Professional Documents

Culture Documents

Rugged, Proven Construction For Wire Welding: CV DC

Uploaded by

victorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rugged, Proven Construction For Wire Welding: CV DC

Uploaded by

victorCopyright:

Available Formats

CV-400

MIG WELDERS

Output

Rugged, Proven Construction CV

for Wire Welding DC

The rugged CV-400 is ready to tackle MIG and cored wire

fabrication and production work in a variety of industries:

transportation, heavy equipment, structural steel, railroad, Input

furniture, appliances and sheet metal fabrication. Simple

fixed inductance, time-proven technology and heavy-duty 3

construction will deliver years of reliable performance. PHASE

60

Hz

Processes

MIG, Flux-Cored, Gouging

Advantage Lincoln

• Lincoln’s unique fixed inductance design delivers exceptional • Electronic and thermostatic protection from current overload and

short-circuit metal transfer characteristics. excessive temperatures. Indicator light lets you know when machine

• 115V and 42V wire feeder auxiliary power with circuit breaker is reset.

protection. • Three year warranty on parts and labor.

• Connect wire feeders via either 14-pin MS-type or • Seven year warranty on the power rectifier.

terminal strip.

• Internal components, including windings, rectifiers and circuit

boards, are coated to protect against the effects of moisture

and corrosion.

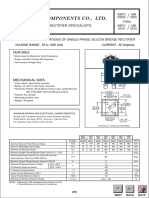

TECHNICAL SPECIFICATIONS

Dimensions

Product Product Rated Output Input Current @ HxWxD Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

CV-400 K1346-13 230/460/3/60 400A/36V/100% 77/39A 60-500A 27.5 x 22.2 x 32 383

(w/meters) 450A/38V/60% 80/40A 12-42V (699 x 564 x 813) (174)

K1346-22 230/460/575/3/60 77/39/31A

(w/meters) 80/40/32A

Publication E4.30 11/05

www.lincolnelectric.com

web update 7/08

More user manuals on ManualsBase.com

A CLOSER LOOK

PERFORMANCE

• Provides line voltage compensation for maintaining weld

consistency, even with changes of ±10%.

• Full output control potentiometer lets operator accurately

regulate power levels.

• Excellent arc stability and weld consistency.

FEATURES

• Quick, simple 14-pin MS-type (amphenol) wire feeder connection. • Thermal trip indicator light.

• Low flat-top case can be placed under a workbench or stacked • “Cold” electrode with a solid state

on top of each other for smaller footprint. contactor when the trigger is released for added safety.

• Remote control of output is possible via 14 pin connector on the

10 9 8 7

control panel or terminal strip connection.

Key Controls

1. Strain Relief for Terminal Strip Connection

2. Analog Amps & Volts Meters

3. Local / Remote Control Switch

4. Input Power On / Off Switch 6

5. Input Power Pilot Light

6. Output Voltage Control Knob 5

7. Circuit Breakers

1 4

8. Thermal Overload Light

9. Voltmeter Polarity Switch

10. 14 Pin MS Type Connector 3

2

QUALITY AND RELIABILITY

• Electronic and thermostatic protection from current overload or • Three-year warranty on parts and labor.

excessive temperatures. • Manufactured under a quality system certified to ISO 9001

• Solid state circuitry provides extra long life during repetitive requirements and ISO 14001 environmental standards.

applications.

SYSTEM SELECTION

Ready-Pak® Packages

Take the hassle out of ordering. Order a Ready-Pak pre-assembled welding package.

CV-400 / LF-74 Ready-Pak Package CV-400 / LF-72 Ready-Pak Package

Order K2496-1 Order K2439-1

• CV-400 Power Source (K1346-13) • CV-400 Power Source (K1346-13)

• LF-74 Bench Model, Heavy Duty • LF-72 Bench Model, Heavy Duty

(Heavy Duty Wire Reel Stand) (Heavy Duty Wire Reel Stand)

• .045” Drive Rolls for Solid Wire • .035"-.045” Drive Rolls for Solid Wire

• Heavy Duty Wire Reel Stand • Heavy Duty Wire Reel Stand

• Control Cable – 10 ft. (3.0m) • Control Cable – 10 ft. (3.0m)

• Weld Power Cable – 10 ft. (3.0m) • Weld Power Cable – 10 ft. (3.0m)

• Work Clamp • Work Clamp

• Magnum 400 MIG Gun with 15 ft. cable (4.5m) • Magnum 400 MIG Gun with 15 ft. cable (4.5m)

• Harris Flowmeter Regulator and Gas Hose • Harris Flowmeter Regulator and Gas Hose

Shown: CV-400 / LF-72 Ready-PakTM Package

CV-400

[2] www.lincolnelectric.com

More user manuals on ManualsBase.com

A CLOSER LOOK

Typical MIG Welding Systems

CV-400 / LN-742 Wire Feeder CV-400 / DH-10 Wire Feeder

Best for applications where more process control is required – For maximum welding flexibility – select the DH-10 dual feeder.

for arc starting, welding and crater control! Weld with two different types and sizes of wire – with two different

• CV-400 Power Source K1346-13 welding procedures!

• LN-742 (Two Roll) Wire Feeder K617-1 • CV-400 Power Source K1346-13

• Control Cable – 10 ft. (3.0m) K1819-10 • DH-10 Wire Feeder K1499-3

• .045" (1.2mm) Drive Roll & Guide Tube Kit KP653-052S • .045" (1.2mm) Drive Roll & Guide Tube Kit KP1505-045S(2)

• Universal Stand K1524-1 • Magnum 400 Gun & Cable Assembly K471-21(1)(2)

• Swivel Platform K1557-1 and Connector Kit

• Magnum 400 Gun & Cable Assembly K2286-1(1) • 600 Amp Weld Cable K1842-10(2)

and Connector Kit • Work Clamp K910-2

• 600 Amp Weld Cable K1842-10(2) • Harris Flowmeter Regulator and Gas Hose K586-1

• Work Clamp K910-2 • Undercarriage (twin cylinder) K841

• Harris Flowmeter Regulator and Gas Hose K586-1

• Undercarriage (twin cylinder) K841 (1)Fully assembled, gun connector included.

(2)Two required.

CV-400 / LN-10 Wire Feeder

Where premium welding performance and control is demanded –

this system delivers!

• CV-400 Power Source K1346-13

• LN-10 Wire Feeder K1559-3

• .045" (1.2mm) Drive Roll & Guide Tube Kit K1505-045S

• Swivel Platform K1557-1

• Magnum 400 Gun & Cable Assembly K471-21(1)

and Connector Kit

• 600 Amp Weld Cable K1842-10(2)

• Work Clamp K910-2

• Harris Flowmeter Regulator and Gas Hose K586-1

• Undercarriage (twin cylinder) K841

RECOMMENDED OPTIONS

GENERAL OPTIONS Undercarriage

Platform undercarriage with

Remote Output Control

mountings for two gas cylinders

Consists of a control box with

at rear of welder.

choice of two cable lengths.

Order K841

Permits remote adjustment of

output. 6-pin connection.

Order K857 for 25 ft. (7.6m).

Jumper Plug Kit

Order K857-1 for 100 ft. (30m).

Required to close the contactor

in the power source when the

power source is used with a

Remote Control Adapter

remote output contactor such as

Y connection adapter for connect-

the contactor in the K449 LN-25,

ing K857 Remote Output Control

or K1870-1 LN-15 wire feeder.

(6 pin plug connection) and wire

Order K484

feeder input cable (14-pin plug

connection) to power source

14-pin receptacle.

Order K864

CV-400

[3] www.lincolnelectric.com

More user manuals on ManualsBase.com

CV-400 ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

CV-400 with meters 230/460/3/60 K1346-13

CV-400 with meters 230/460/575/3/60 K1346-22

Ready-Pak® Package

CV-400/LF-72 K2439-1

CV-400/LF-74 K2496-1

Recommended General Options

Remote Output Control, 25 ft. (7.6m) K857

100 ft. (30m) K857-1

Remote Control Adapter K864

Undercarriage K841

Jumper Plug Kit K484

Recommended Wire Feeder Options

LF-72, LF-74 See publication E8.11

LN-742 See publication E8.20

LN-8 See publication E8.30

LN-9 See publication E8.50

LN-9 GMA See publication E8.50

LN-10 See publication E8.200

DH-10 See publication E8.200

LN-15 See publication E8.60

LN-25 See publication E8.100

Cobramatic® See publication E8.300

NA-3 See publication E9.10

NA-5 See publication E9.30

NA-5R See publication E9.45

TOTAL:

C U S T O M E R A S S I S TA N C E P O L I C Y

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

T H E L I N C O L N E L E C T R I C C O M PA N Y

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- UPS DesignDocument47 pagesUPS DesignHari Kishor100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unit1 Diode CircuitsDocument41 pagesUnit1 Diode CircuitsJagan GNNo ratings yet

- PowerManagement TIDocument129 pagesPowerManagement TITuan NgoNo ratings yet

- George Salvan Architectural Utilities 2 Electrical and Mechanical Equipment PDFDocument434 pagesGeorge Salvan Architectural Utilities 2 Electrical and Mechanical Equipment PDFmiaad alsamah100% (1)

- PD Delta OutD V Outdoor Cabinet en Rev.00Document34 pagesPD Delta OutD V Outdoor Cabinet en Rev.00bousseyf100% (1)

- IGBT Retrofit Rectifier-SIM-D Device Manual - 1Document43 pagesIGBT Retrofit Rectifier-SIM-D Device Manual - 1Luis Carlos DurazoNo ratings yet

- TR - White Paper - How Finnacial Institutions Can Prepare For 2021Document6 pagesTR - White Paper - How Finnacial Institutions Can Prepare For 2021victorNo ratings yet

- Todos Los MetodosDocument22 pagesTodos Los MetodosvictorNo ratings yet

- The Strain Index To Analyze Jobs For Risk of Distal Upper Extremity Disorders: Model ValidationDocument4 pagesThe Strain Index To Analyze Jobs For Risk of Distal Upper Extremity Disorders: Model ValidationvictorNo ratings yet

- 436 438 Letter ColombiniDocument4 pages436 438 Letter ColombinivictorNo ratings yet

- Naval DiagramsDocument39 pagesNaval DiagramsAsif AliNo ratings yet

- Lift Automation SystemDocument6 pagesLift Automation SystemjaydeepjivaniNo ratings yet

- 2022-TC 1st Class ElectroDocument105 pages2022-TC 1st Class ElectromecambNo ratings yet

- Datasheet PDFDocument2 pagesDatasheet PDFnassarkiNo ratings yet

- Module 1-18EE53-NotesDocument20 pagesModule 1-18EE53-NotesAshwiniNo ratings yet

- L 6599 DDocument36 pagesL 6599 DVidal VelasquezNo ratings yet

- Analogue Instruments 06Document87 pagesAnalogue Instruments 06iyilmaz1No ratings yet

- AURETR129 Diagnose and Repair Charging Systems V1Document237 pagesAURETR129 Diagnose and Repair Charging Systems V1jaredmuge808No ratings yet

- Synopsis (Cell Phone Detector Circuit)Document7 pagesSynopsis (Cell Phone Detector Circuit)44 Tejas JadhavNo ratings yet

- Valere Smps Gs150aDocument41 pagesValere Smps Gs150areddi_mohanNo ratings yet

- TL 3.26 Electrical SytemsDocument42 pagesTL 3.26 Electrical SytemsMilorad PavlovicNo ratings yet

- Thyrotronic (R1 10) 667Document2 pagesThyrotronic (R1 10) 667philcogabiNo ratings yet

- Wireless Power Transfer Literature Review by Naters BishDocument15 pagesWireless Power Transfer Literature Review by Naters BishNaters BishNo ratings yet

- Old Quesition Papers (III Sem) Dec-13Document52 pagesOld Quesition Papers (III Sem) Dec-139966197483No ratings yet

- Tower 3300 Instruction ManualDocument23 pagesTower 3300 Instruction ManualMark RobertsNo ratings yet

- Active RectifierDocument11 pagesActive RectifierMohan RajuNo ratings yet

- Advanced Power ElectronicsDocument1 pageAdvanced Power ElectronicshoangductuanNo ratings yet

- PC-EE-504-Module 3 Power Electronics: Diode Rectifiers & Phase Controlled ConvertersDocument34 pagesPC-EE-504-Module 3 Power Electronics: Diode Rectifiers & Phase Controlled ConvertersSanjoy PathakNo ratings yet

- Electronic Science: Test Booklet No. Time: 2 Hours) (Maximum Marks: 200 Instructions For The CandidatesDocument32 pagesElectronic Science: Test Booklet No. Time: 2 Hours) (Maximum Marks: 200 Instructions For The Candidatesjassi7010No ratings yet

- HSCBDocument4 pagesHSCBSunayan PalNo ratings yet

- K24 SchottkyDocument3 pagesK24 SchottkyLeon MartinezNo ratings yet

- Static Var CompensatorDocument23 pagesStatic Var CompensatorsetyawanNo ratings yet

- Arduino AC-DC Voltmeter PDFDocument6 pagesArduino AC-DC Voltmeter PDFyb3hgf2222No ratings yet

- Moduflex Power Core (12kW) Rev01Document2 pagesModuflex Power Core (12kW) Rev01Steven SeNo ratings yet