Professional Documents

Culture Documents

Attachment For BB Calcultions

Uploaded by

Prashant TrivediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachment For BB Calcultions

Uploaded by

Prashant TrivediCopyright:

Available Formats

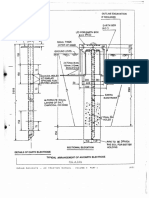

1 ANNEXURE-1 (Table 12 of Copper Developement Association)

PDF created with pdfFactory Pro trial version www.pdffactory.com

PDF created with pdfFactory Pro trial version www.pdffactory.com

Enclosed copper conductors

In many cases busbars are surrounded by enclosures, normally metallic, which

reduce the busbar heat dissipation due to reduction in cooling air flow and

radiation losses and therefore give current ratings which may be considerably

less than those for free air exposure. Ventilated enclosures, however, provide

mechanical protection and some cooling air flow with the least reduction in

current rating.

The reduction in rating for a given temperature rise will vary considerably with the

type and size of bar and enclosure. The greatest decrease in current rating

occurs with bars which depend mainly on free air circulation and less on uniform

current distribution such as the modified hollow square arrangement (Figure 9d).

In these cases the rating may be reduced to between 60 and 65% when the

conductors are enclosed in non-magnetic metal enclosures. In the case of

tubular conductors or those of closely grouped flat laminations, which are

normally not so well cooled by air circulation, the ratings may be reduced to

about 75% of free air ratings for normal temperature rises.

Where the busbar system is enclosed in thick magnetic enclosures, such

as in metal-clad switchgear, the reduction is approximately a further 15%.

The effect of thin sheet-steel enclosures is somewhat less. These additional

reductions are due to the heat generated by the alternating magnetic fields

through hysteresis and eddy current losses. Besides the derating caused by

enclosure conditions, other limitations on maximum working temperature are

often present, such as when the outside of enclosures should not exceed a given

safety value. These deratings are affected by the electrical clearances involved

and the degree of ventilation in the enclosure. The above figures and the curves

shown in Figure 12 should only be taken as a rough guide to the required

derating; an accurate figure can only be obtained by testing.

All parts such as conductor and switch fittings, enclosures and interphase

barriers may be subject to appreciable temperature rise due to circulating and

eddy current losses when close to the heavy current bars and connections.

These losses can be reduced to a minimum by making these parts from high

conductivity non-magnetic material such as copper or copper alloy.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Figure 12 Comparison of approximate current ratings for busbars in different enclosures

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- A-212 Pressure Vessel Steel - A Case Against Continued UseDocument11 pagesA-212 Pressure Vessel Steel - A Case Against Continued Usealexthecrusader7206100% (4)

- (CDA) Pub-22 Copper For BusbarsDocument116 pages(CDA) Pub-22 Copper For Busbarsnooruddinkhan1100% (2)

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing GuideKhaled Eid100% (5)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Copper For BusbarDocument60 pagesCopper For BusbarSunil Gadekar100% (3)

- Copper For BusbarsDocument104 pagesCopper For Busbarst_syamprasadNo ratings yet

- Silo - Tips Avoiding Burning Through Control The Inside Surface Temperature Not The PressureDocument7 pagesSilo - Tips Avoiding Burning Through Control The Inside Surface Temperature Not The PressuremariliaNo ratings yet

- GMAW (CO2) Welding CourseDocument129 pagesGMAW (CO2) Welding Courseanon_554333607No ratings yet

- Copper Busbar Design GuideDocument136 pagesCopper Busbar Design GuideOscar SchmüthNo ratings yet

- Current Calculation For BusbarsDocument41 pagesCurrent Calculation For Busbarsraghuveeranush0% (1)

- Design ConsiderationsDocument5 pagesDesign ConsiderationsKhalith MansoorNo ratings yet

- Design Considerations: Types of Busbar Choice of Busbar MaterialDocument96 pagesDesign Considerations: Types of Busbar Choice of Busbar MaterialNikhilesh BabuNo ratings yet

- Copper For BusbarsDocument104 pagesCopper For BusbarsKhaled Salahul Den100% (1)

- Engineering Considerations for Sour Gas TrapsDocument4 pagesEngineering Considerations for Sour Gas TrapsbloggerparthiNo ratings yet

- DG RoofingDocument12 pagesDG RoofingChung Yiung YungNo ratings yet

- Guidance Note Plate Bending No. 5.04: ScopeDocument3 pagesGuidance Note Plate Bending No. 5.04: ScoperoldoguidoNo ratings yet

- Cooling Coil Design (SI Units)Document3 pagesCooling Coil Design (SI Units)Christopher PersaudNo ratings yet

- Job Knowledge 51Document5 pagesJob Knowledge 51Mehmet SoysalNo ratings yet

- Best Practice Manual-Transformers 11Document1 pageBest Practice Manual-Transformers 11sunny_nsecNo ratings yet

- Selecting Filler MetalsDocument4 pagesSelecting Filler MetalsumeshNo ratings yet

- HTLS and HVDC Solutions For Overhead Lines Uprating: 1. AbstractDocument5 pagesHTLS and HVDC Solutions For Overhead Lines Uprating: 1. Abstractdandanache1970No ratings yet

- Composite Overhead ConductorsDocument21 pagesComposite Overhead ConductorsEnrique Garcia100% (1)

- Littelfuse GDT Catalog PDFDocument60 pagesLittelfuse GDT Catalog PDFMisko PiskoNo ratings yet

- Power Transformers: Electrical Bushings Are Essential Components For A Wide Range of ElectricalDocument6 pagesPower Transformers: Electrical Bushings Are Essential Components For A Wide Range of ElectricalSandeep BNo ratings yet

- Air Core Versus Iron Core ReactorsDocument4 pagesAir Core Versus Iron Core ReactorsBISLA ANONo ratings yet

- 75°c Temperatura Maxima de Diseño para Conductores de AluminioDocument22 pages75°c Temperatura Maxima de Diseño para Conductores de AluminioVICTORMARCENo ratings yet

- A Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesDocument8 pagesA Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesAdibah BiagiNo ratings yet

- Duplex Stainless Steel - Welding-TwiDocument4 pagesDuplex Stainless Steel - Welding-TwiNatrajj SivakumarNo ratings yet

- LNG Applications of Diffusion Bonded HEXDocument9 pagesLNG Applications of Diffusion Bonded HEXrowanlimNo ratings yet

- Agitated Vessel Heat Transfer PDFDocument6 pagesAgitated Vessel Heat Transfer PDFMuthuKumar ArunachalamNo ratings yet

- Packaging SiC Power Semiconductors - Challenges Technologies and StrategiesDocument6 pagesPackaging SiC Power Semiconductors - Challenges Technologies and StrategiesgeniuspsunNo ratings yet

- Bushing Technology Review: Design TendenciesDocument10 pagesBushing Technology Review: Design TendenciesSandeep BNo ratings yet

- Protect electrical devices from lightning with proper groundingDocument13 pagesProtect electrical devices from lightning with proper groundingdigit133No ratings yet

- Iron Core Vs Air CoreDocument5 pagesIron Core Vs Air CorebansalrNo ratings yet

- Flux-Cored Arc Welding: A. Process PrinciplesDocument3 pagesFlux-Cored Arc Welding: A. Process Principlessn200709No ratings yet

- Shipyard Welding ProcessesDocument6 pagesShipyard Welding ProcessesPawan KumarNo ratings yet

- Electroslag Strip Cladding for Hydrogen RefineriesDocument12 pagesElectroslag Strip Cladding for Hydrogen RefineriesSANKET SINGHNo ratings yet

- Transformer EfficiencyDocument12 pagesTransformer EfficiencyhaysomaNo ratings yet

- Chapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design OptimizationDocument17 pagesChapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design OptimizationxiaomiNo ratings yet

- Metal Transfer Modes: Short Circuit Surface TensionDocument3 pagesMetal Transfer Modes: Short Circuit Surface TensionRaman GuptaNo ratings yet

- Material and Energy Efficient Busbar Systems in Zinc and Copper PlantsDocument17 pagesMaterial and Energy Efficient Busbar Systems in Zinc and Copper PlantsAngelito_HBKNo ratings yet

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing Guidecharlie kurzawskiNo ratings yet

- Duplex Stainless Steel Part 1Document2 pagesDuplex Stainless Steel Part 1aviant_gardNo ratings yet

- Energy Station Post Insulator White PaperDocument10 pagesEnergy Station Post Insulator White PaperTravis WoodNo ratings yet

- wj1106 54Document5 pageswj1106 54koner_debasishNo ratings yet

- Expanding Rated Voltage of Dry-Type Transformers Using Grounded Metallic MeshDocument8 pagesExpanding Rated Voltage of Dry-Type Transformers Using Grounded Metallic MeshMahali Nizar SafriNo ratings yet

- Conductor RequirementsDocument8 pagesConductor RequirementsLJ IDANE ARANASNo ratings yet

- Braze WeldingDocument2 pagesBraze Weldingkevin herryNo ratings yet

- IntroDocument3 pagesIntroMUHAMMAD AFIQ IQWAN KAMARUL BADRINNo ratings yet

- High VoltageDocument5 pagesHigh VoltageAnnie ToddNo ratings yet

- Air Circuit BreakerDocument5 pagesAir Circuit BreakerEnglish words BY Utkarsh johriNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryFrom EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryRating: 5 out of 5 stars5/5 (2)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- N0. 5/2 (T/NT) /2020/data Bank/Pers.: Wapcos LimitedDocument1 pageN0. 5/2 (T/NT) /2020/data Bank/Pers.: Wapcos LimitedPrashant TrivediNo ratings yet

- Vibration Damping For Transmission Line ConductorsDocument6 pagesVibration Damping For Transmission Line ConductorsWaqar Ali Sher100% (1)

- Exploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesDocument10 pagesExploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesPrashant TrivediNo ratings yet

- 77 PE 12 10 310-314 BendaoudDocument6 pages77 PE 12 10 310-314 BendaoudPrashant TrivediNo ratings yet

- Understanding Electrical Treeing Phenomena in XLPEDocument8 pagesUnderstanding Electrical Treeing Phenomena in XLPEPrashant TrivediNo ratings yet

- Kim Joong C 1963Document66 pagesKim Joong C 1963karimiNo ratings yet

- Technical Specification For 11Kv DG Set: Rail Coach Factory, Rae BareliDocument38 pagesTechnical Specification For 11Kv DG Set: Rail Coach Factory, Rae BareliPrashant Trivedi0% (1)

- N - Arc Consulting IrconDocument13 pagesN - Arc Consulting IrconPrashant TrivediNo ratings yet

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Document20 pagesProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediNo ratings yet

- L01 Introduction To Deregulation 1Document28 pagesL01 Introduction To Deregulation 1Samarendu BaulNo ratings yet

- Protection Philosophy for 132kV Substation SCADADocument11 pagesProtection Philosophy for 132kV Substation SCADAPrashant TrivediNo ratings yet

- Electrical Power Engineering Reference AmpDocument27 pagesElectrical Power Engineering Reference AmpTony lorenzNo ratings yet

- 10 Insulation Co-OrdinationDocument18 pages10 Insulation Co-Ordinationdaegerte100% (3)

- Technical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliDocument8 pagesTechnical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliPrashant TrivediNo ratings yet

- AL-LIN-50002 - 2009-Oct-27 - Rev3Document25 pagesAL-LIN-50002 - 2009-Oct-27 - Rev3Prashant TrivediNo ratings yet

- AL-LIN-10013 - InsulatorDocument7 pagesAL-LIN-10013 - InsulatorPrashant TrivediNo ratings yet

- Pipe Earthing DRG - ACTM Rly0001Document1 pagePipe Earthing DRG - ACTM Rly0001Prashant TrivediNo ratings yet

- 50V Battery, Battery Charger and DCDBDocument14 pages50V Battery, Battery Charger and DCDBPrashant TrivediNo ratings yet

- Ep 21 00 00 01 SPDocument13 pagesEp 21 00 00 01 SPPrashant TrivediNo ratings yet

- Specification of LT Capcitor PannelDocument12 pagesSpecification of LT Capcitor PannelPrashant TrivediNo ratings yet

- Dereg PDFDocument7 pagesDereg PDFninja_1234No ratings yet

- 1rDocument11 pages1rPrashant TrivediNo ratings yet

- Re P Ub L I C o F Bul G Ar I A: EDI CT OF GovernmentDocument66 pagesRe P Ub L I C o F Bul G Ar I A: EDI CT OF Governmentrrrrmmmm1No ratings yet

- Power Control CableDocument15 pagesPower Control Cablebhargavram1987No ratings yet

- C 10: D D D S: "What Gets Measured Gets Managed."Document16 pagesC 10: D D D S: "What Gets Measured Gets Managed."Prashant TrivediNo ratings yet

- Technical Specification for LT AC Distribution BoardDocument41 pagesTechnical Specification for LT AC Distribution BoardPrashant TrivediNo ratings yet

- Current Transformers: For Worldwide CooperationDocument40 pagesCurrent Transformers: For Worldwide CooperationPrashant TrivediNo ratings yet

- Joints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsDocument14 pagesJoints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsPrashant TrivediNo ratings yet

- Calculation for busbar & conductor sizing in 400/132 kV switchyardDocument4 pagesCalculation for busbar & conductor sizing in 400/132 kV switchyardPrashant TrivediNo ratings yet

- Bed Material Dan Heat TransferDocument44 pagesBed Material Dan Heat Transfer07putra07No ratings yet

- KTM50S1 50Hz SS304 MergedDocument7 pagesKTM50S1 50Hz SS304 MergedEdbaac BANo ratings yet

- Protein FoldingDocument9 pagesProtein FoldingAyush ZalaNo ratings yet

- Open Channel FlowDocument34 pagesOpen Channel Flowjss_devNo ratings yet

- Prob Set QMDocument31 pagesProb Set QMStephanie Palomares LevitaNo ratings yet

- Efficiency SFR 2003Document10 pagesEfficiency SFR 2003Kemal Tuşat YücelNo ratings yet

- Data AirDocument68 pagesData AirJohn Jairo Paez MesaNo ratings yet

- What Is Cationic Bitumen Emulsion?Document2 pagesWhat Is Cationic Bitumen Emulsion?zaheer0406No ratings yet

- Material Case StudyDocument8 pagesMaterial Case StudyI'NhonqMinnie100% (1)

- Kia Sensor and Actuator TrainingDocument6 pagesKia Sensor and Actuator Trainingrobert100% (49)

- In Situ Measurement of Masonry Mortar Joint Shear Strength IndexDocument7 pagesIn Situ Measurement of Masonry Mortar Joint Shear Strength Indexjuli_rad0% (1)

- Week 3 SID OID 122Document16 pagesWeek 3 SID OID 122tranlehuyNo ratings yet

- F 2162 - 01 - RjixnjitmdffmqDocument4 pagesF 2162 - 01 - RjixnjitmdffmqSTAFFORDNo ratings yet

- Corrosion in PulpDocument11 pagesCorrosion in PulpSatyam MadameNo ratings yet

- Din 69002Document3 pagesDin 69002Dule JovanovicNo ratings yet

- Electrowinning and Electrorefining of Copper (Murdoch University)Document76 pagesElectrowinning and Electrorefining of Copper (Murdoch University)Victor100% (8)

- 2.6 Scavengers O2 H2S Bruce Adams PDFDocument67 pages2.6 Scavengers O2 H2S Bruce Adams PDFJoel Siegel100% (1)

- Theory of Magnetism, Magnetic Effect of Current For Iit PMTDocument10 pagesTheory of Magnetism, Magnetic Effect of Current For Iit PMTumved singh yadavNo ratings yet

- Centrifugal Chiller 2stageDocument17 pagesCentrifugal Chiller 2stageDoan ThanhBinhNo ratings yet

- 1 Lab Handout PDFDocument5 pages1 Lab Handout PDFKhud SarNo ratings yet

- Mechanical Engineering Stress Analysis VisualizedDocument7 pagesMechanical Engineering Stress Analysis VisualizedHamood Al-bahraniNo ratings yet

- Rotary Heat ExchangersDocument32 pagesRotary Heat Exchangerspal_stephenNo ratings yet

- En 1442 - LPGDocument9 pagesEn 1442 - LPGPrabhanshu TripathiNo ratings yet

- 1 Multi-Phase Flow Analysis in Oil and Gas Engineering Systems and Its Model PDFDocument5 pages1 Multi-Phase Flow Analysis in Oil and Gas Engineering Systems and Its Model PDFWesam Al shoumariNo ratings yet

- 28Document24 pages28Rogelio Arellano LawayanNo ratings yet

- 9702 w11 QP 43Document24 pages9702 w11 QP 43Hubbak KhanNo ratings yet

- Evs Project Topic (Global Warming) Project WorkDocument16 pagesEvs Project Topic (Global Warming) Project WorkTanmayNo ratings yet

- CHEM LAB 1108 CHAPTER 1. Basic Lab TechniquesDocument6 pagesCHEM LAB 1108 CHAPTER 1. Basic Lab Techniquesiyaoleyaali61No ratings yet

- DDBD Priestley-Calvi-y-KowalskyDocument733 pagesDDBD Priestley-Calvi-y-KowalskyEvelyn DomínguezNo ratings yet

- M Alkalinity and P AlkalinityDocument4 pagesM Alkalinity and P AlkalinityiastraNo ratings yet