Professional Documents

Culture Documents

Procurement of Materials (Production - ACG) QSP 08

Uploaded by

Abdul Gafoor ShaikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procurement of Materials (Production - ACG) QSP 08

Uploaded by

Abdul Gafoor ShaikhCopyright:

Available Formats

BANGALORE

QUALITY SYSTEM Prepared

by

Approved

by

PROCEDURE

DOC NO: QAP / 08 TRK RVM

Revision No. & Date: 00 / 15/12/2009

PROCUREMENT OF MATERIALS (PRODUCTION - ACG.).

1. PURPOSE:

To ensure that materials (includes products / components / parts and job processing)

required for production of finished products are planned and procured to meet production /

delivery schedules of products.

To select and approve suppliers through evaluation on the basis of their ability to meet

specified requirements and to evaluate the performance of the supplier periodically in line

with QMS Procedures, EMS Procedures & OMS Procedures.

2. SCOPE:

Applicable to procurement of materials / job processing required for production and servicing

of AC Generators and associated spares and any production aids as required.

Applicable to evaluation, selection, approval and registration of suppliers for purchased

product.

Applicable for supplier re-evaluation.

3. RESPONSIBILITY:

HOD – PP & MM - ACG.

4. REFERENCE:

ISO 9001:2008 (QMS) – Clause 7.4, ISO 14001:2004 (EMS) & ISO 18001:2007 (OHSAS)

5. PROCEDURE:

5.1 PROCUREMENT OF MATERIALS

5.1.1 Materials required for production of TDPS products as per Sales Order / monthly

production program, material are procured against the specific products / projects

or combination of products / projects, except for procurement of safety materials,

consumable, hard wares & stock items.

5.1.2 Materials required and quantities to be procured are received from design dept in

the form of BOM / AOI.

5.1.3 PP & MM dept. shall receive the Manufacturing indent from marketing which

forms the basis for production planning.

5.1.4 PP & MM will prepare activity schedule for orders, which forms the basis for

design & for initiating planning action for long lead items.

5.1.5 PP & MM dept will prepare a monthly production program, based on

requirements / priorities of marketing. Refer Work Instruction No TJM009.

5.1.6 PP & MM dept shall work out material requirement against each of the project

in the production Programme / activity schedule from the specified BOM, advance

ordering information etc., and take action for procurement. This work is divided

among PP&MM personnel as per work instruction – TJM 004.

5.1.7 PP & MM dept shall release purchase order / LOI on approved suppliers for

procurement of components or raw materials.

5.1.8 Suppliers are selected from the approved suppliers list.

5.1.9 In case of emergency, a new supplier, not yet approved can be considered

for procurement by taking approval of factory chief. Depending on supplier’s

request & based on their performance, they may be considered for inclusion in

the approved supplier list subsequently.

5.2 Consumables/Production Aids/Maintenance spares/Instruments etc.:

Materials covered under this category are procured based on the purchase Request

received from concerned departments in format no. T68018R0 Production consumables

ALL INFORMATIONS CONTAINED IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF TD POWER SYSTEM PVT., LTD.

REPRODUCTION OF THESE IN ANY FORM IS TO BE DONE WITH THE SPECIFIC PERMISSION OF THE COMPANY.

TDPS – 02 UNCONTROLLED COPY IF PRINTED Page 1 of 5

BANGALORE

QUALITY SYSTEM Prepared

by

Approved

by

PROCEDURE

DOC NO: QAP / 08 TRK RVM

Revision No. & Date: 00 / 15/12/2009

PROCUREMENT OF MATERIALS (PRODUCTION - ACG.).

like welding electrodes, brazing rods, brazing flux, paint, gases, safety items, etc. are

procured based on stock & consumption.

5.3 Contents of Purchase Order:

5.3.1 Purchase Orders shall contain the below given information as relevant for the

specific material being ordered:

a. Material Code.

b. Description.

c. Drawing No with latest Revision status.

d. Quantity .

e. Delivery Schedule.

f. Scope of supply, as / if applicable.

g. Machine No / Project / Frame .. as applicable.

h. Warranty Period .. as & if applicable.

i. Test Certificates / Reports, as / if applicable.

j. Inspection at.

k. Attachments, if any.

l. Commercial details like Price, Taxes & Duty, transportation, Payment terms,

etc.,

m. Any other special Notes / Remarks, as applicable.

5.3.2 Purchase orders shall be authorized by HOD - PP & MM or General Manager –

Manufacturing.

5.3.3 Any changes/modifications required, in the original purchase order already

issued to the supplier shall be affected by means of amendment to original PO

and issued to supplier.

5.3.4 P.O may be for service contract or for supply of material / components of

products manufactured from either suppliers’ own material or TDPS supplied

material in which case required material will be issued to the suppliers under a

separate Chelan governed by statutory requirements.

5.3.5 PP & MM dept. shall ensure that the relevant drawing /document as per PO. Is

available with the supplier.

5.3.6 Drawings and document issue and control to the suppliers are recorded in

drawing control register, ref. Work instruction TJM011.

5.3.7 PP & MM dept shall keep a scanned copy PO / PO-amendments issued by them

and accordingly ensure that the required material is planned and followed-up for

deliveries (based on production Programme) on the due dates and monitor

processing at the suppliers.

5.4 Materials received at TDPS are handled as per Work Instruction No. TJM007. Issue of

materials to manufacturing is handled as per Work Instruction No.TJM008. A Goods

Receipt Note is created for each supply & the same is signed by Q.A for having

accepted the supply. The GRN is then forwarded to Finance Department for bill passing

& effecting payment to suppliers.

5.5 Supplier evaluation, approval & registration of supplier:-

5.5.1 Suppliers are evaluated and approved on the basis of their capability to effect

supplies of required quality levels.

5.5.2 The method of evaluation consists of one or more of the following methods:

Method I: Supplier capability survey.

ALL INFORMATIONS CONTAINED IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF TD POWER SYSTEM PVT., LTD.

REPRODUCTION OF THESE IN ANY FORM IS TO BE DONE WITH THE SPECIFIC PERMISSION OF THE COMPANY.

TDPS – 02 UNCONTROLLED COPY IF PRINTED Page 2 of 5

BANGALORE

QUALITY SYSTEM Prepared

by

Approved

by

PROCEDURE

DOC NO: QAP / 08 TRK RVM

Revision No. & Date: 00 / 15/12/2009

PROCUREMENT OF MATERIALS (PRODUCTION - ACG.).

Method II: Based on past performance.

Based on past performance as decided jointly by a team comprising of HOD’s of

PP&MM, Q.A, & Manufacturing & Engineering. These suppliers are included in

approved supplier list.

Method III: ISO 9000 or other quality system certified company:

A Supplier capability survey form, duly filled, will be obtained along with ISO-

9000 certificate copy. No separate evaluation / survey is deemed necessary, in

case of proprietary/branded item supply. The evaluation is applicable only in case

of non-branded item supply.

5.5.3 The evaluation of supplier’s capability through survey is as follows;

5.5.3.1 Receipt of letter by PP&MM from supplier, requesting registration / offering

to supply materials.

5.5.3.2 HOD- PP&MM & to decide whether supplier evaluation is required

immediately or to file the request for future use.

5.5.3.3 If it is decided to evaluate, supplier capability survey form in the relevant

format is sent to the supplier seeking registration and is obtained back,

duly filled in.

5.5.3.4 HOD-PP&M scrutinizes the details furnished by the supplier & arranges for

the visit of all/some members of supplier evaluation team for detailed

evaluation at supplier’s premises. Supplier evaluation team consists of

the following persons:

T.MIYANISHI SAN / S V MANJUNATH

R.VASUDEVA MURTHY (Leader).

T.R.KRISHNA MURTHY – PP&MM.

R.K.VARNA – MANUFACTURING

S. PRABHAMANI / VISHWANATH HANGARI – ENGINEERING

N.S. RAMESH / PRASANNA / M.R.MANJUNATH, VENKATESH -- QA.

SHRIPAD HEGDE – SUPPLIER QUALITY

5.5.3.6 The supplier evaluation team examines the supplier’s facility & quality

control systems with reference to requirements for the materials

intended to be procured from the supplier and verifies the correctness of

the information provided by the supplier in the capability survey form and

gives it’s report to HOD-PP&MM. The report shall, among other aspects,

include one or more of the following recommendations;

A To approve the supplier straight away.

B To disapprove the supplier if the facilities / quality systems or any

other critical aspects are found totally inadequate w.r.t. our

requirement.

C To re-evaluate -- list of improvements required to be made by the

supplier before granting approval. This is mainly if the deficiencies

noticed by the team are major in nature in the opinion of the team

members. This implies re-evaluation where the improvements made

by the supplier are verified to the team’s satisfaction.

D To approve, but-improvements are required, this is mainly if the

deficiencies are not major / critical in the opinion of the team

members. List of improvements required to be made by the supplier

are recorded.

ALL INFORMATIONS CONTAINED IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF TD POWER SYSTEM PVT., LTD.

REPRODUCTION OF THESE IN ANY FORM IS TO BE DONE WITH THE SPECIFIC PERMISSION OF THE COMPANY.

TDPS – 02 UNCONTROLLED COPY IF PRINTED Page 3 of 5

BANGALORE

QUALITY SYSTEM Prepared

by

Approved

by

PROCEDURE

DOC NO: QAP / 08 TRK RVM

Revision No. & Date: 00 / 15/12/2009

PROCUREMENT OF MATERIALS (PRODUCTION - ACG.).

E To be approve after trial order.

5.5.3.5 If the recommendation is to disapprove, the same will be conveyed to the

supplier by way of a formal letter.

5.5.3.6 If the recommendation is to re-evaluate, list of required improvements

recommended by the S.E.T. is sent to the supplier with instruction to

implement the recommendations and call for re-evaluation.

5.5.3.7 If the recommendation is to approve and insist on improvements to be

made, approval is granted to the supplier with the recommended list of

required improvements and a time schedule to comply with the same is

collected from the supplier. This is monitored periodically as per the

drawn schedule.

5.5.3.8 If the recommendation is to approve after trial order, a trial order/s is

placed on the supplier. Q.A / Engg. Will inspect the supply against the

trial order and based on its feed back, supplier’s approval is decided by

HOD-PP&MM.

5.5.3.9 When ever a supplier is approved, an approval letter is sent to the supplier

vide format no T68020.

5.5.3.10 The approved supplier is allotted with a supplier code and included in

approved supplier’s list.

5.5.4 Supplier directory is updated as and when a new supplier is approved, an

existing supplier is disapproved or category of supplier is changed based on

periodic supplier rating.

5.6 Self inspection status :

QA can recommend self-inspection status for specific suppliers based on their

performance rating. This is conveyed to the supplier by HOD-PP & MM.

5.7 Periodic supplier rating: -

5.7.1 Supplier performance is evaluated and rated once in six months provided the

supplier has affected supplies during the period considered. The period

considered for rating is April – September and October – March.

5.7.2 The following factors are considered for supplier rating: -

A. Quality level of the supplies made (Quality rating)

B. Competitiveness of the prices quoted by the supplier (Price rating).

C. Adherence to delivery schedules (delivery rating).

5.7.3 Supplier rating is done as below: -

The weight age factors considered for rating are as below;

A 75% for quality.

B 15% for delivery.

C 10% for price.

5.7.4 The quality rating is calculated by Q.A as per formulae in the relevant work

instruction and furnished to HOD-PP&MM. (Work Instruction No. TJM003)

5.7.5 A supplier has to score a minimum of 75 over a scale of 100 in quality rating to

continue as an approved supplier.

5.7.6 PP & MM converts the quality rating received from Q.A, which is for 100 marks to

75 marks in order to calculate the total supplier rating.

ALL INFORMATIONS CONTAINED IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF TD POWER SYSTEM PVT., LTD.

REPRODUCTION OF THESE IN ANY FORM IS TO BE DONE WITH THE SPECIFIC PERMISSION OF THE COMPANY.

TDPS – 02 UNCONTROLLED COPY IF PRINTED Page 4 of 5

BANGALORE

QUALITY SYSTEM Prepared

by

Approved

by

PROCEDURE

DOC NO: QAP / 08 TRK RVM

Revision No. & Date: 00 / 15/12/2009

PROCUREMENT OF MATERIALS (PRODUCTION - ACG.).

5.7.7 Delivery & price ratings are calculated by HOD-PP&MM as per formulae in the

relevant work instruction.

5.7.8 Quality & other ratings are consolidated to arrive at total supplier rating.

5.7.9 Supplier performance is evaluated and suppliers are rated under A/B/C

categories as follows:

1 A – for score of 91 & above.

2 B - for score between 81 & 90.

3 C - for score between 65 & 80

4. D - for score below 64

5.7.10 Based on the rating, supplier performance / status is communicated to the

supplier through the supplier performance rating appraisal sheet.

5.7.11 Supplier’s response for the above communication will be obtained to ensure

effective implementation of corrective measures.

5.7.12 Supplier falling under category `C’ continuously for three (3) consecutive

periods & ‘D’ for 2 periods will be considered for deletion from the approved

supplier directory.

5.7.13 HOD – PP&MM is authorized to delete any supplier from the approved list for

reasons outside the preview of the supplier rating aspects.

5.8 Periodic supplier audit: - Audit is carried out on selected suppliers based on criticality of

the product supplied to the performance of our product. The selected supplier shall

undergo audit as per the audit plan prepared by PP&MM dept. Based on the audit

results. Corrective actions are initiated and implemented by the supplier/s for

improvement.

6 REFERENCE DOCUMENTS/RECORDS:

Sales Order.

Work instruction for calculation of supplier rating.

Work Instruction for Material Receipt & Issues – Stores activity.

Work Instruction for Order handling & Production Program updating.

Supplier capability survey form.

Supplier audit plan.

Supplier audit report.

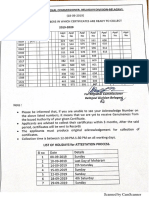

7 REVISION DETAILS:

Sl. Rev. Date Brief Details of Basis for

No. No. amendment Amendment

1 00 First Issue

ALL INFORMATIONS CONTAINED IN THIS DOCUMENT IS CONFIDENTIAL AND THE PROPERTY OF TD POWER SYSTEM PVT., LTD.

REPRODUCTION OF THESE IN ANY FORM IS TO BE DONE WITH THE SPECIFIC PERMISSION OF THE COMPANY.

TDPS – 02 UNCONTROLLED COPY IF PRINTED Page 5 of 5

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Tools, Plans, and DIY Projects Index PDFDocument5 pagesTools, Plans, and DIY Projects Index PDFCivil War75% (4)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cape Physics U1 Ia BookletDocument10 pagesCape Physics U1 Ia Bookletedgeboy47100% (2)

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarNo ratings yet

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarNo ratings yet

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarNo ratings yet

- EPS: Electric Power Steering Components & ModesDocument9 pagesEPS: Electric Power Steering Components & ModesTilahun Worku100% (1)

- Monthly HSE Statistic and Performance - Blank FormatDocument6 pagesMonthly HSE Statistic and Performance - Blank FormatZamir Mustafa67% (3)

- Inspection Test Plan Check Hold Points For Piping WorksDocument4 pagesInspection Test Plan Check Hold Points For Piping WorksYoucef Chorfa100% (1)

- Questions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopDocument19 pagesQuestions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopNico RoaNo ratings yet

- Carbon TaxDocument24 pagesCarbon Taxasofos100% (1)

- Drill Pipe Performance DataDocument35 pagesDrill Pipe Performance DatasnatajNo ratings yet

- Duoc Dien Duoc Lieu Dai Loan - 3rd - 2019Document639 pagesDuoc Dien Duoc Lieu Dai Loan - 3rd - 2019Hương Nguyễn100% (1)

- Boiler Hydro Test-StepsDocument6 pagesBoiler Hydro Test-StepsAbdul Gafoor Shaikh100% (1)

- Trade BW Logistic ExtractionDocument54 pagesTrade BW Logistic Extractionlittlebros100% (1)

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Manual for Operating a Distillation ColumnDocument12 pagesManual for Operating a Distillation ColumnAbdul Gafoor ShaikhNo ratings yet

- Pressure and Leak Testing-1Document19 pagesPressure and Leak Testing-1Abdul Gafoor ShaikhNo ratings yet

- Boiler Hydro Test: Work Components To Be TestedDocument4 pagesBoiler Hydro Test: Work Components To Be TestedAbdul Gafoor ShaikhNo ratings yet

- Quality Control in Fabrication General Erection ProceduresDocument4 pagesQuality Control in Fabrication General Erection ProceduresAbdul Gafoor ShaikhNo ratings yet

- 007 SOP For UT in StructureDocument7 pages007 SOP For UT in StructureAbdul Gafoor ShaikhNo ratings yet

- Boiler Leak Test - Compl-ProcedDocument7 pagesBoiler Leak Test - Compl-ProcedAbdul Gafoor ShaikhNo ratings yet

- Scan Doc by CamScannerDocument1 pageScan Doc by CamScannerAbdul Gafoor ShaikhNo ratings yet

- Manual for Operating a Distillation ColumnDocument12 pagesManual for Operating a Distillation ColumnAbdul Gafoor ShaikhNo ratings yet

- Job Title Reference Code:: Qhse Engineer EC-2001998Document1 pageJob Title Reference Code:: Qhse Engineer EC-2001998Abdul Gafoor ShaikhNo ratings yet

- Step by Step Procedure For Scheduling in PrimaveraDocument1 pageStep by Step Procedure For Scheduling in PrimaveraAbdul Gafoor ShaikhNo ratings yet

- API 570 Recertification Publications Effectivity Sheet: Effective: March 1, 2018Document1 pageAPI 570 Recertification Publications Effectivity Sheet: Effective: March 1, 2018ashok_04meNo ratings yet

- RCBGM Attest Stat 04102019 PDFDocument1 pageRCBGM Attest Stat 04102019 PDFAbdul Gafoor ShaikhNo ratings yet

- Job Title Reference Code:: Qhse Engineer EC-2001998Document1 pageJob Title Reference Code:: Qhse Engineer EC-2001998Abdul Gafoor ShaikhNo ratings yet

- 09022017Document1 page09022017Abdul Gafoor ShaikhNo ratings yet

- Definitions and Acronyms: Engineering Standards Manual STD-342-100Document9 pagesDefinitions and Acronyms: Engineering Standards Manual STD-342-100Abdul Gafoor ShaikhNo ratings yet

- API 570 Recertification Publications Effectivity Sheet: Effective: March 1, 2018Document1 pageAPI 570 Recertification Publications Effectivity Sheet: Effective: March 1, 2018ashok_04meNo ratings yet

- Satip A 004 03 PDFDocument3 pagesSatip A 004 03 PDFAbdul Gafoor ShaikhNo ratings yet

- Closed Book API 570 Practice Exam SummaryDocument21 pagesClosed Book API 570 Practice Exam Summarypratheepshans03No ratings yet

- Section IX QDocument10 pagesSection IX QAbdul Gafoor ShaikhNo ratings yet

- NCR 003 NaceDocument4 pagesNCR 003 NaceAbdul Gafoor ShaikhNo ratings yet

- Current LogDocument1 pageCurrent LogAbdul Gafoor ShaikhNo ratings yet

- Abdul Gafoor Ebarahim Procurement Engineer: Mohammed Ashpak Balkunja Mohammed AshifDocument2 pagesAbdul Gafoor Ebarahim Procurement Engineer: Mohammed Ashpak Balkunja Mohammed AshifAbdul Gafoor ShaikhNo ratings yet

- Does Dataset Complexity Matters For Model Explainers?: 1 Jos e Ribeiro 2 Ra Issa Silva 3 Lucas CardosoDocument9 pagesDoes Dataset Complexity Matters For Model Explainers?: 1 Jos e Ribeiro 2 Ra Issa Silva 3 Lucas CardosoJoão PauloNo ratings yet

- Unit 4 FSQCDocument28 pagesUnit 4 FSQCvaralakshmi KNo ratings yet

- Letter of RecommendationDocument2 pagesLetter of RecommendationnaveenNo ratings yet

- CH9-Diversification and AcquisitionsDocument9 pagesCH9-Diversification and AcquisitionsVincent LeruthNo ratings yet

- (Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Document3 pages(Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Hoai Ngoc NguyenNo ratings yet

- Methanol from Syngas Plant DesignDocument13 pagesMethanol from Syngas Plant DesignKhalidMadaniNo ratings yet

- BukuDocument39 pagesBukusimon sembiringNo ratings yet

- CAT D7H Track-Type Tractor Electrical System Schematic - SENR4182SENR4182 - SIS PDFDocument2 pagesCAT D7H Track-Type Tractor Electrical System Schematic - SENR4182SENR4182 - SIS PDFKomatsu Perkins HitachiNo ratings yet

- Reedisha Spinning LTD - Industrial ReportDocument112 pagesReedisha Spinning LTD - Industrial ReportShuvashish Chakma100% (4)

- Sakha DictionaryDocument14 pagesSakha DictionarySojeong MinNo ratings yet

- Project Management Remote ExamDocument4 pagesProject Management Remote ExamAnis MehrabNo ratings yet

- (Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)Document276 pages(Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)monikaNo ratings yet

- How To Avoid PlagiarismDocument2 pagesHow To Avoid PlagiarismShiny Deva PriyaNo ratings yet

- 4 - Microsoft PowerPoint - JDC Company ProfileDocument12 pages4 - Microsoft PowerPoint - JDC Company ProfileBill LiNo ratings yet

- CA ruling on fertilizer disputeDocument16 pagesCA ruling on fertilizer disputeRuby Anna TorresNo ratings yet

- Guided Noteboo Kin GED10 2 (Mathe Matics in The Modern World)Document5 pagesGuided Noteboo Kin GED10 2 (Mathe Matics in The Modern World)Aaronie DeguNo ratings yet

- 3-IBM-RB - Sales - Selling Ibm Innovative SolutionsDocument226 pages3-IBM-RB - Sales - Selling Ibm Innovative Solutionsjusak131No ratings yet

- Kolej Matrikulasi Pulau Pinang Kementerian Pelajaran Malaysia 13200 Kepala BatasDocument9 pagesKolej Matrikulasi Pulau Pinang Kementerian Pelajaran Malaysia 13200 Kepala Bataskelisa157100% (2)

- InstallDocument1 pageInstallVictor ZambranoNo ratings yet

- Chap3-2e SO2 Absorption ExampleDocument8 pagesChap3-2e SO2 Absorption Exampledarkelf_riderNo ratings yet

- Build Pulse Oximeter InstructionsDocument3 pagesBuild Pulse Oximeter InstructionsPrabhuDevNo ratings yet

- Acros Organics Acta N°006Document20 pagesAcros Organics Acta N°006Atomer FormationNo ratings yet