Professional Documents

Culture Documents

Risk Management of Chlor-Alkali Industry Based On Cvar: Dong Chen, Tomohiro Murata

Uploaded by

Rathish RagooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Management of Chlor-Alkali Industry Based On Cvar: Dong Chen, Tomohiro Murata

Uploaded by

Rathish RagooCopyright:

Available Formats

Proceedings of the International MultiConference of Engineers and Computer Scientists 2017 Vol II,

IMECS 2017, March 15 - 17, 2017, Hong Kong

Risk Management of Chlor-Alkali Industry

based on CVaR

Dong Chen, Tomohiro Murata

be utilized to reduce the environmental pollution. And paper [4]

Abstract—In recent years, risk management has increased suggested a risk management approach in chemical industry

widely from financial institutions, regulators and portfolio supply Chain, but this research didn’t mention the loss in risk

managers, such as Value-at-Risk (VaR) and Conditional factors.

Value-at-Risk (CVaR). Using this model can measure the risks in

Nevertheless, all researchers ignore a problem that there are

uncertainty factors and decisions the production planning for a

fluctuations in actual markets. Here we take the market between

plant. Now, China's Chlor-Alkali industries had to face the grim

situation. Comparing with other industries, production planning 2015-2016 as an example, caustic soda products prices rose as

of Chlor-Alkali industries is more complicated. Especially for an 45%, while the price of liquid chlorine products decreased

imbalance between demand and response in Chlor-Alkali products about 70%. In the current market environment, Chlor-Alkali

market, how to reduce the loss is a major problem for the plant must make a viable decision while considering the risks

policymaker. In the current market environment, the plant must from the market. That requires a risk analysis of complex

make a viable decision while considering the risks from market. markets. Another issue we should take into consideration is that

That required a market risk analysis. In this paper, we proposed a due to the accident risk of the liquid chlorine, there is the

risk measurement model with a restrictive condition which can

restriction on the liquid chlorine inventory if the limit has been

optimize the production while taking uncertainties into

consideration, such as material price, electricity price, product exceeded meanwhile the plant must discontinue the whole

price, order changes, and especially the restriction of liquid production line.

chlorine inventory. Eventually, a case study is submitted to In recent years, risk management is increasing widely from

demonstrate the feasibility of the developed model, and verify the financial institutions, regulators and portfolio managers, such as

effectiveness of the algorithm employed. Value-at-Risk (VaR) and Conditional Value-at-Risk (CVaR).

Index Terms—uncertainty inventory restriction Conditional The greatest advantage of VaR is that it can describe the

Value-at-Risk estimated loss of a portfolio with a given confidence level in a

value [5]. However, paper [6] indicated that it is not a coherent

risk measure since it fails to the subadditivity and does not

I. INTRODUCTION

consider the losses over the value. Because of the limitations, a

Comparing with other countries, although China’s Chlor-Alkali new risk measurement has been put forward that is CVaR. It is

industries started relatively backward, there also some great superior to VaR as a risk measure because it measured the

progress has been achieved after 30 years of development. At expected loss than the VaR at a specified confidence level [7].

the end of 2010, the full capacity of China’s caustic soda In paper [8], based on recent data in the actual stock market, the

production China’s had already reached the first place in the optimal portfolio is calculated by computing the ratio of the

world. But rapid progress also brought serious problems. minimum risk CVaR. Paper [9], applied this method in the

Especially in recent years, under the influence of irrational electricity market and established a risk evaluation model.

industrial structure and vicious competition, China's In this paper, we will consider the restriction of liquid

Chlor-Alkali plant is in the face of the grim situation. Now that, chlorine inventory and the uncertainties caused by risk factors,

China's Chlor-Alkali industries have entered a period of such as raw material prices, market prices, electricity prices, the

adjustment. delivery ratio of orders and so on. Here we proposed a risk

Now most of the Chlor-Alkali industry research were measurement model with a restrictive condition which can

concentrated on the producing technology [1] and pollution optimize the production planning for Chlor-Alkali plant and

control [2]. In paper [3], it proposed a circular economy that can

ensure normal production.

Manuscript received December 20, 2016.

Dong Chen is a master student in Graduate school of Information, II. SOME CHARACTERISTICS IN CHLOR-ALKALI INDUSTRY

Production and System, Waseda University, Japan. (e-mail: PRODUCTION

cireck@akane.waseda.jp).

Tomohiro Murata is a professor in Graduate school of Information, Here we take ion-exchange membrane electrolysis as an

Production and System, Waseda University, Japan. (e-mail: example [10]. The Chlor-Alkali process produces caustic soda,

t-murata@waseda.jp).

ISBN: 978-988-14047-7-0 IMECS 2017

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the International MultiConference of Engineers and Computer Scientists 2017 Vol II,

IMECS 2017, March 15 - 17, 2017, Hong Kong

chlorine and hydrogen through the electrolysis of sodium month fixed costs. This paper focuses on the variable costs

chloride solution. which include crude salt and electricity costs. Presently, the

2NaCl + 2H2O = 2NaOH + H 2↑ + Cl2↑ (1) framework contract is primarily applied in the procurement of

Through t chemical equation, we could know the particularity raw materials crude salt. But the prices will still have a

of the products of Chlor-Alkali industry. Usually, 1kg caustic fluctuation in the market. In order to simulate these uncertain

soda production is accompanied by the 0.89kg of chlorine and effects, here we use Pr to represent changes of the salt prices,

0.025kg of hydrogen. In some literature, it is called the balance and assume Pr follows the normal distribution to represent

industry [11]. According to the Equation (1), if the production changes of the crude salt price which means value μr and

planning of the caustic soda is determined in ith month, the standard deviation σr. If the crude salt price Pr(i) in ith month

consumption of the crude salt and the production of the chlorine can be simulated, then the cost of crude salt would be:

could be determined at the same time. We assume the following Cnacl (i ) = Q p nacl (i ) × Pr (i ) (4)

as this formula.

The other variable cost is electricity price. Especially for high

QPna ( i )= r1 QPnacl ( i )= r2QPcl ( i ) (2)

consumption industries, the price changes will have a huge

Where the QPna,, QPcl represent ith month production of

impact [13]. Existing literature shows that the Geometric

caustic soda and chlorine, and QPnacl represent ith consumption

Brownian motion could better simulate seasonally changing

of the crude salt, and r1 , r2 are the rate of the production.

trends [14]. So here we use the geometric Brownian motion to

Actually, caustic soda products can be divided into 32%

describe the electricity prices changes.

solution, 50% solution, and solid caustic soda. In this paper, we

The formula is as follow:

take 32% solution caustic soda solution production to discuss

σ2 (5)

(50% and solids can be obtained from it). Similarly, liquid P = P × exp(( μ -

t )+ σw )

t

0

2

chlorine as the chlorine production was made because it was The electricity price is denoted by Pt at time t with the

used in marketing. There is no consideration of hydrogen expected return by μ, and the standard deviation by σ if the

production because its output is low and the market price is initial electricity price P0 was given, we can use Equation (5) to

stable. calculate the price at each time. About wt is a Brownian motion.

Compared with the individual production planning, it has μ and σ are constants and can be estimated through statistical

become a more complex plan for Chlor-Alkali plant to consider analysis of historical data.

the market demand and prices of the two products separately. According to production electricity consumption rate r3 the

Caustic soda products are in short supply because of its wide cost of electricity could be calculated as:

range of uses in marketing. However, liquid chlorine market is

Cel (i) = r3 × Q p na (i) × Pel (i) (6)

just the opposite. Taking one product of caustic soda solution

Sodium Hydroxide 32% as an example, in Chinese market the Cel and Pel are the electricity cost and electricity price of the

cost is about 180 US$ per t, and market price is as high as 350 ith month.

US$ per t (on 100% basis price). Unfortunately, liquid chlorine B. order and price factors.

products are about 160 US$ per t in cost and 15US$ per t in Here we will discuss the uncertain factors of the market and

market sales, and the price may be lower at disposal. their effects on product price and order. In this paper, caustic

In the current profitable market state of caustic soda products, soda products and liquid chlorine products will be discussed

decision makers may then choose a relatively high-risk separately due to their different market situations. Usually,

production plan in order to obtain more benefits, but they often marketing of caustic soda products includes two ways, order

have to consider a serious problem of dealing with the excessive contract and trade market. Most part of the production is

loss of liquid chlorine. And another problem of the production selected to deliver orders, while the other part of the production

planning is influences under the uncertainty factors. is sold in the trade market. The amount of caustic soda order

Qdna and price Pna of order contract are relatively stable, but the

trade market is subject to considerable changes. The prices in

III. UNCERTAIN FACTORS FROM MARKET

trade market P’na may be higher than the order price, but

A. cost impact factors sometimes lower. Here we also use a normal distribution P’na

(μna, σna) to describe the price changes in the market.

Generally, the costs of Chlor-Alkali plant include fixed costs In contrast to short supply of caustic soda product market,

and variable costs [12]. Fixed costs include equipment liquid chlorine products market is not so optimistic. In the

depreciation, transportation, labor fee, water fee and pollution overall current tight market, its orders and prices are lower than

treatment fee. And the variable costs are mainly considered the the caustic soda products. Because of the total inventory

raw material costs and the electricity costs. The cost of the ith constraints, the price may be reduced to sell the redundant part.

month can be expressed as: Compared with the order price Pcl, the disposal price P’cl has a

C (i) = Cnacl (i) + Cel (i) + C fix (i) (3) highly unstable, and sometimes there exists a negative price.

Where the Cnacl (i) represents salt costs of the ith month, Cel (i) That means the plant will pay extra money to the disposal of

represents ith month electricity costs, Cfix (i) represents ith remanding products that usually happen in the market. Here we

ISBN: 978-988-14047-7-0 IMECS 2017

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the International MultiConference of Engineers and Computer Scientists 2017 Vol II,

IMECS 2017, March 15 - 17, 2017, Hong Kong

also use a normal distribution P’cl (μcl, σcl) to describe the price paper [7] introduced an approximate method by adding a new

changes. function Fβ (x, a) to solve this problem. The expected value of

However, there still exist some uncertainties in the that Fβ (x, a) could be approximated by sample mean. And the

implementation of the contract, transport capacity and quality of sampling calculation of Fβ (x, a) can be assumed by F̂β (x, a).

production. In order to represent the order change, here we

We introduce the variables Zk= (−R (x, y) – α) + (k=1,2,…,N)

assume that both the amount of orders Qdna and Qdcl follows a

for simplification. The CVaR model for Chlor-Alkali plant has

normal distribution with mean values μdna, μdcl, and standard

been established as described in formula (12)-(21).

deviations σdna, σdcl.

Through the above discussion, we can get the sales of ith

Objective:

month caustic soda and liquid chlorine. 1 N

min Fˆβ ( x, α ) = min( α +

(12)

S (i) Qd na (i) * Pna (i) (Q p na (i) - Qd na (i))* P'na (i) (7) ∑ Z )

N × (1 - β ) k =1 k

na

Scl (i) = Q d cl (i) * Pcl (i) + Q'cl (i) * P'cl (8)

Where Sna (i) and Scl(i) are the two product sales in the ith Subject to:

12 12 (13)

month. ∑S na (i ) =∑{Q d na (i ) * Pna (i ) + (Q p na (i ) - Q d na (i ))* P'na (i )}

12 12 (14)

IV. FORMULATION OF THE MODEL ∑S cl (i ) = ∑{Q d cl (i ) * Pcl (i ) + Q'cl (i ) * P'cl }

First, we will describe the constraints of liquid chlorine 12 12 (15)

inventory in the production planning. Fig 1 show the new liquid ∑C nacl (i ) = ∑{Q p

nacl (i ) × P(i )}

chlorine inventory process. The formula is 12 12

(16)

Q cl inv(i) = Q p cl (i) - Q d cl (i) - Q’ (9) ∑C (i ) = r3 ∑{Q p na (i ) × Pel (i )}

cl (i )

el

Where the Q’cl ( i ) represents the monthly amount of disposal 12 12 12 12 (17)

∑ C (i) = ∑ Cnacl (i ) + ∑ Cel (i ) + ∑ C fix (i )

and Qclinv ( i ) shows the monthly production of new liquid

12 12

chlorine inventory. ∑S na (i ) +∑S cl (i ) (18)

E( 12 ) -1 ≥ e

∑C (i)

12 12 12 12 (19)

∑Q cl

inv(i ) = ∑ Q p cl (i ) -∑ Q d cl (i ) - ∑ Q’ (i)

cl

12 (20)

∑Q cl

inv (i ) ≤ Qcap

Zk= (−R (x, y) – α) + ≥ 0 (21)

Where i =1,2, … ,12; k=1, 2, … N; Equation (13) -(14)

described the sales of two productions in 12 months. Equation

(15) -(17) described the cost of one year. Equation (18) is the

expected return of the Chlor-Alkali plant and e stand for the

lower bound of the expected return rate. (where 0≤e≤1)

Equation (19) -(20) are the constraints of liquid chlorine

inventory. (−R (x, y) – α) +mean max (−R (x, y) – α, 0). Using

Fig 1 liquid chlorine inventory the Monte Carlo Sampling method to generate a sample of the

random vector y, and calculated the CVaR with a linear

In order to guarantee the normal production of the factory, the programming problem.

liquid chlorine inventory of 12 months must less than the

inventory capacity Qcap.

12

(10) V. CASE STUDIES AND DISCUSSION

∑ Q cl inv (i ) Q

cap

Through the above analysis, let R (x, y) be the revenue A. Data of the Case

function of the Chlor-Alkali plant. Where xT = [Qpna (1), Qpna (2), First, we use the geometric Brownian motion to simulate the

… Qpna (12)] mean the production plan and it is a decision electricity price trends for 12 months form historical data at

vector. yT= [Pr ,Pel, Qdna, Qdc, P’na, P’cl ] is the random vector. The Fig.2. The initial electricity price as 0.1162 US$ per kWh.

function as follows: Generally, it is difficult to forecast the electricity price

12 12 12 (11) accurately. But to predict its future trend according to the

R ( x, y ) ∑S na ∑S

(i ) cl (i ) ∑C (i)

-

historical price data and economic trend is feasible. Therefore,

So, we define the loss function of the Chlor-Alkali plant would this paper tries to simulate the changing trends of price, rather

be −R (x, y). In general, CVaR calculation is complicated, in than to find methods to accurately predict the price.

ISBN: 978-988-14047-7-0 IMECS 2017

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the International MultiConference of Engineers and Computer Scientists 2017 Vol II,

IMECS 2017, March 15 - 17, 2017, Hong Kong

Here we take the capacity of caustic soda production Qpna

200,000 ton one year the Chlor-Alkali plant as an example. The

monthly average of caustic soda order is 15,000 tons, and the

average of liquid chlorine order 11,00 tons. Liquid chlorine

inventory capacity 200t and the initial value is 0, and crude salt

quantity is enough. With the current market price [15], here we

set the caustic soda order price as 350 US$ per t, liquid chlorine

products order price as 15US$ per t, crude salt price as 35

US$ per t, liquid chlorine disposal price as 5 US$ and the fixed

cost is 20 US$ per t. r1, r2 and r3 is1.46,0.89 and 2600Kwh/t.

The other random parameters in the model are generated

through Monte Carlo method with100 samples and Parameters

Values are shown in Table I Calculation the CVaR in different

expected return rates by MATLAB.

Table I Parameters Values Fig.2. electricity price changes in 12 month.

Para Value Para Value US$

σdna 4

0.15 x10 ton σna 35 US$ B. Results and discussion

Based on the values of the parameters given in Table 1 with

σdcl 0.11 x104 ton σcl 2 US$

the Monte Carlo Sampling Method. We calculated results of

Qcap. 200 ton σr 3 US$ optimization of production planning in Fig.3 and sensitivity

analysis of CVaR and expected return rate was shown in Fig.4.

Fig.3 Optimization result of production planning

ISBN: 978-988-14047-7-0 IMECS 2017

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the International MultiConference of Engineers and Computer Scientists 2017 Vol II,

IMECS 2017, March 15 - 17, 2017, Hong Kong

The results show that here is a lower production when the cost [3] Jacob Parka, Joseph Sarkis, Zhaohui Wu “Creating integrated

business and environmental value within the context of China’s

increases. A high production needs to consider the liquid

circular economy and ecological modernization” Journal of Cleaner

chlorine disposal of the cost reduction. The plant should Production Volume 18, Issue 15, November 2010, Pages 1494–1501

determine a minimum safe yield to preclude running out of [4] Liping Liu,Jianhua Ji,Tijun Fan" Risk Management in Chemical

supply due to fluctuation in orders. Industry Supply Chain" IEEE International Conference

10.1109/SOLI.2006.329039

[5] S Basak, A Shapiro "Value-at-risk-based risk management: optimal

policies and asset prices" Rev Fianc Stud, 14 (2) (2001), pp. 371–405

[6] P. Artzner, F. Delbaen, J.-M. Eber, D. Heath"Coherent measures of

risk"Math. Finance, 9 (3) (1999), pp. 203–228

[7] R.T. Rockafellar, S Uryasev "Optimization of conditional

value-at-risk" J Risk, 2 (2000), pp. 21–42

[8] Yuling Wang; Junhai Ma “Application of mean-CVaR optimization

model in investment portfolio”2010 International Conference on

Computer, Mechatronics, Control and E Pages: 255 - 258

[9] R. Dahlgren, Chen-Ching Liu,J. Lawarree "Risk assessment in energy

trading" IEEE Transactions on Power Systems ( Volume: 18, Issue: 2,

May 2003 )

[10] Robert M. Hruda; Jack R. Harbaugh “Fault Contribution of Chlor -

Alkali Cell Line” IEEE Journals & Magazines Volume: IA-17 Pages:

95 - 97,

[11] HONDA massahiro "Present and future of electrolytic Soda

Fig.4. CVaR in different confidence levels Industry"The Chemical Society of Japan Chemical education 61(9),

with different expected return rates. 430-433, 2013-09-20

[12] Yongkui Shi; Xin Zhou; Songmei Zhang “The Design of Safety Early

Warning System for Chlor-Alkali Chemical Industry” Engineering

Fig.4 shows the calculation results of CVaR with different Design and Manufacturing Informatization Year: 2010, Volume: 2

confidence levels with different expected return rates. Through Pages: 3 - 6,

the analysis, we can realize that the two curves are increasing. [13] A. K. David and F. S. Wen “Market power in electricity supply” IEEE

The increasing expected return rate will inevitably lead to an Trans. on Energy Conversion, vol. 16, pp. 352-360, Dec., 2001

[14] C. W. Wang, M. B. Wang, Z. F. Tan and P. J. Xie “Calculation model

increase in CVaR. At the same expected return rate, and the

of retail price based on pool purchase price simulated by Brownian

CVaR value increases as the confidence level increases. This is motion” Power System Technology, vol. 32, no. 9, pp. 21-26, May,

also consistent with the current market and the validity of the 2008

model is verified. [15] "China chemical products net" http://www.chemcp.com/

VI. CONCLUSION

We should take a risk measurement to consider the uncertain

factors bring risks of plants. In the competitive market, making

production planning under different demand and supply of the

two products is extremely important to Chlor-Alkali plants. In

this paper, we proposed a restrictive condition programming

CVaR model to optimize the production planning while taking

uncertainties into consideration, such as material price,

electricity price, product price, order delivery, and especially

the restriction of liquid chlorine inventory. A case study is

presented to demonstrate the feasibility of the developed model,

and verify the effectiveness of the algorithm employed. Also,

how to accurately reflect the changes in market prices will be the

future work in research.

REFERENCES

[1] Imad Moussallema, Stefan Pinnowa, Norbert Wagnerb, Thomas

Tureka, “Development of high-performance silver-based

gas-diffusion electrodes for chlor-alkali electrolysis with oxygen

depolarized cathodes” Chemical Engineering and Processing Volume

52, February 2012, Pages 125–131

[2] Xiaoping Jiaa, Gang Xina, Yi Qiana, Yu Qianb “Sectoral co-control of

air pollutants: case of a chlor-alkali/polyvinyl chloride sector in

China” Journal of Cleaner Production Volume 112, Part 2, 20

January 2016, Pages 1667–1675

ISBN: 978-988-14047-7-0 IMECS 2017

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

You might also like

- Predicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyFrom EverandPredicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyNo ratings yet

- Modelling of Solid Recovered Fuel (SRF) Properties Based On Material Composition - Chloride QualityDocument13 pagesModelling of Solid Recovered Fuel (SRF) Properties Based On Material Composition - Chloride QualitySlovenaccNo ratings yet

- 4 Cumulative Production Forecast of An OilDocument15 pages4 Cumulative Production Forecast of An OilDaniel ChiriacNo ratings yet

- 1 s2.0 S0360319915313835 MainDocument19 pages1 s2.0 S0360319915313835 MainKyleneNicoleCadaNo ratings yet

- Petroleum: Shuyong Hu, Yi Deng, Yongkai Li, Ran WangDocument5 pagesPetroleum: Shuyong Hu, Yi Deng, Yongkai Li, Ran WangSathia ShekarNo ratings yet

- SPE-166365-MS-P - Comparison of Decline Curve Analysis Methods With Analytical Models in Unconventional Plays - 2013Document32 pagesSPE-166365-MS-P - Comparison of Decline Curve Analysis Methods With Analytical Models in Unconventional Plays - 2013Belen FourcadeNo ratings yet

- SPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsDocument16 pagesSPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsEdgar GonzalezNo ratings yet

- IACPE Magazine May 2022 IssueDocument35 pagesIACPE Magazine May 2022 IssueGuglielmoNo ratings yet

- Inhibition of Calcium Carbonate (CaCo3) Scale Using Plant Scale (Raffia Gum and Orange Mesocarp)Document7 pagesInhibition of Calcium Carbonate (CaCo3) Scale Using Plant Scale (Raffia Gum and Orange Mesocarp)International Journal of Innovative Science and Research TechnologyNo ratings yet

- CMMT 245Document74 pagesCMMT 245Gilcimar Cavalcante GilcimarNo ratings yet

- Predicting Corrosion in PipelinesDocument11 pagesPredicting Corrosion in PipelinesAderobaki GbengaNo ratings yet

- Chemical Engineering Journal: 2 Ariane D.N. Kamkeng, Meihong Wang, Jun Hu, Wenli Du, Feng QianDocument29 pagesChemical Engineering Journal: 2 Ariane D.N. Kamkeng, Meihong Wang, Jun Hu, Wenli Du, Feng QianKingsultan IsahNo ratings yet

- Current Status of Hydrogen Liquefaction CostsDocument10 pagesCurrent Status of Hydrogen Liquefaction CostsDilla WahabNo ratings yet

- Catalytic Hydrogenation of - Xylose Over Ru Decorated Carbon Foam Catalyst in A Spinchem Rotating Bed ReactorDocument13 pagesCatalytic Hydrogenation of - Xylose Over Ru Decorated Carbon Foam Catalyst in A Spinchem Rotating Bed ReactorDavid BaronNo ratings yet

- CO2 Utilization Pathways Techno-Economic AssessmenDocument8 pagesCO2 Utilization Pathways Techno-Economic AssessmenNestor TamayoNo ratings yet

- Carbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialDocument22 pagesCarbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialLoredana Veronica ZalischiNo ratings yet

- Guía Basada en GHG Protocol - Fossil FuelsDocument20 pagesGuía Basada en GHG Protocol - Fossil FuelsNicolás FerrerNo ratings yet

- 10.0000@Www - Onepetro.org@conference Paper@WPC 30025Document8 pages10.0000@Www - Onepetro.org@conference Paper@WPC 30025AhmadFauziNo ratings yet

- Estimating Process Design Gold Extraction, Leach Residence Time and Cyanide ComsumptionDocument10 pagesEstimating Process Design Gold Extraction, Leach Residence Time and Cyanide ComsumptionAldoNo ratings yet

- CaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisDocument8 pagesCaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisGhochapon MongkhonsiriNo ratings yet

- Brine Purification For Chlor-Alkalis Production Based On Membrane TechnologyDocument8 pagesBrine Purification For Chlor-Alkalis Production Based On Membrane TechnologyMuhammad KhurramNo ratings yet

- Carbon Dioxide Compressibility Factor Determination Using A Robust Intelligent Method, Erfan Mohagheghian, 2015Document10 pagesCarbon Dioxide Compressibility Factor Determination Using A Robust Intelligent Method, Erfan Mohagheghian, 2015joreliNo ratings yet

- ImportantDocument15 pagesImportantMohammad BaqerNo ratings yet

- Sustainable Production of Chemical Intermediatesfor Nylon Manufacture A Techno-Economicanalysis For Renewable Production of Caprolactone - 2018Document13 pagesSustainable Production of Chemical Intermediatesfor Nylon Manufacture A Techno-Economicanalysis For Renewable Production of Caprolactone - 2018Jacopo de tommasoNo ratings yet

- IEAGHG Information Paper: 2015-IP23 Status Report On Direct Air CaptureDocument4 pagesIEAGHG Information Paper: 2015-IP23 Status Report On Direct Air CaptureGary BurnNo ratings yet

- Journal of Cleaner Production: Yong Shi, Yanjie Zhou, Wenhui Ye, Qian Qian ZhaoDocument24 pagesJournal of Cleaner Production: Yong Shi, Yanjie Zhou, Wenhui Ye, Qian Qian ZhaoM. Alfi ZahamsyahNo ratings yet

- THW Twelve Priciples of Circular HydrometallurgyDocument25 pagesTHW Twelve Priciples of Circular Hydrometallurgyachint GoelNo ratings yet

- Evaluation of Scale Inhibitors PerformanceDocument14 pagesEvaluation of Scale Inhibitors PerformanceLaura Natalia SalcedoNo ratings yet

- Clean CCUDocument21 pagesClean CCUezlkNo ratings yet

- Carbonyl Sulfide (COS) Removal From Propane GPADocument53 pagesCarbonyl Sulfide (COS) Removal From Propane GPAshitals_18100% (1)

- PHD Thesis UuDocument6 pagesPHD Thesis UuWriteMyPaperForMeIn3HoursCanada100% (2)

- Techno-Economic Analyses of CO2 Liquefaction - Impact of Product Pressure and ImpuritiesDocument15 pagesTechno-Economic Analyses of CO2 Liquefaction - Impact of Product Pressure and Impuritieskglorstad100% (1)

- Co2 Utilization ReviewDocument20 pagesCo2 Utilization ReviewLaila FaeizahNo ratings yet

- Bauxite Residue Utilization and The Lack Thereof Craig Klauber, Markus Gräfe, Greg Power ISSOBA 2011Document8 pagesBauxite Residue Utilization and The Lack Thereof Craig Klauber, Markus Gräfe, Greg Power ISSOBA 2011laurentiu_filipescuNo ratings yet

- Vinyl Chloride Production-SummaryDocument9 pagesVinyl Chloride Production-Summarysatyendraparmar091425che100% (1)

- Solvents and Supporting ElectrolytesDocument26 pagesSolvents and Supporting ElectrolytesagusNo ratings yet

- Chem EngineeringDocument61 pagesChem EngineeringVIMALNo ratings yet

- Better Understanding of CO2 Liquefaction Towards Identifying Optimal Transport Conditions For Ship-BaDocument4 pagesBetter Understanding of CO2 Liquefaction Towards Identifying Optimal Transport Conditions For Ship-BakglorstadNo ratings yet

- Surrogate Reservoir ModelDocument27 pagesSurrogate Reservoir ModelMartik MartikianNo ratings yet

- Energy Science Engineering - 2022 - Yun - Forecasting Carbon Dioxide Emission Price Using A Novel Mode DecompositionDocument18 pagesEnergy Science Engineering - 2022 - Yun - Forecasting Carbon Dioxide Emission Price Using A Novel Mode DecompositionRaquel CadenasNo ratings yet

- CBA For Change Over of Hg-Cell To Membrane Cell Technology in Chlor-Alkali IndustryDocument62 pagesCBA For Change Over of Hg-Cell To Membrane Cell Technology in Chlor-Alkali Industryvraj2002No ratings yet

- Ascorbic AcidDocument17 pagesAscorbic AcidNURUL SYAHIRAH BINTI ABDUL HALIMNo ratings yet

- Cassandra BPDocument102 pagesCassandra BPGabriel PatrunoNo ratings yet

- Project Descriptions 2012-13. Supplementary List 9.10.12Document7 pagesProject Descriptions 2012-13. Supplementary List 9.10.12Moao AomoNo ratings yet

- Chlor-Alkali: PERP 2011-7Document8 pagesChlor-Alkali: PERP 2011-7kaimanwatsoNNo ratings yet

- Processes: Adsorption As A Process For Produced Water Treatment: A ReviewDocument22 pagesProcesses: Adsorption As A Process For Produced Water Treatment: A ReviewZakiah Darajat NurfajrinNo ratings yet

- CasandraDocument102 pagesCasandraJorgeMVilar100% (5)

- Energies: The Valuation of The Operational Flexibility of The Energy Investment Project Based On A Gas-Fired Power PlantDocument16 pagesEnergies: The Valuation of The Operational Flexibility of The Energy Investment Project Based On A Gas-Fired Power Plantateet_07No ratings yet

- Effect of Contamination Towards Proton Exchange Membrane Fuel Cell Performance: A Review On Modeling and Simulation WorksDocument12 pagesEffect of Contamination Towards Proton Exchange Membrane Fuel Cell Performance: A Review On Modeling and Simulation WorksBotol KosongNo ratings yet

- 2011 7 Abs PDFDocument8 pages2011 7 Abs PDFRamakrishna ReddyNo ratings yet

- Desalination: F. El-Gohary, A. Taw Fik, U. MahmoudDocument7 pagesDesalination: F. El-Gohary, A. Taw Fik, U. MahmoudAnonymous V8g0m4No ratings yet

- Hydrogen Generation by Treatment of Aluminium Metal With Aqueous Solutions: Procedures and UsesDocument24 pagesHydrogen Generation by Treatment of Aluminium Metal With Aqueous Solutions: Procedures and UsesJohn TorrezNo ratings yet

- Mahmud 2017 IOP Conf. Ser. Mater. Sci. Eng. 217 012022Document15 pagesMahmud 2017 IOP Conf. Ser. Mater. Sci. Eng. 217 012022Ayleen QuezadaNo ratings yet

- A Fuzzy Linear Programming Model For Production Planning in Coal MinesDocument9 pagesA Fuzzy Linear Programming Model For Production Planning in Coal MineskellyllNo ratings yet

- Double Suction Centrifugal PumpDocument8 pagesDouble Suction Centrifugal PumpBilal WaseemNo ratings yet

- PDFDocument17 pagesPDFviktorija bezhovskaNo ratings yet

- Green Ports: Inland and Seaside Sustainable Transportation StrategiesFrom EverandGreen Ports: Inland and Seaside Sustainable Transportation StrategiesRating: 5 out of 5 stars5/5 (1)

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Petroleum PropertiesDocument28 pagesPetroleum PropertiesRathish RagooNo ratings yet

- Problem Solving Techniques: Co CoDocument25 pagesProblem Solving Techniques: Co CoRathish RagooNo ratings yet

- Sandpiper Product Catalog Rev0316Document37 pagesSandpiper Product Catalog Rev0316Rathish RagooNo ratings yet

- ProgrammingBasic 1Document21 pagesProgrammingBasic 1Rathish RagooNo ratings yet

- Character Arrays - StringsDocument26 pagesCharacter Arrays - StringsRathish RagooNo ratings yet

- Lecture 3 Project Management - 2 PDFDocument38 pagesLecture 3 Project Management - 2 PDFRathish RagooNo ratings yet

- Lecture 2 Project Management - 1a For StudentsDocument38 pagesLecture 2 Project Management - 1a For StudentsRathish RagooNo ratings yet

- Piper Alpha Accident A Summary of IChemE PerspectiveDocument5 pagesPiper Alpha Accident A Summary of IChemE PerspectiveRathish RagooNo ratings yet

- Lecture 6 Project Time ManagementDocument63 pagesLecture 6 Project Time ManagementRathish RagooNo ratings yet

- Project Management & FinanceDocument48 pagesProject Management & FinanceRathish RagooNo ratings yet

- Project Management & FinanceDocument88 pagesProject Management & FinanceRathish RagooNo ratings yet

- Lecture 9 Project Communication ManagementDocument39 pagesLecture 9 Project Communication ManagementRathish RagooNo ratings yet

- Project Management & FinanceDocument59 pagesProject Management & FinanceRathish RagooNo ratings yet

- Challenges in Influencing Process Safety Culture in Chlor-Alkali IndustryDocument32 pagesChallenges in Influencing Process Safety Culture in Chlor-Alkali IndustryRathish RagooNo ratings yet

- Hazard Identification Process For A Chlor Alkali Operation: AlbertoDocument17 pagesHazard Identification Process For A Chlor Alkali Operation: AlbertoRathish RagooNo ratings yet

- Poka Yoke in PracticeDocument4 pagesPoka Yoke in PracticeRathish RagooNo ratings yet

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooNo ratings yet

- SDS 42 PDFDocument494 pagesSDS 42 PDFRathish RagooNo ratings yet

- Solution Manual-Statistical Physics of Particles by Meheran KardarDocument165 pagesSolution Manual-Statistical Physics of Particles by Meheran KardarDanielle Nguyen7% (14)

- A Software Architecture For The Control of Biomaterials MaintenanceDocument4 pagesA Software Architecture For The Control of Biomaterials MaintenanceCristian ȘtefanNo ratings yet

- Dr. N. Kumarappan IE (I) Council Candidate - Electrical DivisionDocument1 pageDr. N. Kumarappan IE (I) Council Candidate - Electrical Divisionshanmugasundaram32No ratings yet

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFDocument9 pagesPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaNo ratings yet

- Test Iii Cultural Social and Political OrganizationDocument2 pagesTest Iii Cultural Social and Political OrganizationTin NatayNo ratings yet

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesNo ratings yet

- Philips fwt9200Document37 pagesPhilips fwt9200Alex BrazNo ratings yet

- 2 TolentinoDocument12 pages2 TolentinoMA. ANGELINE GRANADANo ratings yet

- Text Descriptive Tentang HewanDocument15 pagesText Descriptive Tentang HewanHAPPY ARIFIANTONo ratings yet

- Soal PTS Vii BigDocument6 pagesSoal PTS Vii Bigdimas awe100% (1)

- Yazaki BrochureDocument4 pagesYazaki Brochureguzman_10No ratings yet

- CHAPTER 2 (C) Innovation in EntrepreneurDocument36 pagesCHAPTER 2 (C) Innovation in EntrepreneurHuiLingNo ratings yet

- Coastal Blue Carbon - Methods For Assessing Carbon Stocks and Emissions Factors in Mangroves Tidal Salt Marshes and Seagrass MeadowsDocument182 pagesCoastal Blue Carbon - Methods For Assessing Carbon Stocks and Emissions Factors in Mangroves Tidal Salt Marshes and Seagrass Meadowsapi-245803001No ratings yet

- Refrigerant Unit Lab ReportDocument19 pagesRefrigerant Unit Lab Reportakmal100% (2)

- Compal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentDocument56 pagesCompal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentSuhpreetNo ratings yet

- 1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADDocument15 pages1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADDaniel MartinsNo ratings yet

- GTAG-14 Edited With Ad 05-20-20101 PDFDocument32 pagesGTAG-14 Edited With Ad 05-20-20101 PDFpiornelNo ratings yet

- BROMINE Safety Handbook - Web FinalDocument110 pagesBROMINE Safety Handbook - Web Finalmonil panchalNo ratings yet

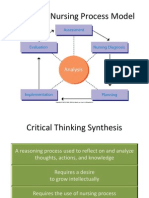

- NUR 104 Nursing Process MY NOTESDocument77 pagesNUR 104 Nursing Process MY NOTESmeanne073100% (1)

- Branch & Category Wise Opening & Closing Rank of JEE (Main) 2019Document46 pagesBranch & Category Wise Opening & Closing Rank of JEE (Main) 2019soni dwivediNo ratings yet

- Learning Theories Behaviourism, Cognitivism, Social ConstructivismDocument39 pagesLearning Theories Behaviourism, Cognitivism, Social ConstructivismJuan Miguel100% (3)

- Stamp 07 eDocument6 pagesStamp 07 eDumitru TuiNo ratings yet

- The Four Types of Gaps and How To Play Them PDFDocument17 pagesThe Four Types of Gaps and How To Play Them PDFshaikiftakar100% (2)

- Using The Words in The Box, Fill in All The GapsDocument23 pagesUsing The Words in The Box, Fill in All The GapsMo NoNo ratings yet

- Revised LabDocument18 pagesRevised LabAbu AyemanNo ratings yet

- S P 01958 Version 2 EPD OVO ArmchairDocument16 pagesS P 01958 Version 2 EPD OVO ArmchairboiNo ratings yet

- Bo Sanchez-Turtle Always Wins Bo SanchezDocument31 pagesBo Sanchez-Turtle Always Wins Bo SanchezCristy Louela Pagapular88% (8)

- RG-RAP6260 (G) Hardware InstallationDocument26 pagesRG-RAP6260 (G) Hardware InstallationrazuetNo ratings yet

- Pediatric Infectious DiseasesDocument3 pagesPediatric Infectious DiseasesAiri FirdausiaNo ratings yet

- California Academy For Lilminius (Cal) : Lesson PlanDocument4 pagesCalifornia Academy For Lilminius (Cal) : Lesson Plandarryl franciscoNo ratings yet