Professional Documents

Culture Documents

How To Select A Pump For Industrial Applications

Uploaded by

Mohammad Yasser Ramzan0 ratings0% found this document useful (0 votes)

30 views3 pagesOriginal Title

how-to-select-a-pump-for-industrial-applications

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views3 pagesHow To Select A Pump For Industrial Applications

Uploaded by

Mohammad Yasser RamzanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

HOW TO SELECT A PUMP FOR

INDUSTRIAL APPLICATIONS

FACTORS TO CONSIDER TO ENSURE LONG SERVICE LIFE WITH MINIMAL MAINTENANCE

installed outdoors for protection from the

elements. Heating or cooling of the enclosure

may be required in locations with extreme

temperatures. Operation at higher altitude will

also affect pump flow performance due to the

reduced air pressure.

Often, pumps are required in environments that

contain combustible gases. These hazardous

location areas require equipment rated to match

the explosive potential of what will be present.

The Class, Division, Gas Groups, and

Temperature Codes must meet or exceed the

requirements of the HazLoc area. ATEX pumps

may be used in certain situations. Consultation

with personnel familiar with NEC/NFPA

regulations or the authority with jurisdiction

over the area is recommended.

INTRODUCTION SYSTEM FACTORS

Designers are usually familiar with the flow and Pressure drops through various system

pressure needs of their applications and what components, such as heat exchangers, getters,

they plan on pumping, but that’s just a start. etc., must be accounted for when selecting a

There are many factors specific to each pump. Just like in a tangled garden hose, the

application that need to be evaluated before the more resistance there is in a pumping

correct pump can be selected. Most of these application, the more force it takes to push a

factors can be grouped into environmental, fluid through it. That is why every flow-path

system, and media issues. Consulting early in characteristic (tube ID, material, finish, length,

the design process with a pump company helps filters, orifices, valves, fittings, elbows,

ensure that the pump selected will perform as mufflers, etc.) should be evaluated for the

expected while minimizing ongoing pressure drop across it. Adding them all up

maintenance. determines the total change in pressure the

pump must overcome to generate flow.

PUMP ENVIRONMENT Restrictions on the pump’s inlet are especially

Most diaphragm pumps operate comfortably in significant because 14.7 psig is the largest

the same conditions we do. The highest possible suction difference at sea level. Pumps

probability for a long pump lifetime comes from should also be sized to produce the required

a clean, temperate, sheltered location. A clean flow rate even when the filters are dirty and

supply of air will provide plenty of cooling by need servicing.

keeping insulating dirt from adhering to the

surfaces and fouling internal components. Designers should know what the pump’s duty

Shelter from the elements will be required if cycle will be. Sometimes there is a question as

to whether the pump should run full speed

because it poses a danger (e.g. pyrophoric

continuously, be cycled on and off, or if a speed

gases). The pump manufacture can make pump

control system is required. A list of factors

modifications to mitigate leakage and air

should be weighed to determine the best

intrusion. A leakage monitoring system can also

solution for the application. These factors

be added.

include motor type (Single phase AC, 3-phase

AC, brushless DC, air-driven), noise limits,

Media temperatures must also be considered.

desired life of the pump, susceptibility to

Some gases, such as helium, are exothermic

current spikes and vibrations, heat generation,

and heat up when compressed. Depending on

and load at start up and shut down. Controlling

the gas and the ultimate system pressure,

the motor’s speed with a BLDC or three phase

accommodations to deal with this heat may be

motor driven by a variable frequency drive is

required. Water-cooling 316 stainless steel

becoming a popular and successful way to

heads, air-cooling aluminum heads, and inter-

address these factors. Running the pump at

head coolers are possible solutions for handling

lower speeds also saves power and extends

such media. For other applications – such as

the preventive maintenance schedule.

hot/wet continuous monitoring systems – the

media must remain hot. Not all pumps can

THE MEDIA

handle elevated temperature media, therefore a

Media can have a large impact on the system

heat-resistant model may be required. These

pump choice. Aside from the obvious chemical

pumps are usually made of 316 stainless steel

compatibility issues affecting pump component

and PTFE to handle temperatures up to 460°F

material selection, other aspects must be

(240°C). The heads are extended to keep heat

examined.

from transferring to the rest of the pump and

vented components aid in cooling.

The effect of gas media density must be

considered. Light gases such as helium and

hydrogen pump at significantly different rates

than air through the same system. Most pumps

are rated for air flow. Therefore, flow differences

due to gas density must be compensated for or

the pump will be undersized. The opposite

holds true for very dense gases. The pressure

drop across the components and line will be

greater than with air and will reduce the flow

through the system. Liquid media viscosity and

flow characteristics must also be considered.

Consult the pump manufacturer to determine

the correct pump size to compensate for media

density/viscosity and flow needs.

Leakage must also be accounted for with

lighter gases, especially those that are very

costly (e.g. Helium-3) or that are dangerous to

Rev: November 2019

release to the atmosphere. Depending on the

gas media, leakage of air into the pump (air

intrusion) is equally undesirable, either because

of contamination/dilution of the media, or

KNF Neuberger Inc. ■

2 Black Forest Rd, Trenton, NJ 08691 ■

609-890-8600 ■

knfusa@knf.com ■

www.knfusa.com

to consider include pump orientation and

mounting, system sensitivity to pulsation,

self-priming needs for liquid pumps, dynamic

pump performance control, safeguards against

downstream blockages (especially if dangerous

media are involved), possible condensation and

liquids (for gas systems), regulatory and

certification documentation requirements, etc.

In summary, there are many factors that a

designer must consider when selecting a pump

that will perform successfully over the lifetime

of a system. The best solution is determined by

assessing the unique application needs and

weighing the possible solutions with a trusted

Another common media issue is particulates.

pump supplier. A consultative and thorough

Pump technologies have different tolerances for

approach is the path that most often leads to a

particulate size, hardness, etc. For instance, the

success.

gears in gear pumps can be abraded by

particulates, potentially shortening their service

life to unacceptable levels. Fibers can cause

potential issues with certain pump

Richard Aerts is a Process Products Engineer who

technologies. Ideally, particulates should be

partners with designers in a variety of industries to

removed from media by eliminating their entry

understand their system requirements and develop

and/or development, or be filtered out on the

robust pumping solutions. With over 30 years of

inlet side of the pump. If elimination is

experience working with electrical, gas powered,

impossible or particles are an intrinsic and

and pneumatic systems, he has focused on

necessary part of the media, then their

diaphragm pump technology at KNF Neuberger for

characterization is important to proper pump

the past 14 years. Rich holds a BS in Mechanical

selection.

Engineering and likes to build and modify guitar

effects pedals and amplifiers in his spare time.

OTHER FACTORS TO CONSIDER

A trusted pump manufacturing partner will have

the application experience necessary to provide

guidance through many of the common pitfalls

of system design. Some other possible factors

"A trusted pump manufacturing partner will

have the application experience necessary

Rev: November 2019

to provide guidance through many of the

common pitfalls of system design."

KNF Neuberger Inc. ■

2 Black Forest Rd, Trenton, NJ 08691 ■

609-890-8600 ■

knfusa@knf.com ■

www.knfusa.com

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Worksheet Oxidation ReductionDocument7 pagesWorksheet Oxidation ReductionRudi BerlianNo ratings yet

- Commpressed Air TipsDocument11 pagesCommpressed Air TipsfructoraNo ratings yet

- Compressor AntisurgeDocument12 pagesCompressor AntisurgeSaqib NazirNo ratings yet

- Surge Control Dynamic Simulation Centrifugal CompDocument3 pagesSurge Control Dynamic Simulation Centrifugal CompAnil B YadavNo ratings yet

- Steam Tracing TipsDocument2 pagesSteam Tracing TipsRam SudarshanNo ratings yet

- Leslie Stevenson - David L. Haberman - Peter Matthews Wright - Charlotte Witt - Thirteen Theories of Human Nature (2018, Oxford University Press, USA)Document334 pagesLeslie Stevenson - David L. Haberman - Peter Matthews Wright - Charlotte Witt - Thirteen Theories of Human Nature (2018, Oxford University Press, USA)Mohammad Yasser Ramzan100% (2)

- Fire in Thermal Fluid SystemsDocument8 pagesFire in Thermal Fluid SystemsEvert AlexNo ratings yet

- Sop Fumigation Vapour Hydrogen Peroxide-H2o2 VHPDocument6 pagesSop Fumigation Vapour Hydrogen Peroxide-H2o2 VHPMohamed FetouhNo ratings yet

- Compressed Air Pipe SystemDocument9 pagesCompressed Air Pipe Systemkeanncruz100% (1)

- Process Thermodynamic Steam Trap PDFDocument9 pagesProcess Thermodynamic Steam Trap PDFhirenkumar patelNo ratings yet

- Here are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideDocument67 pagesHere are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideCacey Daiwey CalixtoNo ratings yet

- Special Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDDocument6 pagesSpecial Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDGhasem Bashiri100% (1)

- Gas Turbine Compressor System Design Using Dynamic Process Simulation PDFDocument7 pagesGas Turbine Compressor System Design Using Dynamic Process Simulation PDFredhotriderNo ratings yet

- USGUIDE1 AirCompGuide GettingMostForYourMoney 0Document8 pagesUSGUIDE1 AirCompGuide GettingMostForYourMoney 0Adeilton CabocloNo ratings yet

- Heat exchanger tube rupture case study: Addressing metal embrittlement risksDocument6 pagesHeat exchanger tube rupture case study: Addressing metal embrittlement risksaegean227100% (1)

- Astm D86Document27 pagesAstm D86dennise8100% (1)

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- System Practices For Ammonia RefrigerationDocument27 pagesSystem Practices For Ammonia RefrigerationAnonymous 1XHScfCI100% (1)

- A Breath of Fresh Air: Mine VentilationDocument6 pagesA Breath of Fresh Air: Mine VentilationMuhammad FarhadNo ratings yet

- GE Cooling System Guidelines for Waukesha Gas EnginesDocument4 pagesGE Cooling System Guidelines for Waukesha Gas EnginesFaisal NaeemNo ratings yet

- ChE307-2 Gas Absorption ColumnDocument10 pagesChE307-2 Gas Absorption ColumnJudgement AslemiNo ratings yet

- Dale Carnegie-How To Enjoy Your Life and Your Job-Pocket (1990) PDFDocument6 pagesDale Carnegie-How To Enjoy Your Life and Your Job-Pocket (1990) PDFAnadi MayankNo ratings yet

- O & M Manual - Foam SystemDocument12 pagesO & M Manual - Foam SystemahsanNo ratings yet

- Guide to Designing Heat Transfer SystemsDocument13 pagesGuide to Designing Heat Transfer SystemsAnonymous QSfDsVxjZ100% (3)

- Performance HRSGDocument7 pagesPerformance HRSGalfnusi173100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Cooling System Guidelines For Waukesha PDFDocument4 pagesCooling System Guidelines For Waukesha PDFFaisal NaeemNo ratings yet

- 100 Years of Subatomic PhysicsDocument559 pages100 Years of Subatomic PhysicsEdgar Soriano100% (1)

- Improving Fan System Performance - A Sourcebook For IndustryDocument12 pagesImproving Fan System Performance - A Sourcebook For IndustryluismcmcNo ratings yet

- Catalogo Automotriz KPEDocument8 pagesCatalogo Automotriz KPERuddy Fabrizio Galvez JustinianoNo ratings yet

- Heat Exchanger For Gas CoolingDocument4 pagesHeat Exchanger For Gas CoolingAssdasdas AssadasdasdNo ratings yet

- PM PeraturanDocument2 pagesPM Peraturanyan energiaNo ratings yet

- PISTON VS TORNILLODocument4 pagesPISTON VS TORNILLOVictor Hugo Rodriguez CelyNo ratings yet

- Air-Pro Design Overview - 1Document4 pagesAir-Pro Design Overview - 1Thaiminh VoNo ratings yet

- Ejector technology for efficient and cost effective flare gas recoveryDocument10 pagesEjector technology for efficient and cost effective flare gas recoverySdadNo ratings yet

- How To Avoid The Biggest Wastewater Aeration MistakeDocument2 pagesHow To Avoid The Biggest Wastewater Aeration Mistakesriram sNo ratings yet

- Veizades Gas Removal SystemsDocument3 pagesVeizades Gas Removal SystemsChristos BountourisNo ratings yet

- Heated Regulators For Vapor and Liquid HydrocarbonsDocument4 pagesHeated Regulators For Vapor and Liquid HydrocarbonsSamit ShaikhNo ratings yet

- An Oven Explosion - Lessons Learned On PSM ApplicationsDocument7 pagesAn Oven Explosion - Lessons Learned On PSM Applicationshuat86No ratings yet

- Smokelesss Flare - Air AssistsedDocument19 pagesSmokelesss Flare - Air AssistsedvasuNo ratings yet

- Safety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose AssembliesDocument4 pagesSafety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose Assembliesphankhoa83-1No ratings yet

- Crossflow ScrubberDocument8 pagesCrossflow Scrubbermourinho2No ratings yet

- Protect Your PumpDocument4 pagesProtect Your PumpAmar SheteNo ratings yet

- G2040 FR3 Retrofill Power Class Guide - 10-21 PDFDocument4 pagesG2040 FR3 Retrofill Power Class Guide - 10-21 PDFRuben GutierrezNo ratings yet

- Thermocompressors Preventative Maintenance PDFDocument3 pagesThermocompressors Preventative Maintenance PDFalicardozoNo ratings yet

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocument8 pagesSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNo ratings yet

- Installation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsDocument8 pagesInstallation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsJosé LuísNo ratings yet

- 5 Common Misconceptions Lyo2Document3 pages5 Common Misconceptions Lyo2DholakiaNo ratings yet

- Compressed Air Systems: Best Practices For Maintenance ManagementDocument6 pagesCompressed Air Systems: Best Practices For Maintenance ManagementAdeilton CabocloNo ratings yet

- Electric Head Transfer Chromalox Service ManualDocument6 pagesElectric Head Transfer Chromalox Service ManualJorge ReyesNo ratings yet

- TF 33 VaporPhaseDesignDocument12 pagesTF 33 VaporPhaseDesignAdnen GuedriaNo ratings yet

- Basics of Pressure RegulatorDocument7 pagesBasics of Pressure RegulatornvhcycoukNo ratings yet

- ME482 M4 Ktunotes - inDocument14 pagesME482 M4 Ktunotes - inTHIAGARAJAN ANo ratings yet

- FD Application ManualDocument43 pagesFD Application ManualM.H.No ratings yet

- HTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewDocument15 pagesHTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewPalash KayathwalNo ratings yet

- User's Guide Packaged HVAC SystemsDocument9 pagesUser's Guide Packaged HVAC SystemsMADENo ratings yet

- Build Your Working Knowledge of Process Compressors 1710445622Document10 pagesBuild Your Working Knowledge of Process Compressors 1710445622Luis MarshNo ratings yet

- Selecting Flare Gas Recovery System For A Greenfield RefineryDocument5 pagesSelecting Flare Gas Recovery System For A Greenfield RefineryRobert Montoya100% (1)

- 4VOL R02ipDocument30 pages4VOL R02ipzhyhhNo ratings yet

- Power Magazine EprintDocument4 pagesPower Magazine EprintArun BabuNo ratings yet

- Freon Hot Shot 2 Conversion GuidelinesDocument2 pagesFreon Hot Shot 2 Conversion Guidelinesmates isNo ratings yet

- Centrifugal compressor applicationsDocument2 pagesCentrifugal compressor applicationssyazani syazwiNo ratings yet

- Coil - Fundamentals Question & AnswerDocument12 pagesCoil - Fundamentals Question & AnsweroiramhoangNo ratings yet

- Systematic procedure for selecting heat exchangersDocument19 pagesSystematic procedure for selecting heat exchangersRahul ParmarNo ratings yet

- Facts at Your Fingertips-200909-Heat Transfer System Design IIDocument1 pageFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263No ratings yet

- Condenser Water SystemsDocument4 pagesCondenser Water SystemsYemane KirosNo ratings yet

- RP Maint GuideDocument10 pagesRP Maint GuideRaja Sekaran SajjaNo ratings yet

- Above & Beyond Refrigerated Air DryersDocument8 pagesAbove & Beyond Refrigerated Air DryersMauricio GómezNo ratings yet

- Centrifugal Pumps Troubleshooting - Magdy Aly - LinkedInDocument9 pagesCentrifugal Pumps Troubleshooting - Magdy Aly - LinkedInMohammad Yasser RamzanNo ratings yet

- Honeywell Apc CasestDocument3 pagesHoneywell Apc CasestMohammad Yasser RamzanNo ratings yet

- Air Separation Units (Asus) Simulation Using Aspen Hysys at Oxinor I of Air Liquid Chile S.A PlantDocument8 pagesAir Separation Units (Asus) Simulation Using Aspen Hysys at Oxinor I of Air Liquid Chile S.A PlantMohammad Yasser RamzanNo ratings yet

- Scott Vedder - Signs of A Great Résumé - How To Write A Résumé That Speaks For Itself-CreateSpace (2012)Document84 pagesScott Vedder - Signs of A Great Résumé - How To Write A Résumé That Speaks For Itself-CreateSpace (2012)Mohammad Yasser RamzanNo ratings yet

- CastrolDocument29 pagesCastrolironiteNo ratings yet

- Comment Response Sheet - Gas Line Sizing Sheet (26.04.2012) PDFDocument2 pagesComment Response Sheet - Gas Line Sizing Sheet (26.04.2012) PDFmohdnazirNo ratings yet

- Humidity Conversion Formulas B210973EN-F PDFDocument17 pagesHumidity Conversion Formulas B210973EN-F PDFGyana MatiNo ratings yet

- OGC - JD - Operations SupervisorDocument4 pagesOGC - JD - Operations SupervisorMohammad Yasser RamzanNo ratings yet

- Title: Cyber Security Implementation in IOT Project Using Cyber Ciege Vivek Jain Saturday, 11-4-2020Document3 pagesTitle: Cyber Security Implementation in IOT Project Using Cyber Ciege Vivek Jain Saturday, 11-4-2020Mohammad Yasser RamzanNo ratings yet

- Direct-to-Home (DTH) Services: Overview of The Required Architecture and Regulatory ConsiderationsDocument12 pagesDirect-to-Home (DTH) Services: Overview of The Required Architecture and Regulatory Considerationskrishna kumarNo ratings yet

- Active Learning With The Cyberciege Video Game: Naval Postgraduate SchoolDocument8 pagesActive Learning With The Cyberciege Video Game: Naval Postgraduate SchoolMohammad Yasser RamzanNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial IVDocument19 pagesMobatec Modeller Intorduction Course Tutorial IVMohammad Yasser RamzanNo ratings yet

- AppliedPM Flyer Su17 UpdatedDocument2 pagesAppliedPM Flyer Su17 UpdatedHemprasad BadgujarNo ratings yet

- Utilization of Aspen Hysys Simulation To PDFDocument6 pagesUtilization of Aspen Hysys Simulation To PDFMohammad Yasser RamzanNo ratings yet

- What Is Commissioning and Related Terms Rev 01Document1 pageWhat Is Commissioning and Related Terms Rev 01sunil601No ratings yet

- Thesis Rapid Development Consistent Process Models PDFDocument231 pagesThesis Rapid Development Consistent Process Models PDFMohammad Yasser RamzanNo ratings yet

- Model Developer I - Buffer Tank SimulationDocument13 pagesModel Developer I - Buffer Tank SimulationMohammad Yasser RamzanNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial V PDFDocument17 pagesMobatec Modeller Intorduction Course Tutorial V PDFMohammad Yasser RamzanNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial IIDocument13 pagesMobatec Modeller Intorduction Course Tutorial IIMohammad Yasser RamzanNo ratings yet

- Essential Guide to Dynamic SimulationDocument6 pagesEssential Guide to Dynamic SimulationMohammad Yasser RamzanNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial IDocument10 pagesMobatec Modeller Intorduction Course Tutorial IMohammad Yasser RamzanNo ratings yet

- Comment Response Sheet - Gas Line Sizing Sheet (26.04.2012) PDFDocument2 pagesComment Response Sheet - Gas Line Sizing Sheet (26.04.2012) PDFmohdnazirNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial V PDFDocument17 pagesMobatec Modeller Intorduction Course Tutorial V PDFMohammad Yasser RamzanNo ratings yet

- Essentials Of: The Modern DcsDocument7 pagesEssentials Of: The Modern DcsMohammad Yasser RamzanNo ratings yet

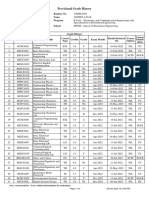

- StudentGradeHistory 21BML0190Document3 pagesStudentGradeHistory 21BML0190brotin2002No ratings yet

- Answer Sa StemDocument7 pagesAnswer Sa Stemyvette garciaNo ratings yet

- Myp 2 Term 1 SciencesDocument6 pagesMyp 2 Term 1 Sciencesishaq.yakubuNo ratings yet

- AdsorptionDocument5 pagesAdsorptionLina TaposhiNo ratings yet

- CAD Cavity Model Analysis of High TC Superconducting Rectangular Patch Printed On Anisotropic SubstratesDocument4 pagesCAD Cavity Model Analysis of High TC Superconducting Rectangular Patch Printed On Anisotropic SubstratesHoucine HoucineNo ratings yet

- Phys11 3 4Document5 pagesPhys11 3 4Elizabeth MeghaNo ratings yet

- Process Modeling in The Pharmaceutical Industry Using The Discrete Element MethodDocument29 pagesProcess Modeling in The Pharmaceutical Industry Using The Discrete Element MethodRonaldo MenezesNo ratings yet

- Energy Conversion and Efficiency Hasan Maridi Part1Document73 pagesEnergy Conversion and Efficiency Hasan Maridi Part1Simo LabibNo ratings yet

- Vulkem 350NF - Tremco Epoxy Primer - CVDocument5 pagesVulkem 350NF - Tremco Epoxy Primer - CVAriel Sepúlveda CaroNo ratings yet

- 4ph1 2pr Que 20230121Document24 pages4ph1 2pr Que 20230121Nang Seng Tawng HparawNo ratings yet

- R 410a Si PDFDocument20 pagesR 410a Si PDFMarin Munteanu0% (1)

- 721547000Document2 pages721547000Kuldeep MalNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- Coulson ProblemsDocument22 pagesCoulson ProblemsMarielle TamboleroNo ratings yet

- Ionic and Covalent BondingDocument51 pagesIonic and Covalent BondingBilly STEVENo ratings yet

- SP 5160Document2 pagesSP 5160Dileepa DissanayakeNo ratings yet

- SolutionsDocument509 pagesSolutionssknoushad126No ratings yet

- Metallurgical Engineering Scheme of Teaching and ExamDocument12 pagesMetallurgical Engineering Scheme of Teaching and ExamSuraj KumarNo ratings yet

- 04Document15 pages04Aravindan KrishnamoorthyNo ratings yet

- Predicting Hydrocarbon Dew PointDocument12 pagesPredicting Hydrocarbon Dew PointOng SooShinNo ratings yet

- RadioactivityDocument15 pagesRadioactivityBenjamin Teo0% (2)

- 759-Article Text-1948-1-10-20150627Document6 pages759-Article Text-1948-1-10-20150627hayet debbichNo ratings yet

- Reactions of MercuryDocument2 pagesReactions of MercuryWeare1_busyNo ratings yet

- Mass Balance FixDocument125 pagesMass Balance FixAbdullah AbdulNo ratings yet

- 10 1021@acsreagents 4191Document2 pages10 1021@acsreagents 4191Hans TorresNo ratings yet

- Col (Ret) Rob Fredell, Ph.D. Office: 6L-165 Robert - Fredell@afacademy - Af.eduDocument14 pagesCol (Ret) Rob Fredell, Ph.D. Office: 6L-165 Robert - Fredell@afacademy - Af.eduBenNo ratings yet