Professional Documents

Culture Documents

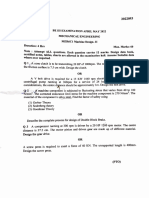

P.S.V College of Engineering and Technology

Uploaded by

Suresh NatarajanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P.S.V College of Engineering and Technology

Uploaded by

Suresh NatarajanCopyright:

Available Formats

P.S.

V COLLEGE OF ENGINEERING AND TECHNOLOGY

DEPARTMENT OF MECHANICAL ENGINEERING

THIRD YEAR/SIXTH SEMESTER- SECTION-A

DESIGN OF TRANSMISSION SYSTEMS Date: 19-2-2019

PART-A

1. A longer belt will last more than a shorter belt, why?

2. Brief the term “Crowning of Pulley”?

3. How is V belt specified?

4. Give the speed ratio range of worm-wheel drive.

5. Usually worm is made of hard material and worm gear is made of softer material-justify.

6. What are preferred numbers?

7. Define geometric progression.

8. What is meant by positive clutch?

9. Why it is necessary to dissipate the heat generated during clutch operation

10. What are the factors upon which the torque capacity of a clutch depends?

PART-A

11. A hardened steel worm rotates at 1440 rpm and transmits 12 k W to a phosphor bronze

gear. The speed of the worm wheel should be 60 rpm. Design a worm gear drive if an

efficiency of at least 82% is desired.

12. Design a V-belt drive to the following specifications: power to be transmitted: 75Kw;

speed of driving Wheel: 1440 rpm; speed of driven wheel: 400 rpm; diameter of driving

wheel: 300 mm: centre distance: 2500mm: service: 16 hours/day.

13. It is required to select a flat belt drive for a fan running at 360rpm.which is driven by a

10kw, 1440rpm motor. The belt drive is open type and space available for a center

distance of 2m approximately. The diameter of a driven pulley is 1000mm.

14. A nine speed gear box, used as a head stock gear box of a turret lathe, is to provide a

speed range of 180 rpm to 1800 rpm. Using step ratio, draw the speed diagram and the

kinematic layout. Also find and fix the number of teeth on all gears.

15. A single plate clutch transmits 25 kW at 900 rpm. The max. Pressure intensity between

the plates is 85 kN/m2. The ratio of radii is 1.25. Both the sides of the plate are effective

and the coefficient of friction is .25. Determine (i) the dia of the plate (ii) the axial force

to engage the clutch. Assuming the uniform wear theory.

PART-C

16. Design a 12 speed gear box for a lathe. The minimum and maximum speeds are 100 and

1200 rpm. Power is 5 k W from 1440 rpm induction motor.

Staff-In charge HoD Principal

You might also like

- Sec5a4 Abs AsrDocument94 pagesSec5a4 Abs AsrNguyễn Hữu Hà88% (8)

- Detroit™ Transmissions Electronic Application and Installation ManualDocument80 pagesDetroit™ Transmissions Electronic Application and Installation ManualSonder B50% (2)

- Xv1700 2008-2012 Service Repair ManualDocument413 pagesXv1700 2008-2012 Service Repair ManualIgor LukNo ratings yet

- WS Class 3 PDFDocument61 pagesWS Class 3 PDFumdb2205100% (1)

- WS Class 3 PDFDocument61 pagesWS Class 3 PDFumdb2205100% (1)

- Form-093-Dump Truck Safety ChecklistDocument2 pagesForm-093-Dump Truck Safety Checklistshamroz khan100% (2)

- Dgca Module 1302 Feb 2018Document6 pagesDgca Module 1302 Feb 2018momenNo ratings yet

- Mech 325 Tutorials (Questions Only)Document54 pagesMech 325 Tutorials (Questions Only)Shahriar Norouzi ZadehNo ratings yet

- Honda engine bushings and mountings catalogDocument30 pagesHonda engine bushings and mountings catalogПавел Скорец100% (1)

- Sustainable Agricultural Practices HandbookDocument101 pagesSustainable Agricultural Practices Handbookperma_y100% (2)

- Part 14 Lifting, Moving and JackingDocument7 pagesPart 14 Lifting, Moving and JackingYiannis GregoriouNo ratings yet

- T120Document35 pagesT120이세형No ratings yet

- Design of Transmission ElementDocument42 pagesDesign of Transmission ElementVenkatesh MohanNo ratings yet

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniNo ratings yet

- ME6601 Transmission Design QuestionsDocument11 pagesME6601 Transmission Design QuestionsMURUGANNo ratings yet

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Document3 pagesJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixNo ratings yet

- Design of Transmission System Question BankDocument18 pagesDesign of Transmission System Question BankAravind50% (2)

- Me-1352 Design of Transmission SystemDocument7 pagesMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Belt Types and Wire Rope ApplicationsDocument14 pagesBelt Types and Wire Rope ApplicationsmechfameNo ratings yet

- DtsDocument11 pagesDtsSridiwakaran ParameswaranNo ratings yet

- Design of Transmission SystemsDocument6 pagesDesign of Transmission SystemsSelva KumarNo ratings yet

- Me 1352Document6 pagesMe 1352arunramakrishnanNo ratings yet

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganNo ratings yet

- Dts Model Que Type B 2018-19Document2 pagesDts Model Que Type B 2018-19rammit2007No ratings yet

- DMD PDFDocument14 pagesDMD PDFAstik ThombareNo ratings yet

- Design of Transmission Systems Question BankDocument10 pagesDesign of Transmission Systems Question BankDesejo SozinandoNo ratings yet

- ME2352-DTS Question BankDocument8 pagesME2352-DTS Question BankNaresh015No ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- DTS QBDocument19 pagesDTS QBHem KumarNo ratings yet

- 2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesDocument2 pages2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesKunal MohurleNo ratings yet

- Design of Transmission System-QbDocument5 pagesDesign of Transmission System-QbGanapathi SekaranNo ratings yet

- Design of Transmission Systems - Important QuestonsDocument5 pagesDesign of Transmission Systems - Important QuestonsPost BoxNo ratings yet

- Me 2352 - DTS Q BankDocument5 pagesMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- Design of Transmission Systems examDocument3 pagesDesign of Transmission Systems examCyril JasonNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- ACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDocument3 pagesACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDept of MechanicalNo ratings yet

- Dts Important Ques 2 16 MarksDocument5 pagesDts Important Ques 2 16 MarksBas RamuNo ratings yet

- Machine Design IIDocument8 pagesMachine Design IIShashi Bhushan PatelNo ratings yet

- ME6601 QbsdfwsdfsDocument8 pagesME6601 QbsdfwsdfsvivekzzNo ratings yet

- Me 8651Document10 pagesMe 8651selvam cNo ratings yet

- MD2 end sem papersDocument7 pagesMD2 end sem papers21bmc025No ratings yet

- Design of Transmission System - 2 Marks - All 5 UnitsDocument20 pagesDesign of Transmission System - 2 Marks - All 5 UnitsMohan Prasad.M80% (15)

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- Design of Machine Elements-II Exam QuestionsDocument9 pagesDesign of Machine Elements-II Exam QuestionsPrasinNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- ME6601.16 MarksDocument6 pagesME6601.16 Markssathiskumar411No ratings yet

- DTS Question BankDocument21 pagesDTS Question BankSam TirshathNo ratings yet

- Iat-I QPDocument2 pagesIat-I QPBalaChandarNo ratings yet

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- 7 Dts Question Bank-1Document22 pages7 Dts Question Bank-1Placements DhaanishNo ratings yet

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411No ratings yet

- 3 Mech Me8594 Dom QBDocument29 pages3 Mech Me8594 Dom QBSurya SNo ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- DTS 2Document2 pagesDTS 2Soundaryan PraveenNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- DTSDocument7 pagesDTSmithundme659No ratings yet

- Design of Machine Elements - II: Assignment 5Document2 pagesDesign of Machine Elements - II: Assignment 5Abhishek KulkarniNo ratings yet

- Design of Mechanical Drives w17Document4 pagesDesign of Mechanical Drives w17aniket ingle100% (1)

- Apollo Institute Gear Design Cycle TestDocument3 pagesApollo Institute Gear Design Cycle TestRamar Madasamy100% (1)

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Machine Design-IIDocument2 pagesMachine Design-IIPrathamesh MhatreNo ratings yet

- Some Possible QuestionsDocument1 pageSome Possible QuestionsMANIKANDAN S (PA2011002040064)No ratings yet

- VedicReport1 5 201810 26 53PMDocument54 pagesVedicReport1 5 201810 26 53PMSuresh NatarajanNo ratings yet

- Jog Falls: A Pervasive Healthcare Platform For Diabetes ManagementDocument19 pagesJog Falls: A Pervasive Healthcare Platform For Diabetes ManagementSuresh NatarajanNo ratings yet

- Slip - BeltsDocument1 pageSlip - BeltsSuresh NatarajanNo ratings yet

- Dynamics and Pattern of A Managed ConiferousDocument14 pagesDynamics and Pattern of A Managed ConiferousSuresh NatarajanNo ratings yet

- Sacred Heart College Self Study Report for AccreditationDocument122 pagesSacred Heart College Self Study Report for AccreditationSuresh NatarajanNo ratings yet

- Cell PhoneDocument15 pagesCell PhoneSuresh NatarajanNo ratings yet

- Wetlands: Ecosystem Services and ThreatsDocument8 pagesWetlands: Ecosystem Services and ThreatsSuresh NatarajanNo ratings yet

- SurfacesMEG09 PDFDocument17 pagesSurfacesMEG09 PDFSuresh NatarajanNo ratings yet

- Hidden Surface RemovalDocument2 pagesHidden Surface RemovalSuresh NatarajanNo ratings yet

- Great EscapDocument21 pagesGreat EscapSuresh NatarajanNo ratings yet

- ME6403 EngineeringMaterialsandMetallurgyquestionbankDocument10 pagesME6403 EngineeringMaterialsandMetallurgyquestionbankSuresh NatarajanNo ratings yet

- Nadep MethodDocument8 pagesNadep MethodSandeep_AjmireNo ratings yet

- Slip - BeltsDocument1 pageSlip - BeltsSuresh NatarajanNo ratings yet

- Freedom FightersDocument48 pagesFreedom FightersSuresh NatarajanNo ratings yet

- Tree Planting On Private LandsDocument19 pagesTree Planting On Private LandsSuresh NatarajanNo ratings yet

- Coordinate Systems: MW MW MW MW MWDocument4 pagesCoordinate Systems: MW MW MW MW MWSuresh NatarajanNo ratings yet

- Page 39 SageDocument1 pagePage 39 SageSuresh NatarajanNo ratings yet

- How To Predict Certain Matter in KP PDFDocument20 pagesHow To Predict Certain Matter in KP PDFgunjaanthakurNo ratings yet

- VedicReport5 9 20187 10 48PMDocument5 pagesVedicReport5 9 20187 10 48PMSuresh NatarajanNo ratings yet

- Number 1Document1 pageNumber 1Suresh NatarajanNo ratings yet

- 782 2360 1 PBDocument4 pages782 2360 1 PBSuresh NatarajanNo ratings yet

- Foliar SpraysDocument10 pagesFoliar SpraysdevzNo ratings yet

- Me6403 Emm Rejinpaul April May 2015Document2 pagesMe6403 Emm Rejinpaul April May 2015Suresh NatarajanNo ratings yet

- RameshDocument1 pageRameshSuresh NatarajanNo ratings yet

- JASA 1st Anniversary Issue 2012 PDFDocument103 pagesJASA 1st Anniversary Issue 2012 PDFSuresh NatarajanNo ratings yet

- ME6412 Thermal Engineering Lab IDocument65 pagesME6412 Thermal Engineering Lab IHimanshu ChaudhariNo ratings yet

- Wepp bttl74Document2 pagesWepp bttl74Azre mohd norNo ratings yet

- Deutz Fahr Agrotron TTV 1130 1145 1160 Workshop ManualDocument20 pagesDeutz Fahr Agrotron TTV 1130 1145 1160 Workshop Manualamy100% (30)

- SRM Motors Pvt. Ltd. Goldrush Sales & Services Ltd Ledger AccountDocument16 pagesSRM Motors Pvt. Ltd. Goldrush Sales & Services Ltd Ledger AccountAYUSH PRADHANNo ratings yet

- Wa200-8 Venss06304 1904 PDFDocument24 pagesWa200-8 Venss06304 1904 PDFOktiano BudiNo ratings yet

- Fluid Coupling CKDMDocument32 pagesFluid Coupling CKDMCookiezi 's Stream HighlightsNo ratings yet

- Defence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Document2 pagesDefence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Aamir ArainNo ratings yet

- The 2017 A4 Electronic and Electrical Systems: Eself Study Program 970563Document66 pagesThe 2017 A4 Electronic and Electrical Systems: Eself Study Program 970563Mohd AliNo ratings yet

- JFE H1e-001 PDFDocument24 pagesJFE H1e-001 PDFMohsin Ul Amin KhanNo ratings yet

- Fikret Yu Ksel 2004Document11 pagesFikret Yu Ksel 2004Tito Adi SuryantoNo ratings yet

- CVT FWD (Electronic Control) : Revision 12/2011Document4 pagesCVT FWD (Electronic Control) : Revision 12/2011Haji RashidNo ratings yet

- SE370LC英文Document2 pagesSE370LC英文Karl KarlNo ratings yet

- Commander 510 Parts Manual Issue 01EGDocument81 pagesCommander 510 Parts Manual Issue 01EGAlberto LopezNo ratings yet

- Engine Oil Cooler - Install - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Document4 pagesEngine Oil Cooler - Install - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- NZ Hitachi Inverter Wall Splits AC 0417 PDFDocument13 pagesNZ Hitachi Inverter Wall Splits AC 0417 PDFbudimir2310No ratings yet

- TFT LCD 2.0inch Ili9225 SMD SchematicDocument1 pageTFT LCD 2.0inch Ili9225 SMD SchematicEmanuel ValenciaNo ratings yet

- MOTOR Selectline 1-FusionadoDocument16 pagesMOTOR Selectline 1-FusionadoHerrera Balam EdwinNo ratings yet

- MM - Harley Davidson CaseDocument2 pagesMM - Harley Davidson CaseHoneyNo ratings yet

- VCDS Log Identifies Faults in Audi A4 SystemsDocument5 pagesVCDS Log Identifies Faults in Audi A4 SystemsIlenuca SacalasNo ratings yet

- 850 T5 Press Kit 1993Document18 pages850 T5 Press Kit 1993Rodrigo FischNo ratings yet

- EPL152 Operation ManualDocument56 pagesEPL152 Operation ManualXULFATONo ratings yet

- .CAD Modeling and FEA Analysis of Wheel Rim For Weight ReductionDocument8 pages.CAD Modeling and FEA Analysis of Wheel Rim For Weight ReductionEnijad ArnautNo ratings yet

- Pricelist Dacia DusterDocument5 pagesPricelist Dacia Dusterbon bonjataNo ratings yet