Professional Documents

Culture Documents

Eng DS MS4525 B9 PDF

Uploaded by

Hichem MabroukiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng DS MS4525 B9 PDF

Uploaded by

Hichem MabroukiCopyright:

Available Formats

MS4525

SPECIFICATIONS

PCB Mounted Pressure Transducers

Amplified Ratiometric Analog Output

Differential, Gage, Absolute, Compound, &

Vacuum

Temperature Compensated

3.3 or 5.0 VDC Supply Voltage

The MS4525 is a small, ceramic based, PCB mounted

FEATURES pressure transducer from TE Connectivity. The transducer is

built using our proprietary UltraStable™ process and the latest

PSI Pressure Ranges

CMOS sensor conditioning circuitry to create a low cost, high

PCB Mountable

performance transducer designed to meet the strictest

High Level Analog Output

requirements from OEM customers.

Barbed Pressure Ports

The MS4525 is fully calibrated and temperature compensated

APPLICATIONS with a total error band (TEB) of less than 1.0% over the

compensated range. The sensor operates from single supply of

Blocked Filter Detection either 3.3 or 5.0VDC and requires a single external component for

Altitude and Airspeed Measurements proper operation.

Medical Instruments

Fire Suppression System The rugged ceramic transducer is available in side port, top port,

Panel Meter and manifold mount and can measure absolute, gage,

differential, or compound pressure from 1 to 150psi. The 1/8”

Air Movement/Environmental Controls

Pneumatic Controls barbed pressure ports mate securely with 3/32” ID tubing.

SENSOR SOLUTIONS /// MS4525 04/2019 Page 1

MS4525

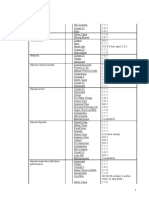

STANDARD RANGES (PSI)

Pressure Absolute Gage Differential Compound Vacuum Option Availability

1 DS, SS, TP, MM DS, SS, TP -F

2 DS, SS, TP, MM DS, SS, TP -F

5 DS, SS, TP, MM DS, SS, TP -F

15 SS, TP DS, SS, TP, MM DS, MM SS, TP SS, TP, DS -F

30 SS, TP DS, SS, TP, MM DS, MM SS, TP -F

50 SS, TP DS, SS, TP, MM DS, MM SS, TP -F

100 SS, TP DS, SS, TP, MM DS, MM SS, TP -F

150 SS, TP DS, SS, TP, MM DS, MM SS, TP -F

See Package Configurations: DS= Dual Side Port, SS= Single Side Port, TP= Top Port, MM= Manifold Mount

Pin Style “L” is only available SS and MM port types.

Pin Style “C” is only available SS, TP and MM port types.

BLOCK DIAGRAM

SENSOR SOLUTIONS /// MS4525 04/2019 Page 2

MS4525

ABSOLUTE MAXIMUM RATINGS

Parameter Conditions Min Max Unit Notes

Supply Voltage TA = 25 °C 2.7 5.5 V

Output Current TA = 25°C 3 mA

Load Resistance (RL) TA = 25°C 10 kΩ

Storage Temperature -40 +125 °C

Humidity TA = 25°C 95 %RH Non Condensing

Overpressure TA = 25 °C, both Ports Not to Exceed 300 psi

Burst Pressure TA = 25 °C, Port 1 psi See Table 1

ESD HBM -4 +4 kV EN 61000-4-2

Solder Temperature 250°C, 5 sec max.

TABLE 1- BURST PRESSURE BY RANGE AND PACKAGE STYLE

Range DS TP, SS, MM Unit

001 20 20 psi

002 20 20 psi

005 15 20 psi

015 45 90 psi

030 90 200 psi

050 150 300 psi

100 300 300 psi

150 300 300 psi

ENVIRONMENTAL SPECIFICATIONS

Parameter Conditions

Mechanical Shock Mil Spec 202F, Method 213B, Condition C, 3 Drops

Mechanical Vibration Mil Spec 202F, Method 214A, Condition 1E, 1Hr Each Axis

Thermal Shock 100 Cycles over Storage Temperature, 30 minute dwell

Life 1 Million FS Cycles

MTTF >10Yrs, 70 ºC, 1.188 Million Pressure Cycles, 120%FS

Pressure

SENSOR SOLUTIONS /// MS4525 04/2019 Page 3

MS4525

PERFORMANCE SPECIFICATIONS

Supply Voltage1: 5.0V or 3.3 VDC

Ambient Temperature: 25°C (unless otherwise specified)

PARAMETERS MIN TYP MAX UNITS NOTES

Output 0.500 4.500 V 1,2,3

0.250 4.750

Accuracy -0.25 0.25 %Span 2

Total Error Band (TEB) -1.0 1.0 %Span 3,5

Supply Current 3 mA 5

Long Term Stability (Offset & Span) ±0.5 %Span

Compensated Temperature -10 +85 ºC 4

Operating Temperature -25 +105 ºC

Response Time 1 mS 5

Weight 3 grams

Start time to data ready 5 ms

Media Non-Corrosive Dry Gases Compatible with Ceramic, Silicon, Borosilicate Glass,

RTV, Gold, Aluminum and Epoxy. See “Wetted Material by Port Designation” chart

below.

Notes

1. Proper operation requires an external capacitor placed as shown in Connection Diagram. Output is ratiometric to supply voltage

variations of less than 10%.

2. The maximum deviation from a best fit straight line (BFSL) fitted to the output measured over the pressure range at 25°C. Includes all

errors due to pressure non linearity, hysteresis, and non repeatability.

3. Total error band includes all accuracy errors, thermal errors over the compensated temperature range, and span and offset calibration

tolerances. For ideal sensor output with respect to input pressure, reference Pressure Transfer Function charts below. TEB values are

valid only at the calibrated supply voltage.

4. For errors beyond the compensated temperature range, see Extended Temperature Multiplier chart below.

5. This product can be configured for custom OEM requirements, contact factory for lower power consumption or higher accuracy.

6. Long term stability over a year period with constant voltage and temperature

7. Pressure connection: barbed ports are designed for use with tubing 3/32” ID, 60-70A durometer (PVC).

8. For details on environmental conditions and pressure type descriptions, reference to relative tables.

CONNECTION DIAGRAM

Notes:

1. Place 100nF capacitor between Supply and GND to within 2 cm of sensor.

SENSOR SOLUTIONS /// MS4525 04/2019 Page 4

MS4525

PRESSURE AND TEMPERATURE TRANSFER FUNCTION

Sensor Output at Significant Percentages, (Vs=5.00)

OUTPUT (%Vs) Output Type A (psi) Output Type B (psi) Voltage (V)

0 PMIN-(PMAX-PMIN)*10/80 PMIN-(PMAX-PMIN)*5/90 0.000

5 PMIN 0.250

10 PMIN 0.500

50 2.500

90 PMAX 4.500

95 PMAX 4.750

100 PMAX+(PMAX-PMIN)*10/80 PMAX+(PMAX-PMIN)*5/90 5.000

Sensor Output at Significant Percentages, (Vs=3.30)

Output (%Vs) Output A (psi) Output B (psi) Voltage (V)

0 PMIN-(PMAX-PMIN)*10/80 PMIN-(PMAX-PMIN)*5/90 0.000

5 PMIN 0.165

10 PMIN 0.330

50 1.650

90 PMAX 2.970

95 PMAX 3.315

100 PMAX+(PMAX-PMIN)*10/80 PMAX+(PMAX-PMIN)*5/90 3.300

SENSOR SOLUTIONS /// MS4525 04/2019 Page 5

MS4525

Sensor Output at Significant Percentages, (Vs=5.00)

% Output (%Vs) Output Type A [psiG] Output Type B [psiG] Voltage [V]

0 1.6875 0.833 0.000

5 0 0.250

10 0 0.500

50 2.500

90 -15 4.500

95 -15 4.750

100 5.000

Sensor Output at Significant Percentages, (Vs=3.30)

% Output (%Vs) Output Type A [psiG] Output Type B [psiG)] Voltage [V]

0 1.6875 0.833 0.000

5 0 0.165

10 0 0.330

50 1.650

90 -15 2.970

95 -15 3.315

100 3.300

SENSOR SOLUTIONS /// MS4525 04/2019 Page 6

MS4525

EXTENDED TEMPERATURE MULTIPLIER CHART

PACKAGE, PINOUT & PRESSURE TYPE CONFIGURATION

SENSOR SOLUTIONS /// MS4525 04/2019 Page 7

MS4525

Pin Name Pin Function

SUPPLY 2 Positive Supply Voltage

OUTPUT 3 Analog Output

GND 4 Ground

1, 5-8 No Connection

Pressure Type Description

Pressure Type Pmin Pmax Description

Absolute 0psiA +Prange Output is proportional to the difference between 0psiA (P min) and pressure applied

to Port 1.

Differential/ -Prange +Prange Output is proportional to the difference between Port 1 and Port 2. Output swings

Bidirectional positive when Port 1> Port 2. Output is 50% of supply voltage when Port 1=Port 2.

Gage 0psiG +Prange Output is proportional to the difference between 0psiG (P min) and Port 1. Output

swings positive when Port 1> Port 2.

Compound -15psiG +Prange Output is proportional to the difference between -15psiG pressure (Pmin) and

pressure applied to Port 1.

Vacuum -15psiG +0psiG Output is inversely proportional to the difference between -15psiG (Pmin) and

pressure applied to Port 1.

Prange is equal to the maximum full scale pressure specified in the ordering information.

WETTED MATERIAL BY PORT DESIGNATION

Material

Style Port Ceramic Silicon Borosilicate Glass RTV Gold Aluminum Epoxy

DS, MM Port 1 X X X X X

Port 2 X X X X X X X

SS, TP, SM Port 1 X X X X X X X

"X" Indicates Wetted Material

SENSOR SOLUTIONS /// MS4525 04/2019 Page 8

MS4525

DIMENSIONS

(in INCHES [mm])

Model: MS4525-DSvoxxxyP

Model: MS4525-DSvoxxxyS

SENSOR SOLUTIONS /// MS4525 04/2019 Page 9

MS4525

Model: MS4525-SSvoxxxyP

Model: MS4525-SSvoxxxyS

SENSOR SOLUTIONS /// MS4525 04/2019 Page 10

MS4525

Model: MS4525-TPvoxxxyP

Model: MS4525-TPvoxxxyS

SENSOR SOLUTIONS /// MS4525 04/2019 Page 11

MS4525

Model: MS4525-SSvoxxxyL

Model: MS4525-MMvoxxxyL

SENSOR SOLUTIONS /// MS4525 04/2019 Page 12

MS4525

Model: MS4525-MMvoxxxyP

Model: MS4525-MMvoxxxyS

SENSOR SOLUTIONS /// MS4525 04/2019 Page 13

MS4525

Model: MS4525-SSvoxxxyC

Model: MS4525-TPvoxxxyC

SENSOR SOLUTIONS /// MS4525 04/2019 Page 14

MS4525

Model: MS4525-MMvoxxxyC

AVAILABLE OPTIONS

Gel Coat (-F Option)

The MS4525 is designed for nonionic and clean dry air applications. Select this option for added protection in

high humidity or slightly corrosive environments with the application of a silicone gel elastomer to sensor and

ASIC. For questions concerning media compatibility, contact the factory.

SENSOR SOLUTIONS /// MS4525 04/2019 Page 15

MS4525

ORDERING INFORMATION

4525 – TP 3 A 030 C P F

Package Type Option Type

SS Single Sideport F Gel Coating

DS Dual Sideport [Blank] No Option

TP Top Port

MM Manifold Mount Pin Type

P Thru Hole

Supply Voltage S J lead

3 3.3VDC L In Line

5 5.0 VDC C Castellation

Pressure Type

Output Type

G Gage

A 10% to 90% A Absolute

B 5% to 95% D Differential

C Compound

Pressure Range [psi] V Vacuum

001

002

005

015

030

050

100

150

EUROPE ASIA

NORTH AMERICA

Measurement Specialties (Europe), Ltd., Measurement Specialties (China) Ltd.,

Measurement Specialties, Inc., a TE Connectivity company

a TE Connectivity company a TE Connectivity Company

Tel: +31 73 624 6999 Tel: 86 0400-820-6015

Tel: 1 800-522-6752

Email: customercare.bevx@te.com Email: customercare.shzn@te.com

Email: customercare.frmt@te.com

TE.com/sensorsolutions

Measurement Specialties, Inc., a TE Connectivity company.

Measurement Specialties, TE Connectivity, TE Connectivity (logo) and EVERY CONNECTION COUNTS are trademarks. All other logos, products and/or company names referred to herein

might be trademarks of their respective owners.

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes only, is believed to be reliable. However, TE Connectivity makes

no warranties as to its accuracy or completeness and disclaims any liability in connection with its use. TE Connectivity‘s obligations shall only be as set forth in TE Connectivity‘s Standard

Terms and Conditions of Sale for this product and in no case will TE Connectivity be liable for any incidental, indirect or consequential damages arising out of the sale, resale, use or misuse

of the product. Users of TE Connectivity products should make their own evaluation to determine the suitability of each such product for the specific application.

© 2015 TE Connectivity Ltd. family of companies All Rights Reserved.

SENSOR SOLUTIONS /// MS4525 04/2019 Page 16

You might also like

- Eng DS Ms4525do B10Document19 pagesEng DS Ms4525do B10Rene KurniadiNo ratings yet

- Eng DS Ms5525dso D20-786470Document24 pagesEng DS Ms5525dso D20-786470ANo ratings yet

- DB DMP331 eDocument5 pagesDB DMP331 egilad.leizerNo ratings yet

- Voltage Regulator DatasheetDocument6 pagesVoltage Regulator DatasheetSteveNo ratings yet

- DB DMP331 eDocument6 pagesDB DMP331 etouili majdiNo ratings yet

- ASVM (N) - Performance CurveDocument5 pagesASVM (N) - Performance Curvemarpaung saberindoNo ratings yet

- LM 317 MPDocument25 pagesLM 317 MPsuhaila38No ratings yet

- Mosfet: OptimosDocument12 pagesMosfet: OptimosAriel Rodrigo MuñozNo ratings yet

- N-Channel JFET General Purpose AmplifierDocument1 pageN-Channel JFET General Purpose AmplifierDaniela Cardenas LuboNo ratings yet

- IPT015N10N5ATMA1Document12 pagesIPT015N10N5ATMA1Boulegheb SkanderNo ratings yet

- REF3012 REF3020 REF3025 REF3030 REF3033 REF3040 50ppm/ C Max, 50 A in SOT23-3 Cmos Voltage ReferenceDocument17 pagesREF3012 REF3020 REF3025 REF3030 REF3033 REF3040 50ppm/ C Max, 50 A in SOT23-3 Cmos Voltage ReferenceachtashNo ratings yet

- LM 337KDocument15 pagesLM 337Kmaster55No ratings yet

- CMOS 1.8 V to 5.5 V, 2.5 Ω SPDT Switch/2:1 Mux in Tiny SC70 Package ADG779Document12 pagesCMOS 1.8 V to 5.5 V, 2.5 Ω SPDT Switch/2:1 Mux in Tiny SC70 Package ADG779Fer TgNo ratings yet

- Screw-In Transmitter: Stainless Steel SensorDocument4 pagesScrew-In Transmitter: Stainless Steel SensorjOAONo ratings yet

- 3685 FBDocument24 pages3685 FBPravin MevadaNo ratings yet

- M3200 DatasheetDocument22 pagesM3200 DatasheetWilliams RobinsonNo ratings yet

- LM117/LM317A/LM317 3-Terminal Adjustable Regulator: General DescriptionDocument20 pagesLM117/LM317A/LM317 3-Terminal Adjustable Regulator: General Descriptionjacctito2No ratings yet

- Metal Film Resistors MRS16S/25: Philips Components Product SpecificationDocument12 pagesMetal Film Resistors MRS16S/25: Philips Components Product SpecificationnrsaranNo ratings yet

- LM79XX Series 3-Terminal Negative Regulators: General DescriptionDocument10 pagesLM79XX Series 3-Terminal Negative Regulators: General DescriptionDaniel JaimesNo ratings yet

- Re95138 2007-01Document8 pagesRe95138 2007-01gasNo ratings yet

- 1.5SMC Series-1864824 PDFDocument8 pages1.5SMC Series-1864824 PDFRizwan RanaNo ratings yet

- DatasheetDocument28 pagesDatasheetKakaroto Maximo Decimo MeridioNo ratings yet

- STP 5 NK 100 ZDocument15 pagesSTP 5 NK 100 ZJimmy LinaresNo ratings yet

- Features Description: LT3085 Adjustable 500ma Single Resistor Low Dropout RegulatorDocument28 pagesFeatures Description: LT3085 Adjustable 500ma Single Resistor Low Dropout Regulatoram1liNo ratings yet

- Copa-Cm / Mag-Cm: Electromagnetic Flowmeter With Capacitive Electrodes in Compact and Remote DesignsDocument20 pagesCopa-Cm / Mag-Cm: Electromagnetic Flowmeter With Capacitive Electrodes in Compact and Remote DesignsAli JawadNo ratings yet

- Cat 662R0-SLT PDFDocument9 pagesCat 662R0-SLT PDFk v s s GuptaNo ratings yet

- RF Power Mosfet: N - Channel Enhancement Mode 125V 750W 40MhzDocument4 pagesRF Power Mosfet: N - Channel Enhancement Mode 125V 750W 40MhzDurbha RaviNo ratings yet

- Infineon IPP023N10N5 DS v02 - 03 ENDocument11 pagesInfineon IPP023N10N5 DS v02 - 03 ENWilson Yecit OrtizNo ratings yet

- Pressure Transmitter For Shipbuilding and Offshore: Stainless Steel SensorDocument5 pagesPressure Transmitter For Shipbuilding and Offshore: Stainless Steel SensorVariya DharmeshNo ratings yet

- LM317Document26 pagesLM317Diego DumaniNo ratings yet

- TST PM82 enDocument2 pagesTST PM82 endawitNo ratings yet

- LM7905 PDFDocument9 pagesLM7905 PDFManuelNo ratings yet

- LM342 Series 3-Terminal Positive Regulators: General DescriptionDocument8 pagesLM342 Series 3-Terminal Positive Regulators: General DescriptionAprilia MaharaniNo ratings yet

- PTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsDocument12 pagesPTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsjvtamilanbanNo ratings yet

- Low Pressure Transmitter in Short and Compact Design: DescriptionDocument4 pagesLow Pressure Transmitter in Short and Compact Design: DescriptionJordi AltayóNo ratings yet

- Ipp023n10n5 DteDocument12 pagesIpp023n10n5 DteDávid KisNo ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- Features Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverterDocument28 pagesFeatures Description: Ltc3536 1A Low Noise, Buck-Boost DC/DC ConverternevdullNo ratings yet

- US1881Document11 pagesUS1881Gustavo Iván VázquezNo ratings yet

- D D D D D D D D: DescriptionDocument21 pagesD D D D D D D D: DescriptionCENEMEM ANDRADENo ratings yet

- 1525AJDocument7 pages1525AJSalim BlognetNo ratings yet

- Sensors High PressureDocument5 pagesSensors High PressureGiuseppe DonatoNo ratings yet

- LM341, LM78M05, LM78M12, LM78M15: LM341/LM78MXX Series 3-Terminal Positive Voltage RegulatorsDocument13 pagesLM341, LM78M05, LM78M12, LM78M15: LM341/LM78MXX Series 3-Terminal Positive Voltage RegulatorskevharveyNo ratings yet

- Fusibles para PSTXDocument1 pageFusibles para PSTXDaniel Eduardo Carretero OlguínNo ratings yet

- LM338TDocument16 pagesLM338TWildan BudimanNo ratings yet

- lm741 NacionalDocument10 pageslm741 NacionalChristian PaulNo ratings yet

- Pressure Transmitter For General Purpose Type MBS 1700 and MBS 1750Document8 pagesPressure Transmitter For General Purpose Type MBS 1700 and MBS 1750mquaiottiNo ratings yet

- LM117 Voltage RegulatorDocument26 pagesLM117 Voltage Regulatore_bahamondesNo ratings yet

- ST3232 Data SheetDocument12 pagesST3232 Data SheetcredioNo ratings yet

- DatasheetDocument7 pagesDatasheetjamalludin jamal jamalNo ratings yet

- STP40N20-STF40N20: STB40N20 - STW40N20Document14 pagesSTP40N20-STF40N20: STB40N20 - STW40N20Rodrigo GarceteNo ratings yet

- SL32C Thru SL310C: Surface Mount Schottky Rectifier Reverse Voltage 20 - 100V Forward Current 3ADocument3 pagesSL32C Thru SL310C: Surface Mount Schottky Rectifier Reverse Voltage 20 - 100V Forward Current 3Aakshay rajNo ratings yet

- User Manual TT7SDocument5 pagesUser Manual TT7Stransient matterNo ratings yet

- IPB407N30N Optimos From InfineonDocument12 pagesIPB407N30N Optimos From Infineonnithinmundackal3623No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Macleod - 1974 - Lucian's Knowledge of TheophrastusDocument2 pagesMacleod - 1974 - Lucian's Knowledge of TheophrastusSIMONE BLAIRNo ratings yet

- Mid-Year Examination, 2023 Science Year 7 1 HourDocument23 pagesMid-Year Examination, 2023 Science Year 7 1 HourAl-Hafiz Bin SajahanNo ratings yet

- Mechanical Advantage HomeworkDocument8 pagesMechanical Advantage Homeworkafeurbmvo100% (1)

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocument39 pagesTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Rein RoundRobinModelling FSJ09Document30 pagesRein RoundRobinModelling FSJ09Noah RyderNo ratings yet

- Vintage Tavern - PrintInspectionDocument4 pagesVintage Tavern - PrintInspectionBryce AirgoodNo ratings yet

- Offsetting Macro-Shrinkage in Ductile IronDocument13 pagesOffsetting Macro-Shrinkage in Ductile IronmetkarthikNo ratings yet

- Feature Writing EnglishDocument2 pagesFeature Writing EnglishAldren BababooeyNo ratings yet

- Suneet Narayan Singh (Updated CV), NDocument4 pagesSuneet Narayan Singh (Updated CV), Nnishant gajeraNo ratings yet

- IsdettaDocument2 pagesIsdettaHa Phuoc HoaNo ratings yet

- Varactor AssignmentDocument9 pagesVaractor Assignmentjawad_h89No ratings yet

- Mwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToDocument7 pagesMwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToMateo AponteNo ratings yet

- Extrahepatic Biliary Tract Pathology - Cholidolithiasis, Cholidocholithiasis, Cholecystitis and CholangitisDocument60 pagesExtrahepatic Biliary Tract Pathology - Cholidolithiasis, Cholidocholithiasis, Cholecystitis and CholangitisDarien LiewNo ratings yet

- Introduction To Reproduction PDFDocument8 pagesIntroduction To Reproduction PDFLmssvNo ratings yet

- Smart Watch User Manual: Please Read The Manual Before UseDocument9 pagesSmart Watch User Manual: Please Read The Manual Before Useeliaszarmi100% (3)

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDocument6 pagesModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕNo ratings yet

- FORD Falcon XA Repair ManualDocument770 pagesFORD Falcon XA Repair ManualMark Kenzie100% (10)

- Data Sheet: W-Series WSI 6/LD 10-36V DC/ACDocument12 pagesData Sheet: W-Series WSI 6/LD 10-36V DC/ACLUIS FELIPE LIZCANO MARINNo ratings yet

- Ac 521 007Document10 pagesAc 521 007JacquesNo ratings yet

- Cold N Brew MenuDocument3 pagesCold N Brew MenuRizki FitriaNo ratings yet

- The Ecological Effects of Eucalyptus PDFDocument97 pagesThe Ecological Effects of Eucalyptus PDFgejuinaNo ratings yet

- 14 WosDocument6 pages14 WosATUL KURZEKARNo ratings yet

- Afectiuni Si SimptomeDocument22 pagesAfectiuni Si SimptomeIOANA_ROX_DRNo ratings yet

- IMS Institute BelgradeDocument10 pagesIMS Institute BelgradeBoško JanjuševićNo ratings yet

- Fantasy AGE - Spell SheetDocument2 pagesFantasy AGE - Spell SheetpacalypseNo ratings yet

- DiodeDocument3 pagesDiodeManishNo ratings yet

- FENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BDocument388 pagesFENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BQUOC LENo ratings yet

- Nammiaca 000032Document5,323 pagesNammiaca 000032gangadhark196No ratings yet

- Over Current & Earth Fault RelayDocument2 pagesOver Current & Earth Fault RelayDave Chaudhury67% (6)

- Tempera 2018 AbstractsDocument45 pagesTempera 2018 AbstractsGerard Emmanuel KamdemNo ratings yet