Professional Documents

Culture Documents

Pipe Support Procedure

Pipe Support Procedure

Uploaded by

Efrain PonseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Support Procedure

Pipe Support Procedure

Uploaded by

Efrain PonseCopyright:

Available Formats

Whessoe – Volker Stevin JV

Document No. Revision Date: Sheet:

WMWK28-174-360-PI-PR-001 2 10-11-05 1 of 21

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 2 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 3 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 4 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 5 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 6 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 7 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 8 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 9 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

PIPE SUPPORT

PROCEDURE

Client:

Dragon LNG Ltd.

Contract No.: 28

Project Title:

DRAGON LNG IMPORT TERMINAL

MILFORD HAVEN

This document and the information/data contained therein has been provided by M W Kellogg Ltd. on behalf of Whessoe Volker Stevin for

use on the Dragon LNG Terminal project only. The use of this document and the information/data contained therein is in accordance with

the terms of the Confidentiality Agreements between Dragon LNG, Whessoe Volker Stevin JV and M W Kellogg. It must not be otherwise

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 10 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

copied, loaned or transferred nor must the information it contains be disclosed to any third party without the written consent of M W

Kellogg Ltd.

REVISION RECORD SHEET

Issue Description Date Prepared Checked Approved WVS

By By

By Approval

1 Issued for design 1-10-05 PK HM HM

2 Re-issued for design 10-11-05 PK HM HM

RESPONSIBILITIES

This document is the responsibility of the Engineering Manager and any revision or

amendments shall require his approval. The Engineering Manager is responsible for the

maintenance of this document and for arranging controlled distribution through Project

Document Controller.

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 11 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

CONTENTS

1 ABBREVATIONS............................................................................................................................ 4

2 CODES, STANDARDS & SPECIFICATIONS.................................................................................5

2.1 CODES................................................................................................................................... 5

2.2 STANDARDS.......................................................................................................................... 5

2.3 PROJECT SPECIFICATIONS................................................................................................ 5

2.4 REFERENCE DOCUMENTS.........................5

3 DESIGN PHILOSOPHY.................................................................................................................. 5

4 INSULATION CODES..................................................................................................................... 5

5 INSULATION CLADDING............................................................................................................... 6

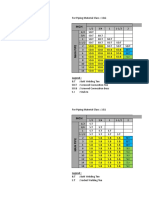

6 PIPE HEIGHT AND SHOE SELECTION TABLE............................................................................6

7 COLD INSULATED LINES............................................................................................................. 6

7.1 VERTICAL LOADS................................................................................................................. 6

7.2 LINE STOPS........................................................................................................................... 6

7.3 GUIDE LOADS....................................................................................................................... 6

7.4 INSTALLATION...................................................................................................................... 6

8 COLD AND ACOUSTIC INSULATED LINES.................................................................................6

8.1 VERTICAL LOADS................................................................................................................. 7

8.2 LINE STOPS........................................................................................................................... 7

8.3 GUIDE LOADS....................................................................................................................... 7

9 WOOD BLOCK PERMALI SHOES................................................................................................. 6

9.1 VERTICAL LOADS................................................................................................................. 7

9.2 LINE STOPS........................................................................................................................... 7

9.3 GUIDE LOADS....................................................................................................................... 7

10 WOOD BLOCKS GENERAL........................................................................................................... 7

11 PTFE SLIDE PLATES..................................................................................................................... 7

12 TICO PADS.................................................................................................................................... 8

13 PIPE SUPPORT NUMBERING...................................................................................................... 8

14 PIPE SUPPORT INDEX................................................................................................................. 9

15 PIPE SUPPORT SPECIALS / NUMBERING..................................................................................9

16 PIPE SUPPORT FOUNDATION SUMMARIES............................................................................10

17 PIPE SUPPORT MTO REQUIRED...............................................................................................10

18 SPRING NUMBERING................................................................................................................. 10

19 SNUBBER NUMBERING.............................................................................................................. 10

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 12 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 13 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

1 ABBREVIATIONS

PUF Polyurethane foam

WMWK Whessoe M W Kellogg

PTFE Polytetraflouroethylene

PIR Polyisocyanurate foam

PDMS Plant Design Management System

MDS Multi Discipline Supports

IPMS Integerated Project Management System

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 14 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

2 CODES, STANDARDS & SPECIFICATIONS

2.1 CODES

N/A

2.2 STANDARDS

MWKL Standard MDS Instruction for pipe supports

5862-PT-170-G20B-001 MWKL pipe support standards

2.3 PROJECT SPECIFICATIONS

WMWK28-170-000-PI-SP-041 Specification for the design and purchase of

Pipe support components and assemblies

WMWK28-170-000-PI-SP-042 Specification for the design and purchase of

Slide plates

W00028-170-000-GE-PR-002 Project numbering system procedure

WMWK28-170-000-PI-SP-038 Insulation Spec

2.4 REFERENCE DOCUMENTS

WMWK28-170-000-EN-TQ-184 Technical query (slide plate clarification)

WMWK28-174-120-CI-DW-073/4 Standard civil pipe support bases

3 DESIGN PHILOSOPHY

The philosophy of supporting pipes on the Dragon LNG project is based on the client

requirement that protective coating on steelwork/pipe (paint) is not damaged by pipe

movement.

To accommodate this requirement all pipes have been placed with PTFE slide plates below

them isolating the steelwork protective coating. Insulated lines on shoes have both a top and

bottom plate assembly while un-insulated lines require a bottom plate only. All centreline of

pipe elevations are based on this criteria. Refer to pipe support standard table for pipe height

and shoe selection “PHASST”.

4 INSULATION CODES

Currently on this project there are 8 insulation codes. All insulation codes are based on

operating temperatures and not design. Basis for selecting shoe types for a line are due to

insulation considerations.

(a) N – No insulation requirement

(b) G - Personnel protection. Steel mesh guard required if area deemed a hazard.

(c) 6 - PIR used for the prevention of condensation. PIR is the cold insulation on a line.

This code is used for lines that may not see a cold temperature but may have

condensation form on the surface.

If the operating temperature is below the ambient then condensation will form. To

avoid condensation falling on areas deemed sensitive the line shall be insulated

locally to certain areas. Standard shoes may be used with cold insulation as ice

formation is unlikely.

(d) 7 - PIR/PUF used for the reduction of heat gain. This code is used for lines that are

required to remain at cold temperatures and not gain heat. Normally the lines

operate at cold temperatures hence cold insulation is required with cold shoes

over the insulation so there is no path for the heat gain or cold temperature to

travel to the surface and cause ice formation. Special cold PUF shoes are

required at support locations. See consideration for PUF shoes below.

(e) 8 - Mineral wool and PUF/PIR – This code is required for lines that need to remain

cold and at the same time require some form of sound control. The PUF/PIR is

used for the heat gain control and a 6 mm thick TICO(expensive rubber) pad for

the sound control. For all line sizes the 100 mm thick mineral wool is added to the

cold insulation.

(f) 9 - PIF/PIR cold personnel protection – Currently not applicable

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 15 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

(g)B - Mineral wool – This code is used for lines that are required to be electrically heat

traced and so require insulation. For all line sizes in this case the insulation

thickness used is 50 mm thick mineral wool.

5 INSULATION CLADDING

Currently on this project there are 8 insulation codes. All insulation codes are based on

operating Cladding thickness is based on outside diameter of insulation for all cases except

type 8 insulation . Refer to PHASST table.

Cold insulated lines type 6 and 7 only have one layer of cladding on the outside of the

insulation.

Lines with insulation type 8 require 2 cladding layers. One layer at 50 mm after the cold

insulation and the second layer on the outside of the pipe. In this case only cladding thickness

for first layer is 0.8 mm and the second layer is 1.0 mm.

6 PIPE HEIGHT AND SHOE SELECTION TABLE - PHASST

Cold insulated lines shall be supported with PUF shoes. Vertical loads are limited for cold

shoes

The “PHASST” table should be used as a guide to select shoe types for supports. This gives

designers a common approach across the project in varying areas. On this project the table is

divided into 2 parts, un-insulated and insulated lines as acoustic fatigue is not applicable to this

project. For use of PHASST table refer to instructions on the bottom right hand of table.

7 COLD INSULATED LINES

Apply specifically to insulation code types 6,7 and 8.

Cold insulated lines shall be supported with PUF shoes at support points. The shoes consist of

an inner layer of high density polyurethane foam and an outer fabric vapour barrier covered

with cladding. The assembly is clamped on to the pipe with steel cradle halves (shoe welded

to bottom) which are bolted together with a disc spring arrangement. The springs ensure that

the clamp still maintains contact with the pipe during various temperature conditions where the

pipe contracts or expands. The spring loads are referred to as clamping forces.

Vertical loads are limited for cold shoes

in the support standard based on standard insulation densities(GNCS sheet 1) and shoe

lengths.

If higher loads are required then specials can be specified by increasing the shoe length and

PUF density. Special drawings should include loads.

7.1 VERTICAL LOADS

Vertical loads are limited for cold shoes in the support standard based on standard insulation

densities(GNCS sheet 1) and shoe lengths. If higher loads are required then specials can be

specified by increasing the shoe length and or trunnions.See section 10 below.

7.2 LINE STOPS

Welded line stops to underside of PUF shoes are not acceptable as the clamping forces applied

by disk springs are not sufficient to withstand large axial forces. Welded trunnions to be used for

these cases. Vertical loads taken by shoe and stop load taken by trunnion.

7.3 GUIDE LOADS

Guide loads are acceptable but limited based on support standards

7.4 INSTALLATION

Cold supports require special consideration for space requirements. Special attention shall be

paid to all piping branches, elbows, bolt removal from flanges, drains,vent,temperature indicators

etc.

8 COLD AND ACOUSTIC LINES

Apply specifically to insulation code types 8 only. PUF shoes for cold acoustic lines are exactly

the same as those for cold lines except there is an extra layer of TICO material 6 mm thick on

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 16 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

the outside of the cladding. On this project shoe selection takes into account acoustic

considerations for most cases. For 4” and below lines which are specified as type 8 acoustic

insulation does not apply.

8.1 VERTICAL LOADS

Vertical loads are as per section 7.1 above. Acoustic consideration from shoe selection.

8.2 LINE STOPS

As per section 7.2 above.

8.3 GUIDE LOADS

As per section 7.3 above but acoustic considerations require additional pad types VU3 if not

included within shoe selection.

9 WOOD BLOCK “PERMALI” SHOES

The Apply to insulation code type N. These lines are un-insulated but may see cold

temperatures and ice formation.To protect the shoe from freezing to steelwork wood

blocks are used as isolators.

The shoe is a clamp arrangement in 2 parts in stainless steel with the bottom part of

high density laminated wood between carbon steel plates.

9.1 VERTICAL LOADS

Vertical loads not an issue for shoes as laminated wood blocks have high compressive stresses.

9.2 GUIDE LOADS

Standard guides and loads are acceptable for permali shoes.

9.3 LINE STOPS

Standard line stops can be used on permali shoes but must be used in conjunction welded shear

lugs support type A3.

10 WOOD BLOCKS GENERAL

Apply specifically to insulation code types N,6,7 and 8 only. These line may be insulated or un-

insulated . For un-insulated lines wood blocks are used where permali shoes have not been

specified in the supporting as isolators. For insulated lines wood blocks are used where

minimum cold insulation requirements can not be met i.e. welded trunnions need to be longer

then T+ 4t or T + 300 mm where T=insulation on line and t=insulation on trunnion. If trunnion

length cannot be achieved then wood block can be welded to the bottom of the trunnion or

placed around it with a clamp. See CW1,2 AND 3.

Permali wood block sizes for trunnions to be standardized. See CW1 in standard.

For wood block lengths “PL” use block lengths in increments of 50 mm. Wood block thickness

same as cold insulation thickness.

11 PTFE SLIDE PLATES

PTFE pads for slide plates SU1 shall be sized based on the maximum and minimum bearing

pressures stated in support standards which must be checked on an individual basis.Below are

recommended plate sizes.

Recommended PTFE Slide Plate Selection Chart

Un-insulated lines without shoes (Bottom plate only required)

OD 0.5” 0.75” 1” 1.5” 2” 3” 4” 6” 8” 10”

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 17 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

PTFE

C/D 60 / 60 60 / 60 60 / 60 60 / 60 60 / 60 70 / 70 70 / 70 70 / 70 100/100 100/100

DIM

Field run carbon steel lines 0.5”-1.5” use UB1 as guide. Slide plate to be pre-drilled to suit U-bolt.

For larger sizes use G1 as guide.

All lines with shoes vertical loads

LOAD (KN) 0-6 6-10 10-15 15-30 30-60 60-100 100-200 200-330

PTFE A/B DIM 150 / 150/ 150/ 200 200 / 250 / 300 / 400 /

80 100 100 /125 125 200 250 300

PTFE C/D DIM 60 / 70 / 80 / 80 100 / 125 / 150 / 200 / 250 /

60 70 100 125 150 200 250

PTFE SIZE = 30 mm less size of bottom plate (C/D dimension)

Top plate (A/B dimension) has been based on max longitudinal movement = +/- 50 mm and transverse =

+/- 25 mm. Top plate to be increased for larger movements

12 TICO PADS

Below are recommended TICO pad sizes.

Recommended Tico Pad selection Chart

All lines with shoes vertical loads

LOAD (KN) 0-6 6-10 10-15 15-30 30-60 60-100 100-200 200-330

PTFE A/B DIM 30 / 40 / 50 / 70 / 70 95 / 120 / 170 / 220 /

30 40 50 95 120 170 220

13 PIPE SUPPORT NUMBERING SYSTEM

Pipe supports shall be identified by a unique mark number. The mark number shall be located

on the isometric at the location of the support point. The numbering will be in the following

form:-

PS-174-321-R-0001

PS - All supports will start with PS to designate pipe supports

174 - is the area code for MWKL responsibility.This number does not change.

321 - is the sub area code under the 174 code

Sub area codes are as follows :- 321 Recondenser area

322 Bog compressor area

323 Vaporiser area

324 Piperacks area

325 HP sendout pumps area

326 Fuel gas area

327 Utilities area

R - Is for rest and indicates the primary function of the support.

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 18 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

Other options for support types are :- A – Full anchor

G - Guide only(lateral restraint)

R - Rest

V – Variable spring support

LS – Line stop

TA – Translation anchor

DV – Double variable spring

0001 – Is a sequential number picked up every time a new support number is required.

Numbers

limited to sub area codes only.

14 PIPE SUPPORT INDEX

Below is example pipe support index to be automatically generated from PDMS once

supports have been input via MDS. The index sheet shall be automatically generated in

PDMS draught.

Example Pipe Support Index Sheet

Pipe Support Index – WMWK28-PI-IM-174-323-NG-171-01-PS

Job Number 5862 Page number 1 of 1

Client Dragon Revision 0

Project Dragon LNG Terminal Piping Class 9ROJ

Location Milford Haven

Isometric number – WMWK28-PI-IM-174-323-NG-171-01

Support Number Support Code No. Pipe Size(“) Remarks

PS-174-323-R-0001 S6 30

PS-174-323-R-0001 G2-F 30

PS-174-323-R-0001 A1-C 30

PS-174-323-R-0001 SU1-M-L-K-K-9 30 Double slide plates

PS-174-323-R-0002 S6 30

PS-174-323-R-0002 G2-F 30

PS-174-323-R-0002 A1-C 30

PS-174-323-R-0002 SU1-M-L-K-K-9 30 Double slide plates

PS-174-323-R-0002 SPS-0001 See special drawing #

WMWK28-174-360-PI-PS-001

15 PIPE SUPPORT SPECIAL NUMBERING SYSTEM / DRAWINGS

Specials which are non-standard support items need to be called up with a special pipe

support (SPS) number. The SPS number shall be sequentially eg. SPS-0001 with

numbers 1 to 10 reserved for index sheets and the first special support number starting

at 0011. All special support numbers shall have only 1 drawing number :-

WMWK28-174-360-PI-PS-001 made up numerous sheet numbers. The sheet numbers

will be the special drawing number. Sheet 11 shall be SPS-0011. Drawings for specials

shall include material take-off quantities, dimensions and loads so pipe support vendor

can fabricate support or install support on site. Standard specials expected on this

project include:-

(a) Non-standard Cold shoes – drawings to include shoe length,PUF density

and supports loads. Vertical and horizontal loads.

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 19 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

(b) Vibration spring hold downs – drawing to include overall dimensions for

frame

and sizes. Spring hold down force required with vertical and horizontal

loads.

(c) Special support frames with loads,sizes and location of bases if required.

16 PIPE SUPPORT FOUNDATION SUMMARY

Foundation summary sheets to include all piping plinths provided by piping mechanical

on

project. Plinths to be selected using civil plinth selection notes in conjunction with

planning

study drawings. Bases to be input using MDS and sizes available in pipe support

standard

only. Note option code “S” requires civils to design plinth. Format of foundation summary

sheets to be generated automatically(or by hand) in PDMS draft with the following

information already filled in:-

17 Support number

18 Line nubmber

19 Support code number – PL1-**-*

20 Northing

21 Easting

22 Elevation POS

Additional information required to be input by hand:-

23 Insert plate details

24 Local grade elevation(ref)

25 Loadings at top of plinth

26 Final foundation selection type.

Summary sheets to be generated by piping support group and issued per area.

Format for drawing numbers as follows:- WMWK28-174-321-PI-SS-001. The only

number

Change will be to sub area code eg 321,322,324,325 etc. as in section 13.

Civil/structural

group to review and sign off foundation summary sheets for civil designed plinths ie

those standard plinths indicated by “S”. Civils to input the size in the model for clash

checking.

27 PIPE SUPPORTS MTO CALL OFF REQUIRED

Currently for this project MTO call-offs required for the following:-

28 Cold PUF shoes all sizes. Standard and SPS drawings.

29 Permali wood block shoes all sizes. Standard and specials.

(a) Permali wood blocks for trunnions (CW1). Standard and special

30 All other standard shoes welded or clamped 2” and above only.

(b) Springs with a summary data sheet.

(c) Snubbers with a summary data sheet.

(d) Pipe support steelwork. Standard and special

(e) Vibration spring holds. Special drawings

The above MTO call-offs will be automatically downloaded from PDMS into IPMS except

in the case of specials which will require manual input and special drawings sent to the

support fabricator.

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 20 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

31 SPRING NUMBERING

Spring support number to be as follows :- SPR-001

Where SPR stands for springs and 001 is a sequential number.

32 SNUBBERS

Ssnubbers support number to be as follows :- SN-001

Where SN stands for snubbers and 001 is a sequential number.

Document No. WMWK28-174-360-PI-PR-001 Date: 10-11-05 Rev: 2 Sheet 21 of 21

Whessoe – Volker Stevin JV Title: PIPE SUPPORT PROCEDURE

You might also like

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- C5000 16 G28 B V04 B02 PDFDocument321 pagesC5000 16 G28 B V04 B02 PDFAhmed OmarNo ratings yet

- Cobalch Aps - PTFE DetailDocument25 pagesCobalch Aps - PTFE DetailMorteza DianatfarNo ratings yet

- API 610 Check CaesarDocument22 pagesAPI 610 Check CaesarSeptian Firdaus100% (1)

- UI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingDocument12 pagesUI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingmahmoud_allam3100% (1)

- L1-R-1132-1003 - Att 1 - LNG Unloading Arms Technical Specification - 0Document66 pagesL1-R-1132-1003 - Att 1 - LNG Unloading Arms Technical Specification - 0sushil100% (1)

- TB 10Document10 pagesTB 10Ankur PandeyNo ratings yet

- AVEVA Bocad Offshore PDFDocument2 pagesAVEVA Bocad Offshore PDFsennimalaiNo ratings yet

- Offshoredesignmanual PDFDocument155 pagesOffshoredesignmanual PDFalekyaNo ratings yet

- Caliper Presentation Pig LauncherDocument34 pagesCaliper Presentation Pig LauncherMix VichaitanapatNo ratings yet

- Equipment List Including Long Lead ItemsDocument6 pagesEquipment List Including Long Lead Itemspapilolo2008No ratings yet

- Dokumen - Tips - Storage Tank Piping 79720 Ps 002 Stress Analysis System Documentation CalculationsDocument25 pagesDokumen - Tips - Storage Tank Piping 79720 Ps 002 Stress Analysis System Documentation CalculationsOflodor ZazuetaNo ratings yet

- 2019.09.03 - EST & SCHED - r.2 - Combined OverviewDocument1 page2019.09.03 - EST & SCHED - r.2 - Combined OverviewSriNo ratings yet

- Sp1 230 SPFL 00 DM RP 406 00 - Ifc Design DossierDocument6 pagesSp1 230 SPFL 00 DM RP 406 00 - Ifc Design Dossierapi-26220184No ratings yet

- PEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingDocument9 pagesPEC-En-GDE-L-10028 - Design Guidelines For Jacketed PipingAkshay DesaiNo ratings yet

- Hot Tapping Procedure: Basrah Oil CompanyDocument8 pagesHot Tapping Procedure: Basrah Oil CompanyAhmed Farman AlqaysiNo ratings yet

- Piping Stress Critical Lines - Basis For Piping Critical Line List PDFDocument3 pagesPiping Stress Critical Lines - Basis For Piping Critical Line List PDFanup15balagarhNo ratings yet

- 26071-100-3DG-P50-00001 Specification For Piping Support 190418Document18 pages26071-100-3DG-P50-00001 Specification For Piping Support 190418Wahono Kris MantonoNo ratings yet

- Procedure To Model API 650 Nozzle1Document4 pagesProcedure To Model API 650 Nozzle1Vishal Kand100% (1)

- PipingDocument4 pagesPipingramthecharm_46098467No ratings yet

- 2004-D-Piping SpecialitiesDocument24 pages2004-D-Piping Specialitiessids82No ratings yet

- IDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverDocument18 pagesIDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverTifano KhristiyantoNo ratings yet

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNo ratings yet

- PIP - Piping Material Specifications Collection - IHSDocument3 pagesPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourde100% (1)

- JET - DR1 - GI - 001 - Reva Issued 20130110 PDFDocument1 pageJET - DR1 - GI - 001 - Reva Issued 20130110 PDFFadria HandayaniNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- A307 6545 104 Enq Rev0Document283 pagesA307 6545 104 Enq Rev0Yogi YuganNo ratings yet

- Jpep 0 1360 T 4141 PDFDocument44 pagesJpep 0 1360 T 4141 PDFNguyen Thanh NguyenNo ratings yet

- Pages From ONGC-SPEC-02-MS-03Document12 pagesPages From ONGC-SPEC-02-MS-03Prathamesh OmtechNo ratings yet

- Ongc 2004a Rev 7Document78 pagesOngc 2004a Rev 7dzardoniNo ratings yet

- ELT-01-EP-TS-0007 - Specification For Insulation - R0Document52 pagesELT-01-EP-TS-0007 - Specification For Insulation - R0jorgekarlosprNo ratings yet

- EPC3-BRT Pj. - Intergral Double Block & Bleed ValvesDocument6 pagesEPC3-BRT Pj. - Intergral Double Block & Bleed ValvesUsman Arif100% (1)

- Branch TableDocument5 pagesBranch TableAbu Akhmad BusanaNo ratings yet

- Mechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)Document7 pagesMechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)you kackNo ratings yet

- 2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisDocument23 pages2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisSachin ShindeNo ratings yet

- NRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor BoltsDocument4 pagesNRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor BoltsdavidgmarksNo ratings yet

- Piping Engineering NotesDocument46 pagesPiping Engineering Noteslightsons100% (1)

- MSS SP90Document26 pagesMSS SP90Andres Camilo BenitezNo ratings yet

- FS PipingDocument317 pagesFS PipingOthman Rejab100% (1)

- The Piping GuideDocument214 pagesThe Piping GuideMohamed RjebNo ratings yet

- 64j0105-C-Piping ClassDocument85 pages64j0105-C-Piping ClassDubois100% (1)

- DGS 1300 160 Bolt TorquingDocument12 pagesDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- One Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsDocument3 pagesOne Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsMainuddin AliNo ratings yet

- Procurement of Piping SP Item PDFDocument1 pageProcurement of Piping SP Item PDFDinda Putri AmaliaNo ratings yet

- ELT-01-EP-TS-0005 - Specification For Manual Valve - R0Document20 pagesELT-01-EP-TS-0005 - Specification For Manual Valve - R0jorgekarlosprNo ratings yet

- TPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016Document10 pagesTPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016OlusayoNo ratings yet

- 903-10004-SPC-M-001 Piping Material SpecificationDocument15 pages903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNo ratings yet

- Hyundai Pump SUBMERGED C PUMP PDFDocument10 pagesHyundai Pump SUBMERGED C PUMP PDFZuzanna Kat-ToporskaNo ratings yet

- S-41-1224-001WR - Rev 1Document38 pagesS-41-1224-001WR - Rev 1heri_prasetyadiNo ratings yet

- Autopipe Vessel Guide Pages 6-10Document5 pagesAutopipe Vessel Guide Pages 6-10fiuto_rights_1404802No ratings yet

- BGA-EnG-MATL-TS-0007 Fabrication of Equipment and Piping Rev 02aDocument44 pagesBGA-EnG-MATL-TS-0007 Fabrication of Equipment and Piping Rev 02aGururaj P Kundapur100% (1)

- Piping Material SpecificationDocument574 pagesPiping Material SpecificationkumarNo ratings yet

- Stress Analysis of Storage Tank Piping Jeba Anand NadarDocument36 pagesStress Analysis of Storage Tank Piping Jeba Anand NadarTree Tawee100% (2)

- PipingDocument15 pagesPipingDerick Mendoza100% (1)

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- MP 4 0004 060Document4 pagesMP 4 0004 060husen123 alhusadaNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

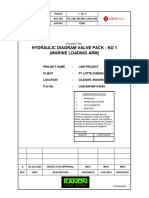

- VD Line 906 MP 4 0004 060 - Hydr. Diag. Valve Pack No 1 - Rev.bDocument4 pagesVD Line 906 MP 4 0004 060 - Hydr. Diag. Valve Pack No 1 - Rev.bhusen123 alhusadaNo ratings yet

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamNo ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet

- PP Compression Fittings: BS EN 713: 1995Document2 pagesPP Compression Fittings: BS EN 713: 1995Milimas Tirta SolusiNo ratings yet

- Pedestrain Guard RailDocument1 pagePedestrain Guard RailShivam SharmaNo ratings yet

- Brosur AC Daikin Non Inverter Cassette Malaysia Dan Standing FloorDocument10 pagesBrosur AC Daikin Non Inverter Cassette Malaysia Dan Standing FloorBen Firdaus100% (1)

- Kaysafe Engineering - DATA SHEET 16 - FIG Y800 Y TYPE STRAINERDocument1 pageKaysafe Engineering - DATA SHEET 16 - FIG Y800 Y TYPE STRAINERSteve NewmanNo ratings yet

- 9A23303 Fluid Flow in BioprocessesDocument4 pages9A23303 Fluid Flow in BioprocessessivabharathamurthyNo ratings yet

- Afc-4551 MPR-30 Jun-2023Document254 pagesAfc-4551 MPR-30 Jun-2023sandesh negiNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed Mujahid0% (1)

- A 447Document4 pagesA 447william_m08No ratings yet

- Galvanizing WeldDocument11 pagesGalvanizing WeldSivaNo ratings yet

- Teoria e Progetto Dei Ponti Elementi Costruttivi PDFDocument56 pagesTeoria e Progetto Dei Ponti Elementi Costruttivi PDFlinus18No ratings yet

- AC Cable 70mm 3.5-C CU-PVC-PVC SpecsDocument1 pageAC Cable 70mm 3.5-C CU-PVC-PVC Specslahore0022No ratings yet

- AM050KXMDCH AzDocument1 pageAM050KXMDCH AzShirley BarreraNo ratings yet

- Suphaa Adaadii Rate HaaraaDocument6 pagesSuphaa Adaadii Rate HaaraaBorana Asnake KumsaNo ratings yet

- c544 Phosphor BronzeDocument2 pagesc544 Phosphor BronzesleonNo ratings yet

- Katalog PropustaDocument7 pagesKatalog PropustaMarkoNo ratings yet

- CIC Catalogues PDFDocument172 pagesCIC Catalogues PDFAbu-Mahmood KhalilNo ratings yet

- PrEN 1993-1!10!2003 Eurocode 3 - Design of Steel Structures - Part 1-10 - Material Toughness and Through-Thickness PropertiesDocument13 pagesPrEN 1993-1!10!2003 Eurocode 3 - Design of Steel Structures - Part 1-10 - Material Toughness and Through-Thickness PropertiesT Asm Al-AniNo ratings yet

- Sandwich Panel Design Calculation Design CriteriaDocument2 pagesSandwich Panel Design Calculation Design CriteriajanethNo ratings yet

- Catalogue ETICS Fixings EWDocument61 pagesCatalogue ETICS Fixings EWMohamed Abdel SamieNo ratings yet

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDocument2 pagesAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigManuel SerranoNo ratings yet

- Topik 1 - Introduction-Ilmu Bahan PDFDocument10 pagesTopik 1 - Introduction-Ilmu Bahan PDFUmar Putra SyahrudinNo ratings yet

- Aer320 Outline f11 FVDocument3 pagesAer320 Outline f11 FVbatmanbittuNo ratings yet

- 3D Printing of Earth-Based Materials Processing AspectsDocument7 pages3D Printing of Earth-Based Materials Processing AspectsGuilherme HoffmanNo ratings yet

- Copper and Copper-Alloy Die Forgings (Hot-Pressed) : Standard Specification ForDocument8 pagesCopper and Copper-Alloy Die Forgings (Hot-Pressed) : Standard Specification ForIsma RioNo ratings yet

- Proceeding ICOME 2015Document184 pagesProceeding ICOME 2015Sally ChytNo ratings yet

- 7b Oil BurnersDocument45 pages7b Oil BurnersArul SankaranNo ratings yet

- Catalogo RescoDocument2 pagesCatalogo RescopamelataboadalozanoNo ratings yet

- Materials For Engineering 12 - Ferritic Stainless SteelDocument14 pagesMaterials For Engineering 12 - Ferritic Stainless SteelKris WilochNo ratings yet

- Bombas PeristalticasDocument8 pagesBombas PeristalticasDar FallNo ratings yet

- Cat Tcavbisz 1270 21600 en NTDocument60 pagesCat Tcavbisz 1270 21600 en NTsarcitoNo ratings yet