Professional Documents

Culture Documents

Astm C 11 - 05

Uploaded by

Felipe Bateman BuenoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm C 11 - 05

Uploaded by

Felipe Bateman BuenoCopyright:

Available Formats

Designation: C 11 – 05

Standard Terminology Relating to

Gypsum and Related Building Materials and Systems1

This standard is issued under the fixed designation C 11; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 84 Test Method for Surface Burning Characteristics of

1.1 This standard covers terminology relating to gypsum Building Materials

and related building materials and systems. The terms are E 96 Test Methods for Water Vapor Transmission of Mate-

generically defined. More specific and expanded definitions rials

may appear in appropriate standards. E 119 Test Methods for Fire Tests of Building Construction

and Materials

2. Referenced Documents E 337 Test Method for Measuring Humidity With a Psy-

2.1 ASTM Standards: 2 chrometer (The Measurement of Wet- and Dry-Bulb Tem-

C 22/C 22M Standard Specification for Gypsum peratures)

C 28/C 28M Specification for Gypsum Plasters

3. Terminology

C 35 Specification for Inorganic Aggregates for Use in

Gypsum Plaster accelerator, n—a material that reduces setting time.

C 36/C 36M Specification for Gypsum Wallboard3 accessories, n—products fabricated for the purpose of forming

C 37/C 37M Specification for Gypsum Lath3 corners, edges, control joints, or decorative effects.

C 52 Specification for Gypsum Partition Tile or Block3 adhesive, n—a substance capable of holding materials together

C 59/C 59M Specification for Gypsum Casting and Mold- by surface attachment.

ing Plaster admixture, n—a material other than water, aggregates, hy-

--``,,`,``,``,``,,,`,`,,,``,,,-`-`,,`,,`,`,,`---

C 61/C 61M Specification for Gypsum Keene’s Cement draulic cementitious material, and fiber reinforcement that is

C 79/C 79M Specification for Gypsum Sheathing Board3 used as an ingredient to modify properties and is added to the

C 317/C 317M Specification for Gypsum Concrete batch before or during its mixture.

C 318/C 318M Specification for Gypsum Formboard aggregate, n—an inert granular material which may be added

C 472 Test Methods for Physical Testing of Gypsum, Gyp- to gypsum plasters. (C 35)

sum Plasters and Gypsum Concrete all purpose compound, n—a compound formulated and

C 473 Test Methods for Physical Testing of Gypsum Panel manufactured to serve as a taping or finishing compound, or

Products both.

C 475/C 475M Specification for Joint Compound and Joint anhydrite, n—the mineral consisting primarily of anhydrous

Tape for Finishing Gypsum Board calcium sulfate, CaSO4.

C 557 Specification for Adhesives for Fastening Gypsum arris (of an arch), n—the outside corner or angle formed by

Wallboard to Wood Framing the meeting of a wall surface with the curved surface of an

C 587 Specification for Gypsum Veneer Plaster arch (see Fig. 1).

C 588/C 588M Specification for Gypsum Base for Veneer basecoat, n—the first layer or layers of plaster applied over

Plasters lath or other substrate.

DISCUSSION—The first application is normally called a scratch coat

1 and the second application is referred to as a brown coat.

This terminology is under the jurisdiction of ASTM Committee C11 on

Gypsum and Related Building Materials and Systems and is the direct responsibility bedding coat, n—that coat of plaster to receive aggregate or

of Subcommittee C11.91 on Terminology and Editorial.

Current edition approved May 1, 2005. Published May 2005. Originally other decorative material of any size, impinged or embedded

approved in 1916. Last previous edition approved in 2004 as C 11 – 04. into its surface, before it sets.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or bond plaster, n—a calcined gypsum plaster specially formu-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

lated for application over rough monolithic concrete as a

the ASTM website. bonding coat for a subsequent gypsum plaster layer.

3

Withdrawn. (C 28/C 28M)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Reproduced by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=malaysia-china hydro joint venture/5964027001

No reproduction or networking permitted without license from IHS Not for Resale, 09/16/2005 18:43:57 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Wed Aug 24 17:49:57 EDT 2005

C 11 – 05

cornerbead, n—an accessory for outside corners.

corner reinforcement, exterior, n—a preformed section of

wire or expanded sheet steel, for the reinforcement of

exterior stucco external corners (arrises).

cure (portland cement plaster or stucco), v—(1) to provide

conditions conducive to the hydration process of portland

cement plaster or stucco, or (2) to maintain proper tempera-

ture and a sufficient quantity of water within the plaster to

ensure cement hydration.

density, n—the weight per unit volume of a material.

(C 472)

edge (of gypsum board), n—the paper-bound edge as manu-

FIG. 1 Arris (of an Arch)

factured.

edge trim, n—an accessory to cover exposed ends or edges of

gypsum board.

bridging, n—in framing, sections of wood or metal pieces

embedding compound—see taping compound.

used between framing members to stiffen, give lateral

end (of gypsum board), n—the end perpendicular to the

support, and minimize rotation.

paper-bound edge. The gypsum core is always exposed.

brown coat, n—the second layer in three-coat plaster applica-

expansion joint, n—see control (expansion-contraction)

tion.

joint.

building construction joint, n—a designed division of a

face, n—the surface designed to be left exposed to view or to

building that allows movement of all component parts of the

receive decoration or additional finishes.

building, in any plane, which may be caused by thermal,

featured edge, n—an edge configuration of the paper bound

seismic, wind loading, or any other force. The construction

edge of gypsum board that provides special design or

of the separation is accomplished by one of the following

performance.

methods: (1) manufactured devices suitable for this applica-

fineness modulus, n—an empirical factor obtained by adding

tion, or (2) by field fabrication of suitable materials.

total percentages of a sample of aggregate retained on each

calcined gypsum, n—a dry powder; primarily calcium sulfate

of a specified series of sieves and dividing by 100. The sieve

hemihydrate, resulting from calcination of gypsum; cemen-

sizes used are: No. 100 (150 µm), No. 50 (300 µm), No. 30

titious base for production of most gypsum plasters: also

(600 µm), No. 16 (1.18 mm), No. 8 (2.36 mm), No. 4 (4.75

called plaster of paris, sometimes called stucco.

mm), 3⁄8 in. (9.5 mm), 3⁄4 in. (19.0 mm), 11⁄2 in. (38.1 mm)

calcium sulfate, n—the chemical compound CaSO4.

and larger, increasing in the ratio of 2 to 1.

cementitious material, n—a material that, when mixed with

finish coat, n—the final layer of plaster applied over a basecoat

water, with or without aggregate, provides the plasticity and

or other substrate.

the cohesive and adhesive properties necessary for place-

finishing compound, n—(sometimes called topping com-

ment, and the formation of a rigid mass.

pound) a compound specifically formulated and manufac-

coat, n—a layer of plaster applied in a single operation.

tured for use over taping or all purpose compounds to

combined water, n—the water chemically held, as water of

provide a smooth and level surface for the application of

crystallization, by the calcium sulfate dihydrate or hemihy-

decoration.

drate crystal.

fire-resistance classification, n—a standard rating of fire-

compressive strength, n—the maximum load sustained by a

resistance and protective characteristics of a building con-

standard specimen of a material when subjected to a crush-

struction or assembly. (E 119)

ing force.

flame spread classification, n—a standard rating of relative

consistency, n—a property of a material determined by the

surface burning characteristics of a building material as

complete flow force relation. (C 557)

compared to a standard material. (E 84)

consistency (normal), n—the number of millilitres of water

flexural strength, n—the maximum load sustained by a

per 100 g of gypsum plaster or gypsum concrete required to

standard specimen of a sheet material when subjected to a

produce a mortar or a slurry of specified fluidity. (C 472)

bending force.

control (expansion-contraction) joint, n—a designed separa-

floating, v—the act of spreading, compacting, or consolidating

tion in the system materials that allows for movement caused

to achieve a specified uniform appearance.

by expansion or contraction of the system. The construction

framing member, n—stud, plate, track, joist, furring, and

of the separation is accomplished by one of the following

other support to which a gypsum panel product, or metal

methods: (1) manufactured devices suitable for this applica-

plaster base is attached.

tion, or (2) by field fabrication of suitable materials.

free water, n—all water contained by gypsum board or plaster

core (of gypsum board), n—the hardened material filling the

in excess of that chemically held as water of crystallization.

space between the face and back papers consisting substan-

gauging plaster, n—a calcined gypsum plaster designed to be

tially of rehydrated gypsum with additives.

mixed with lime putty. (C 28/C 28M)

cored tile or block, n—see gypsum tile or block. (C 52)

--``,,`,``,``,``,,,`,`,,,``,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Copyright by ASTM Int'l (all rights reserved);

Reproduced by IHS under license with ASTM Licensee=malaysia-china hydro joint venture/5964027001

No reproduction or networking permitted without license from IHS Not for Resale, 09/16/2005 18:43:57 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Wed Aug 24 17:49:57 EDT 2005

C 11 – 05

grout, n—gypsum or portland cement plaster used to fill resistant core. (C 79/C 79M)

crevices or to fill hollow metal frames. gypsum tile or block, n—a cast gypsum building unit.

gypsum, n—the mineral consisting primarily of fully hydrated (C 52)

calcium sulfate, CaSO4·2H2O or calcium sulfate dihydrate. gypsum wallboard, n—a gypsum board used primarily as an

(C 22/C 22M) interior surfacing for building structures. (C 36/C 36M)

gypsum backing board, n—a 1⁄4 in. to 5⁄8 in. gypsum board for foil-backed gypsum wallboard—a gypsum wallboard with

use as a backing for gypsum wallboard, acoustical tile, or the back surface covered with a continuous sheet of pure

other dry cladding. bright finished aluminum foil. (C 36/C 36M)

water resistant gypsum backing board—a gypsum board type X gypsum wallboard—a gypsum wallboard specially

designed for use on walls primarily as a base for the manufactured to provide specific fire-resistant characteristics

application of ceramic, or plastic tile. (C 36/C 36M).

gypsum base for veneer plasters, n—a gypsum board used as gypsum wood-fibered plaster, n—a calcined gypsum plaster

the base for application of a gypsum veneer plaster. containing shredded or ground wood fiber added during

(C 588/C 588M) manufacture.

gypsum board, n—the generic name for a family of sheet hemihydrate, n—the dry powder, calcium sulfate hemihy-

products consisting of a noncombustible core primarily of drate, resulting from calcination of CaSO4·2H2O, calcium

gypsum with paper surfacing. sulfate dihydrate. See calcined gypsum.

gypsum concrete, n—a calcined gypsum mixed with wood joining, n—the juncture of two separate plaster applications of

chips or aggregate, or both. (C 317/C 317M) the same coat, usually within a single surface plane.

gypsum core board, n—a 3⁄4 in. (19.0 mm) to 1 in. (25.4 mm) joint compound, n—a compound used for taping or finishing

gypsum board consisting of a single board or factory gypsum board, or both.

laminated multiple boards, used as a gypsum stud or core in joint tape, n—a type of paper, metal, fabric, glass mesh, or

semisolid or solid gypsum board partitions. other material, commonly used with a cementitious com-

gypsum formboard, n—a gypsum panel product used as the pound, to reinforce the joints between adjacent gypsum

permanent form for poured gypsum roof decks. (C 318/ boards. (C 475/C 475M)

C 318M) Keene’s cement, n—an anhydrous gypsum plaster character-

gypsum lath, n—a gypsum board used as the base for ized by a low mixing water requirement and special setting

application of gypsum plaster. (C 37/C 37M) properties, primarily used with lime to produce hard, dense

--``,,`,``,``,``,,,`,`,,,``,,,-`-`,,`,,`,`,,`---

perforated gypsum lath—a gypsum lath having perforations finish coats. (C 61/C 61M)

to provide mechanical keying of the basecoat plaster. key, n—the grip or mechanical bond of one coat of plaster to

foil-backed gypsum lath—the same as plain gypsum lath another coat, or to a substrate.

except that in addition, the back surface shall be covered DISCUSSION—It may be accomplished physically by the penetration of

with a continuous sheet of pure bright finished aluminum wet mortar or crystals into paper fibers, perforations, scoring irregu-

foil. larities, or by the embedment of the lath.

type X lath—a gypsum lath specially manufactured to

provide specific fire-resistant characteristics. lath—see gypsum lath.

gypsum molding plaster, n—a calcined gypsum plaster used load-bearing partition, n—a partition designed to support a

primarily for plaster casts or molds, sometimes used as a portion of the building structure.

gauging plaster. (C 59/C 59M, C 28/C 28M) machine direction, n—the direction parallel to the paper-

gypsum neat plaster, n—a calcined gypsum mixed at the mill bound edge of the gypsum board.

with ingredients to control working quality and setting time. masonry cement, n—a hydraulic cement for use in mortars for

(C 28/C 28M) masonry construction, containing one or more of the follow-

ing materials: portland cement, portland blast furnace slag

DISCUSSION—Neat plaster is either fibered or unfibered. The addition cement, portland-pozzolan cement, natural cement, slag

of aggregate is required on the job. cement, or hydraulic lime; and in addition usually containing

gypsum panel products, n—the general name for a family of one or more materials such as hydrated lime, limestone,

sheet products consisting essentially of gypsum. chalk, calcareous shell, talc, slag, or clay as prepared for this

gypsum plaster, n—the generic name for a family of pow- purpose.

dered cementitious products consisting primarily of calcined mechanical bonds, n—the attachment created when plaster

gypsum with additives to modify physical characteristics, penetrates, into or through, the substrate, or envelops irregu-

and having the ability, when mixed with water, to produce a larities in the surface of the substrate.

plastic mortar or slurry which can be formed to the desired mill-mixed plaster (ready-mixed plaster), n—material for-

shape by various methods and will subsequently set to a mulated and dry-blended by the manufacturer, requiring only

hard, rigid mass. (C 28/C 28M) the addition of and mixing with water.

gypsum sheathing, n—a gypsum board used as a backing for mortar, n—a mixture of gypsum plaster with aggregate or

exterior surface materials, manufactured with water- hydrate lime, or both, and water to produce a trowelable

repellant paper and may be manufactured with a water- fluidity.

Copyright ASTM International 3

Copyright by ASTM Int'l (all rights reserved);

Reproduced by IHS under license with ASTM Licensee=malaysia-china hydro joint venture/5964027001

No reproduction or networking permitted without license from IHS Not for Resale, 09/16/2005 18:43:57 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Wed Aug 24 17:49:57 EDT 2005

C 11 – 05

neat gypsum plaster—see gypsum neat plaster.

perm, n—a unit of measurement of water vapor permeance; a

metric perm, or 1 g/24 h·m2·mm Hg. U.S. unit, 1 grain/

h·ft2·in. Hg. (E 96)

permeability, n—the property of a porous material that per-

mits a fluid (or gas) to pass through it; in construction,

commonly refers to water vapor permeability of a sheet

material or assembly and is defined as water vapor per-

meance per unit thickness. Metric unit of measurement,

metric perms per centimetre of thickness. See water vapor

transmission, perm, permeance. (E 96)

permeance (water vapor), n—the ratio of the rate of water

vapor transmission (WVT) through a material or assembly

between its two parallel surfaces to the vapor pressure

differential between the surfaces. Metric unit of measure-

ment is the metric perm, 1 g/24 h·m2·mm Hg; U.S. unit, 1

grain/h·ft2·in. Hg. See water vapor transmission, perme-

ability, perm. (E 96)

plaster—see gypsum plaster, gypsum neat plaster.

plaster bond, n—the adhesion between plaster coats or be-

tween plaster and substrate. FIG. 2 Saddle-Tie

plastic cement, n—a hydraulic cement to which one or more

plasticizing agents (but not more than 12 % by volume) have

been added during intergrinding or blending to increase the saddle-tie, for furring, v—to attach furring members to fram-

workability and molding qualities of the resultant cement ing members of wall or ceiling assemblies using a single or

paste, mortar, or plaster. double strand of wire. See Fig. 2.

plasticity, n—the property of freshly mixed cement paste, saddle-tie, for wire hangers, v—to attach wire hangers to main

mortar, or plaster which determines its workability and runners. See Fig. 3.

molding qualities. scratch coat, n—the first layer of plaster applied over lath or

portland cement, n—a hydraulic cement produced by pulver- other substrate.

izing clinker consisting essentially of hydraulic calcium set, n—the chemical and physical change in plaster as it goes

silicates, and usually containing one or more forms of from a plastic, workable state to a rigid state. See setting

calcium sulfate as an interground addition. time. (C 472)

portland cement plaster, n—a plaster mix in which portland

cement or combinations of portland and masonry cements or

portland cement and lime are the principal cementitious

materials mixed with aggregate.

purity, n—the percentage of CaSO4·1⁄2 H2O in the calcined

gypsum portion of a gypsum plaster or gypsum concrete, as

defined by Specification C 28/C 28M, for Gypsum Plasters.

The percentage of CaSO4·2H2O in the gypsum or the

gypsum portion of fully hydrated, dry, set gypsum plaster.

(C 472, C 28/C 28M)

ready-mixed plaster, n—a calcined gypsum plaster with

aggregate added during manufacture. (C 28/C 28M)

--``,,`,``,``,``,,,`,`,,,``,,,-`-`,,`,,`,`,,`---

recessed edge, n—see tapered edge

relative humidity, n—the ratio of actual water vapor pressure

to the saturation water vapor pressure at the same tempera-

ture, expressed as a percentage. (E 337)

retarder, n—a material that extends setting time.

round edge, n—a rounded, paper-bound edge formation on

gypsum board, commonly used for gypsum lath. (C 37/

C 37M, C 473)

saddle-tie, for furring, n—a single or double strand of wire

used to attach furring members to framing members of wall

or ceiling assemblies. See Fig. 2. FIG. 3 Saddle-Tie

Copyright ASTM International 4

Reproduced by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=malaysia-china hydro joint venture/5964027001

No reproduction or networking permitted without license from IHS Not for Resale, 09/16/2005 18:43:57 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Wed Aug 24 17:49:57 EDT 2005

C 11 – 05

setting time, n—the elapsed time required for a gypsum three-coat work, n—plaster applied in three successive coats

plaster to attain a specified hardness and strength after with time between coats for setting or drying, or both.

mixing with water. (C 472) topping compound—see finishing compound.

shipment (of gypsum panel products), n—the quantity of veneer plaster, n—a calcined gypsum plaster formulated to be

gypsum panel products shipped by a manufacturer and applied in thin coats. (C 587)

included on a single invoice. wallboard—see gypsum wallboard. (C 36/C 36M)

smooth-trowel finish, n—a uniform finish free of grainy or water absorption, n—the amount of water absorbed by a

coarse areas, trowel marks, or other avoidable imperfections. material under specified test conditions commonly expressed

stucco, n—a portland cement-aggregate plaster mix designed as weight percent of the test specimen.

for use on exterior surfaces. See portland cement plaster. water-repellent paper, n—gypsum board paper surfacing

synthetic gypsum, n—a chemical product, consisting prima- which has been formulated or treated to resist water pen-

rily of calcium sulfate dihydrate (CaSO4·2H2O) resulting etration.

primarily from an industrial process. water-resistant core, n—a gypsum board specially formulated

tapered edge, n—an edge formation of gypsum board which to resist water penetration.

provides a shallow depression at the paper-bound edge to water vapor transmission (WVT), n—the rate of water vapor

receive joint reinforcement. Also known as a recessed edge. flow, under steady specified conditions, through a unit area

(C 473, C 36/C 36M) of a material, between its two parallel surfaces and normal to

taping compound, n—(sometimes called embedding com- the surfaces. Metric unit of measurement is 1 g/24 h·m2. See

pound) a compound specifically formulated and manufac- permeability,permeance, perm. (E 96)

tured for use in embedding of joint reinforcing tape at wood-fibered plaster, n—a calcined gypsum plaster contain-

gypsum board joints. ing shredded or ground wood fiber added during manufac-

temper, v—to mix or restore to a workable consistency. ture. (C 28/C 28M)

texture finish, n—any applied decorative finish other than

smooth.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--``,,`,``,``,``,,,`,`,,,``,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Copyright by ASTM Int'l (all rights reserved);

Reproduced by IHS under license with ASTM Licensee=malaysia-china hydro joint venture/5964027001

No reproduction or networking permitted without license from IHS Not for Resale, 09/16/2005 18:43:57 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Wed Aug 24 17:49:57 EDT 2005

You might also like

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Gas Chromatography: Principles, Techniques, and ApplicationsFrom EverandGas Chromatography: Principles, Techniques, and ApplicationsNo ratings yet

- Astm C 11-08aDocument6 pagesAstm C 11-08aSig BlackhysteriaNo ratings yet

- Gypsum and Related Building Materials and Systems: Standard Terminology Relating ToDocument5 pagesGypsum and Related Building Materials and Systems: Standard Terminology Relating ToSalma AlzwayNo ratings yet

- Gypsum and Related Building Materials and Systems: Standard Terminology Relating ToDocument6 pagesGypsum and Related Building Materials and Systems: Standard Terminology Relating Tosharon blushteinNo ratings yet

- C 11 - 03, Qzexltazqw - PDFDocument5 pagesC 11 - 03, Qzexltazqw - PDFbasse123No ratings yet

- C 11 Â " 03 QZEXLTAZQQDocument5 pagesC 11 Â " 03 QZEXLTAZQQalicia tigseNo ratings yet

- Gypsum and Related Building Materials and Systems: Standard Terminology Relating ToDocument5 pagesGypsum and Related Building Materials and Systems: Standard Terminology Relating ToDesai NileshNo ratings yet

- Astm C 11Document5 pagesAstm C 11Bugoy VouyNo ratings yet

- C 11 - 01 Qzexltax PDFDocument5 pagesC 11 - 01 Qzexltax PDFipkm123No ratings yet

- Astm C 11-16Document6 pagesAstm C 11-16Saba AhmedNo ratings yet

- ASTM C11-15a Standard Terminology Relating To Gypsum and Related Building Materials and SystemsDocument6 pagesASTM C11-15a Standard Terminology Relating To Gypsum and Related Building Materials and SystemsJesus Prado100% (1)

- Gypsum and Related Building Materials and Systems: Standard Terminology Relating ToDocument7 pagesGypsum and Related Building Materials and Systems: Standard Terminology Relating ToCarlos CmbbNo ratings yet

- C33 - 08 Standard Specification For Concrete Aggregates1Document11 pagesC33 - 08 Standard Specification For Concrete Aggregates1José AlejandroNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument12 pagesReady-Mixed Concrete: Standard Specification ForAnas KhallafNo ratings yet

- Standards For Repair Material C 928 PDFDocument4 pagesStandards For Repair Material C 928 PDFAndrew PiNo ratings yet

- Norm AstmDocument4 pagesNorm AstmEdmundo Jaita CuellarNo ratings yet

- ASTM (2018) Standard Specifications For Conrete Aggregates Designation C33 C33M 08 ASTM Standards Nov 2018astm c33 - Compress 2018Document11 pagesASTM (2018) Standard Specifications For Conrete Aggregates Designation C33 C33M 08 ASTM Standards Nov 2018astm c33 - Compress 2018Melkamu AmareNo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument7 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationJesús Luis Arce GuillermoNo ratings yet

- C 36 - C 36M - 99, Qzm2ltk5rte - PDFDocument3 pagesC 36 - C 36M - 99, Qzm2ltk5rte - PDFbasse123No ratings yet

- Chemical Analysis of Gypsum and Gypsum Products (Metric) : Standard Test Methods ForDocument15 pagesChemical Analysis of Gypsum and Gypsum Products (Metric) : Standard Test Methods ForAquino100% (1)

- ASTM C33 02a Concrete AggregatesDocument11 pagesASTM C33 02a Concrete AggregatesJanice Tatiana Alva DelgadoNo ratings yet

- ASTM C 94 - C 94M - 04 Concreto PremezcladoDocument10 pagesASTM C 94 - C 94M - 04 Concreto PremezcladoIsrael SarmientoNo ratings yet

- ASTM C33 - 2007 - Standard Specification For Concrete AggregatesDocument11 pagesASTM C33 - 2007 - Standard Specification For Concrete AggregatesDayana HernandezNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForEdgardo Humberto GonzálezNo ratings yet

- C94C94M-Concreto PremezcladoDocument11 pagesC94C94M-Concreto PremezcladoAnthony López HuamanNo ratings yet

- Astm C497Document12 pagesAstm C497FrengkiNo ratings yet

- C 442 - C 442M - 04 - Qzq0mi9dndqytqDocument4 pagesC 442 - C 442M - 04 - Qzq0mi9dndqytqEjat ISNo ratings yet

- Astm C 796 Metodo de Prueba para Espuma en CemDocument6 pagesAstm C 796 Metodo de Prueba para Espuma en Cemandrea sanchezNo ratings yet

- Making and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForDocument8 pagesMaking and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForAhmed AbidNo ratings yet

- Astm c-192 PDFDocument8 pagesAstm c-192 PDFProbo100% (2)

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForAnas KhallafNo ratings yet

- Concrete Aggregates': Standard Specification ForDocument8 pagesConcrete Aggregates': Standard Specification ForAhmed AbidNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForEjat ISNo ratings yet

- ASME Standard For Concrete Aggreates (C 33 - 99a)Document8 pagesASME Standard For Concrete Aggreates (C 33 - 99a)Jade Al BoodoosinghNo ratings yet

- Astm C 33 - 03Document11 pagesAstm C 33 - 03Laziz AtmaniNo ratings yet

- Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Document5 pagesPotential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Ahmed AbidNo ratings yet

- ASTM C94 C94M 03 Ready Mixed ConcreteDocument10 pagesASTM C94 C94M 03 Ready Mixed ConcreteJuan Ch100% (1)

- Length Change of Hardened Hydraulic-Cement Mortar and ConcreteDocument7 pagesLength Change of Hardened Hydraulic-Cement Mortar and ConcreteEjat ISNo ratings yet

- C 28 - C 28M - 00 - Qzi4l0myoe0 - PDFDocument4 pagesC 28 - C 28M - 00 - Qzi4l0myoe0 - PDFJORGE IVAN LAMBIS CAMPILLONo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument6 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationJesús Luis Arce GuillermoNo ratings yet

- Length Change C 157Document7 pagesLength Change C 157Vaguiner VieiraNo ratings yet

- Astm C 1116Document7 pagesAstm C 1116Joel Josué Vargas BarturénNo ratings yet

- Glass Fiber Reinforced Gypsum Composites: Standard Specification ForDocument2 pagesGlass Fiber Reinforced Gypsum Composites: Standard Specification ForJesús Luis Arce GuillermoNo ratings yet

- Compressive Strength of Masonry Prisms: Standard Test Method ForDocument9 pagesCompressive Strength of Masonry Prisms: Standard Test Method ForAnas KhallafNo ratings yet

- ASTM C 36 - Standard Specification For Gypsum Wallboard PDFDocument4 pagesASTM C 36 - Standard Specification For Gypsum Wallboard PDFibrahimNo ratings yet

- ASTM C474 - Standard Test Methods For Joint Treatment Materials For Gypsum Board ConstructionDocument12 pagesASTM C474 - Standard Test Methods For Joint Treatment Materials For Gypsum Board Constructionedd11040% (1)

- Ready-Mixed Concrete: Standard Specification ForDocument12 pagesReady-Mixed Concrete: Standard Specification ForjasimabdNo ratings yet

- Sampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcreteDocument10 pagesSampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcreteBruce JameroNo ratings yet

- ASTM C0192 - C0192M - 07 - 15 Preparación y Curado de Especimenes de Concreto en Laboratorio PDFDocument8 pagesASTM C0192 - C0192M - 07 - 15 Preparación y Curado de Especimenes de Concreto en Laboratorio PDFJohnny Araya VigilNo ratings yet

- Silica Fume Used in Cementitious Mixtures: Standard Specification ForDocument7 pagesSilica Fume Used in Cementitious Mixtures: Standard Specification ForNasir HameedNo ratings yet

- ASTM C 1567 - Alkali Silica Reactivity Test For Concrete MixDocument6 pagesASTM C 1567 - Alkali Silica Reactivity Test For Concrete MixRajnikanth GedhadaNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument8 pagesConcrete Aggregates: Standard Specification ForMiguelAngelContrerasOrtizNo ratings yet

- 31-Astm C1077-16Document9 pages31-Astm C1077-16Rolando de GuzmanNo ratings yet

- Astm C 1054-03Document3 pagesAstm C 1054-03Tâm NgôNo ratings yet

- C31 C31M 03aDocument5 pagesC31 C31M 03aJesus Luis Arce GuillermoNo ratings yet

- Glass Fiber Reinforced Gypsum Composites: Standard Specification ForDocument2 pagesGlass Fiber Reinforced Gypsum Composites: Standard Specification Forcristina ramosNo ratings yet

- Astm C 33Document7 pagesAstm C 33alfonso mendoza0% (1)

- Astm C33 C33M-16Document11 pagesAstm C33 C33M-16haval100% (2)

- Astm C 12 - 04Document7 pagesAstm C 12 - 04Felipe Bateman BuenoNo ratings yet

- Astm C 4 - 04Document6 pagesAstm C 4 - 04Felipe Bateman BuenoNo ratings yet

- Weight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsDocument4 pagesWeight (Mass) of Coating On Iron and Steel Articles With Zinc or Zinc-Alloy CoatingsFelipe Bateman BuenoNo ratings yet

- ASTM A 82 - Steel Wire, Plain, For Concrete Reinforcement1 PDFDocument4 pagesASTM A 82 - Steel Wire, Plain, For Concrete Reinforcement1 PDFjojeecaresNo ratings yet

- Composting: Fatima P. Solimen AEW OCAS, Tabuk CityDocument33 pagesComposting: Fatima P. Solimen AEW OCAS, Tabuk CityEthyle Morales LingbawanNo ratings yet

- Landscape Lecture - 4 - All About Landforms - in Landscape ArchitectureDocument61 pagesLandscape Lecture - 4 - All About Landforms - in Landscape ArchitectureSHIVANI GUPTANo ratings yet

- Canadian Rose Annual 1967Document244 pagesCanadian Rose Annual 1967gregariousmonk100% (1)

- Manual of Geotechnical Laboratory Soil TestingDocument415 pagesManual of Geotechnical Laboratory Soil TestingBobNo ratings yet

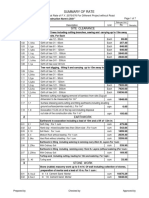

- Rate Analysis-NormsDocument7 pagesRate Analysis-NormsGajendra Joshi0% (1)

- The Final Syllabus On Organic AgriDocument26 pagesThe Final Syllabus On Organic Agrixtine-rey Quinto100% (1)

- MCQs VSC507 - 20-21Document5 pagesMCQs VSC507 - 20-21aditya singhNo ratings yet

- This Article Is From The June 2012 Issue ofDocument9 pagesThis Article Is From The June 2012 Issue ofAlfredo N. Huamaní GarcíaNo ratings yet

- Module 3 - Mud Plastering, Mud ConstructionDocument23 pagesModule 3 - Mud Plastering, Mud ConstructionmUSINo ratings yet

- Cucurbitaceae: (Assignment # 02 Semester Spring-2020) Submission Date (April 27, 2020) BY Group #04Document14 pagesCucurbitaceae: (Assignment # 02 Semester Spring-2020) Submission Date (April 27, 2020) BY Group #04Aqib ShahzadNo ratings yet

- Growth Responses and Root Characteristics of Lettuce Grown in Aeroponics, Hydroponics, and Substrate CultureDocument9 pagesGrowth Responses and Root Characteristics of Lettuce Grown in Aeroponics, Hydroponics, and Substrate CultureChristian Delas HerrasNo ratings yet

- P#1 - Hort-502 - Prun of GrapesDocument3 pagesP#1 - Hort-502 - Prun of Grapesjunaid jutt 05No ratings yet

- Civil Engineering Project Titles Engineering ProjectsDocument43 pagesCivil Engineering Project Titles Engineering ProjectsPratik Rao0% (1)

- References: A concise SEO-optimized titleDocument59 pagesReferences: A concise SEO-optimized titleSyarif HidayatNo ratings yet

- Objectives Biology IDocument3 pagesObjectives Biology IZunaira NoreenNo ratings yet

- Concrete Mix Design Excel SheetDocument12 pagesConcrete Mix Design Excel SheetDhanush SNo ratings yet

- Cauliflower Production Guideline 2019Document4 pagesCauliflower Production Guideline 2019Lesley ShiriNo ratings yet

- Determination of Combined Aggregate Gradation (% Passing)Document5 pagesDetermination of Combined Aggregate Gradation (% Passing)juliovechimgmailNo ratings yet

- Nzs 4298 1998Document91 pagesNzs 4298 1998al_bundiNo ratings yet

- The Impact of Insect Pests On Cowpea Production in NigeriaDocument35 pagesThe Impact of Insect Pests On Cowpea Production in NigeriaOmowunmi A-TNo ratings yet

- Building 2020-2021 Final - M SAND-FinalDocument95 pagesBuilding 2020-2021 Final - M SAND-FinalkamalgkNo ratings yet

- Application of GeosyntheticsDocument30 pagesApplication of GeosyntheticsKiprono VincentNo ratings yet

- Calcium Nitrate BrochureDocument3 pagesCalcium Nitrate BrochuremanojbanNo ratings yet

- Parts of A Plant Song: 1. RootsDocument2 pagesParts of A Plant Song: 1. RootsJamaica Haduca BalleraNo ratings yet

- Bush Sitao ProductionDocument8 pagesBush Sitao Productionpandaypira100% (1)

- ERG 211 Assignment 2018001009Document19 pagesERG 211 Assignment 2018001009erkiruthirajNo ratings yet

- Encyclopedia of Philippine TreesDocument134 pagesEncyclopedia of Philippine TreesDerrick Yson (Mangga Han)100% (1)

- Localized Irrigation v2.08Document179 pagesLocalized Irrigation v2.08YO Batia BiiNo ratings yet

- Atlas Plante de AcvariuDocument142 pagesAtlas Plante de AcvariuValentin CretuNo ratings yet

- Haygrove Multi-Bay Tunnels - 4 SeriesDocument4 pagesHaygrove Multi-Bay Tunnels - 4 SeriesMehdi BassouNo ratings yet