Professional Documents

Culture Documents

Datasheet PDF

Datasheet PDF

Uploaded by

Mohammed sabatinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet PDF

Datasheet PDF

Uploaded by

Mohammed sabatinCopyright:

Available Formats

Data sheet

valid from: 10/1/19

WR 200 / WR 200 S

Welding Recorder for manually operated butt fusion machines (ECOS, TOP, GF)

The WR 200 / WR 200 S assists the welder to ensure the quality of the butt-fusion jointing accord-

ing to country specific standards. The user is guided through all preparation and fusion steps. The

selection of the fusion data like the used material, welding standard, diameter and wall thickness

(SDR) is supported by a menu. The complete fusion sequence is supervised and recorded. The

welding protocols can be easily exported via USB stick to any personal computer for further man-

agement or printout. The welding protocols can be directly printed out at jobsite by means of the

on-board printer (WR 200 only). The recorder is protected by a robust plastic case of IP 65 protec-

tion class. The power and connecting cables are stored in a separate box (WR 200) or in a com-

partment directly integrated in the case (WR 200 S). The WR 200 can be connected to hydraulical-

ly operated butt-fusion machines for construction site, even by later retrofitting of machines in

service centres. The WR 200 S ECO version is also available, to specifically work in combination

with ECO S machine models.

Description:

• Intuitive user guidance menu

• Welding standard selection e.g. DVS, UNI, WIS, ISO

• Welding process customisable: 4 user-defined cycles available

• Additional data input as: operator-ID, job and order number, joint number, GPS coordinates

from an independent device

• On-board printer for direct print pout of welding protocols at jobsite (WR 200 only)

• USB interface for welding protocols transfer

• Internal memory capacity: 250 protocols

• Selection of operator language

• Battery support for an autonomy of 10 hours (no data loss during power interruption)

• “Rent Guardian” function to set and control the rental period of the unit

• Available protocols format: TXT for easy printout, CSV for database management with Welding

Book application

• Fully compatible with butt-fusion machines already working with former welding recorder

models SUVI® 50 and WR 100

• Working temperature range: -10°C to +50°C

Type Performance Dimensions Code Weight

(kg)

WR 200 S - ECO 230 V 350x300x250 mm 790 119 452 5.000

WR 200 S 230 V 350x300x250 mm 790 119 451 5.000

WR 200 230 V 350x300x250 mm 790 119 401 5.000

WR 200 S - ECO CYRILLIC 230 V 350x300x250 mm 790 119 455 5.000

WR 200 S CYRILLIC 230 V 350x300x250 mm 790 119 454 5.000

WR 200 CYRILLIC 230 V 350x300x250 mm 790 119 425 5.500

The technical data are not binding. They neither constitute expressly warranted characteristics nor guaranteed properties nor a guar-

anteed durability. They are subject to modification. Our General Terms of Sale apply.

Georg Fischer Piping Systems Ltd, Postfach, CH-8201 Schaffhausen/Switzerland

Phone +41 -(0)52-631 1111

e-mail: info.ps@georgfischer.com

Internet: http://www.gfps.com

Page 1 of 1

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ansi b56 1 1969Document65 pagesAnsi b56 1 1969Rethfo A Riquelme Castillo100% (1)

- Is 1077 Common Burnt Clay Building BricksDocument7 pagesIs 1077 Common Burnt Clay Building BricksKathiravan ManimegalaiNo ratings yet

- Test Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDocument24 pagesTest Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDavidLarsonDDSfgaq100% (43)

- 547 PDFDocument389 pages547 PDFMohammed sabatinNo ratings yet

- Pathology of The Bile Duct 2017 - Yasuni Nakanuma PDFDocument215 pagesPathology of The Bile Duct 2017 - Yasuni Nakanuma PDFHîrjoabă IoanNo ratings yet

- Brief On Companies Act 2017Document26 pagesBrief On Companies Act 2017Abdul Muneem100% (1)

- 3723 Modernizing HR at Microsoft BCSDocument14 pages3723 Modernizing HR at Microsoft BCSYaseen SaleemNo ratings yet

- MCHW Vol 1 Series 500 Web PDFDocument41 pagesMCHW Vol 1 Series 500 Web PDFMohammed sabatinNo ratings yet

- Unit Plan English 9.4.2-DramaDocument5 pagesUnit Plan English 9.4.2-DramaMa.robelleF. Papa0% (1)

- Comparative Grammar in Five Romance Languages:: Elements ofDocument146 pagesComparative Grammar in Five Romance Languages:: Elements offcjuvencNo ratings yet

- Forex Pair Performance Strength ScoreDocument10 pagesForex Pair Performance Strength ScoreTradingSystem100% (1)

- Large Capacity Oil InterceptorDocument1 pageLarge Capacity Oil InterceptorMohammed sabatinNo ratings yet

- 63mm PE100 SDR11 PN16 ML 20.01.2020 DN - 33504274Document1 page63mm PE100 SDR11 PN16 ML 20.01.2020 DN - 33504274Mohammed sabatinNo ratings yet

- Data Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFDocument2 pagesData Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFMohammed sabatinNo ratings yet

- WeldingDocument80 pagesWeldingMohammed sabatinNo ratings yet

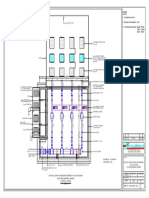

- Multiple Meter Cabinet DetailsDocument1 pageMultiple Meter Cabinet DetailsMohammed sabatinNo ratings yet

- Terracotta Price List TE101 March 1st 2019 Rev1Document22 pagesTerracotta Price List TE101 March 1st 2019 Rev1Mohammed sabatinNo ratings yet

- PVC Schedule 80 Catalogue NEWDocument32 pagesPVC Schedule 80 Catalogue NEWMohammed sabatinNo ratings yet

- Electrofusion Elbow 45° For Gas - SDR11 (ISO S5)Document1 pageElectrofusion Elbow 45° For Gas - SDR11 (ISO S5)Mohammed sabatinNo ratings yet

- Below Ground & Civils Systems: Trade Price ListDocument67 pagesBelow Ground & Civils Systems: Trade Price ListMohammed sabatinNo ratings yet

- Ashghal Training Provider Pre-Qualification FormDocument12 pagesAshghal Training Provider Pre-Qualification FormMohammed sabatinNo ratings yet

- Fusion Technology PDFDocument58 pagesFusion Technology PDFMohammed sabatinNo ratings yet

- 6469 4 Sun-Protection DigitalDocument2 pages6469 4 Sun-Protection DigitalMohammed sabatinNo ratings yet

- Gfps System Specification PVC C Metric en PDFDocument24 pagesGfps System Specification PVC C Metric en PDFMohammed sabatinNo ratings yet

- BS en 1555-3 (2008) PDFDocument29 pagesBS en 1555-3 (2008) PDFMohammed sabatinNo ratings yet

- GF ELGEF Plus Modularni Sistem ENGDocument20 pagesGF ELGEF Plus Modularni Sistem ENGMohammed sabatinNo ratings yet

- Gfps 9200 Brochure CNC Automated Butt Fusion Machine Line enDocument8 pagesGfps 9200 Brochure CNC Automated Butt Fusion Machine Line enMohammed sabatinNo ratings yet

- Qcs 2014 Air Test For Gravity LinesDocument1 pageQcs 2014 Air Test For Gravity LinesMohammed sabatinNo ratings yet

- Iso 13480 (1997) PDFDocument11 pagesIso 13480 (1997) PDFMohammed sabatinNo ratings yet

- Clay Specification BrochureDocument8 pagesClay Specification BrochureMohammed sabatinNo ratings yet

- FINALE GFDO 6202 4b Allgemein iJOINTDocument6 pagesFINALE GFDO 6202 4b Allgemein iJOINTMohammed sabatinNo ratings yet

- Taxable Income and Tax DueDocument13 pagesTaxable Income and Tax DueSheena Gane Esteves100% (1)

- MODULE 2 Analyzing Business TransactionsDocument18 pagesMODULE 2 Analyzing Business TransactionsKirk EscanillaNo ratings yet

- Biofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The FutureDocument5 pagesBiofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The FutureMichael LeirvagNo ratings yet

- Dr. Prajeesh Nath E N PG Dept. of Rasasastra & Bhaishajya Kalpana Amrita School of AyurvedaDocument38 pagesDr. Prajeesh Nath E N PG Dept. of Rasasastra & Bhaishajya Kalpana Amrita School of Ayurvedaj186No ratings yet

- Handbook3 VitaminA-1 PDFDocument5 pagesHandbook3 VitaminA-1 PDFJorge Luis RodríguezNo ratings yet

- DigMandarin Grammar Lesson Comparison Sentence With Bi - 1 PDFDocument4 pagesDigMandarin Grammar Lesson Comparison Sentence With Bi - 1 PDFValentina BeltránNo ratings yet

- Criminology The Essentials 3rd Edition Walsh Test Bank DownloadDocument35 pagesCriminology The Essentials 3rd Edition Walsh Test Bank DownloadJohn Adamson100% (26)

- NetcraftDocument9 pagesNetcraftapi-238604507No ratings yet

- Networking Newsletter Green VariantDocument38 pagesNetworking Newsletter Green VariantEvlyn PasaribuNo ratings yet

- Vendor Registration DetailsDocument3 pagesVendor Registration DetailsSaroj KumarNo ratings yet

- Problems On Hypothesis TestingDocument2 pagesProblems On Hypothesis TestingFarzana AlamgirNo ratings yet

- Review QuestionsDocument5 pagesReview QuestionsAR EddingNo ratings yet

- Conceptual Framework Kel 1Document9 pagesConceptual Framework Kel 1reniwahyuni711No ratings yet

- Vista Safire e IV LHDDocument504 pagesVista Safire e IV LHDSesar Sehat SantosoNo ratings yet

- Factors Affecting Managerial DecisionDocument2 pagesFactors Affecting Managerial DecisionJao MatiasNo ratings yet

- Sustainable DevelopmentDocument3 pagesSustainable DevelopmentAlabi OlawaleNo ratings yet

- Cerruti RegisDocument18 pagesCerruti RegisNick MarkNo ratings yet

- B105 - TRANSCRIPT - BU I 8 - Dang Do Tuan KietDocument4 pagesB105 - TRANSCRIPT - BU I 8 - Dang Do Tuan Kietten dang dangNo ratings yet

- GS2595 Waukesha 16v275gl GeneratorSet BrochureDocument2 pagesGS2595 Waukesha 16v275gl GeneratorSet BrochureMishal SalemNo ratings yet

- Exfoliative Cytology PDFDocument2 pagesExfoliative Cytology PDFStaceyNo ratings yet

- DAX Functions For ReferenceDocument8 pagesDAX Functions For ReferenceDeovratNo ratings yet