalloys: Materials CharacterizationDocument4 pagesMetallography of Superalloys: Materials CharacterizationRaj RajeshNo ratings yet

- Padamata Suryodayam PDFDocument82 pagesPadamata Suryodayam PDFRaj Rajesh75% (4)

- Chinnarisiri PDFDocument54 pagesChinnarisiri PDFRaj RajeshNo ratings yet

- U1. T2. Activity 1. Heat Treatments of SteelDocument11 pagesU1. T2. Activity 1. Heat Treatments of SteelTygaNo ratings yet

- Hot Rolled Products of Structural SteelsDocument28 pagesHot Rolled Products of Structural SteelsAli MarsousiNo ratings yet

- ASME SA 372 - Carbon and Alloy Steels Forgings For Thin Walled Pressure Vessels PDFDocument7 pagesASME SA 372 - Carbon and Alloy Steels Forgings For Thin Walled Pressure Vessels PDFHoangNo ratings yet

- Astm A21 PDFDocument10 pagesAstm A21 PDFPablo SebastianNo ratings yet

- Astm B 148 2009Document5 pagesAstm B 148 2009WillianNo ratings yet

- Impact TestingDocument7 pagesImpact TestingMahrukh JavedNo ratings yet

- JISG3459Document39 pagesJISG3459Son-Tuan PhamNo ratings yet

- HT ProcedureDocument34 pagesHT ProcedureBHAKTAVATSALAM K.K.CNo ratings yet

- MQP - Grain Growth Kinetics in SteelsDocument153 pagesMQP - Grain Growth Kinetics in SteelsYlich SchmittNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNo ratings yet

- Myonic Catalogue enDocument75 pagesMyonic Catalogue enpaula09No ratings yet

- Catalogo PTP 2011 Cadena Transportadoras 10818 - ENDocument136 pagesCatalogo PTP 2011 Cadena Transportadoras 10818 - ENAriel Linder Ureña MontenegroNo ratings yet

- 1 Selection of Heat Treatment and Aluminizing Sequence For Rene 77 SuperalloyDocument4 pages1 Selection of Heat Treatment and Aluminizing Sequence For Rene 77 SuperalloyEnary SalernoNo ratings yet

- Libroduplex PDFDocument183 pagesLibroduplex PDFHugo PeñaNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- WeldMet ExerciseDocument4 pagesWeldMet ExerciseAndaradhi NararyaNo ratings yet

- Lab Manual FOR Metallurgy and Mechanics of Solids: II B.Tech I Semester - Mechanical EngineeringDocument52 pagesLab Manual FOR Metallurgy and Mechanics of Solids: II B.Tech I Semester - Mechanical EngineeringAraveetiCSReddyNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- Guide Specifications For Design of Metal Flagpoles: Ansi/ Naamm American National StandardDocument27 pagesGuide Specifications For Design of Metal Flagpoles: Ansi/ Naamm American National Standardamadan64No ratings yet

- Chain Block - Tiger LiftingDocument7 pagesChain Block - Tiger LiftingYADAGIRI REDDYNo ratings yet

- Machine Rates MIRDC FacilitiesDocument6 pagesMachine Rates MIRDC FacilitiesEfren CamposagradoNo ratings yet

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Document3 pagesASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNo ratings yet

- Introduction To Magnesium AlloysDocument10 pagesIntroduction To Magnesium AlloysHagen_of_Tronje0% (1)

- CrMo Cast AlloysDocument8 pagesCrMo Cast AlloyssgarrabNo ratings yet

- Ferrite Limitation For SS316LDocument12 pagesFerrite Limitation For SS316LAntonio PerezNo ratings yet

- A494Document7 pagesA494carlos ruizNo ratings yet

- 2nd Sem ChemestryDocument29 pages2nd Sem ChemestryJayesh khachaneNo ratings yet

- UntitledDocument258 pagesUntitledapi-155035535No ratings yet

- Astm A479Document8 pagesAstm A479David Anderson100% (1)

- Sa 387Document6 pagesSa 387ismaelarchilacastilloNo ratings yet