Professional Documents

Culture Documents

Low Temperature Operation: UG-20 (F) Figure UCS-66 UCS Figure UCS-66 UG-20

Uploaded by

CITRIX0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

UCS-56_2020_21

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageLow Temperature Operation: UG-20 (F) Figure UCS-66 UCS Figure UCS-66 UG-20

Uploaded by

CITRIXCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ASME BPVC.VIII.

1-2019 UCS-57 – UCS-66

Table UCS-56.1 LOW TEMPERATURE OPERATION

Alternative Postweld Heat Treatment UCS-65 SCOPE

Requirements for Carbon and Low Alloy The following paragraphs contain requirements for

Steels vessels and vessel parts constructed of carbon and low al-

Decrease in loy steels with respect to minimum design metal

Temperature Below temperatures.

Minimum Specified Minimum Holding Time

Temperature, [Note (1)] at Decreased UCS-66 MATERIALS ð19Þ

°F (°C) Temperature, hr Notes

(a) Unless exempted by the rules of UG-20(f) or other

50 (28) 2 …

100 (56) 4 … rules of this Division, Figure UCS-66 shall be used to es-

150 (83) 10 (2) tablish impact testing exemptions for steels listed in Part

200 (111) 20 (2) UCS. When Figure UCS-66 is used, impact testing is re-

quired for a combination of minimum design metal tem-

GENERAL NOTE: Applicable only when permitted in Tables

--`,``,``,,`,`,,````,`,``,,,`-`-`,,`,,`,`,,`---

perature (see UG-20) and governing thickness (as

UCS-56-1 through UCS-56-11.

defined below) that is below the curve assigned to the

NOTES: subject material. If a minimum design metal temperature

(1) Minimum holding time for 1 in. (25 mm) thickness or less. Add and governing thickness combination is on or above the

15 min per inch (25 mm) of thickness for thicknesses greater

curve, impact testing is not required by the rules of this

than 1 in. (25 mm).

(2) These lower postweld heat treatment temperatures permitted Division, except as required by (j) below and

only for P‐No. 1 Gr. Nos. 1 and 2 materials. UCS-67(a)(3) for weld metal. Components, such as shells,

heads, nozzles, manways, reinforcing pads, flanges, tube-

sheets, flat cover plates, backing strips which remain in

place, and attachments which are essential to the struc-

UCS-57 RADIOGRAPHIC EXAMINATION tural integrity of the vessel when welded to

In addition to the requirements of UW-11, complete pressure-retaining components, shall be treated as sepa-

radiographic examination is required for each butt- rate components. Each component shall be evaluated for

welded joint at which the thinner of the plate or vessel impact test requirements based on its individual material

wall thicknesses at the welded joint exceeds the thickness classification, governing thickness as defined in (1) and

limit above which full radiography is required in Table (2) below, and the minimum design metal temperature.

UCS-57. (1) The following governing thickness definitions ap-

ply when using Figure UCS-66:

(-a) Excluding castings, the governing thickness tg

of a welded part is as follows:

(-1) for butt joints except those in flat heads and

tubesheets, the nominal thickness of the thickest welded

Table UCS-57 joint [see Figure UCS-66.3, sketch (a)].

Thickness Above Which Full Radiographic (-2) for corner, fillet, or lap-welded joints, in-

Examination of Butt-Welded Joints Is cluding attachments as defined above, the thinner of the

Mandatory two parts joined.

(-3) for flat heads or tubesheets, the larger of

Nominal Thickness Above (-2) above or the flat component thickness divided by 4.

Which Butt-Welded Joints Shall (-4) for welded assemblies comprised of more

P‐No. and Group No. Be Fully Radiographed,

than two components (e.g., nozzle‐to‐shell joint with rein-

Classification of Material in. (mm)

forcing pad), the governing thickness and permissible

1 Gr. 1, 2, 3 11/4 (32)

3 Gr. 1, 2, 3 3

/4 (19)

minimum design metal temperature of each of the indivi-

4 Gr. 1, 2 5

/8 (16) dual welded joints of the assembly shall be determined,

5A Gr. 1, 2 0 (0) and the warmest of the minimum design metal tempera-

5B Gr. 1 0 (0) tures shall be used as the permissible minimum design

5C Gr. 1 0 (0) metal temperature of the welded assembly. [See Figure

15E, Gr. 1 0 (0) UCS-66.3, sketch (b).]

9A Gr. 1 5

/8 (16) (-5) if the governing thickness at any welded

5

9B Gr. 1 /8 (16) joint exceeds 4 in. (100 mm) and the minimum design me-

3

10A Gr. 1 /4 (19) tal temperature is colder than 120°F (50°C), impact tested

5

10B Gr. 1 /8 (16) material shall be used.

5

10C Gr. 1 /8 (16)

(-b) The governing thickness of a casting shall be

its largest nominal thickness.

181

Licensee=Khalda Petroleum/5986215001, User=Amer, Mohamed

No reproduction or networking permitted without license from IHS Not for Resale, 07/02/2019 13:29:04 MDT

You might also like

- Low Temperature Operation: UG-20 (F) Figure UCS-66 UCS Figure UCS-66 UG-20Document3 pagesLow Temperature Operation: UG-20 (F) Figure UCS-66 UCS Figure UCS-66 UG-20CITRIXNo ratings yet

- Ucs-66 MDMTDocument14 pagesUcs-66 MDMTravi2007No ratings yet

- Asme Viii 1 - PWHT PDFDocument1 pageAsme Viii 1 - PWHT PDFGANGADHAR SAHUNo ratings yet

- Ma App 29Document3 pagesMa App 29ahmedNo ratings yet

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Ucs 66Document17 pagesUcs 66Pratik DhuriNo ratings yet

- (Third Revision) : Use of Structural Steel in Overhead Transmission Line Towers - Code of PracticeDocument16 pages(Third Revision) : Use of Structural Steel in Overhead Transmission Line Towers - Code of PracticeSaumendra RoyNo ratings yet

- Sec Viii D1 Ma App 27Document2 pagesSec Viii D1 Ma App 27fermin.ortueta183No ratings yet

- Compass Vol 43 Impact Testing Exemption For A 105 Forged Steel FLangesDocument7 pagesCompass Vol 43 Impact Testing Exemption For A 105 Forged Steel FLangesLucas GarletNo ratings yet

- Astm B446Document5 pagesAstm B446MaxNo ratings yet

- Is 802 (Part 1/sec 2) : 1992Document14 pagesIs 802 (Part 1/sec 2) : 1992ced32820% (1)

- M 269Document11 pagesM 269Katerin HernandezNo ratings yet

- Should PQR Be Impact Tested-Should There Be Production Test Coupon Decision ChartDocument8 pagesShould PQR Be Impact Tested-Should There Be Production Test Coupon Decision Chartwholenumber100% (1)

- SEISMIC and NUCLEAR ENCLOSURES IEC60721-2-6 FIGURE 5Document2 pagesSEISMIC and NUCLEAR ENCLOSURES IEC60721-2-6 FIGURE 5ericNo ratings yet

- 7452Document12 pages7452wonderskiranNo ratings yet

- Coldrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (Document7 pagesColdrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (VivekNo ratings yet

- Guide for ASME Audit SectionsDocument1 pageGuide for ASME Audit Sectionsanon_673643629No ratings yet

- 071973C - Tabulation FormDocument6 pages071973C - Tabulation Formtrija_mrNo ratings yet

- PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018Document1 pagePV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018GOWTHAMNo ratings yet

- New Compact 72.5kV Gas-Insulated SwitchgearDocument5 pagesNew Compact 72.5kV Gas-Insulated SwitchgearNur FajarNo ratings yet

- 802 1 2 OhtrlinesDocument14 pages802 1 2 Ohtrlinessuman sharmaNo ratings yet

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Document4 pagesTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalNo ratings yet

- Astm A352-A352m-06-1Document5 pagesAstm A352-A352m-06-1Kishor JadhavNo ratings yet

- Use of Structural Steel in Overhead Transmission Line Towers - Code of PracticeDocument14 pagesUse of Structural Steel in Overhead Transmission Line Towers - Code of Practicegaurav singhNo ratings yet

- Is 802 Part1 Sec2Document14 pagesIs 802 Part1 Sec2Yadneshwar JoshiNo ratings yet

- AISI 1035 cs46Document2 pagesAISI 1035 cs46Russell ShacklefordNo ratings yet

- SB 241Document24 pagesSB 241JolettitoNo ratings yet

- Modu Notice 2Document54 pagesModu Notice 2Marco CordonNo ratings yet

- Uha 32-2Document1 pageUha 32-2Lipika GayenNo ratings yet

- Alloy 6022 Sheet: Higher Strength With Improved FormabilityDocument6 pagesAlloy 6022 Sheet: Higher Strength With Improved Formabilitywulfgang66No ratings yet

- Is 2372 - 2021Document10 pagesIs 2372 - 2021Mehul BansalNo ratings yet

- Astm 653Document13 pagesAstm 653Alejandro Garza100% (1)

- FV/PLS: SR2.2 Screws of Strength ClassesDocument13 pagesFV/PLS: SR2.2 Screws of Strength ClassesinspecaodaqualidadeNo ratings yet

- Sfa 5.21Document24 pagesSfa 5.21Luis Evangelista Moura Pacheco0% (1)

- Thuyet Minh PDFDocument62 pagesThuyet Minh PDFNguyen Duc CuongNo ratings yet

- UCS-66 Materials Impact Testing Exemption CriteriaDocument6 pagesUCS-66 Materials Impact Testing Exemption Criteriamuhammad hadiNo ratings yet

- Electroced LB52Document1 pageElectroced LB52ramadh diyyazNo ratings yet

- IS 7098 (Part-2) - 2011 - Up To Amdmnt-2Document30 pagesIS 7098 (Part-2) - 2011 - Up To Amdmnt-2ricky100% (1)

- CODE SummaryDocument17 pagesCODE Summarysobhym453No ratings yet

- Asme Section Ii A Sa-352 Sa-352m PDFDocument8 pagesAsme Section Ii A Sa-352 Sa-352m PDFdavid perezNo ratings yet

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDocument7 pagesSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceNuNo ratings yet

- Abstract of ASTM A320 A320M 2000Document10 pagesAbstract of ASTM A320 A320M 2000Jesse ChenNo ratings yet

- Convbyorandelevatortextile Belting-Specification ': &TV @%VTDocument9 pagesConvbyorandelevatortextile Belting-Specification ': &TV @%VTToufik KarimNo ratings yet

- Figure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66Document2 pagesFigure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66MechanicalNo ratings yet

- Asme Section Ii A-2 Sa-736 Sa-736mDocument6 pagesAsme Section Ii A-2 Sa-736 Sa-736mdavid perezNo ratings yet

- B 101 - 01 Qjewms1sruqDocument7 pagesB 101 - 01 Qjewms1sruqFadjar ZulkarnainNo ratings yet

- Cooling Tower NozzlesDocument4 pagesCooling Tower NozzlesBilly MakoyNo ratings yet

- Permissible Stresses in Concrete and Steel Reinforcement (IS 456Document3 pagesPermissible Stresses in Concrete and Steel Reinforcement (IS 456Design TDLCCS0% (1)

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- VESSEL DESIGN AND STRESS ANALYSIS DUE TO NOZZLE CHANGEDocument5 pagesVESSEL DESIGN AND STRESS ANALYSIS DUE TO NOZZLE CHANGEToniNo ratings yet

- 242.0 and A242.0 : Casting Alloys With High-Temperature StrengthDocument3 pages242.0 and A242.0 : Casting Alloys With High-Temperature Strengthmanjunath k sNo ratings yet

- Design Calculations For Pressure VesselsDocument51 pagesDesign Calculations For Pressure VesselsFuehrerNo ratings yet

- Astm B446-08Document5 pagesAstm B446-08Srinivasan KrishnamoorthyNo ratings yet

- Sheet Over 2 Slab Span - L - 130Document4 pagesSheet Over 2 Slab Span - L - 130Ganeshalingam Ramprasanna3No ratings yet

- A 320 Â " A 320M Â " 02 - QTMYMC9BMZIWTS1SRUQDocument10 pagesA 320 Â " A 320M Â " 02 - QTMYMC9BMZIWTS1SRUQhNo ratings yet

- Technical Specification of Lattice Steel PolesDocument9 pagesTechnical Specification of Lattice Steel PolesCalinB.ACNo ratings yet

- DC Motors, Speed Controls, Servo Systems: An Engineering HandbookFrom EverandDC Motors, Speed Controls, Servo Systems: An Engineering HandbookRating: 5 out of 5 stars5/5 (3)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Efficient LightingDocument1 pageEfficient LightingCITRIXNo ratings yet

- Efficient LightingDocument1 pageEfficient LightingCITRIXNo ratings yet

- Efficient LightingDocument1 pageEfficient LightingCITRIXNo ratings yet

- Recommended Practice For Lightning Protection of Aboveground Storage Tanks For Flammable or Combustible LiquidsDocument1 pageRecommended Practice For Lightning Protection of Aboveground Storage Tanks For Flammable or Combustible LiquidsCITRIXNo ratings yet

- Efficient LightingDocument1 pageEfficient LightingCITRIXNo ratings yet

- Pages From ASME - BPVC - 2013-Brochure-4Document1 pagePages From ASME - BPVC - 2013-Brochure-4CITRIXNo ratings yet

- 3 Terms and DefinitionsDocument1 page3 Terms and DefinitionsCITRIXNo ratings yet

- Efficient LightingDocument1 pageEfficient LightingCITRIXNo ratings yet

- ASME's Boiler and Pressure Vessel Code certification packagesDocument1 pageASME's Boiler and Pressure Vessel Code certification packagesCITRIXNo ratings yet

- RereDocument1 pageRereCITRIXNo ratings yet

- DgnemDocument2 pagesDgnememiliNo ratings yet

- Pages From TAC - 7 PDFDocument1 pagePages From TAC - 7 PDFCITRIXNo ratings yet

- Pages From ASME - BPVC - 2013-Brochure-3Document1 pagePages From ASME - BPVC - 2013-Brochure-3CITRIXNo ratings yet

- ForewordDocument1 pageForewordCITRIXNo ratings yet

- Pages From TAC - 7 PDFDocument1 pagePages From TAC - 7 PDFCITRIXNo ratings yet

- Pages From The Art of Thinking Clearly-4Document1 pagePages From The Art of Thinking Clearly-4CITRIXNo ratings yet

- Pages From ASME - BPVC - 2013-BrochureDocument1 pagePages From ASME - BPVC - 2013-BrochureCITRIXNo ratings yet

- How the Availability Bias Leads to Poor DecisionsDocument1 pageHow the Availability Bias Leads to Poor DecisionsCITRIXNo ratings yet

- Pages From TAC - 7 PDFDocument1 pagePages From TAC - 7 PDFCITRIXNo ratings yet

- Pages From TAC - 11Document1 pagePages From TAC - 11CITRIXNo ratings yet

- How Social Proof Can Lead Us AstrayDocument2 pagesHow Social Proof Can Lead Us AstrayCITRIXNo ratings yet

- Pages From TAC - 6Document1 pagePages From TAC - 6CITRIXNo ratings yet

- Pages From TAC - 7 PDFDocument1 pagePages From TAC - 7 PDFCITRIXNo ratings yet

- Pages From The Art of Thinking 1Document1 pagePages From The Art of Thinking 1CITRIXNo ratings yet

- Pages From TAC - 7 PDFDocument1 pagePages From TAC - 7 PDFCITRIXNo ratings yet

- Pages From TAC - 4Document3 pagesPages From TAC - 4CITRIXNo ratings yet

- See Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)Document1 pageSee Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)CITRIXNo ratings yet

- ArtofyDocument3 pagesArtofyCITRIXNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Survivorship Bias Can Become Especially Pernicious When You Become ADocument1 pageSurvivorship Bias Can Become Especially Pernicious When You Become ACITRIXNo ratings yet

- Dezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bDocument12 pagesDezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bOleg ShkolnikNo ratings yet

- Spec - 2017-02 - A00 SHOP AND FIELD PRESSURE TESTING OF PIPING SYSTEMSDocument30 pagesSpec - 2017-02 - A00 SHOP AND FIELD PRESSURE TESTING OF PIPING SYSTEMSAL Rajhi Zakaria67% (3)

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Schedule of Finishes 20190523 PDFDocument10 pagesSchedule of Finishes 20190523 PDFMuhammad Farhan GulNo ratings yet

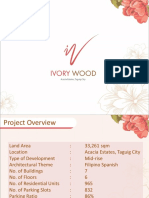

- IVW Ivory Wood Project BriefDocument72 pagesIVW Ivory Wood Project BriefJ SalesNo ratings yet

- NASM21472: National Aerospace StandardDocument10 pagesNASM21472: National Aerospace StandardGeorgeNo ratings yet

- BLDG Est GuideDocument11 pagesBLDG Est GuideVALIENT CANCERANNo ratings yet

- Evalene HDPE Grade SlateDocument1 pageEvalene HDPE Grade Slatepalani.djpNo ratings yet

- Use of Waste Plastic in Concrete Mixture As Aggregate ReplacementDocument4 pagesUse of Waste Plastic in Concrete Mixture As Aggregate ReplacementIJAERS JOURNALNo ratings yet

- ME UW LED lighting installation layoutDocument1 pageME UW LED lighting installation layoutBurak YıldırımNo ratings yet

- Engineering Design Guidelines Pressure Vessel Rev1.2webDocument25 pagesEngineering Design Guidelines Pressure Vessel Rev1.2websachin nagavkarNo ratings yet

- OneSteel Reinforcing Area CalculatorDocument12 pagesOneSteel Reinforcing Area CalculatormingmingminglesNo ratings yet

- Part 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door HardwareDocument2 pagesPart 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door Hardwaremus3b1985No ratings yet

- April 2014: Kumar Neeraj JhaDocument35 pagesApril 2014: Kumar Neeraj JhaNavarang R KobbeNo ratings yet

- HSS Blind Structural Fasteners - May 2021Document7 pagesHSS Blind Structural Fasteners - May 2021David ArndtNo ratings yet

- Spread TowDocument4 pagesSpread TowyigitilgazNo ratings yet

- Astm A711Document4 pagesAstm A711asprclms durgapurNo ratings yet

- Semi-Structural Surfacings Provide Flexible Top LayersDocument2 pagesSemi-Structural Surfacings Provide Flexible Top Layersgimanu100% (1)

- Sampling of Gold BullionDocument30 pagesSampling of Gold BullionOIL TEST INTERNACIONAL DE COLOMBIA S.A.SNo ratings yet

- Electroplating Zinc for Maximum Corrosion ProtectionDocument10 pagesElectroplating Zinc for Maximum Corrosion ProtectionSunil PrasadNo ratings yet

- Tyco Fig.110-190 Ball Valves DatasheetDocument24 pagesTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Catalog CoreDrillDocument16 pagesCatalog CoreDrillgeologerNo ratings yet

- Recovery Recrystallization Grain GrowthDocument13 pagesRecovery Recrystallization Grain GrowthsivaenotesNo ratings yet

- Harga Satuan Dasar Upah dan MaterialDocument576 pagesHarga Satuan Dasar Upah dan MaterialKHOIRUSNo ratings yet

- Injection System Brochure PDFDocument9 pagesInjection System Brochure PDFPavala AyyanarNo ratings yet

- Norma Parte 1Document100 pagesNorma Parte 1Alejandra López100% (1)

- Al WeldingDocument70 pagesAl WeldingTuyen NguyenNo ratings yet

- PROTEX Data SheetDocument2 pagesPROTEX Data SheetDayanand SharmaNo ratings yet

- Steel Melting Shop Procedures..: Prepared By: M G Sunil, Sse /TTCDocument50 pagesSteel Melting Shop Procedures..: Prepared By: M G Sunil, Sse /TTCabhimanyutiwari1234No ratings yet

- QCS 2010 Section 16 Part 2 Materials PDFDocument5 pagesQCS 2010 Section 16 Part 2 Materials PDFbryanpastor10650% (2)