Professional Documents

Culture Documents

Symbols Equations PDF

Uploaded by

YenJangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Symbols Equations PDF

Uploaded by

YenJangCopyright:

Available Formats

SYMBOLS, PHYSICAL PROPERTIES AND USEFUL EQUATIONS

Note that NOT all information included in this list is relevant to the questions in this examination paper!

Symbols used for main physical quantities:

quantity symbol Definition quantity symbol Definition

cartesian coordinates: x, y, z; u velocity: v v = du/dt

spherical coordinates: r; ϑ; φ speed: v v = |v|

cylindrical coordinates: r; ϑ; z acceleration: a a = dv/dt

length: l acceleration of gravity: g

deflection: u, w, z force: F F = ma

maximum deflection: δ internal normal force: N, S

thickness: t internal shear force: Q

width: w force per unit length: w

radial length, radius: r, R moment (torque): M (T) T=u×F

diameter: d bending moment: M

distance from axis: h moment per unit length: Mx,y,r,ϑ

plane angle: ϑ; φ pressure: p, P p = F/A

area: A normal stress: σ σ = F/A

volume: V shear stress: τ τ = F/A

time: t linear strain: ε ε = Δl/l

angular velocity: ω ω = dφ/dt Poisson’s ratio: ν

y dA modulus of elasticity,

first moment of area: J Jx = ∫ A Young’s modulus: E E = σ/ε

second moment of area, shear strain: γ γ = Δx/t

moment of inertia: I Ix = ∫ y 2 dA shear modulus: G G = τ/γ

A

mass: m energy: W

density, mass density: ρ ρ = m/V potential energy: U

Material Properties:

Material: Density: Young’s modulus Yield stress: Poisson’s ratio Thermal expansion coeff.

Stainless steel (AISI 440) ρ = 7800 kg/m3 E = 200 GPa σY = 1280 MPa ν = 0.29 α = 10.1 µm/m K

Aluminium (214-T4) ρ = 2800 kg/m3 E = 73 GPa σY = 276 MPa ν = 0.33 α = 24.0 µm/m K

PVC ρ = 1450 kg/m3 E = 3.2 GPa; σY = 52 MPa; ν = 0.40 α = 50.4 µm/m K

Silicone rubber ρ = 1250 kg/m3 E = 3.5 MPa; σY = 9 MPa; ν = 0.45 α = 270 µm/m K

Useful equations:

Radial and hoop stresses for thick cylinders subjected to pressure:

B and B (A and B constants)

σr = A− 2 σθ = A + 2

r r

Radial and circumferential stresses for rotating discs:

D 3+ ν and D 1+ 3ν (C, D const.)

σr = C − 2 − ρω 2 r 2 σϑ = C + − ρω 2 r 2

r 8 r2 8

Circular Plates of uniform thickness t:

Deflection z, at a radius r, for a circular plate, when:

- deflection for a uniformly distributed normal load p, per unit area: pr d ' 1 d ! dz $* ;

= ) # r &,

2D dr ( r dr " dr %+

- deflection for a concentrated central force F: d ' 1 d ! dz $* F ;

) # r &, =

dr ( r dr " dr %+ 2π rD

where: Et 3

D=

(

12 1 − ν 2 )

Bending moments per unit length: " d 2 z ν dz % and " d 2 z 1 dz % ;

M r = −D $ 2 + ' M ϑ = −D $ν 2 + '

# dr r dr & # dr r dr &

Stress distribution by: 12 M r h and 12 M c h (h distance from neutral surface).

σr = σϑ =

t3 t3

Useful standard integrals:

ϑ 1

∫ sin 2 ϑ dϑ = 2 − 4 sin 2ϑ + C

ϑ 1

∫ cos2 ϑ dϑ = 2 + 4 sin 2ϑ + C

1

∫ sin ϑ ⋅ cosϑ dϑ = 2 sin 2 ϑ + C

END OF PAPER

You might also like

- Wizgiz Limited: Required: A)Document1 pageWizgiz Limited: Required: A)YenJangNo ratings yet

- Chesterfield WanderersDocument2 pagesChesterfield WanderersYenJangNo ratings yet

- HuntingdonDocument1 pageHuntingdonYenJangNo ratings yet

- MAFE Lecture 6 2019-20 Slides StudentDocument29 pagesMAFE Lecture 6 2019-20 Slides StudentYenJangNo ratings yet

- Answers To Lecture 3Document20 pagesAnswers To Lecture 3YenJangNo ratings yet

- (Financial Figures in 000) : ARR Calculation: Invest LimitedDocument15 pages(Financial Figures in 000) : ARR Calculation: Invest LimitedYenJangNo ratings yet

- Aggregate LTD AnswerDocument1 pageAggregate LTD AnswerYenJangNo ratings yet

- Seminar 1: MSIN0065 Business Economics For EngineersDocument1 pageSeminar 1: MSIN0065 Business Economics For EngineersYenJangNo ratings yet

- Material CourseworkDocument4 pagesMaterial CourseworkYenJangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Richard Meier - Beyond AutonomyDocument33 pagesRichard Meier - Beyond AutonomyOtis Sloan BrittainNo ratings yet

- List of Seinfeld EpisodesDocument18 pagesList of Seinfeld EpisodestusarNo ratings yet

- Rudiment Control: Clinic Edition!Document28 pagesRudiment Control: Clinic Edition!USER58679100% (2)

- Extravagant Apartments South MumbaiDocument5 pagesExtravagant Apartments South MumbaiRakeshNo ratings yet

- Artpreneur Course OutlineDocument6 pagesArtpreneur Course OutlineAdithyan Gowtham0% (1)

- Te Unit4Document72 pagesTe Unit4troubadour2404No ratings yet

- Gayatri Mantra and Shaap VimochanaDocument4 pagesGayatri Mantra and Shaap VimochanaSharmila JainNo ratings yet

- Workbook Answer KeysDocument21 pagesWorkbook Answer Keysmatthew wongNo ratings yet

- Microsoft Picture It PublishingDocument22 pagesMicrosoft Picture It PublishingDanielle Elish GocoNo ratings yet

- 2019 TMT Residential BrochureDocument5 pages2019 TMT Residential BrochureGabby CardosoNo ratings yet

- Concept PaperDocument4 pagesConcept PaperAbigail67% (3)

- Irregular Verbs List 2 Respuesta PDFDocument1 pageIrregular Verbs List 2 Respuesta PDFAlberto Segado SanchezNo ratings yet

- Ts 136101v140400pDocument1,451 pagesTs 136101v140400pBhushan ZopeNo ratings yet

- Adjust Global App Trends 2019Document35 pagesAdjust Global App Trends 2019MetropolesNo ratings yet

- Punjab Gyanam NotesDocument14 pagesPunjab Gyanam Notessantosh.manojNo ratings yet

- Comparison of 2d and 3d AnimationDocument15 pagesComparison of 2d and 3d Animationjijay666100% (10)

- HoA 2 ReviewerDocument9 pagesHoA 2 ReviewerSamänthä Mae ParladeNo ratings yet

- Fundamental Concepts of VideoDocument55 pagesFundamental Concepts of VideoAwaisAdnan100% (2)

- Pfof1950 V01 PDFDocument1,006 pagesPfof1950 V01 PDFFilep-LukácsIstvánNo ratings yet

- Hair Love Worksheet Around The Short Movie and The Picture Stories Worksheet Templates Layouts Writin - 132644Document9 pagesHair Love Worksheet Around The Short Movie and The Picture Stories Worksheet Templates Layouts Writin - 132644yuliaNo ratings yet

- Cerruti HistoryDocument4 pagesCerruti HistoryPhan LeNo ratings yet

- Super Dungeon Explore Arena PDFDocument3 pagesSuper Dungeon Explore Arena PDFlars gunnarNo ratings yet

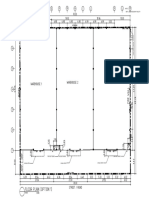

- Floor Plan (Option 1) : Warehouse 2 Warehouse 1 Warehouse 3Document1 pageFloor Plan (Option 1) : Warehouse 2 Warehouse 1 Warehouse 3John Carlo AmodiaNo ratings yet

- MC Script 4 RecogDocument2 pagesMC Script 4 RecogArjel DantesNo ratings yet

- My Greatest Ambition NotesDocument2 pagesMy Greatest Ambition NotesSimran Nova SiddiqueNo ratings yet

- Mo JaresDocument3 pagesMo JaresGr MacopiaNo ratings yet

- Japanese Folk SongsDocument22 pagesJapanese Folk SongsAndre Lorenz Feria100% (1)

- USA - Augusta Read ThomasDocument2 pagesUSA - Augusta Read ThomasEtnoalbanianNo ratings yet

- Britten's Musical Language, by Philip RupprechtDocument370 pagesBritten's Musical Language, by Philip Rupprechtheriberto100% (3)