Professional Documents

Culture Documents

Shipyard Review Form

Uploaded by

Bala MuruganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shipyard Review Form

Uploaded by

Bala MuruganCopyright:

Available Formats

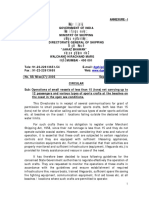

Z23, Appendix 1

Z23

Z23 Appendix 1

(cont)

Page 1 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

Z23 Shipyard Review Record

(cont)

Name of Shipyard Date

1. Details of any Management Systems

Obtained approval Certified by Expiry Date Remarks

(scope, etc.)

ISO-9001

ISO 14001

ISO 18001

Other:

2. Construction Facilities: (Documents such as a brochure of shipyard can be attached in

lieu of completing this section.)

2.1 Building Berth (B) or Dock (D) *In case of berth, Depth is not applicable.

B/D Name Length Width Depth* Building Crane

(m) (m) (m) Capacity (Ton x No.)

(Gross

Tonnage)

2.2 Outfitting Quays

Name Length Width Depth Berthing Crane

(m) (m) (m) Capacity (Ton x No.)

(Gross

Tonnage)

Page 2 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

2.3 Main Fabrication and Erection Facilities

Z23

(cont) (1) Marking and cutting of steel plates (including internal members)

- Marking method (Manual, Photo x ___, EPM x ___, NC x ___ others _______)

- NC cutting machine (Gas x ___, Plasma x ___, Laser x ___)

Control procedure of NC (On-line, other)

- Cutting equipment (Edge planer x ___, Roll-shear x ___)

(2) Marking and cutting of section bar

- Marking method (Manual, NC) - Marking of reference curved line (Manual, NC)

- Cutting method (Manual, NC) - In case of NC (Gas x ___, Plasma x ___)

(3) One-side automatic welding machine (Yes, No)

- Type of welding machine (Flux Backing x ___, Flux and Copper Backing x ___ other _______)

- Existence of special surface plate for plate welding (Yes, No)

(4) Fillet welding machine (Gravity, Automatic) Percentage of automatization except gravity: about ___%

- Line Welder (No, Yes: submerged arc x ___ heads, CO 2 x ___ heads)

- Small automatic fillet welding machine (No, Yes: Name: ____________ x ___)

- Welding robot (No, Yes: Portal x ___, Rectangular x ___, Articulated x ___)

(5) Painting equipment

- Plate shot blasting/primer coating machine (No, Yes: Max. Width ___ m, Length ___ m)

- Section bar shot blasting/primer coating machine (No, Yes: Max. Length ___ m)

- Special coating factory (No, Yes: ___ m x ___ m x ___ sections)

(6) Vertical automatic welding machine (No, Yes: EG x ___, SEG x ___, ES x ___)

EG: Electrogas SEG: Simplified Electrogas ES: Electroslag

(7) Other main fabrication facilities

Page 3 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

3. Shipyard Control of Qualified Welders

Z23 (1) Normal steel

(cont)

maintenance

certification traceability supervision of qualification

confirm system in

Shipyard workers Yes / No Yes / No Yes / No Yes / No

place

confirm system in

Subcontracted workers Yes / No Yes / No Yes / No Yes / No

place

4. Feature of Construction Procedure

(1) Subcontract of hull blocks (weight)

- Sub members (No, Yes: Ratio of subcontracted works ___ %, No., of subcontractors ___)

- Blocks (No, Yes: Ratio of subcontracted works ___ %, No., of subcontractors ___)

(2) Method of plate block assembly

- Method fitting and welding longitudinals and transverse webs on jointed panels

- Method welding longitudinals on jointed panels prior to fitting and welding transverse webs

- Method fitting and welding a frame consists of longitudinals and transverse webs on jointed panels

- Method jointing panels with pre-assembled longitudinals by welding prior to fitting and welding transverse

webs

- Other (please specify in (5) below)

(3) - pre-erection outfitting carried out

grand block/mega block adopted

Method of erection at building berth/dock

- Max. weight of loading block: ton

- Construction method in building dock/berth/land construction etc. (1 ship, 1.5 ships: Semi-tandem, dual

entrance)

- Block loading process (single starting block, multi starting blocks, inserting block: No, Yes)

(4) Final dock (No, Yes: In-house, Other place of the same company, Use other company)

(5) Other feature of construction procedure

Page 4 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

5. Quality Control System: (Refer to Quality Manual, if available.)

Z23

(cont) Item and description Result Remarks

(1) Existence of the organization chart including the departments

of design, purchasing, manufacturing and quality assurance

- Are the function, responsibility and competence of the

organization clear?

(2) Quality control organization

- Existence of quality control organization

- Number of employees in this organization _____ persons

including the chief

- Existence of procedures or plans related to tests and

inspections

(3) Pre-inspection system of shipyard

- Is pre-inspection carried out prior to Class inspection?

- Are pre-inspectors assigned? (Check the list.)

- Number of pre-inspectors (related to hull only)

- Are inspection results marked on the object and/or _____ persons

recorded in the checklist?

(4) Records of inspections and tests

- Are records made and kept properly?

- Does the responsible person verify the records?

- Can the adoption of necessary corrective actions against

non-conformity happened be checked?

(5) Condition at the time of the surveys in the presence of class

surveyors

- Is the schedule of the surveys changed often?

- Are pre-inspection, shipyard inspection and repairs

completed beforehand?

- Are the sufficient preparations for surveys such as

scaffoldings, lighting, cleaning made?

Note:

Above-mentioned (3) and (4) include the acceptance inspection of subcontracted items.

Page 5 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

6. Measures for Safety and Health

Z23

(cont) Item and description Result Remarks

(1) Are conditions of scaffolding, nets, safety belt, lighting and

ventilation good?

(2) Does sufficient attention paid for radiographic examination

and operation of cherry picker?

Note:

7. Control System of Non-Destructive Examination (NDE)

Item and description Result Remarks

(1) Number of NDE supervisors in shipyard (including

persons responsible for judging results) _____ persons

(2) Dependence on subcontracted NDE work

- Number of shipyard employees _____ persons

- Number of sub-contractors _____ persons

(3) NDE sub-contractor company’s name and official Name ___________

technical qualifications

(approved by) __________

Name ___________

(approved by) __________

(4) Grade and number of NDE employees with official

technical qualifications in shipyard

Specialized in radiography ____ Grade ____ persons

Specialized in ultrasonic ____ Grade ____ persons

Specialized in surface detection ____ Grade ____ persons

(5) If non-destructive examinations are subcontracted, the

grade and number of officially qualified persons

Specialized in radiography ____ Grade ____ persons

Specialized in ultrasonic ____ Grade ____ persons

Specialized in surface detection ____ Grade ____ persons

(6) Non-destructive examination equipment (in house)

- Number of radiographic equipment ______________

- Number of ultrasonic equipment ______________

Note:

Even if all works are subcontracted, it is recommendable to attach the qualified person(s) who can verify the

works.

Page 6 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

8. Quality Control on Production Line

Z23

(cont) Item and description Result Remarks

8.1 Preventative measures for misuse of materials

(1) Job title of supervisor and person in charge of collating Title of supervisor:

ordered steel and received steel, and checking of mill

sheet ____________________

Title of person in charge:

___________________

(2) Are means for checking the material grade in hand

prescribed for high-grade steels

(3) Are regulations prescribed for checking the material

grade for high-tensile steel for low-temperature

applications?

Are there regulations for inscribing high tensile steel on the

surface of the high tensile steel and special indication for

steel for low temperature applications?

(4) Are procedures for re-using of remaining cut-off mild

steel?

(5) Are there procedures for re-using of remaining cut-off

high-tensile steel?

(6) In the case of (4) and (5) above, can a collation be

made with the mill sheet?

(7) Section of controlling the lists of remaining cut-off steel Name of section:

____________________

Note:

- In case of high tensile steel, are means identifying different grades

- In the case of (3) and (4) above, are the materials approved by other classes controlled similarly?

8.2 Shot blasting/Primer coating

(1) Existence of surface preparation standards

(2) Existence of coating thickness control standards

- Existence of thickness measurement records

Note:

- The standard is to include the description related traceability after shot blasting and primer coating.

8.3 Marking and cutting (Assembly work)

(1) Existence of standards for accuracy and periodical

inspection of tape measures, tapes, stencils, etc.

(2) Existence of standards for accuracy of cut dimensions

and edge preparation

(3) Existence of standards for finish of cutting face

(4) What is the frequency and extent of maintenance and

inspection carried out for ensuring accuracy of NC cutter

and/or flame planer?

Page 7 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

Item and description Result Remarks

Z23 (5) In case of NC, are the disks, tapes etc. maintained in

(cont) good condition?

(6) What are the measures adopted and guidance given to

make the worker fully conversant with cutting work

standards for maintaining accuracy?

Note:

- In case of (2) and (3) above, check items are to include confirmation of edge preparations free from

piercing hole.

- NC for section bars is also to be in accordance with the above.

8.4 Bending and strain free

(1) Existence of standards for maximum heating

temperatures during water cooling and at the time of

bending and distortion removal of steel by quick heating

and cooling

(2) Existence of regulations for plate thickness and

bending radius for flange processing

(3) What are the measures adopted and guidance given to

make the worker fully conversant with maintaining quality

and accuracy during the bending process?

Note:

8.5 Control of welding procedure

(1) Are all welding procedures applied to the ships

approved by the Society or other IACS members?

Note:

8.6 Treatment of serious non-conformities

(1) Are repair plans submitted to the Society when serious

non-conformities happened?

(2) Were the NDE (RT/UT) plans submitted at appropriate

timing?

(3) Was the extent of tests extended considering the

results of the test?

Note:

8.7 Hydrostatic and watertight tests

(1) Is the test plan submitted to the Society?

(2) Are vacuum tests applied to?

(3) Are local air injection tests during sub-assembly works

applied to?

Page 8 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 1

Item and description Result Remarks

Z23 (4) If (2) or (3) above is applied to, are the test procedures

(cont) approved by the Society?

Note:

Page 9 of 9 IACS Req. 2006/Rev.6 2016

Z23, Appendix 2

Z23

Z23 Appendix 2

(cont)

Requirements for Tankers and Bulk Carriers subject to

SOLAS Chapter II-1 Part A-1 Regulation 3-10

Goal-based ship construction standards for bulk carriers and oil tankers

Page 1 of 10 IACS Req. 2006/Rev.6 2016

You might also like

- Dalian Developer Presentation - Rev 2Document24 pagesDalian Developer Presentation - Rev 2jklepsvik213No ratings yet

- Tecnoplast SRL - Product ListDocument44 pagesTecnoplast SRL - Product Listbarino1966No ratings yet

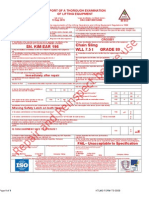

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting Equipmentoriza100% (1)

- Almansoori Inspection Services: Travelling Block AssemblyDocument2 pagesAlmansoori Inspection Services: Travelling Block AssemblyRanjithNo ratings yet

- DNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFDocument44 pagesDNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFrami ghorbelNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- MP 2585Document5 pagesMP 2585Juan Sebastián Martinez NunciNo ratings yet

- W14-661 (0 To 40 Bar) PDFDocument3 pagesW14-661 (0 To 40 Bar) PDFBalaji BobadeNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- ABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Document3 pagesABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Dagoberto AguilarNo ratings yet

- End User StatementDocument1 pageEnd User StatementTouati SaidNo ratings yet

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- ASTM E 1003 Practica Estandar para PHDocument12 pagesASTM E 1003 Practica Estandar para PHrodoNo ratings yet

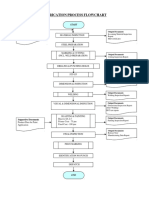

- Process Flow Chart - SeeDocument2 pagesProcess Flow Chart - Seesukanth tejaswiNo ratings yet

- SN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentDocument1 pageSN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentorizaNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Asme IX BQ Art 11Document5 pagesAsme IX BQ Art 11Maria Alexandra Lange LenzNo ratings yet

- Metal Magnetic MemoryDocument41 pagesMetal Magnetic MemoryBogdan MunteanuNo ratings yet

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Document1 pageAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNo ratings yet

- Article 16 Magnetic Flux Leakage (MFL) ExaminationDocument4 pagesArticle 16 Magnetic Flux Leakage (MFL) ExaminationAnonymous ihanyMJNo ratings yet

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument14 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNo ratings yet

- Thread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTDocument38 pagesThread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTInChy Rencarnation PoseidonNo ratings yet

- Manual CalidadDocument23 pagesManual CalidadGabriel GaraventaNo ratings yet

- GPS InspectionDocument48 pagesGPS InspectionAhmed AluoshNo ratings yet

- DrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsDocument1 pageDrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsmarcotplNo ratings yet

- Mil STD 2219a PDFDocument43 pagesMil STD 2219a PDFRaron1No ratings yet

- Panametrics MG2DLDocument137 pagesPanametrics MG2DLpjhollowNo ratings yet

- ABS-Lifting Appliances Guide E-May17 PDFDocument232 pagesABS-Lifting Appliances Guide E-May17 PDFLeonardo Lannes VieiraNo ratings yet

- Chapter 5 - Conclusion & RecommendationDocument4 pagesChapter 5 - Conclusion & RecommendationMohamad Shukri0% (1)

- QAP For FlangesDocument2 pagesQAP For FlangesGOPINATH KRISHNAN NAIRNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Supplier Template - Rev A - NAVSEA Tech Pub 248 WPS Essential Variable ChecklistDocument5 pagesSupplier Template - Rev A - NAVSEA Tech Pub 248 WPS Essential Variable ChecklistHenry CedeñoNo ratings yet

- ITP FORMAT - PSV Modified FormateDocument1 pageITP FORMAT - PSV Modified Formatemurthy challapalliNo ratings yet

- Mordec-Catalogue 2011 MayDocument83 pagesMordec-Catalogue 2011 Maykiiru88100% (1)

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaNo ratings yet

- Derrick Sample Report PDFDocument11 pagesDerrick Sample Report PDFRajesh ThorweNo ratings yet

- End Use Declaration - Russia Sanctions v.1.0Document1 pageEnd Use Declaration - Russia Sanctions v.1.0masicljNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- Written Schemes of Examinations Example Template - Course DownloadDocument9 pagesWritten Schemes of Examinations Example Template - Course Downloadgamil2No ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- Welding Machine ChecklistDocument34 pagesWelding Machine ChecklistShahid BhattiNo ratings yet

- DNV, TIFF TIN For Case-Hardened GearsDocument6 pagesDNV, TIFF TIN For Case-Hardened GearsPeter Carden100% (1)

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick VazquezNo ratings yet

- SNEL2Document27 pagesSNEL2CarTech Dyno100% (2)

- HTTPSWWW Sis Seapidocumentpreview922803Document11 pagesHTTPSWWW Sis Seapidocumentpreview922803Matt DNo ratings yet

- Catalogus VMLGDocument148 pagesCatalogus VMLGgeorgekc77No ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- TDS Link Ears and Pins MPIDocument1 pageTDS Link Ears and Pins MPIRanjithNo ratings yet

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Wca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemDocument97 pagesWca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemANo ratings yet

- Shipyard Review Record 202205191212483Document8 pagesShipyard Review Record 202205191212483effendy purnomoNo ratings yet

- Shipyard Review RecordDocument8 pagesShipyard Review Recordptbbs engineeringNo ratings yet

- Fucrerfttrt'Cq, Iffi: Order No.37Document7 pagesFucrerfttrt'Cq, Iffi: Order No.37Bala MuruganNo ratings yet

- CFT (Fi: Iil,'-I ( I Tirii RaDocument7 pagesCFT (Fi: Iil,'-I ( I Tirii RaBala MuruganNo ratings yet

- Guidelines On Welding ProcedureDocument9 pagesGuidelines On Welding ProcedureadelNo ratings yet

- Ur Z23rev6Document41 pagesUr Z23rev6Giancarlo Rivera LeonNo ratings yet

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDocument11 pagesIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnNo ratings yet

- 202011050340485982243DGS Order No 36 2020Document2 pages202011050340485982243DGS Order No 36 2020Bala MuruganNo ratings yet

- F (6arorfrtlrrd, Q,: FiflraDocument7 pagesF (6arorfrtlrrd, Q,: FiflraBala MuruganNo ratings yet

- 202010221057039565516DGS Order 31of2020 21102020Document5 pages202010221057039565516DGS Order 31of2020 21102020Bala MuruganNo ratings yet

- Din en 1563Document2 pagesDin en 1563Tayfun Tezanlar78% (9)

- Ur w35 PDFDocument5 pagesUr w35 PDFBala MuruganNo ratings yet

- GL Huyett EngineeringHandbookDocument95 pagesGL Huyett EngineeringHandbookSwetha PattelaNo ratings yet

- Longitudinal Stability, I.E. TrimDocument3 pagesLongitudinal Stability, I.E. TrimBala MuruganNo ratings yet

- NDMA India's Pocketbook of Do's and Don'ts For Various DisastersDocument118 pagesNDMA India's Pocketbook of Do's and Don'ts For Various DisastersNdma India100% (2)

- Angle of LollDocument5 pagesAngle of LollBala MuruganNo ratings yet

- MSC 338Document36 pagesMSC 338Jym GensonNo ratings yet

- Axial Momentum TheoryDocument4 pagesAxial Momentum TheoryBala MuruganNo ratings yet

- MS Notice 8 of 2013 - TowingDocument44 pagesMS Notice 8 of 2013 - TowingBala MuruganNo ratings yet

- MS Notice 3 of 2014 - Bunker Audit PDFDocument12 pagesMS Notice 3 of 2014 - Bunker Audit PDFBala MuruganNo ratings yet

- Mepc 279Document40 pagesMepc 279Bala MuruganNo ratings yet

- HKKJR LJDKJ Ikksr Ifjogu Ea Ky Uksogu Egkfuns'Kky SSTGKT Hkouþ Okypan Ghjkpan Ekxz EqacbzDocument4 pagesHKKJR LJDKJ Ikksr Ifjogu Ea Ky Uksogu Egkfuns'Kky SSTGKT Hkouþ Okypan Ghjkpan Ekxz EqacbzBala MuruganNo ratings yet

- Ship Hydrodynamics Lecture Notes Part 4 Propeller Basic Design3Document6 pagesShip Hydrodynamics Lecture Notes Part 4 Propeller Basic Design3MahdiNo ratings yet

- Dgsorder18 2013 BDocument92 pagesDgsorder18 2013 BVenugopal RajagopalNo ratings yet

- 201311180302415411728engcir6 2013 Solas A PDFDocument15 pages201311180302415411728engcir6 2013 Solas A PDFshajiNo ratings yet

- Axial Momentum TheoryDocument4 pagesAxial Momentum TheoryBala MuruganNo ratings yet

- Aluminium WeldingDocument3 pagesAluminium WeldingAgustine SetiawanNo ratings yet

- mc1696 PDFDocument4 pagesmc1696 PDFBala MuruganNo ratings yet

- Guidelines On Welding ProcedureDocument9 pagesGuidelines On Welding ProcedureadelNo ratings yet

- Shipbuilding Assistance PolicyDocument34 pagesShipbuilding Assistance PolicyBala MuruganNo ratings yet

- mc1696 PDFDocument4 pagesmc1696 PDFBala MuruganNo ratings yet

- 3.3 Motherboard SchematicsDocument49 pages3.3 Motherboard SchematicsJoanna WęgielNo ratings yet

- Procreate GuideDocument283 pagesProcreate GuideDiego D'Andrea100% (2)

- Social Studies Lesson Plan 3Document4 pagesSocial Studies Lesson Plan 3api-260708940No ratings yet

- BCSP GuideDocument44 pagesBCSP GuideCarol Sarmiento DelgadoNo ratings yet

- Past:: Simple Indefinite Continuous Perfect Perfect ContinuousDocument12 pagesPast:: Simple Indefinite Continuous Perfect Perfect ContinuousAhmed Abd El HafeezNo ratings yet

- Halftrack Track Chains InstructionsDocument4 pagesHalftrack Track Chains Instructionsddlevy0% (1)

- Nasser Al AmryDocument31 pagesNasser Al AmrymohamadNo ratings yet

- Gibbs VerBeek CorrespondenceDocument3 pagesGibbs VerBeek CorrespondenceWXMINo ratings yet

- FINAS A8 Riippumattomuuden Arv Finasin Toimperiaatteet enDocument2 pagesFINAS A8 Riippumattomuuden Arv Finasin Toimperiaatteet enMariam KhanNo ratings yet

- DLP1Document6 pagesDLP1Ben Joseph CapistranoNo ratings yet

- Gears DifferentialDocument13 pagesGears Differentialpulkitymcaust_112907100% (1)

- Gerry Mulligan DiscographyDocument491 pagesGerry Mulligan DiscographyIan SinclairNo ratings yet

- The Baldur's Gate Series 1 - Baldur GateDocument125 pagesThe Baldur's Gate Series 1 - Baldur GateJustin MooreNo ratings yet

- Maintenance of Building ComponentsDocument4 pagesMaintenance of Building ComponentsIZIMBANo ratings yet

- The Brand AuditDocument9 pagesThe Brand AuditRohit RoyNo ratings yet

- Romanian Association of Drilling Contractors ACFRDocument83 pagesRomanian Association of Drilling Contractors ACFRFuBasho33% (3)

- NS-3 With Ndnsim Patch - TutorialDocument8 pagesNS-3 With Ndnsim Patch - TutorialAli NawazNo ratings yet

- AX Performance Tools1Document21 pagesAX Performance Tools1Htun Lin AungNo ratings yet

- Isp-1730 OasDocument2 pagesIsp-1730 OasJaiNo ratings yet

- AAE Migration GuideDocument29 pagesAAE Migration GuideNguyen Hung0% (1)

- Aviation EbookDocument36 pagesAviation Ebookmeroka2000No ratings yet

- Europe MapDocument13 pagesEurope MapNguyên ĐỗNo ratings yet

- 14.victorian Era Inventions and Changes Pupils PDFDocument1 page14.victorian Era Inventions and Changes Pupils PDFSam FairireNo ratings yet

- Literature Review Topics RadiographyDocument8 pagesLiterature Review Topics Radiographyea7w32b0100% (1)

- Applications & Tools: Prevention of Overload Using "CPU - RT"Document22 pagesApplications & Tools: Prevention of Overload Using "CPU - RT"Jeronimo JeronimoNo ratings yet

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUNo ratings yet

- Oops MCQ (Unit-1)Document7 pagesOops MCQ (Unit-1)Jee Va Ps86% (14)

- 50 Studies Every Anesthesiologist Shoud Know 2019Document305 pages50 Studies Every Anesthesiologist Shoud Know 2019pcut100% (2)

- Turkish Verbs - Basics O'f Turkish Grammar IDocument27 pagesTurkish Verbs - Basics O'f Turkish Grammar IAzza BakhtiNo ratings yet

- Regulatory Guide 1.71Document5 pagesRegulatory Guide 1.71Siis IngenieriaNo ratings yet