Professional Documents

Culture Documents

Mn/DOT Blending Chart: Determine RAP % for Target PG Grade

Uploaded by

Rafael EstradaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mn/DOT Blending Chart: Determine RAP % for Target PG Grade

Uploaded by

Rafael EstradaCopyright:

Available Formats

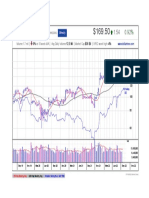

Mn/DOT Blending Chart

Procedure to determine allowable % RAP to reach target PG Grade

with virgin asphalt binder used as softening agent.

1. Determine PG Grade (not verify) virgin asphalt binder to be used for softening agent.

One Failing and One Passing test must be conducted for RTFO DSR , PAV DSR and BBR.

2. RAP asphalt binder is recovered and PG graded. See 1. Recovery preferably done

by rotovap method. Virgin binder PG temp are plotted at 0%RAP and RAP

PG temp is plotted as 100% RAP.

3. Draw line using RAP & RTFO PG grade temp for high temp line. Draw line

using RAP & Virgin PAV BBR PG grade temp for low temp line. Draw a line

using RAP & Virgin PAV DSR PG grade temp for intermediate temp line.

4. Estimated allowable % RAP is determined where the high, intermediate and low temp

blending chart lines cross target PG high and low values. For example using 58-28 as at

target PG. Lines are drawn at 58 & -28 to detemine max RAP allowed.

The example shows about 20% RAP used with PG 52-34 would give a PG 58-28

0 52 -34

100 80 -11

Example of Blending Chart based on PG

Temperatures of RAP & Virgin Asphalt

Binder

100

Temperature for Aged Binder

80

PG Criteria Satisfied

60 58

(degrees C)

40

20

0

-20 0 50 100

-28

-40

20 % RAP

G*/Sin delta BBR M value or S

You might also like

- Sensitivity Plot for Tire PressureDocument3 pagesSensitivity Plot for Tire PressureSameer ShashwatNo ratings yet

- Table 1 - Pressure Ratings For Internal Threaded End orDocument1 pageTable 1 - Pressure Ratings For Internal Threaded End orAbdul Rafiq SoudagarNo ratings yet

- Acidic Additives - Proton Conductivity on PBI Membranes - Escorihuela2020_SupplDocument3 pagesAcidic Additives - Proton Conductivity on PBI Membranes - Escorihuela2020_SupplSureshBharadwajNo ratings yet

- Hydraulic Control, Pilot Pressure Dependent: D CharacteristicsDocument1 pageHydraulic Control, Pilot Pressure Dependent: D CharacteristicsgnowasNo ratings yet

- Baumgardner - Industry PerspectiveDocument40 pagesBaumgardner - Industry PerspectiveAPE MKTNo ratings yet

- 5-Fluids PhaseDiagrams PDFDocument21 pages5-Fluids PhaseDiagrams PDFwalidNo ratings yet

- How To Measure GSHP Efficiency For Forced Air UnitsDocument8 pagesHow To Measure GSHP Efficiency For Forced Air UnitsPamela De Melo-LangfordNo ratings yet

- Asphalt Mixtures Produced With 100 ReclaDocument6 pagesAsphalt Mixtures Produced With 100 ReclaMILON KUMAR HORENo ratings yet

- Gradation Test (C - A) : Qap/HwDocument1 pageGradation Test (C - A) : Qap/HwIEGDR MaharashtraNo ratings yet

- Standard Spreader Pipe For Use With Ac25C End Eye Caps (Ac22P)Document2 pagesStandard Spreader Pipe For Use With Ac25C End Eye Caps (Ac22P)Gonzalo De Jesús Márquez Jr.No ratings yet

- Fan With Available Pressure (Option 10) : ExampleDocument1 pageFan With Available Pressure (Option 10) : ExampleRoger AklNo ratings yet

- Regulators Edge 3 Series Regulators: Slam™Document1 pageRegulators Edge 3 Series Regulators: Slam™Dries VandezandeNo ratings yet

- Radiation Pattern Envelope MA 0245 - 16A: (Azimuth Diagram.)Document1 pageRadiation Pattern Envelope MA 0245 - 16A: (Azimuth Diagram.)Carlos León PalominoNo ratings yet

- Derivatives CIA 3 - Christ UniversityDocument10 pagesDerivatives CIA 3 - Christ UniversityRNo ratings yet

- Road To MaterialsDocument10 pagesRoad To MaterialsWajhi Ul HassanNo ratings yet

- Section View B B Scale: 1:1Document1 pageSection View B B Scale: 1:1kmeisubbuNo ratings yet

- VU Score-Sheet GPA CalculatorDocument2 pagesVU Score-Sheet GPA CalculatorNajam Us SaqibNo ratings yet

- ExtractPage23 24B PDFDocument4 pagesExtractPage23 24B PDFDries VandezandeNo ratings yet

- MGFS45V2527ADocument3 pagesMGFS45V2527AewnatalNo ratings yet

- VISOR DE NIVEL Stauff - Level - Gauge - Type - SNADocument2 pagesVISOR DE NIVEL Stauff - Level - Gauge - Type - SNAMarcelo Godinho BatistaNo ratings yet

- Technical Data: Heat Dissipation - PWO K5Document4 pagesTechnical Data: Heat Dissipation - PWO K5amin nozariNo ratings yet

- Case Studies, Optimizations and Trials For PSDDocument5 pagesCase Studies, Optimizations and Trials For PSDIbrahim Nick DibalNo ratings yet

- Sc1-380a, 170608Document1 pageSc1-380a, 170608fonpereiraNo ratings yet

- ESAB ExtractPage25-26cDocument8 pagesESAB ExtractPage25-26cDries VandezandeNo ratings yet

- r48 500 Rectifier Data SheetDocument2 pagesr48 500 Rectifier Data SheetDendy PurnamaNo ratings yet

- Elecmit Cam Switch - p.132-138Document7 pagesElecmit Cam Switch - p.132-138Sara BatresNo ratings yet

- Thermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilDocument4 pagesThermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilIoana StanciuNo ratings yet

- Rosa de ManiobrasDocument2 pagesRosa de ManiobrasCuevas Sánchez MarielNo ratings yet

- Installing Vapor Recovery Units To Reduce Methane LossesDocument29 pagesInstalling Vapor Recovery Units To Reduce Methane LossesandresNo ratings yet

- Introductory Chapter: Cancun PledgesDocument25 pagesIntroductory Chapter: Cancun PledgesLaura Vanessa Rojas KulmanNo ratings yet

- Introductory Chapter: Cancun PledgesDocument51 pagesIntroductory Chapter: Cancun PledgesLaura Vanessa Rojas KulmanNo ratings yet

- Using The Shimadzu GC System in The Fuel-Grade Ethanol Production Laboratory. Application Note (Shimadzu)Document2 pagesUsing The Shimadzu GC System in The Fuel-Grade Ethanol Production Laboratory. Application Note (Shimadzu)Maikel Perez NavarroNo ratings yet

- GSB Mix Design NSK-66 PDFDocument63 pagesGSB Mix Design NSK-66 PDFJalgaon100% (3)

- Electric Controls: M P M e T e S AtrDocument24 pagesElectric Controls: M P M e T e S AtrArshad MahmoodNo ratings yet

- Bao On TPFLEX CatalogueDocument12 pagesBao On TPFLEX CatalogueTùng Chu báNo ratings yet

- r48 5800a DatasheetDocument2 pagesr48 5800a DatasheetCharmer JiaNo ratings yet

- LECTURE 5 - 0 Compressive Tests PDFDocument38 pagesLECTURE 5 - 0 Compressive Tests PDFΝικος σαταNo ratings yet

- Week 7 - Vapor Compression System Analysis 2T 2023-2024 - V.2Document71 pagesWeek 7 - Vapor Compression System Analysis 2T 2023-2024 - V.2Wency CariagaNo ratings yet

- Reciprocity Th. ResultDocument1 pageReciprocity Th. Resultkanishka3912No ratings yet

- Home Work 1Document6 pagesHome Work 1Italo Acuña UriolNo ratings yet

- Dollar Tree Stock Up 1.5% After Beating Earnings EstimatesDocument1 pageDollar Tree Stock Up 1.5% After Beating Earnings EstimatesYS FongNo ratings yet

- Chapter 2. Methods and InstrumentationDocument11 pagesChapter 2. Methods and Instrumentationkim haksongNo ratings yet

- S40148C 3Document81 pagesS40148C 3Claudio AlmiciNo ratings yet

- 20PR502Document1 page20PR502g1ann1sNo ratings yet

- 16PR628Document1 page16PR628g1ann1sNo ratings yet

- GEA - Bock - SemiHerm - Catalogue - GB 25Document1 pageGEA - Bock - SemiHerm - Catalogue - GB 25hadi mehrabiNo ratings yet

- EMM_5542584 motor stribor 17-8 bote1372 22_01_2021 9_54_37 p. m.Document5 pagesEMM_5542584 motor stribor 17-8 bote1372 22_01_2021 9_54_37 p. m.URIEL CABALLERONo ratings yet

- Curvas de DesempeñoDocument116 pagesCurvas de DesempeñoRene RodriguezNo ratings yet

- Nominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Document1 pageNominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Zikko FirmansyahNo ratings yet

- Gn001 Application Guide: Design With Gan Enhancement Mode HemtDocument44 pagesGn001 Application Guide: Design With Gan Enhancement Mode HemtTuan TranNo ratings yet

- MAX GAS 40 - 70 - 105 - 120: Range ModelsDocument1 pageMAX GAS 40 - 70 - 105 - 120: Range ModelsDarshan PanchalNo ratings yet

- Carbon Composite Resistors for Surface MountingDocument2 pagesCarbon Composite Resistors for Surface Mountingivasi ivasiNo ratings yet

- Competitive Performance Summary: Emissions Capable Tolerance of Associated Gas Warranty Global Product SupportDocument5 pagesCompetitive Performance Summary: Emissions Capable Tolerance of Associated Gas Warranty Global Product SupportالمهندسوليدالطويلNo ratings yet

- Compact OEM Dew Point Transmitter Down to -60°C TdDocument2 pagesCompact OEM Dew Point Transmitter Down to -60°C TdRonak PanchalNo ratings yet

- S40148e 3Document85 pagesS40148e 3Claudio AlmiciNo ratings yet

- Performance Outline: EC4-250-NO Nitric Oxide Electrochemical SensorDocument2 pagesPerformance Outline: EC4-250-NO Nitric Oxide Electrochemical SensorAdrian ZarnescuNo ratings yet

- Mfac34-High Impedance Differential RelayDocument2 pagesMfac34-High Impedance Differential RelayTHILAKKUMARNo ratings yet

- HướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GDocument41 pagesHướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GThong LaoNo ratings yet

- API STD 682 EtraDocument1 pageAPI STD 682 EtrasuharminNo ratings yet

- ASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocument8 pagesASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusRafael EstradaNo ratings yet

- ModulosDocument39 pagesModulosRafael EstradaNo ratings yet

- LAS SpecificationDocument8 pagesLAS SpecificationRafael EstradaNo ratings yet

- ASTM D 1633-17 Compresión de Briquetas de Suelo CementoDocument4 pagesASTM D 1633-17 Compresión de Briquetas de Suelo CementoAbelino GarcíaNo ratings yet

- Astm D 6433 PciDocument48 pagesAstm D 6433 PciRafael Estrada100% (1)

- ASTM D 2487 Standard Practice For Classification of Soils For Engineering Purposes (Unified Soil Classification System)Document10 pagesASTM D 2487 Standard Practice For Classification of Soils For Engineering Purposes (Unified Soil Classification System)Rafael EstradaNo ratings yet

- ASTM C1097 Standard Specification For Hydrated Lime For Use in Asphalt Cement or Bituminous Paving MixturesDocument2 pagesASTM C1097 Standard Specification For Hydrated Lime For Use in Asphalt Cement or Bituminous Paving MixturesRafael EstradaNo ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument7 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice ForANDREA ARROYAVE SEPULVEDA100% (1)

- ASTM D 4791 (Flat and Elongated Particles)Document8 pagesASTM D 4791 (Flat and Elongated Particles)Rafael EstradaNo ratings yet

- Norma EsclerometroDocument4 pagesNorma EsclerometroManuel Aliaga TorresNo ratings yet

- Instructions For Authors Submitting For TRR PublicationDocument12 pagesInstructions For Authors Submitting For TRR PublicationRafael EstradaNo ratings yet

- Astm C 39-2021Document8 pagesAstm C 39-2021Mohammed AliNo ratings yet