Professional Documents

Culture Documents

PXL 2000 HP Triplex Drilling Pump Performance Ratings

Uploaded by

gustavo animas0 ratings0% found this document useful (0 votes)

120 views2 pagesOriginal Title

PXL

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

120 views2 pagesPXL 2000 HP Triplex Drilling Pump Performance Ratings

Uploaded by

gustavo animasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

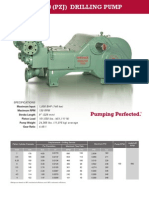

Specifications Drilling Service

Maximum Input 2,000 BHP (1,491 kw)

Maximum RPM 115 RPM

Stroke Length 11" (279 mm)

Piston Load 186,875 lbs. (85,220 kg)

Pump Weight 41,750 lbs. (18,975 kg)

Gear Ratio 4.38:1

PXL 2000 HP Triplex Drilling Pump Performance Ratings

Cylinder Displacement

Diameter Per Revolution Per Minute Maximum PSI Piston Load Pump JackShaft Input Input

Inch mm Gal. Lit. Gal. Lit. PSI Kg/sq.cm2 lbs. Kg/sq.cm2 RPM RPM HP KW

7 178 5.5 20.78 632 2,385 4,880 343 187,875 85,220 115 504 2,000 1,007

6.5 165 4.74 17.94 545 2,063 5,660 398 187,875 85,220 115 504 2,000 1,491

6 152 4.04 15.29 465 1,760 6,645 467 187,875 85,220 115 504 2,000 1,491

5.5 140 3.40 12.87 390 1,476 7,500 527 178,200 80,832 115 504 1,900 1,417

5 127 2.80 10.60 323 1,223 7,500 527 147,260 66,797 115 504 1,570 1,171

Weight: Complete pump with large steel skid – 46,250 pounds.

Ratings are based on 90% mechanical efficiency and 100% volumetric efficiency.

Standard Features

• Advanced homogenous nodular iron power frame with internal ribbing of critical areas

for improved strength and higher horsepower

• Expanded eccentric wall thickness by 14% with improved tensile strength of 25%

• Cross sectional increases in the connecting rod and an increase in the crosshead slide

Optional Equipment

area of 16%, improves bearing capacity and strengthen

• Double-row-spherical roller bearnings carry eccentric • Steel skid under pump only

• Increased length of double extneded jackshift 5'' and diameter by 1/2'' carried on • Large steel skid with non-skid decking

heavy-duty straight roller bearings improve strength and provide a more generous • Centrifugal suction charging pump

sprocket/sheave engagement • Rubber valve inserts

• Enlarged dual roller bearing connecting rods for increased load carrying capacity • Suction and/or discharge dampeners

• Main gears cut on heat-treated rolled alloy steel rings • Oil heat exchanger cooling system

• Replaceable bronze crosshead slides

• External electric powered lube pump

• Full splash lubrication, with oil pump to feed working parts

• Custom packaging available

• 7,500 PSI fluid end modules

• Full open valve

• Heat-treated alloy steel, interchangeable fluid cyclinders

• Three-rib API-6 urethane insert valves and seats

• Replaceable-type element oil filter and oil pressure gauge

• Threaded valve cover locks and rings

• Plated piston rods

• Complete piston washing and lubrication system

• Fabricated suction manifold

Note: All installations must contain a pressure relief valve in the discharge line near the pump.

GEOQUIP SERVICE CENTER CHAPARRAL SERVICE CENTER

Drilling & Production Pumps Drilling & Production After-Market Well Service Pumps After-Market & Repair Facility After-Market & Repair Facility

Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division

1800 Gardner Expressway 2200 South Prospect 4747 South 83rd East Avenue 7533 Kathy Lane 2121 West 44th Street

Quincy, IL 62301 Oklahoma City, OK 73129 Tulsa, OK 74145 Fort Worth, TX 76126 Odessa, TX 79764

Phone: 217-224-8800 Phone: 405-677-5736 Phone: 918-828-7800 Phone: 817-249-6400 Phone: 432-366-5433

Fax: 217-224-7814 Fax: 405-677-5807 Fax: 918-447-6487 Fax: 817-249-6383 Fax: 432-363-9940

< www.gardnerdenver.com >

Bulletin: DR11-02-2000 REV.B Copyright 2003 Gardner Denver, Inc. Litho in U.S.A. Specficiation subject to change without notice.

You might also like

- PZ 10 PDFDocument2 pagesPZ 10 PDFGabriel Aguilar SosaNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- PZ11 Manual PDFDocument2 pagesPZ11 Manual PDFJuan Miguel Robledo100% (1)

- Meeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceFrom EverandMeeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceNo ratings yet

- POMPA PZL 1600 HP Triplex PDFDocument2 pagesPOMPA PZL 1600 HP Triplex PDFVali Bazdaga0% (1)

- PZ 8 PDFDocument2 pagesPZ 8 PDFgustavo animasNo ratings yet

- PAH Well ServiceDocument2 pagesPAH Well ServiceJuanes CantanteNo ratings yet

- pz-11 - High - Flow - Special - Bulletin RevisedDocument2 pagespz-11 - High - Flow - Special - Bulletin Revisedo_tostaNo ratings yet

- PZ-9 FlyerDocument2 pagesPZ-9 FlyerChris KNo ratings yet

- GD 1250-LW Intermittent Duty Well Service RatingsDocument2 pagesGD 1250-LW Intermittent Duty Well Service RatingsyelmustafaaliNo ratings yet

- Bomba de Lodo Gardner Denver Pz10Document2 pagesBomba de Lodo Gardner Denver Pz10Luis Alfredo Gregorio RivasNo ratings yet

- PZH (PZ-8) : Triplex Drilling Mud PumpDocument2 pagesPZH (PZ-8) : Triplex Drilling Mud PumpamericaNo ratings yet

- Gardener Denver PZ8 SpecsDocument2 pagesGardener Denver PZ8 SpecsExpertum99No ratings yet

- Garden Denver - 1054 GD Compact Well Service PumpDocument2 pagesGarden Denver - 1054 GD Compact Well Service PumpjjjjjjNo ratings yet

- 106.7 - Beam Pump UnitsDocument30 pages106.7 - Beam Pump UnitsHassan GDOURANo ratings yet

- TEED 4x5 For Well Servicing Performance RatingDocument2 pagesTEED 4x5 For Well Servicing Performance RatingMauricio Furque GordilloNo ratings yet

- TEED 4x5 For Well Servicing Performance RatingDocument2 pagesTEED 4x5 For Well Servicing Performance RatingJimy BarronNo ratings yet

- Mud Pump Gardner Denver GD-3000 BrochureDocument2 pagesMud Pump Gardner Denver GD-3000 Brochureo_tostaNo ratings yet

- For Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingDocument2 pagesFor Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingcacaunpsNo ratings yet

- Bomba Triplex TEEF 5 de in Gardner DenverDocument2 pagesBomba Triplex TEEF 5 de in Gardner DenverPeponSera100% (2)

- PZ 8Document2 pagesPZ 8Yimmy Alexander Parra MarulandaNo ratings yet

- PZ 7Document2 pagesPZ 7Yimmy Alexander Parra Marulanda100% (1)

- Affordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDocument2 pagesAffordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDyddier RojasNo ratings yet

- Quintuplex Well Stimulation Pump: Standard FeaturesDocument2 pagesQuintuplex Well Stimulation Pump: Standard FeaturesAkhmad SebehNo ratings yet

- Bomba de Lodo Gardner Denver Pz9Document2 pagesBomba de Lodo Gardner Denver Pz9Luis Alfredo Gregorio RivasNo ratings yet

- PZL (PZ-11) Drilling Service RatingsDocument2 pagesPZL (PZ-11) Drilling Service RatingsLibros Universitarios DigitalesNo ratings yet

- Bomba Triplex Pz8 GDDocument2 pagesBomba Triplex Pz8 GDVictor Dasilva100% (1)

- PAH 275 HP Triplex Drilling Pump Performance RatingsDocument2 pagesPAH 275 HP Triplex Drilling Pump Performance RatingsJavier Andres Betancourt FernandezNo ratings yet

- GDEP - 2250T - Spec Sheet - 2021Document2 pagesGDEP - 2250T - Spec Sheet - 2021bayuNo ratings yet

- GDEP - TEED - Spec Sheet - 2022Document2 pagesGDEP - TEED - Spec Sheet - 2022soroush niliNo ratings yet

- 65602-Gd Cutsheet Template Pzgpz7 2015 LRDocument2 pages65602-Gd Cutsheet Template Pzgpz7 2015 LRroberto restrepoNo ratings yet

- AHPB AHPBDS Product-Brochure 20210119 PDFDocument8 pagesAHPB AHPBDS Product-Brochure 20210119 PDFFelySaezNo ratings yet

- Udr 200Document2 pagesUdr 200Dam63% (8)

- Dhillon, Randy - Nov 27, 2019 948 PM - Mod PresentationDocument35 pagesDhillon, Randy - Nov 27, 2019 948 PM - Mod PresentationGURNOOR SINGHNo ratings yet

- Acert: Marine Propulsion EngineDocument2 pagesAcert: Marine Propulsion EngineEsmaeil RahmaniNo ratings yet

- PZG (PZ-7) : Triplex Drilling Mud PumpDocument2 pagesPZG (PZ-7) : Triplex Drilling Mud PumpYuliana Andrea Zapata RubioNo ratings yet

- TGH 400 Data SheetDocument2 pagesTGH 400 Data SheetMiriam SalazarNo ratings yet

- Flexiroc T20 R: Atlas Copco Surface Drill RigsDocument4 pagesFlexiroc T20 R: Atlas Copco Surface Drill RigsalmirNo ratings yet

- GDEP - GD 2250T Continuous Duty - Spec Sheet - 2022Document2 pagesGDEP - GD 2250T Continuous Duty - Spec Sheet - 2022bayuNo ratings yet

- QF-450HC 2016Document2 pagesQF-450HC 2016David BahenaNo ratings yet

- MC High Pressure Stage Casing Pump E10026Document6 pagesMC High Pressure Stage Casing Pump E10026Deepak PandeyNo ratings yet

- Pulv RiserDocument62 pagesPulv RiserMuskan KNo ratings yet

- Aurora Pump 6-491-12aDocument28 pagesAurora Pump 6-491-12ajuan yenqueNo ratings yet

- GD 1600Document2 pagesGD 1600Muaz AliNo ratings yet

- PZL Pz11 Triplex 5000 PsiDocument2 pagesPZL Pz11 Triplex 5000 PsiJimy BarronNo ratings yet

- GD Cutsheet Template PZLPZ11 MS PDFDocument2 pagesGD Cutsheet Template PZLPZ11 MS PDFCesar MoraNo ratings yet

- 4000 Series: 4006-23TAG2ADocument5 pages4000 Series: 4006-23TAG2AJan AhmedNo ratings yet

- Presentaciòn SunfloDocument25 pagesPresentaciòn SunfloGustavo Fajardo PulidoNo ratings yet

- DozerDocument45 pagesDozerAndry Perdana PutraNo ratings yet

- Tulsa Triplex Tt-600Document2 pagesTulsa Triplex Tt-600miguelgarciamartinezNo ratings yet

- Xpress Pump Brochure2Document2 pagesXpress Pump Brochure2fernando.itt6No ratings yet

- L & C Series: Lubrication & Circulation PumpsDocument6 pagesL & C Series: Lubrication & Circulation PumpsValeria AlmazanNo ratings yet

- Gaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsDocument3 pagesGaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsÆmanuel J SilvaNo ratings yet

- Fast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPDocument2 pagesFast & Affordable Convertibility: Pressures To 20,000 PSI Flows To 54 GPM Power To 330 HPFrederik CañabiNo ratings yet

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocument6 pagesDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNo ratings yet

- Technical Specifications: DozerDocument10 pagesTechnical Specifications: DozerFaizan MdNo ratings yet

- Flowrox PC-pump EL-series Datasheet ENGDocument2 pagesFlowrox PC-pump EL-series Datasheet ENGAlberto Diaz100% (1)

- PL87Document8 pagesPL87Стоян МитевNo ratings yet

- Product Guide - Rosco - Rev 02 12Document2 pagesProduct Guide - Rosco - Rev 02 12Özer YildirimNo ratings yet

- Supplier Business Compliance Questionnaire - Feb2018Document4 pagesSupplier Business Compliance Questionnaire - Feb2018gustavo animasNo ratings yet

- DUPLEX STEAM PUMPS For Mud Service - Continuous DutyDocument1 pageDUPLEX STEAM PUMPS For Mud Service - Continuous Dutygustavo animasNo ratings yet

- PZ 7Document2 pagesPZ 7Yimmy Alexander Parra Marulanda100% (1)

- DRILLING PUMPS - Triplex Mud Pumps - Continuous DutyDocument2 pagesDRILLING PUMPS - Triplex Mud Pumps - Continuous Dutygustavo animasNo ratings yet

- Chapter EnglishDocument27 pagesChapter EnglishTavo AnimasNo ratings yet

- Chase, A. J. (1998) .Document29 pagesChase, A. J. (1998) .Juan Carlos Dominguez BtaNo ratings yet

- 85010-0089 - Intelligent Audio AmplifiersDocument2 pages85010-0089 - Intelligent Audio AmplifiersmohammadNo ratings yet

- Microprocessor For Bca Bit BeDocument0 pagesMicroprocessor For Bca Bit Bewww.bhawesh.com.npNo ratings yet

- Escorts TRX-1550 EnquiryDocument6 pagesEscorts TRX-1550 EnquirySiddhi SparesNo ratings yet

- Pololu G2 High-Power Motor Driver 24v13Document11 pagesPololu G2 High-Power Motor Driver 24v13nikkiNo ratings yet

- E3301 p5k3 Deluxe v3Document176 pagesE3301 p5k3 Deluxe v3Daniel AlejandroNo ratings yet

- Application Guideline #1: Bearing Greasing IntervalsDocument2 pagesApplication Guideline #1: Bearing Greasing IntervalsWONG TSNo ratings yet

- Lesson 8: Cpus Used in Personal ComputersDocument14 pagesLesson 8: Cpus Used in Personal ComputersahsanloverboyNo ratings yet

- AREVA ALSTOM gl317xDocument20 pagesAREVA ALSTOM gl317xAdrian RodriguesNo ratings yet

- A3377module1+2 NumericalDocument11 pagesA3377module1+2 NumericalSomil GuptaNo ratings yet

- 86 366 1 PB PDFDocument6 pages86 366 1 PB PDFMuhammad Cendekia AirlanggaNo ratings yet

- CAM-ReachForks-LEAF-2104-EN (2) Telescopic ForkDocument3 pagesCAM-ReachForks-LEAF-2104-EN (2) Telescopic ForkThanh NgocNo ratings yet

- Puma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and CranksDocument11 pagesPuma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and Cranksspidermaan67% (3)

- Maint Instructions For Ferrule FittingsDocument13 pagesMaint Instructions For Ferrule FittingsLakhwant Singh KhalsaNo ratings yet

- Comp JKSSB Fundamentals of ComputerDocument25 pagesComp JKSSB Fundamentals of Computerreena deviNo ratings yet

- Crossvent-3+: Operation & Service ManualDocument102 pagesCrossvent-3+: Operation & Service ManualIngenieria NemoconNo ratings yet

- Holtek Semicon HT7750SA C192571Document17 pagesHoltek Semicon HT7750SA C192571a637888No ratings yet

- Kit 26. One-Way Audio by Fiber Optic Cable: Circuit DescriptionDocument2 pagesKit 26. One-Way Audio by Fiber Optic Cable: Circuit DescriptionJohn Peter Sosa GutierrezNo ratings yet

- Receiving and Inspection: Installation, Operation and Maintenance ManualDocument16 pagesReceiving and Inspection: Installation, Operation and Maintenance ManualIvy LeeNo ratings yet

- DTSC-200A Product TrainingDocument45 pagesDTSC-200A Product TrainingEliyanto E BudiartoNo ratings yet

- SD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Document1 pageSD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Huy Trần QuốcNo ratings yet

- Engineering Utilities 1 CE 354: Group-CentinoDocument16 pagesEngineering Utilities 1 CE 354: Group-CentinoAnnie TheExplorerNo ratings yet

- Hydraulic Austoft9900 - ENDocument146 pagesHydraulic Austoft9900 - ENSugeng Ariyadi100% (1)

- Fresadora B40pte B40e 2 PDFDocument70 pagesFresadora B40pte B40e 2 PDFRaul Alanoca ColqueNo ratings yet

- Placa 1156 - Pegatron Ipmip-Dp (Pos-Piq57bq) Rev 1.01Document68 pagesPlaca 1156 - Pegatron Ipmip-Dp (Pos-Piq57bq) Rev 1.01Francisco FreireNo ratings yet

- SB As 350800007 enDocument11 pagesSB As 350800007 enDouglas de OliveiraNo ratings yet

- Manual Cargadores de Carros GolfDocument4 pagesManual Cargadores de Carros GolfLuis Carlos PerezNo ratings yet

- p2 1375607098Document104 pagesp2 1375607098Marko RajkovicNo ratings yet

- Philips 1498Document5 pagesPhilips 1498zaphossNo ratings yet

- Digger Cal UTSDocument61 pagesDigger Cal UTSConnor TabainNo ratings yet

- Design and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019Document52 pagesDesign and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019kawsar ahmmedNo ratings yet