Professional Documents

Culture Documents

GD 1250-LW Intermittent Duty Well Service Ratings

Uploaded by

yelmustafaali0 ratings0% found this document useful (0 votes)

112 views2 pagesOriginal Title

96479

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

112 views2 pagesGD 1250-LW Intermittent Duty Well Service Ratings

Uploaded by

yelmustafaaliCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

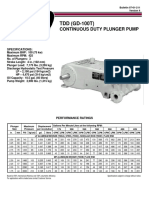

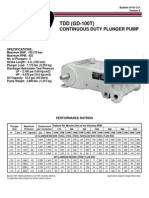

Specifications Well Service

Maximum Input 1,250 BHP (912 kW)

Maximum RPM 330

No. of Plungers 3

Stroke Length 8" (203 mm)

Plunger Load 200,000 lbs. (90,720 kg)

Pump Weight 8,550 lbs. (3,878 kg)

Gear Ratio 9:1

GD 1250-LW Intermittent Duty Well Service Ratings

Plunger Displacement Displacement at Pump RPM - Well Stimulation Application

Diameter per Revolution 100 150 200 330

Gal/ Liter/ kg/sq. GPM LPM PSI kg/sq. GPM LPM

in. mm. Rev. Rev. GPM LPM PSI PSI kg/sq. GPM LPM PSI kg/sq.

cm cm cm cm

Forged Steel Autofrettaged High Pressure Valve Over Valve Fluid Ends

3.75 95 1.15 4.34 115 434 18100 1273 172 651 11200 787 229 868 8400 591 378 1433 5100 359

Forged Steel Autofrettaged Medium Pressure Valve Over Valve Fluid Ends

4.5 114 1.65 6.25 165 625 12600 886 248 938 7800 548 330 1250 5850 411 545 2063 3550 250

5 127 2.04 7.72 204 772 10200 717 306 1158 6300 443 408 1544 4750 334 673 2547 2850 200

5.5 140 2.47 9.34 247 934 8400 591 370 1401 5200 366 493 1868 3900 274 814 3082 2350 165

Forged Steel Autofrettaged Low Pressure Valve Over Valve Fluid Ends

5.5 140 2.47 9.34 247 934 8400 591 370 1401 5200 366 493 1868 3900 274 814 3082 2350 165

6 152 2.94 11.11 294 1111 7100 499 440 1667 4400 309 587 2223 3300 232 969 3668 2000 141

6.5 165 3.45 13.04 345 1304 6050 425 517 1957 3750 264 689 2609 2800 197 1137 4304 1700 120

Input Power: BHP 1250 1250 1250 1250

kW 932 932 932 932

Notes: Ratings are based on 90% mechanical efficiency and 100% volumetric efficiency.

Standard Features

• Gearbox design

• Crankshaft type construction Optional Equipment

• Left or right gear box mounting

• Suction and discharge on either side

• Clamp connections between plungers and extension rods • Dual discharge flanges

• Colmonoy plungers • Multiple center gauge connections

• Cradle cover • Suction stabilizers

• Autofrettaged fluid cylinder with through stud design • Discharge pulsation dampeners

• Forged steel fluid end and plunger sizes ranging from 3.75'' to 6.5'' • Valve seat puller assembly

• Replaceable WECO discharge connections • Hydraulic torque wrench

• 6'' suction manifold with Victaulic or flanged connections • Companion flanges

• Header-ring style packs

• Standard fluid end tool kit

Material Specifications

• Cylinder Forged SAE 4330 steel

• Packing Adjustable or header ring

• Stuffing Box Replaceable steel

• Crankshaft Forged steel surface hardened

• Connecting Rods Steel hardened surface

• Crossheads High strength 4140 steel

• Crossheads Slides High strength steel

• Tie Rods Alloy steel with cold rolled threads

• Main Bearings Roller

• Spherical Crosshead Bearing Bronze

Note: Line drawings are available from

Engineering per application.

GEOQUIP SERVICE CENTER CHAPARRAL SERVICE CENTER

Drilling & Production Pumps Drilling & Production After-Market Well Service Pumps After-Market & Repair Facility After-Market & Repair Facility

Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division Gardner Denver Pump Division

1800 Gardner Expressway 2200 South Prospect 4747 South 83rd East Avenue 7533 Kathy Lane 2121 West 44th Street

Quincy, IL 62301 Oklahoma City, OK 73129 Tulsa, OK 74145 Fort Worth, TX 76126 Odessa, TX 79764

Phone: 217-224-8800 Phone: 405-677-5736 Phone: 918-828-7800 Phone: 817-249-6400 Phone: 432-366-5433

Fax: 217-224-7814 Fax: 405-677-5807 Fax: 918-447-6487 Fax: 817-249-6383 Fax: 432-363-9940

< www.gardnerdenver.com >

Bulletin: WS08-02-1201 Copyright 2003 Gardner Denver, Inc. Litho in U.S.A. Specficiation subject to change without notice.

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- PZ 8 PDFDocument2 pagesPZ 8 PDFgustavo animasNo ratings yet

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

- PZ 10 PDFDocument2 pagesPZ 10 PDFGabriel Aguilar SosaNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- PZ11 Manual PDFDocument2 pagesPZ11 Manual PDFJuan Miguel Robledo100% (1)

- POMPA PZL 1600 HP Triplex PDFDocument2 pagesPOMPA PZL 1600 HP Triplex PDFVali Bazdaga0% (1)

- Mud Pump Gardner Denver GD-3000 BrochureDocument2 pagesMud Pump Gardner Denver GD-3000 Brochureo_tostaNo ratings yet

- PXL 2000 HP Triplex Drilling Pump Performance RatingsDocument2 pagesPXL 2000 HP Triplex Drilling Pump Performance Ratingsgustavo animasNo ratings yet

- PAH Well ServiceDocument2 pagesPAH Well ServiceJuanes CantanteNo ratings yet

- 1051 GD 2250tDocument2 pages1051 GD 2250tJunior Francisco QuijanoNo ratings yet

- pz-11 - High - Flow - Special - Bulletin RevisedDocument2 pagespz-11 - High - Flow - Special - Bulletin Revisedo_tostaNo ratings yet

- Gardner Denver QAF GD-300QDocument2 pagesGardner Denver QAF GD-300QAndres Felipe Garcia ReinaNo ratings yet

- GDEP - GD 2250T Continuous Duty - Spec Sheet - 2022Document2 pagesGDEP - GD 2250T Continuous Duty - Spec Sheet - 2022bayuNo ratings yet

- GDEP - 2250T - Spec Sheet - 2021Document2 pagesGDEP - 2250T - Spec Sheet - 2021bayuNo ratings yet

- Data Sheet TDD-GD100T PDFDocument2 pagesData Sheet TDD-GD100T PDFjhon peñaNo ratings yet

- Gardner Denver 1050 C 2500 Quintuplex Well Service PumpDocument2 pagesGardner Denver 1050 C 2500 Quintuplex Well Service PumpMvarik MarioNo ratings yet

- TEED 4x5 For Well Servicing Performance RatingDocument2 pagesTEED 4x5 For Well Servicing Performance RatingMauricio Furque GordilloNo ratings yet

- TEED 4x5 For Well Servicing Performance RatingDocument2 pagesTEED 4x5 For Well Servicing Performance RatingJimy BarronNo ratings yet

- 1040 Tee GD 125t Continuous Duty Brochure Data Sheet PDFDocument2 pages1040 Tee GD 125t Continuous Duty Brochure Data Sheet PDFAndres SerranoNo ratings yet

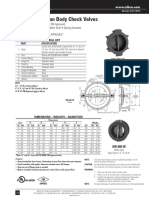

- Valvula Check Wafer 250psiDocument1 pageValvula Check Wafer 250psiOscar Fernandez SanchezNo ratings yet

- PZ-9 FlyerDocument2 pagesPZ-9 FlyerChris KNo ratings yet

- Accelerated Multiplex Plunger Pumps PDFDocument20 pagesAccelerated Multiplex Plunger Pumps PDFJessica montesNo ratings yet

- CRI 1800 Plunger PumpDocument2 pagesCRI 1800 Plunger Pumpgk218No ratings yet

- Bomba de Lodo Gardner Denver Pz10Document2 pagesBomba de Lodo Gardner Denver Pz10Luis Alfredo Gregorio RivasNo ratings yet

- Union Pump InformationDocument12 pagesUnion Pump Informationgeverett2765No ratings yet

- Check Valves WaferDocument1 pageCheck Valves WaferwfjerrNo ratings yet

- Bomba Triplex TEEF 5 de in Gardner DenverDocument2 pagesBomba Triplex TEEF 5 de in Gardner DenverPeponSera100% (2)

- 05 RR Gardner Denver TEE GD-125TDocument2 pages05 RR Gardner Denver TEE GD-125TDavid AguilarNo ratings yet

- W80 Triplex Pump W375 Quintuplex PumpDocument2 pagesW80 Triplex Pump W375 Quintuplex Pumpadewunmi olufemiNo ratings yet

- 5600 SWING FLEX CHECK VALVEDocument16 pages5600 SWING FLEX CHECK VALVEMahmoud Abd ElnaeimNo ratings yet

- Gaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsDocument3 pagesGaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsÆmanuel J SilvaNo ratings yet

- Affordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDocument2 pagesAffordable Convertibility: Pressures To 10,000 PSI Flows To 200 GPM Power To 600 HPDyddier RojasNo ratings yet

- PDF s2h Series BrochureDocument8 pagesPDF s2h Series BrochureMahmoud MagdyNo ratings yet

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocument11 pages1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- GDEP - TEED - Spec Sheet - 2022Document2 pagesGDEP - TEED - Spec Sheet - 2022soroush niliNo ratings yet

- Warren FSXB Series Spec SheetDocument3 pagesWarren FSXB Series Spec SheetEmmanuel Ber SNo ratings yet

- Garden Denver - 1054 GD Compact Well Service PumpDocument2 pagesGarden Denver - 1054 GD Compact Well Service PumpjjjjjjNo ratings yet

- 1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetDocument2 pages1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetYeins Edson OrdoñezNo ratings yet

- TGH 400 Data SheetDocument2 pagesTGH 400 Data SheetMiriam SalazarNo ratings yet

- PZ 8Document2 pagesPZ 8Yimmy Alexander Parra MarulandaNo ratings yet

- Pennar Sheet Piling Brochure - Revised (7 Feb 13)Document8 pagesPennar Sheet Piling Brochure - Revised (7 Feb 13)AnurupaNo ratings yet

- ZF 85 IvDocument4 pagesZF 85 IvAhmet GelişliNo ratings yet

- Gate - Globe - Check - Strainer - Dual CheckDocument32 pagesGate - Globe - Check - Strainer - Dual CheckSacre EwaNo ratings yet

- For Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingDocument2 pagesFor Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingcacaunpsNo ratings yet

- PRD Doc Pro 2910-00005 Sen Ain V1Document14 pagesPRD Doc Pro 2910-00005 Sen Ain V1László BabracsánNo ratings yet

- RR 24-Weatherford Model Q375Document2 pagesRR 24-Weatherford Model Q375adewunmi olufemiNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- Kat-A 1321 Ekn-Awwa 6-3 10-12 enDocument3 pagesKat-A 1321 Ekn-Awwa 6-3 10-12 enSathishkumar DhamodaranNo ratings yet

- RR 18-Weatherford Model T270Document2 pagesRR 18-Weatherford Model T270julio cesar medinaNo ratings yet

- Tulsa Triplex Tt-600Document2 pagesTulsa Triplex Tt-600miguelgarciamartinezNo ratings yet

- Leistritz Re Eng L3 Pump WebDocument4 pagesLeistritz Re Eng L3 Pump WebChuong DongNo ratings yet

- ZF 2000Document4 pagesZF 2000garendro tcahyoNo ratings yet

- ZF 320 Series: Product DetailsDocument4 pagesZF 320 Series: Product Detailsrhandalf100% (1)

- PF260Document4 pagesPF260sundyaNo ratings yet

- Bentec Mud Pump T-1600-Ac - 130209Document2 pagesBentec Mud Pump T-1600-Ac - 130209leo100% (2)

- Bombas HydacDocument16 pagesBombas HydacTiago CamposNo ratings yet

- Model THE: Horizontal Drilling Duty PumpDocument2 pagesModel THE: Horizontal Drilling Duty PumpzhujianglongNo ratings yet

- Ch165a 25120 01Document8 pagesCh165a 25120 01surya jaya bearingNo ratings yet

- ZF 9000 Series: Product DetailsDocument4 pagesZF 9000 Series: Product DetailsArama Eduard AlexandruNo ratings yet

- DPCO411 V 2 SiemensmotorDocument1 pageDPCO411 V 2 SiemensmotoryelmustafaaliNo ratings yet

- Digital Gauge I II 26-102bDocument210 pagesDigital Gauge I II 26-102bvipequi50No ratings yet

- Mdtotco General Catalog SM VerDocument44 pagesMdtotco General Catalog SM VeryelmustafaaliNo ratings yet

- MD Totco Instrumentation Products CatalogDocument9 pagesMD Totco Instrumentation Products CatalogDaniel PaezNo ratings yet

- Mud Pump Parts ExpendablesDocument82 pagesMud Pump Parts ExpendablesAnonymous Yo43Kif0No ratings yet

- Garrett Gas TrainDocument2 pagesGarrett Gas TrainyelmustafaaliNo ratings yet

- Evlabsf 45a e Da 5Document3 pagesEvlabsf 45a e Da 5yelmustafaaliNo ratings yet

- Gulf Proforma 20220803Document1 pageGulf Proforma 20220803yelmustafaaliNo ratings yet

- TSC Mud Pump Spare PartsDocument186 pagesTSC Mud Pump Spare PartsJuan Diego Vargas100% (1)

- Jurrog 2Document64 pagesJurrog 2yelmustafaaliNo ratings yet

- Cf1000utr 25by4 380102 Eu188om Ece167 20180810Document131 pagesCf1000utr 25by4 380102 Eu188om Ece167 20180810yelmustafaaliNo ratings yet

- WRVD0M22Bpdf 1521Document3 pagesWRVD0M22Bpdf 1521yelmustafaaliNo ratings yet

- NOV Shale Shaker Excerpt VSM300 Manual - Parts & DrawingsDocument27 pagesNOV Shale Shaker Excerpt VSM300 Manual - Parts & Drawingsyelmustafaali100% (1)

- Drilling Valve Seat Puller Head Cross Reference 1Document1 pageDrilling Valve Seat Puller Head Cross Reference 1yelmustafaaliNo ratings yet

- Gulf Rig CatalogDocument49 pagesGulf Rig CatalogyelmustafaaliNo ratings yet

- Mission Centrifugal Pumps CatalogDocument60 pagesMission Centrifugal Pumps CatalogSebastian Plata100% (1)

- Basket 1 Envanter InsertDocument1 pageBasket 1 Envanter InsertyelmustafaaliNo ratings yet

- Beverage Air Victory Refrigeration Accessories Parts ListDocument219 pagesBeverage Air Victory Refrigeration Accessories Parts ListyelmustafaaliNo ratings yet

- BRJ Catalog.Document73 pagesBRJ Catalog.yelmustafaaliNo ratings yet

- Allison Transmission Service Manual PDFDocument326 pagesAllison Transmission Service Manual PDFMitul Patel96% (27)

- NOV - King Cobra SeriesDocument136 pagesNOV - King Cobra Seriesyelmustafaali100% (1)

- B+V Elevator Insert ListDocument1 pageB+V Elevator Insert ListyelmustafaaliNo ratings yet

- Dp600 ScreenDocument1 pageDp600 ScreenyelmustafaaliNo ratings yet

- VSM 300 Elek EnvanterDocument1 pageVSM 300 Elek EnvanteryelmustafaaliNo ratings yet

- Nov Brandt Elek ListeDocument1 pageNov Brandt Elek ListeyelmustafaaliNo ratings yet

- B+V Elevator Insert ListDocument1 pageB+V Elevator Insert ListyelmustafaaliNo ratings yet

- Offshore Cement-Pumping Skid: ApplicationsDocument2 pagesOffshore Cement-Pumping Skid: ApplicationsyelmustafaaliNo ratings yet

- Dp600 ScreenDocument2 pagesDp600 ScreenyelmustafaaliNo ratings yet

- 4'' Hammer Union ListDocument1 page4'' Hammer Union ListyelmustafaaliNo ratings yet

- 4.0 Manual Kelman TransfixDocument31 pages4.0 Manual Kelman Transfixcorreo_hechizo100% (2)

- Mechanism of Bioenergy HealingDocument11 pagesMechanism of Bioenergy HealingHayley As Allegedly-Called YendellNo ratings yet

- NCFPDocument40 pagesNCFPJAY PARIKHNo ratings yet

- Study of 132/33kV GIS Pedawaltair SubstationDocument38 pagesStudy of 132/33kV GIS Pedawaltair SubstationNavya PendurthiNo ratings yet

- Delta-Sks (En)Document2 pagesDelta-Sks (En)maserrasNo ratings yet

- Vetting Inspectors.Document5 pagesVetting Inspectors.Pavel ViktorNo ratings yet

- Gamma Rays: Irawati Nurani Siti Ishmah Tamimi Winda Rismayani Class 11-6Document18 pagesGamma Rays: Irawati Nurani Siti Ishmah Tamimi Winda Rismayani Class 11-6Winda RismayaniNo ratings yet

- Ecs 1ZR PDFDocument17 pagesEcs 1ZR PDFReinaldo Arrivillaga100% (3)

- Thermodynamics 1 - Energy Analysis of Closed SystemsDocument26 pagesThermodynamics 1 - Energy Analysis of Closed SystemsFlorasaurus17100% (2)

- 1015p Io BoardDocument13 pages1015p Io BoardContreras CarlosNo ratings yet

- Documentación Ziel 400w - Wall Washer 150w PDFDocument250 pagesDocumentación Ziel 400w - Wall Washer 150w PDFJonathanTenorio89No ratings yet

- PTW 6.0 EnhancementsDocument36 pagesPTW 6.0 EnhancementsBreno AlmeidaNo ratings yet

- On-Load Tap-Changers For Power Transformers: MR PublicationDocument24 pagesOn-Load Tap-Changers For Power Transformers: MR Publicationcarlos albertoNo ratings yet

- Time Leadership V 2 0Document77 pagesTime Leadership V 2 0zolikelemenNo ratings yet

- Skript QFT2Document271 pagesSkript QFT2Tom GrevenaNo ratings yet

- Cyclone Separator Design and Working PrinciplesDocument22 pagesCyclone Separator Design and Working PrinciplesVANDINI BANSALNo ratings yet

- Module 3 - Fire SafetyDocument5 pagesModule 3 - Fire SafetyvonsonNo ratings yet

- High-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigDocument4 pagesHigh-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigMateusDinizNo ratings yet

- Ams 3125 Bearing Vibration Monitor en 39920Document3 pagesAms 3125 Bearing Vibration Monitor en 39920EyuNo ratings yet

- Master Plumbing Reviewer 2Document24 pagesMaster Plumbing Reviewer 2mcpayodNo ratings yet

- Induced Polarization Survey TechniquesDocument7 pagesInduced Polarization Survey TechniquesJavedkhanaNo ratings yet

- Powerful Mini ExcavatorDocument8 pagesPowerful Mini ExcavatorShailesh Khodke100% (1)

- Phys Chem Chem Phys 2010 12 10365-10372Document8 pagesPhys Chem Chem Phys 2010 12 10365-10372Dulce BaezaNo ratings yet

- ReportDocument54 pagesReportVinayKumar100% (1)

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet

- Riser Diagram PDFDocument1 pageRiser Diagram PDFChristian FloresNo ratings yet

- Diagrama Electrico 966dDocument2 pagesDiagrama Electrico 966dpedro melendez100% (1)

- Single Electron Transistor NanoDocument2 pagesSingle Electron Transistor NanoDerry PermanaNo ratings yet

- De Longhi Heating Radiators Provide Quality, Practicality and Environmental BenefitsDocument16 pagesDe Longhi Heating Radiators Provide Quality, Practicality and Environmental BenefitsVladimirNo ratings yet