Professional Documents

Culture Documents

Installation Guidelines: 1. Preparing The Subgrade

Uploaded by

Elard QAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guidelines: 1. Preparing The Subgrade

Uploaded by

Elard QACopyright:

Available Formats

®

Installation Guidelines

1. Preparing the subgrade

Surface, on which you plan to install the Eurobent must be free

of sharp rock, organic matter and other objects also larger that

50 mm. The subgrade should be compacted at least 90% of it's

proctor density. While compacting with a smooth-wheeled or

rubber-tired roller, try to keep the surface free of water.

2. Delivery and storage

Eurobent is in rolls with a width of 5m and a length of 40m.

Average roll diameter is 60-70cm, and the weight is

approximately 1000kg. Eurobent GCL are wound on tubes with

an inner diameter of 10 cm. Every roll is packed in a plastic

sleeve UV resistant. All rolls are marked with a label containing

the dimensions, lot and roll number.

We supply a 25kg bag of bentonite powder for each roll of

Eurobent. The bag is ment for application in the overlapping

areas.

Each roll is equipped into a set of two belts. It is recommended

while unloading from the truck to put a steal pipe inside to

prevent bending of the roll.

While storing Eurobent do not place the rolls directly on the

ground but provide for pallets or similar constructions

underneath.

Rolls should not be stacked more than 4 rolls high.

Eurobent should not be directly exposed to the elements during

the storage. Cover all rolls with a plastic sheet or a tarpaulin. Do

not remove the plastic sleeves prior to installation.

Poland 58-100 Świdnica, ul. Kliczkowska 42

+48 510 255 205; +48 74 857 50 81

+43 664 443 0814

www.eurobent.com

office@eurobent.com

Installation Guidelines

3. Installation of Eurobent

The installation can only proceed during dry weather conditions.

Never place the liner on top of standing water.

Eurobent should be placed on the prepared subgrade without

wrinkles or folds. Position the Eurobent GCL with the woven

down and the nonwoven facing up. When you use Eurobent

Combi remember also to put the PE coating facing up. Unroll

the Eurobent roll like a carpet.

For easier handling and positioning of Eurobent it is

recommended to provide a lifting device which allows to lift the

rolls with a bulldozer or front end loader. The iron pipe may

serve as such a device for unloading as well as for installation

of the liner.

On slopes the orientation of panels shall be parallel to the

slope. The panels should be secured in an anchor trench at the

top of the slope. The requirement as well as dimensioning

should be based on a stability calculation.

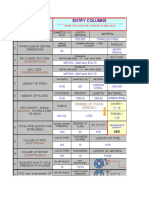

4. Panel overlaps

Each panel is marked with two lines, the first located 15 cm from

the edge, and the second one is 7 cm farther. It is

recommended to make the overlapping between these two

lines, which are for assist purpose. If mayor settlements are to

be expected the overlapping area is to be increased. When

making the overlapping use the bags which are supplied

together with the rolls.

Cover material should be placed on the bentonite liner

immediately after installation. The thickness of the cover

material should be min. 20 - 25 cm after compaction. The cover

material should be free of stones larger than 50mm and should

be composed of well graded material.

Apply the cover over head and do not allow construction

vehicles to move directly on top of the GCL.

Poland 58-100 Świdnica, ul. Kliczkowska 42

+48 510 255 205; +48 74 857 50 81

+43 664 443 0814

www.eurobent.com

office@eurobent.com

Installation Guidelines

5. Damage repair

Even if installation is out with utmost care the liner may have suffered some damage in the

process. Due to the swelling properties of the bentonite minor defects will heal and seal

themselves.

More serious defects should be marked immediately and be repaired by cutting a patch of

bentonite liner large enough to allow an overlap of at least 30cm on all edges. Then place

bentonite powder on the area to be repaired and cover the damaged area with the patch.

6. Attachment to concrete structures and pipe penetrations

6.1. Pipe penetrations

Before installing the bentonite liner clear an area 15 - 20 cm deep and 30 cm around the pipe from

surrounding soil.

Pack this area up to half its total depth with bentonite powder or paste and place the bentonite

liner that is to be cut in star shape to fit around the pipe on top. Then fill the rest of the excavated

area with bentonite powder and place another bentonite liner cut in star shape on top of it. To hold

the second bentonite liner firmly in place it is recommended to attach it with a pipe shell.

6.2. Attachment to concrete structures

Generally speaking attachments to concrete structure should end above ground water level. In the

attachment area dig a small trench along the structure to be sealed. Pack it with bentonite powder

or paste up to half of its total depth. Then trim the bentonite liner to fit against the wall of the

structure and fill the remaining trench with bentonite powder. For additional anchorage it is

recommended to affix a plastic or metal strip along the edge and cover this area with a piece of

bentonite liner or a piece of fabric.

Poland 58-100 Świdnica, ul. Kliczkowska 42

+48 510 255 205; +48 74 857 50 81

+43 664 443 0814

www.eurobent.com

office@eurobent.com

You might also like

- Method Statement For Stamped ConcreteDocument4 pagesMethod Statement For Stamped ConcreteAndré van Schalkwyk100% (1)

- Method Statement for Treating Building Expansion JointsDocument4 pagesMethod Statement for Treating Building Expansion JointsGhaffar Laghari100% (2)

- Box Culvert, VUP & Minor BridgeDocument22 pagesBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNo ratings yet

- REPORT ON EXPANSION JOINTSDocument19 pagesREPORT ON EXPANSION JOINTSAr Dinesh GaikwadNo ratings yet

- Special Foundation Works - CursDocument149 pagesSpecial Foundation Works - CursCarina PopescuNo ratings yet

- FRAMELESS GLASS INSTALL METHODDocument4 pagesFRAMELESS GLASS INSTALL METHODNita Jamnu60% (5)

- Australian Hardwood Domestic Deck Span TablesDocument8 pagesAustralian Hardwood Domestic Deck Span Tablesandrewb2005No ratings yet

- Remington PowerHammer Model 476 ManualDocument20 pagesRemington PowerHammer Model 476 ManualStephen Girard50% (2)

- CPI Site-Activities PDFDocument30 pagesCPI Site-Activities PDFmassive85No ratings yet

- Guidelines for Shop Inspection - Heat Treatment PrinciplesDocument17 pagesGuidelines for Shop Inspection - Heat Treatment PrinciplesManoranjan Nayak100% (2)

- Epoxy Grout Handbook - MasterFlowDocument17 pagesEpoxy Grout Handbook - MasterFlowaruncg2No ratings yet

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- Complete Outline SpecificationsDocument16 pagesComplete Outline SpecificationsChoco MartiniNo ratings yet

- Waterproofing in ToiletDocument11 pagesWaterproofing in ToiletchaityaNo ratings yet

- Specifications For Waterproofing WorksDocument16 pagesSpecifications For Waterproofing WorkssplashierprinceNo ratings yet

- GOST Steels PDFDocument88 pagesGOST Steels PDFDiogo Roesler MeloNo ratings yet

- Hardness Test SpecDocument12 pagesHardness Test SpecAmir100% (1)

- Method of Statement For Interlocking Block and Curb StoneDocument4 pagesMethod of Statement For Interlocking Block and Curb StoneTAHER AMMAR100% (1)

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraNo ratings yet

- Induction Furnaces LiningDocument20 pagesInduction Furnaces LiningAkash Sharma100% (1)

- Precast Cement Concrete Block Construction GuideDocument12 pagesPrecast Cement Concrete Block Construction GuideDjajithNo ratings yet

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- Method Statement of Waterproofing (Wet Area & Brick Bat Coba)Document4 pagesMethod Statement of Waterproofing (Wet Area & Brick Bat Coba)Salman Shah100% (1)

- Building SpecificationsDocument7 pagesBuilding SpecificationsElvin PrestoNo ratings yet

- Building A Fish PondDocument4 pagesBuilding A Fish PondAndry HarmonyNo ratings yet

- Brick Lining InstallationDocument34 pagesBrick Lining Installationmkpq100% (1)

- MeconDocument6 pagesMeconAnbarasanNo ratings yet

- Technical ProposalDocument6 pagesTechnical ProposalMark Sinclair100% (1)

- Norsok M630 Edition 6 PDFDocument156 pagesNorsok M630 Edition 6 PDFLakshit SethNo ratings yet

- Architectural Treatment For Joint GapsDocument25 pagesArchitectural Treatment For Joint GapsRoze-Anne JopsonNo ratings yet

- Ocbre Spec.Document12 pagesOcbre Spec.Rana MahatoNo ratings yet

- Technical SpecificationsDocument3 pagesTechnical SpecificationsJohnNo ratings yet

- 1limitation of MixingDocument4 pages1limitation of MixingJei EmNo ratings yet

- VDF flooring technical specificationDocument9 pagesVDF flooring technical specificationBasava NNo ratings yet

- Bitustick XLDocument2 pagesBitustick XLaldred_chezkaNo ratings yet

- Portland Cement GroutingDocument18 pagesPortland Cement Groutingapoorv mishraNo ratings yet

- Flexible Expansion Joint MembraneDocument4 pagesFlexible Expansion Joint MembranemilanbrasinaNo ratings yet

- BestPractices Thermoplastic Sep08Document10 pagesBestPractices Thermoplastic Sep08geverett2765No ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- Euco TopDocument2 pagesEuco Toppravi3434No ratings yet

- Concrete PathwayDocument1 pageConcrete PathwaymrameshceNo ratings yet

- CETCO Voltex Waterproofing System Specification GuidelinesDocument4 pagesCETCO Voltex Waterproofing System Specification GuidelinesjbonvierNo ratings yet

- Under Water ConcreteingDocument7 pagesUnder Water ConcreteingDinesh Kumar PatelNo ratings yet

- Qcs 2010 Section 13 Part 5 Masonry Laying PDFDocument11 pagesQcs 2010 Section 13 Part 5 Masonry Laying PDFbryanpastor106No ratings yet

- Repair Concrete Cracks Injection GroutsDocument18 pagesRepair Concrete Cracks Injection Grouts153-B RAKSHITHANo ratings yet

- Diaphragm WallDocument36 pagesDiaphragm WalltharazainNo ratings yet

- BMC 4 - Expansion JointsDocument12 pagesBMC 4 - Expansion JointsKreya PatelNo ratings yet

- Cell Filled Concrete PavementDocument23 pagesCell Filled Concrete PavementDEVIKA ANIL79% (14)

- Sandwich Panel Lindab AssemblyDocument24 pagesSandwich Panel Lindab AssemblyIsye RuisNo ratings yet

- A Guide To Epoxy GroutingDocument17 pagesA Guide To Epoxy GroutingCloudy DayNo ratings yet

- EucocreteDocument2 pagesEucocretepravi3434No ratings yet

- PVC-O Tecnical Spesification MolecorDocument11 pagesPVC-O Tecnical Spesification MolecorRusdy NugrahaNo ratings yet

- APGENCO Proposal For ORG WP On 13-12-23 PDFDocument6 pagesAPGENCO Proposal For ORG WP On 13-12-23 PDFSun NyNo ratings yet

- MR Fix Itumat Plus 502Document2 pagesMR Fix Itumat Plus 502Israel ExporterNo ratings yet

- Glass Fibre Grids MethodologyDocument4 pagesGlass Fibre Grids MethodologyRaghavNo ratings yet

- A Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionDocument4 pagesA Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionMICHAELNo ratings yet

- SPECIFICATIONS by SALVANDocument22 pagesSPECIFICATIONS by SALVANmark manalangNo ratings yet

- Fibre Optic Cable Duct Installation SpecificationsDocument1 pageFibre Optic Cable Duct Installation SpecificationsAli MustafaNo ratings yet

- Laying Guidelines For MarbleDocument4 pagesLaying Guidelines For Marbledhirendra singhNo ratings yet

- Easy steps for laying clay bricks installationDocument2 pagesEasy steps for laying clay bricks installationmutazsalihNo ratings yet

- Instalatii Complete de DrenajDocument6 pagesInstalatii Complete de DrenajCatalinaLixandruNo ratings yet

- Item Particular Dedailed Specification 1 Site Clearing: MortarDocument11 pagesItem Particular Dedailed Specification 1 Site Clearing: MortarcantybuoyNo ratings yet

- Backer RodDocument2 pagesBacker RodCassy AbulenciaNo ratings yet

- Instructions For Putting Ceramic Tiles in PlaceDocument6 pagesInstructions For Putting Ceramic Tiles in PlaceabobeedoNo ratings yet

- 2 Rail Hydroponic System Build Instructions - Simple GreensDocument12 pages2 Rail Hydroponic System Build Instructions - Simple GreensJo MathewNo ratings yet

- Practical guide for placing, compacting and curing concreteDocument1 pagePractical guide for placing, compacting and curing concreteSha RasonabeNo ratings yet

- Permintaan Material Data BaruDocument30 pagesPermintaan Material Data BaruM Iqbal AdmanNo ratings yet

- Https Freepaper - Me D PDF 13 .PDF Hash 63f1vnpF2iwxK5Yx1QWAhA&doi 10.1109 Cicn.2015Document3 pagesHttps Freepaper - Me D PDF 13 .PDF Hash 63f1vnpF2iwxK5Yx1QWAhA&doi 10.1109 Cicn.2015mazaherramazaniNo ratings yet

- Material Specification for Forged Bar and Ring in ASTM A182-F51Document2 pagesMaterial Specification for Forged Bar and Ring in ASTM A182-F51Amjath PallasNo ratings yet

- LEEA Correspondence Courses: Assignment 1.8Document3 pagesLEEA Correspondence Courses: Assignment 1.8Primelift Safety Resources LimitedNo ratings yet

- Standar AISI-1035 SteelDocument2 pagesStandar AISI-1035 SteelNurulImanPristiadiNo ratings yet

- Roca contact proposal for Balai Bomba Kuala TahanDocument7 pagesRoca contact proposal for Balai Bomba Kuala TahanAffendi Hj AriffinNo ratings yet

- Chemical Formula Writing WorksheetDocument5 pagesChemical Formula Writing WorksheetÂziz ShuvoNo ratings yet

- Ceramics Course Chapter 1: Introduction to Properties and ApplicationsDocument56 pagesCeramics Course Chapter 1: Introduction to Properties and ApplicationsSobhe ShoshaNo ratings yet

- MD Elements 04Document100 pagesMD Elements 04Prince JairoNo ratings yet

- Zamil Steel Buildings Design Manual: 1.5. Skylight PanelsDocument1 pageZamil Steel Buildings Design Manual: 1.5. Skylight PanelsvuvandanNo ratings yet

- Minerals Assignment - EafDocument18 pagesMinerals Assignment - Eafbridget mutsutsururuNo ratings yet

- SPCE Visits Nilkanth Steel IndustriesDocument6 pagesSPCE Visits Nilkanth Steel IndustriesMeet PatelNo ratings yet

- c21014 PDFDocument2 pagesc21014 PDFKhaled A MarashliNo ratings yet

- Quick Shaft-Locking Clamps: L L D LDocument2 pagesQuick Shaft-Locking Clamps: L L D LTri SetiaNo ratings yet

- FINAL SMAW-12-Quarter-3-module 1 PDFDocument22 pagesFINAL SMAW-12-Quarter-3-module 1 PDFRandy Sacatani100% (1)

- Report of Jaminy End Quench TestDocument92 pagesReport of Jaminy End Quench TestBharathi K 2018100% (1)

- Tool Steels: Højerslev, CDocument27 pagesTool Steels: Højerslev, Ctosse atanasovNo ratings yet

- B16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesDocument12 pagesB16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesInaamNo ratings yet

- Nomenclature For Wire Leads Used As Conductors in Electron TubesDocument3 pagesNomenclature For Wire Leads Used As Conductors in Electron TubesCasey RybackNo ratings yet

- CDP 4666 Wearplates Castodur Diamond PlatesDocument2 pagesCDP 4666 Wearplates Castodur Diamond PlatesFrederico MeirelesNo ratings yet

- Entry Columns: DescriptionDocument21 pagesEntry Columns: Descriptiondilema_pgNo ratings yet

- Class Notes - Sheet MetalDocument6 pagesClass Notes - Sheet MetalVedurupaka Venkata SaiNo ratings yet