Professional Documents

Culture Documents

Problem 1. Komet Machine Tool Problem PDF

Problem 1. Komet Machine Tool Problem PDF

Uploaded by

Mohan BollaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Problem 1. Komet Machine Tool Problem PDF

Problem 1. Komet Machine Tool Problem PDF

Uploaded by

Mohan BollaCopyright:

Available Formats

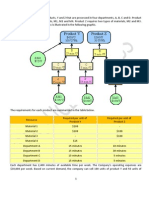

The

Kommet

Machine

Tool

Company

produces

two

products,

muffler

bearings

and

torque

amplifiers.

One

muffler

bearing

requires

.20

hours

of

assembly

labor,

.45

hours

in

the

stamping

department

and

9

square

feet

of

sheet

steel.

Each

torque

amplifier

requires

.50

hours

in

assembly

and

.30

hours

in

stamping

and

uses

8

square

feet

of

sheet

steel.

Current

weekly

capacities

in

the

two

departments

are

400

hours

of

assembly

labor

and

500

hours

of

stamping

capacity.

Sheet

steel

costs

35

cents

per

square

foot.

Muffler

bearings

can

be

sold

for

$20.00

each.

Torque

amplifiers

can

be

sold

for

$17.00

each.

Unused

capacity

in

either

department

cannot

be

laid

off

or

otherwise

fruitfully

used.

1. Formulate

and

solve

a

LP

useful

in

maximizing

the

weekly

profit

contribution.

Determine

the

optimal

schedule,

i.e.

production

levels

of

the

two

products,

assembly

labor

used,

time

required

in

the

stamping

department

and

sheet

steel

required.

2. It

has

just

been

discovered

that

up

to

150

hours

of

overtime

assembly

labor

can

be

scheduled

at

a

cost

of

$7

per

hour.

Modify

the

formulation

and

solve.

What

if

an

overtime

assembly

hour

costs

$10.00?

You might also like

- Stats QuestionsDocument3 pagesStats QuestionsSaurav PatroNo ratings yet

- Teknik Resim 2Document2 pagesTeknik Resim 2Muhammad UsmanNo ratings yet

- Selections in Present EconomyDocument12 pagesSelections in Present EconomyCristina HaliliNo ratings yet

- Selection of Materials: Present EconomyDocument9 pagesSelection of Materials: Present Economymayka mawrin50% (2)

- H EN103 Ch2S Cost ConceptsDocument1 pageH EN103 Ch2S Cost ConceptsMichael John RamosNo ratings yet

- Selections in The Present EconomyDocument3 pagesSelections in The Present EconomyNeil100% (3)

- Lesson 1Document7 pagesLesson 1Ma Aaron Gwyneth BalisacanNo ratings yet

- Problem Set1Document17 pagesProblem Set1Bianca TiuNo ratings yet

- OR6205 M5 Practice ExamDocument3 pagesOR6205 M5 Practice ExamMohan BollaNo ratings yet

- English 1 PDFDocument76 pagesEnglish 1 PDFNala NalaNo ratings yet

- Chapter 4 - Part I Centrifugal CompressorsDocument17 pagesChapter 4 - Part I Centrifugal CompressorsDina FouadNo ratings yet

- Assignment No 1 (ME 461)Document6 pagesAssignment No 1 (ME 461)Jayant Raj SauravNo ratings yet

- Abrasive Jet MachiningDocument25 pagesAbrasive Jet MachiningAjay BhaleraoNo ratings yet

- Manufacturing Example PDFDocument6 pagesManufacturing Example PDFAbdul RahmanNo ratings yet

- Econ 6Document7 pagesEcon 6ceejay RedondiezNo ratings yet

- Selection in Present Economy (Extra Problems)Document4 pagesSelection in Present Economy (Extra Problems)Lawrence BelloNo ratings yet

- Process SelectionDocument2 pagesProcess Selectionhoang.phamnguyetminhNo ratings yet

- Selections in Present Economy: Problem Set: MethodDocument4 pagesSelections in Present Economy: Problem Set: MethodAlvaro LaureanoNo ratings yet

- Activity 1Document2 pagesActivity 1DENZ RAYMOND LACUESTANo ratings yet

- Engineering Economics Prelim Quiz 1Document3 pagesEngineering Economics Prelim Quiz 1Johnjacob GerardoNo ratings yet

- MS HandOut 02Document1 pageMS HandOut 02mark anthony espirituNo ratings yet

- UGRD ENG6203 Engineering EconomicsDocument4 pagesUGRD ENG6203 Engineering EconomicsJitlee PapaNo ratings yet

- ECON - 313 - Unit - V - Assignment - 5-1 - Schoology QuestionsDocument5 pagesECON - 313 - Unit - V - Assignment - 5-1 - Schoology QuestionsJohn SantosNo ratings yet

- Activity 6890Document3 pagesActivity 6890Raymond Gicalde RementillaNo ratings yet

- Tutorial 1 EME 3056 Industrial ManagementDocument4 pagesTutorial 1 EME 3056 Industrial ManagementSivanesh KumarNo ratings yet

- LINEAR PROGRAMMING (35 Points) : Kingfisher School of Business and Finance Finals Written Work #2Document6 pagesLINEAR PROGRAMMING (35 Points) : Kingfisher School of Business and Finance Finals Written Work #2Romulo MarquezNo ratings yet

- Tutorial 5 Sheet - MA MGMT Final 2Document3 pagesTutorial 5 Sheet - MA MGMT Final 2Mohamed ManoNo ratings yet

- Takehomequiz2 (Presenteconomy) Engineering EconomyDocument3 pagesTakehomequiz2 (Presenteconomy) Engineering EconomyNeil BrionesNo ratings yet

- c2 Selection of Present EconomyDocument12 pagesc2 Selection of Present EconomyJen67% (3)

- 1 Formulation - AssignmentDocument4 pages1 Formulation - AssignmentNamanNo ratings yet

- ES 33 - Plate No. 1Document10 pagesES 33 - Plate No. 1Maybelline DipasupilNo ratings yet

- 2 - Present Economy - GLDocument17 pages2 - Present Economy - GLHanna Rosette SeñoNo ratings yet

- EcoDocument13 pagesEcocarminavelasco21No ratings yet

- Linear Programming QuestionsDocument2 pagesLinear Programming QuestionskhanNo ratings yet

- Assignment 1 (LP Models)Document2 pagesAssignment 1 (LP Models)Usman GhaniNo ratings yet

- Interm Report DraftDocument1 pageInterm Report DraftMohamed SouthallNo ratings yet

- Untitled DocumentDocument5 pagesUntitled DocumentPatleen Monica MicuaNo ratings yet

- Lecture 1Document6 pagesLecture 1محمد احمدNo ratings yet

- Formulation of LPP ProblemsDocument7 pagesFormulation of LPP ProblemsBhavesh KundnaniNo ratings yet

- OR Question BankDocument29 pagesOR Question BankSuhas Mv50% (4)

- QAMD - Work Sheet (SC)Document19 pagesQAMD - Work Sheet (SC)Tesfu100% (1)

- The Goodparts Company Produces A Component That Is Subsequently UsedDocument1 pageThe Goodparts Company Produces A Component That Is Subsequently UsedAmit PandeyNo ratings yet

- Present Economy - BDocument18 pagesPresent Economy - BAdrianPaul TosocNo ratings yet

- QAMD Tena QuestionsDocument21 pagesQAMD Tena QuestionsCheru TerefeNo ratings yet

- LPP AssignmentDocument3 pagesLPP AssignmentMohammed Marfatiya100% (1)

- Example - LPP FormulationDocument4 pagesExample - LPP Formulationrdeepak99No ratings yet

- Sheet 1 PDFDocument2 pagesSheet 1 PDFIniyan I TNo ratings yet

- LPP - orDocument12 pagesLPP - orbharat_v79No ratings yet

- Taller OPT-SoluciónDocument14 pagesTaller OPT-SoluciónMauricio Alejandro Buitrago Soto100% (1)

- Lec#3 Elementary Economic AnalysisDocument12 pagesLec#3 Elementary Economic AnalysisShahzaib Anwar OffNo ratings yet

- Assignment1 2016Document3 pagesAssignment1 2016Youssef LebroNo ratings yet

- Linear Programming WW2 Set ADocument6 pagesLinear Programming WW2 Set APrecious PerezNo ratings yet

- LP Assignement 2022 SolutionDocument11 pagesLP Assignement 2022 Solutionsohilamohsen46No ratings yet

- Study and Improvement of Small Scale Industry SystemDocument10 pagesStudy and Improvement of Small Scale Industry SystemRajneesh SinghNo ratings yet

- Outdoors Inc.Document3 pagesOutdoors Inc.Dev SharmaNo ratings yet

- Case StudyDocument11 pagesCase StudyLynDioquinoNo ratings yet

- AOR Problem SetDocument41 pagesAOR Problem SetChandra MathiNo ratings yet

- Engineering EconomicsDocument57 pagesEngineering EconomicsRadNo ratings yet

- Ece TutorialDocument7 pagesEce TutorialShreeji EnggNo ratings yet

- Eastern Company Manufactures Special Electrical Equipment and PaDocument2 pagesEastern Company Manufactures Special Electrical Equipment and PaAmit PandeyNo ratings yet

- 2 Spring LLCDocument80 pages2 Spring LLCmscarreraNo ratings yet

- OR6205 Syllabus Fall 18 Sec 05Document5 pagesOR6205 Syllabus Fall 18 Sec 05Mohan BollaNo ratings yet

- OR6205 M9 Practice Exam 2Document5 pagesOR6205 M9 Practice Exam 2Mohan BollaNo ratings yet

- Module 3 Intro To SimplexDocument36 pagesModule 3 Intro To SimplexMohan BollaNo ratings yet

- Linear Programming Formulation Examples PDFDocument16 pagesLinear Programming Formulation Examples PDFMohan BollaNo ratings yet

- Project Proposal Topic Selection ReportDocument3 pagesProject Proposal Topic Selection ReportMohan BollaNo ratings yet

- Sample Project Proposal - Dynamic ServerDocument26 pagesSample Project Proposal - Dynamic ServerMohan BollaNo ratings yet