Professional Documents

Culture Documents

Manual Depthometer PDF

Manual Depthometer PDF

Uploaded by

Hendra Jurbon0 ratings0% found this document useful (0 votes)

417 views11 pagesOriginal Title

Manual Depthometer.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

417 views11 pagesManual Depthometer PDF

Manual Depthometer PDF

Uploaded by

Hendra JurbonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

*

. CAVINS OILWELL TOOLS

A Division of Dawson Enterprises

2853 Cherry Ave.

Long Beach, Ca. 90806

TECHNICAL MANUAL

CAVINS DEPTHOMETER

WITH ILLUSTRATED PARTS LIST

ee i

wy

Lang Bowe CA 90808

, Pr (mm aan

Fax (82) 5559174

E BOLT HANGER

he safe handling of the Cavins

‘on rigs whore it impractical oF

Ps sand line or

Catlin from the rig lop. The hanger engages

the Depthometer in exactly the same manner

in which the floor stand is attached and sim-

pilfies the removal ofthe tool

CAVINS DEPTHOMETER

For Wire Line Well Measuring =~ cs

361

Ol WELL TOOLS

DEPTHOMETER WITH FLOORSTAND

“The Cavins Depthomoir has no cal for quick, accurate wire

line maacuroments of ol, gae and water wal, parteuary whee

perforating, ating, desning out swabbing, single shot er sen

fperatons has froven vshiato In both on-shore and oft hors

operations, This foo i also used for measuring armorud cable ee

submersible pumps, The Caving Depthomater has male “ong,

ing'in’ obsolete, and is berg adopted as standard equipment ey

reduction and welding operations. The Caving erie

Byalabe for 7A18*~ 5/6" OO. wie ines and Sf

The range for which the Depthometer is tobe used must be

spectied onthe ordor I the tol eto bo used for bolh anges,

sxira_main measuring wheo! can be supped, wich Gan’ fe

exchanged inthe ‘fold in afew minutes tine, Caving

Dapthometers are avallalefo:rcordng meesuroments in feotor

‘motors, They canbe supplied wih al onze bearing constuction

Modo BL" o all bai-bearng conection Modal “ets

‘When ordering, ploase state the fallewing information

ange of Wire Line size

Measuring in feet or meters

Model BL" Al Bronze Bearing ype

Model CL" Al Bal Bearing ype wn or witht

{eran case an stand or wh Caying Case

snd Hanger °

Each Cavins Depthometer bears a Model Number and Serial

Number. The range of size lines for which it is 9'be used is,

stamped on one spoke of tha main wheel. When ordering spare

parts please mention the Model, Serial Number and Wire Line

Shipping Weights and Measurements

Net Weight 38 Lbs. 18.3 Kg

Tare Woight 24 Ls, 10.9 Ke,

Gross Weigh! 80 Lbs 27.2 Ka

Export Shipping Case: 14°x 17" x21"= 29 Cu. —

36 x 43 x83 Gm, =.08 Cu, Meters,

Depthometers for special uire tine size re avaliable on application

Maximum Reading 999,295 Feat or 999,899 Meters.

Not Weight of Denthometer Onlyit Lbs 5.0 Kg.

DEPTHOMETER:

CARRYING CASE

The Cavins Depthometer

and Stand or Eye Bolt

‘ang2e can be supplied with

insinuent and especially ine

counler fom the elements

and provides a compact stor-

age place for complete

assombly,

ILLUSTRATED

seer’ | PARTS LIST

oe FOR MODELS “BL” & “CL

AGE 2 5

1

+

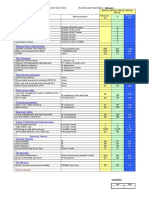

Cavins Modes "BL" & “CL Dephomte pane (fer wasuing in FEET on)

Pan Nome Descigion Sat | ree

sod Fama 1] $3606]

MINO-THSTORA | Maia wie pam wana | 2540

SRO gi8 | Mi wed ssa eda CL i 37500)

Na z 700

301 ig wel es, ode BL z St

CORT Til-wil as adel CL 2 #509

Ma lean apn = 300

100500 Geutar h ger a

Mata Cauterguard 1 260

Mast Foe Sanda 1 1500]

Na Eye to ge 588

MODEL "BL"

cavins

; DEPTHOMETER, PARTS LIST oe

# THe co, 4000

Bronze Bearing Type raceme

FOR ASSEMBLIES MBL500, MBL.800-H,OR

MBL-500-1. MEASUREMENT IN FEET

PART NO. PART NAME. eae ee WEIGHT

MIDE FRAME ASSEMBLY ONLY 7 i

Includes:

Net00-1_ | __Adapur Pin fr Stand or Hanger 2 Hox,

ine6 MAIN WHEEL ASSEMBLY — COMPLETE 1 ibe.

bes {Stand anges 716" 5/8" er 314" 1" 0.0,

Wire Line, Pest Spat! 2

onaing of pest |

2003 "| “tan Whee Sub-Avsembly 1 Piss aon

Ince :

11314200: aia Wel ‘ 1 11 49

(01101 lon . 1 Tie 2on

(11202 Dring Gear 1 tor

M203. Gronra Bushing 1 Thor,

208 See Spc 1 ten

205 ap Soren — 2" ong) 1 wen

M26 HoxNoe 4 no,

ina TOLER ARH ASSEMBLY ~ COMPLETE 2 7 Ties

Conseon of pars 7

wea003 | lec Arm Sub-Astombly 1 Son,

thelude:

13004 lor Acre 1 10 Sm

1308 ler Arm Basing 1 . tes,

moa later Arm Spring 1 Von

30a alex ar Cap Screws ' ton

304 lder Arr Cap Serv Nut 1 so.

M05 fale Arm Whar i oe

W302 TOLEA WHEEL ASSENSLY — COMPLETE cae ea Pon

Consisting of pr

M3013, | Ider Wheel Sub-Assembly | Thor

core

M304 tae Wet 1 bon

14.203 Bronze Buching : vio,

mace | suatsoncer 1 tox

4205 Hoenut 1 nos,

M207 sp Sree 2" ton! 1 on

aco (GIgOUNTER ASSeMsLY — COMPLETE 1 Bib th of

soot] Count tat Soo jae ib. 12%

‘rota |

i. NAOT Counter Gear 1 tex

M06 Plastic Reet Knob for Counter 1 ‘een

Counter Quart 1 Bon

Machine Beret (/8" long) 2 ‘san.

Mechine Screw (3/4 tng) 2 fon

Hox nue 4 vor.

Lock Washer ‘ hoe

"IANO ASSEMBLY COMPLETE a4 Tae

Foor Plate Asem

Soring Fork Asser |

Entention Tbe Race

(1). Main Wheels

{posi Laver to inatll il be added to sure. (See Deprnomater Section 4000, Pope tha,

(21 Oationa Sex Depthomster Saction 4000, F

8 for dsaie)

(31 For conversion of ebtlete Modele "8 o¢

Wiiaaesodne edna oy

Sale

i)

apthoratert a Large Counters pease rater to Section 4000, Poses 19-15

Fma.and Ouiving Gsors should not be ordred sepratly nists Main Wheel Assemoties canbe returned to the factory for

cavins | TECHNICAL DATA &

i i m1

a DerTHoweTER | Operating Instructions} °°!’

oe 0 4000

Fon moves “BL &“cL” | ace 4,

‘The CAVINS Depthomefer is on INSTRUMENT for the purpose of doing ewoy with the hand method of “stringing-in””

When moking depth measurements with sand lines or drilling lines. It is porticularly valuable in connection with

cleaning out, bailing, swabbing, single-shot surveys and similar work where send lines ot drilling lines are weed

Observe the following recommendations carefully:

1, With o,tope line, measure the length of the boiler, swab, eter, which Is to be run. The free end of the tape may

be tied on the line at ony convenient point above the ropa socket or bail.

2. Lower the tools into the well UNTIL THE POINT AT WHICH THE TAPE LINE HAS BEEN TIED COMES To

THE WELL HEAD. This Is your starting point, no matter how for above the well hecd you place the Denthone,

ter It registers only the emount of line thet passes through IY.

3. Set the counter dials to zero by pressing in on the wing nut ond then turning toward yourself until all diols show

zero, Release the wing nut ond it will spring outwardly of its own eceord. DONOT TRY TO FORCE THE

TURNING OF THE RESET WING NUT ELTHER BY HAND OR WITH PLIERS, AS THIS WILL ONLY RESULT.

IN BREAKING OR DISLOCATING THE GEARING INSIDE THE COUNTER.

4. After the counter has been reset, 30 that oll dials show se10, revelve the moin wheal by hand in o fafward direc:

Hon until the counter registers the some as the length of the tools as measured by the tape line.

5. Attach the Depthometer to the line by engaging the lower Idler wheel with the line end then tipping the Deptho-

Meter sidewoys to engage the top idler, 4

& When using the Stond to mount the Depthometer, screw pipe nipples into the base plate, using ax many os ore

required to give sufficient height to clear the well head. Screw the forked spring am essembly Into the top ni

ple. Next, spread the forked spring arms opart and place the Depthometer between the open ends xe that the

Fins on both sides of the frame extend through the holes in the forked spring, thus supporting the Degtheme ex

7. In place of the Stand cssembly an Eye Bolt Hanger exsembly me

forked Soring Arm assembly. Next spread the fork

open ends se thet the plas on both sides of

be used. Screw the Eye Bolt Honger inte the

d Spring Arms sper? ond place the Depthometer between the

2 frame extend through the holes in the forked spring.

8. The stond should be inclined ot about a 45° ongle. This keeps the weight of the Depthometer agoinst the line

snd helps the idler wheel springs in keeping good traction against the line. DO NOT HOLD ON TO THE DEP-

THOMETER WITH YOUR HAND WHILE IT 1S BEING RUN. “IF you do, you will only succeed in causing o lozs

of traction between the tool and the line, which will result in a faulty measueement.. Furthermore, it may couse

‘an accident.

9. Yau ete now ready to lower the tools into the well and make the line measurement. This should be done with

goed degree of caution. HOLD THE LINE SPEED WITHIN 200 FEET TO 300 FEET PER MINUTE. IF YOU

“RUN FASTER THAN THIS YOU WILL CAUSE A CERTAIN AMOUNT OF SLIPPAGE WHICH WILL GIVE YOU A

WRONG READING. If your hoisting equipment will permit it, on excellent way to feed the line off ef the dium

evenly is to de it In reverse geor. This prevents line whip end losh which connct be avetdes

foulty or the dums out of round. (1-2 FT/1000 FT) Tolerance

Jo. IN ALL PROBABILITY YOU WILL NOT BE ABLE TO MAKE THE DEPTHOMETER CHECK IN AND OUT TO

ZERO. When tools re being withicawn from the well, the line is under graster tension thon whee the foals sre

bing lowered into the well. Consequently, the line is actually stretched wheh pulled ram the well. A number

af things tend fo act onthe degree of stresch; such ea the omoust and govityof eval ad Weee ohn al

Jeoth speed of withdrowal, wc. IF IT HAS BEEN YOUR PRACTICE TO “STRINGIN™, THEN YOU SHOULD

TREWISE “MEASURE-IN" THE WELL WITH THE DEPTHOMET ER

The size of the Lina for which the wain wheel hos been calibrated is stomped on one of the mein wheel’spokes. »

le THIS STAMPING READS 7/16" 5/8"", DO NOT EXPECT A GOOD MEASUREMENT IF YOU ARE USING IT

ON 3/4!"— 1" LINES, AND VICE VERSA.

THE CAVING COMPANY

Son

TECHNICAL DATA

seevio’ | & Operating Instructions

000°

: FOR MODELS "BL" a “CL”

PAGE 12

a

12, NEVER |MWERSE THE DEPTHOMETER IN SOLVENT, ETC., TO CLEAN IT, Solvents con enter the counter

case ond damage its mechanism. ‘The counter case and cover will keep out ell fluids that may baceme slashed

» When you hava finished with the Depthometer, wipe It eff with a reg and solvent

ALWAYS TREAT (T LIKE AN INSTRUMENT. Do not allow wax, or other foreign

to accumulate in the freme behind the main wher

13. 4 wear on the idler wheels, os well as fotigue of the tension springs, tends to loosen pressure of the

main wheel ogcinst the line, and if ellowed to progress too fer, can result in slippage. In lieu of ordering

ldler wheels or springs, this slackening of prasaure con be compenscted for by untestaning the

from the hole in the idler arm and moving it out fo the second hole which hes been drilled th

14. From time fo time pour « little lubricating ofl on the Idler wheel and main wheel bolt.

Remember, the Dapthometer ix designed to take the place of “etringing-in'". If for any reson you doubt the

1d by the Depthometer and wish to check it agsinst enother stondurd of mecaurement, then

inging-in" fob, but be sure the "'stringing-in" job is © good one, carefully

the ure of « good steal tape ling in “mecsuring-over

Blocking, or locking, of a spring hook aginst the tea

ts hung on the hoak. {t ix-not intended to com

ments, but it will consistently giv> you m

" for such operations ax bailing, clean

Ing line operations.

pipe, casing, of

a

id fo

‘thon you will get by “"

ot similar send line ond

in the Idler wheels ond in the moin measuring

se sealed boll beorings in the idler wheels ond in the main mecsuring wheel.

for Depthomet alibroted t9 meosure on wire lines from 7/1

snd will be so fumtshed ualees otherwise specified

nd including 5/8" diameter

4: If the instrument is wanted for use on wire fines from 3/4" to and including 1!" diometer, this Information should

be given in your inguity or purchase order s0 that we mey supply the proper main wheel. Main wheels calibrated

for one ronge of line sizes will not give satisfactory results when used on enother range al line sizes. Mein

wheels ore built to order for ameller wire line sizes than 7/16” 0.0. and leryer than 1" OD.

All Moin wheels ore interchangeable in the Depthometar frames, 40 that if the tool is used fer both sand lin

ad drilling linea, only one extra main whee! Assembly complete need be ordered,

6. Model ""BUand Hodel"'CL'' Depthometers are available for meosuting in feet & meters.

INSTRUCTIONS FOR ORDERING THE DEPTHOMETER

‘The standord Depthometer Is designed to meosure 7/16""— 5/8" inclusive tond

otherwise, this size renga will be supplied. If the Depthome

3/4" 1", this should be specified on your order, Some u!

Hinge end an axtcs main wheel for the lorger

tall the offer.

send

arning Depthsnetars which have

ake.

and line sia don the mela whee

This information should be fureished at time

record measurements in me!

+ if the Depthometer Ia fo be used for thot purpos

caviNs

ogPTHOMETER

MODEL “CL”

PARTS LIST

11 Maa Wels Rims, and Oriving Geant should not be ordered

fepais. Lator to istal wil be ad

“HIEVE SOUT WANGER.

(2) Opttonal.(S4e Deothometer Section 4000, Pope 9 for desis

{31 For conversion f obsolete Mesels"B” or "C™ Depthometers to Large Counters, plas refer to Section 4000, Pages 13418

perce oi gevouiy ue pg intgrmatin,

a HE co. oe

fe Ball Bearing Type leace 7

: FOR ASSEMBLIES MCL-500, Mct-S00-H

(OF MCL.500-1. MEASUREMENT IN FEET!

:

isteace] 49,

vant No, pant Nawe TERE] AS | wane

TT0E | FRAME ABEL GALT i Tin

A Toc:

T mtn Adapter Pin for Stand or Hanger = 2 ox

e200 | AWN WwEL ASSENDLY ~ COMPLETE 7 Tiber

ee | MStnded Reng 110 ieee 910,

ire Ui, Po Specie

contstog otras

meas | “tani Anembiy 1 2s. shoe

fees

(1) MC-2001 Main Wheel 1 1b, tor

(hier Bie : ceva

(hmg02 Bing oe ' et

fio202 Bal pean 2 Mee

MeO Stel ane’ or Ua Geange : te

wwc2061 | andere su easy : He

taker

E205" cap Seo 212" ng) 1 noe

YSazt_ Gree Fria i ker

08 ents cuales ner

waco IDLER ARI ABSEWBLY = COWPLETE ies Wier

Contigo pare :

3003 dag Am Bul"Anenbly ‘ ae

tro

Woe tr Arm : ce

M306 Idler Arm Bushing + a Jaz.

soz ter arm Spring : ie

ed toe Arm Cap Sere : ee

hace Ie A Cap Ser Nat ; ve

ieise ter Am owes : ee

W7e9012 | TOLER WHEEL ASSEMBLY — COMPLETE 2 Ber

Conon peer

wcaesa | sir tne StrAsemsy 1 Tho

tnd

MeGOT itecvheet + , Pee.

Neos bl aeinge 2 ton

Neo Sel Sone’ Yor Bal ering ; i

1.200 tector i wee

haaers | Gasser Sub-uemy : tee

ircuare

E207 cap Sci 2" tora) 1 ton

Feta _ Grows ne i ce

WRG. —)— BI COUNTER Assen COMPLETE i Tike Wie

Const ofan

wsoos | "Baume a ae : 1h 12% 00

ica |

ae ci :

oe. Plan Ret Knob for Cou :

moa. | Goumereeet : |

M-403-L, Machine Serew 15/3" tony? ae |

wate | Meche Sore Flat 2

tani | feenwe :

waret | Usiewne #

450, ‘STAND ASSEMBLY — COMPLETE. ee ‘2 Ibs,

az | SRR f 2

Sere i BR se

pee ey i Hs

‘separa unless Man Wheel Assembles can be returned 10 the factory for

ed 10 he part. See Depthometr Section 400. Pay tor deta |

AI ist orcas are F.0.8.fsefOw, Lona Baseh, Caitorni, US.A.

TECHNICAL DATA

sgerion

4000 MODELS “BL & “CL?

PAGE 10 BEARING CONSTRUCTION

: ane weet Me-200

MAIN WHEEL m-200

Steet SPACER M204

, FRAME s-109-.

nur-nao nur n206 g

sour M205

BALL AEARING

MG-203

Ne tiaa

MODEL “BL”

IDLER WHEEL ASSEMBLY

Modalae

sree.

SPACER M

MODEL “cL

ee

IDLER WHEEL Assemacy

medel"ee

(e-208

Ao can

Sehew

e-n0s

Grease

Fitine

8123

Fi

GEAR N-202

© 2

THE co.

GUARD Wi

CAVING

DEPTHOMETER

INSTRU

FOR MODELS “B™ & "CO"

ITH LARGE COUNTER UNIT.

CONVERSION

ICTIONS

REPLACEMENT OF SMALL COUNTER AND COUNTER

ASSEMBLY INSTRUCTIONS FOR MOUNTING COUNTER

7 REPLACEMENT UNIT TO CAVINS DEPTHOMETER

The larger sized counter replacement unit for the CAVIN:

ment for accurate wire

counter to the larger counter takes but a

special tools.

Sives you greater readability and provides you with a pi

line measurement. The changeovei

STEP 1:

Remove four existin

nuts from the depthoneter counter

STEP 2

S Depthometer

reciston instru-

r from the smaller

few minutes and requires no

and remove cover,

3

SECTION

4000

PAGE 13

@ counter COVER mounting screws and

Remove four existing counter BODY nomting screva from

the depthometer coumter and remove old counter wit,

STEP 3:

The new replacement counter unit has been factory assem

bled and includes:

© Adapter Plate

® Counter Guard

® Counter Assen

Insere gear end of counter into

frame and engage couter drive g

on the main wheel in the Depthom

.

port hole in Depth

ear with the matin

jeter housing.

ig gear

SEGTION

4000

PAGE 14

CONVERSION

INSTRUCTIONS

STEP 4:

The four (4) stud serews extending from the bottom of the

Feplacement counter assenbly will be in true alignnent

with the four inboard screw holes in the couter shelf of

the depthoneter. Insert the studs thru the four holes ead

secure with nuts provided, Sea step 5 before tightening.

STEP 5:

Bafore tightening nuts, check the mating alignment of the

counter shaft gear with the fixed position drive gear in

the depthometer housing. Tura the main wheel by hand

to determine perfect running alignment. Tighten nuts.

THe depthometer {3 now ready for continued operation.

SEER 6: (For Model "c" Depthometer Conversion Only)

ipplied with each Conversion

A 45° Angular Grease Fitting is su

n_conversion of the

Assembly and should he used as foll

Model "C" (Ball Bearing Type) Depthometer only.

© Remove bolt from Main Wheel and remove strai

Fitting.

through Main Wheel in Frame and

Fitting to facillitate easy use

© Re-insert bole

position Grease

: of grease gun.

eavus | COUNTER cane

veernoveres | CONVERSION

3 tHe co, ac)

s ~ FOR MODELS "B @ “CG” PAGE IE

a

EP RO: 5

~ PART NO PART WE Uist FE TRO] _weant

y H410-L COUNTER COAVERSION ASSEMBLY. L ‘ibs. 10s oz.

Complete - For Model "3" or "c"

c Depthoneter measuring in FEET

Consisting of parts: :

M-400-1-L | Counter with Gear < Ab. 12% oz.

M-402-L | Counter Guard 1 a oz.

1404 Hex Nat 8

w-to7- | Adapter Piate 1 6 oz.

M-408-L 45° angular Grease Fitting L 4g on.

Huot | Lock Washer 4

Neilic | Machine Serew 3

ms10-L | COUNTER conVERStON ASSEMBLY 1 |2 tbe. 13°02,

Complete for Model "5" or "c"'

Depthoaeter measuring in METERS

Consisting of parts: i

W0400-1-] Counter with Gear 1 | 2 te.

u-4o2-L | counter Guard i 8 oz.

2404 ex Nur 8

wesoet | Adapter Plate 1 6 oz.

408-1 | 45° angular Grease Fitting s Ss oz,

N-409-L | Lock Washer 4

wallet | achine Screw 8

M-408-L Grease Fitcing

M-411-L Machine Screws

M-409-L Lock Washer

M-404 Hex Nut

M40!

Cobats

Guard

¥-400-I-L Counter with Gear

\"ssparcae ail previously Fayed ie inomtion,

AN tories ne FO) Rtas Vann Base Palitrenin S.A.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aps - ADocument3 pagesAps - AHendra JurbonNo ratings yet

- Drops Object (Rev.3!04!06)Document21 pagesDrops Object (Rev.3!04!06)Hendra JurbonNo ratings yet

- Panduan Lengkap Budidaya Ikan LeleDocument8 pagesPanduan Lengkap Budidaya Ikan LeleHendra Jurbon0% (1)

- Mempersiapkan Air Untuk Ternak Lele Dengan System BioflokDocument7 pagesMempersiapkan Air Untuk Ternak Lele Dengan System BioflokHendra JurbonNo ratings yet

- Resep Masakan NusantaraDocument8 pagesResep Masakan NusantaraHendra JurbonNo ratings yet

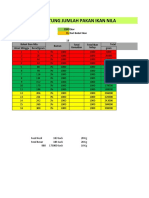

- Perhitungan Pakan Ikan NilaDocument2 pagesPerhitungan Pakan Ikan NilaHendra Jurbon100% (2)

- Perhitungan Dasar Well ControlDocument6 pagesPerhitungan Dasar Well ControlHendra JurbonNo ratings yet

- Manual Rod TongDocument31 pagesManual Rod TongHendra JurbonNo ratings yet

- Highland Hotel: MR Rio Molex Butar Butar SPRTDocument6 pagesHighland Hotel: MR Rio Molex Butar Butar SPRTHendra JurbonNo ratings yet

- Manual DepthometerDocument11 pagesManual DepthometerHendra JurbonNo ratings yet

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Soal-Soal Maintenance TransmisiDocument2 pagesSoal-Soal Maintenance TransmisiHendra JurbonNo ratings yet

- Manual TransmissionDocument31 pagesManual TransmissionHendra Jurbon100% (1)

- Form Pengambilan Hand Glove: PT - SpaDocument8 pagesForm Pengambilan Hand Glove: PT - SpaHendra JurbonNo ratings yet

- KOROSIDocument22 pagesKOROSIHendra JurbonNo ratings yet

- NWW BP - Spa Metric Rig 07Document3 pagesNWW BP - Spa Metric Rig 07Hendra JurbonNo ratings yet