Professional Documents

Culture Documents

Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor Underlayment

Uploaded by

Francois-Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor Underlayment

Uploaded by

Francois-Copyright:

Available Formats

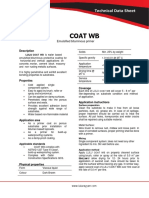

Mastertop®528

Commercial grade self-levelling cementitious floor underlayment

Description Performance data (typical)∗

Mastertop®528 is a self-smoothing, cementitious,

non-structural, floor underlayment for use over 1 day 28 days

poured in-situ and precast concrete floors which will Compressive strength (AS

>12N/mm² >25N/mm²

2073)

be covered by resin overlays, carpet, vinyl, ceramic

Flexural strength >2N/mm² >4N/mm²

tiles or natural stone. Only water needs to be added Tensile strength (28 days) >2N/mm²

on site to obtain the desired consistency for pumping Work time @ 23°C 30 mins Max.

or manual installation. Setting times @ 23°C – Initial 1½ - 2hours

– Final 2 – 3 hours

Mastertop®528 is applied at thickness from 2mm. Foot traffic @ 23°C 50%RH approx. 3 hours

Drying shrinkage @ 7 days

<300 microstrain

(BASF CC SA Test Method)

Recommended for

Pull off bond strength 1.0MPa

• Finishing rough undulating floors ∗

Properties listed are only for guidance and are not a guarantee

• Levelling up floors of performance

• Refurbishing old floors

Application directions

Features and benefits Substrate condition

• Highly fluid and pumpable for fast installation Substrate must be clean and free of oil, sealers,

• Rapid strength gain for fast installation of floor curing compounds, paint, polymer coatings, dust or

coverings other foreign (contaminating) matter.

• Low installed cost

• Ready for foot traffic after 3-4 hours Remove all weak or broken pieces of concrete. If

• Return to service in 24 hours necessary, employ mechanical cleaning methods

• Suitable for most carpet and tile adhesives and equipment. If sealers, paint, polymer coatings or

curing compounds are present on concrete

substrate, remove with mechanical shotblasting or

Packaging

surface grinding equipment.

Mastertop®528 is available in 25kg bags.

Mastertop®528 is best applied where the application

temperature is between 5°C and 35°C. Outside this

range, please refer to your local BASF Construction

Chemicals SA Technical Representative.

Mastertop®528

Voids and cracks (water pipes, holes, drainage pipes Method of use

etc) should be filled to prevent seepage through to Pour mixture over substrate or pump through a

lower levels. Consult with your local BASF suitable pump to desired thickness. Whether

Construction Chemicals SA Technical pouring from a mixing vessel or using a mechanical

Representative for product recommendations. Note: mixer with an application hose, the discharge point

Joints should always be cut in toppings directly should be approximately 200mm from the floor to

above those in the base slab to avoid random prevent splashing and air entrapment.

cracking.

Progress should be steady and even. Application

Priming should take place continuously into the preceding

Apply Rheomix 111-2 to the dry substrate by roller, wet material to ensure even thickness and flow. Do

brush, low pressure spray or squeegee at a rate of not make new edges and ‘fill in’ the middle.

approximately 5m° / Litre. On very porous or

absorbent substrates, 2 coats may be required to The fresh wet topping can be rolled immediately with

effectively seal the substrate. Take care to avoid a suitable long spiked roller to release all air retained

ponding of the primer. Allow to fully dry before within the underlayment. Do not roll material that has

application of Mastertop®528. been applied for more than 2-3 minutes.

Mixing Maximum thickness should be 20mm. If greater

Mechanical mixing is required for Mastertop®528. For thickness is required, Mastertop®528 should be

small areas, a slow speed stirrer of not more than mixed with silica sand (0.7-1.2mm or 1.0-2.0mm) on

600 rpm fitted with a helical paddle is suitable. a 1:1 basis by volume and applied to a maximum of

Mixing time is 3 minutes. 50mm.

Place the required quantity of water into the mixing Curing

vessel. Whilst mixing, slowly add the powder to the Mastertop®528 is self-curing, but as with all

water within 2 minutes then mix for a further 1 cementitious products in hot weather, take adequate

minute. Allow mixed Mastertop®528 to stand for 3 measures to protect it from exposure to direct

minutes and then remix prior to application. Use sunlight and hot winds. Do not use water spray or

chilled water at high temperatures for longer liquid membrane curing compounds as these may

application time. affect the surface texture or prevent bonding of

subsequent adhesives used with floor coverings.

For improved efficiency and continuous production of

Mastertop®528, it is recommended to use at least

two mixing buckets. For larger jobs, the use of a

mechanical mixer/pump unit is recommended. Refer

to your local BASF Construction Chemicals SA

Technical Representative for suitable machines.

Mastertop®528

Coverage Storage

A 25kg bag of Mastertop®528 mixed with 5.5 litres of Store under cover, out of direct sunlight and protect

water yields 15.2 litres. A 25kg bag of from extremes of temperatures.

Mastertop 528 with 25kg of Mastertop®SRA No3 and

®

5.5 litres of water will yield 24 litres of mixed Failure to comply with the recommended storage

product. conditions may result in premature deterioration of

the product or packaging. For specific storage

Cleaning advice consult BASF Construction Chemicals SA’s

Tools should be cleaned with water before the Technical Services Department.

material hardens. Hardened material will need to be

mechanically removed. Safety precautions

As with all chemical products, care should be taken

Shelf life during use and storage to avoid contact with eyes

Mastertop®528 can be stored in tightly sealed mouth, skin and foodstuffs (which can also be

original bags for 6 months if kept dry and at a tainted with vapour until product fully cured or dried).

moderate temperature. Treat splashes to eyes and skin immediately. If

accidentally ingested, seek immediate medical

Precautions attention. Keep away from children and animals.

Mastertop®528 is not toxic, but as with other Reseal containers after use.

products containing cement it has an alkaline nature

and thus can be irritating to skin and eyes. Wear Note

simple dust masks and gloves when handling. Keep Field service, where provided, does not constitute

out of reach of children. Wash off splashes of supervisory responsibility. For additional information

material with clean water. If irritation persists, seek contact your local BASF Construction Chemicals SA

medical advice. Refer to Material Safety Data Sheet representative. BASF Construction Chemicals SA.

for further information. reserves the right to have the true cause of any

difficulty determined by accepted test methods

Quality and care

All products originating from BASF Construction

Chemicals’ SA facility are manufactured under a

management system independently certified to

conform to the requirements of the quality,

environmental and occupational health & safety

standards ISO 9001:2000.

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or

implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any

labour involved in the application are beyond our control.

As all BASF’s technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

BASF Construction Chemicals South Africa (Pty) Ltd

P.O. Box 420, Westonaria, 1780

852 Sixteenth Road, Midrand

11 Pullinger Street, Westonaria, 1779 PO Box 2801, Halfway House, 1685

Tel: +27 11 754 1343 Tel: +27 11 203 2405

Fax: +27 11 754 1105

Website : basf-cc.co.za

You might also like

- Ma'Aden SpecificationDocument14 pagesMa'Aden Specificationahmed elesawyNo ratings yet

- Method Statement For Roof Water ProofingDocument6 pagesMethod Statement For Roof Water ProofingSagar ParabNo ratings yet

- DOC-IMB-SH-MS-0004 - Method Statement For Fill Compaction Using RICDCDocument31 pagesDOC-IMB-SH-MS-0004 - Method Statement For Fill Compaction Using RICDC01095902062ahmedNo ratings yet

- Civil+Defence+Technical+Requirements+Guide+2023+ ( (+LAST+OFFICAL+UPDATE) )Document465 pagesCivil+Defence+Technical+Requirements+Guide+2023+ ( (+LAST+OFFICAL+UPDATE) )shaikmohdhajiNo ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- Lessons: Diesel Generator Failures: Taught byDocument2 pagesLessons: Diesel Generator Failures: Taught byAnonymous a19X9GHZNo ratings yet

- 052876-005 Patio Awning Installation ManualDocument8 pages052876-005 Patio Awning Installation ManualStacy OneillNo ratings yet

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- Is SP 25 Handbook On Causes and Prevention of Cracks in BuildingDocument76 pagesIs SP 25 Handbook On Causes and Prevention of Cracks in BuildingBala SubramanyamNo ratings yet

- Cicobond EPDocument2 pagesCicobond EPmud44450% (2)

- Amico Athletic Track & Epdm BrochureDocument24 pagesAmico Athletic Track & Epdm BrochureVENKATNo ratings yet

- Epoxy Painting Method GuideDocument3 pagesEpoxy Painting Method GuideKaram MoatasemNo ratings yet

- Ni 43 101 Report Boa PDFDocument338 pagesNi 43 101 Report Boa PDFevalenciaNo ratings yet

- METHOD - STATEMENTf New ForDocument48 pagesMETHOD - STATEMENTf New Forhysh89No ratings yet

- Jotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Document8 pagesJotafloor Easy Painting Guide For Concrete Floors Tcm29 5703Riski FebriantoNo ratings yet

- Method Statement - Masterseal 345 REV D PDFDocument17 pagesMethod Statement - Masterseal 345 REV D PDFFrancois-No ratings yet

- Method Statement Storm WaterDocument46 pagesMethod Statement Storm WaterchethanshivramNo ratings yet

- Method Statement For Installation of Fire Hydrant Pipes and FittingDocument51 pagesMethod Statement For Installation of Fire Hydrant Pipes and FittingHafiz M WaqasNo ratings yet

- Excavation and Backfilling MethodDocument4 pagesExcavation and Backfilling MethodLAM CONo ratings yet

- Silver Schmidt ManualDocument47 pagesSilver Schmidt ManualEl LlacunaNo ratings yet

- Method Statement of Potable Water and Firefighting Network ConstructionDocument51 pagesMethod Statement of Potable Water and Firefighting Network Constructionmohdshahul543No ratings yet

- 05 01 PM Indore Sewerage DPR 26-07-2017R PDFDocument174 pages05 01 PM Indore Sewerage DPR 26-07-2017R PDFAdditya Choudhhary50% (2)

- Chemical MoonshineDocument22 pagesChemical MoonshineFelipe D. HlibkaNo ratings yet

- Working Method Statement of PLASTERINGDocument4 pagesWorking Method Statement of PLASTERINGfranklin mertoNo ratings yet

- Control & Automation (PLC) Project Topics ListDocument6 pagesControl & Automation (PLC) Project Topics ListMayil Samy KM50% (2)

- Qcs 2010 Part 24.05 TilesDocument6 pagesQcs 2010 Part 24.05 TilesRotsapNayrb100% (1)

- RENDEROC HSXtraDocument48 pagesRENDEROC HSXtraRehan HasanNo ratings yet

- Epoxy Bedding SystemDocument2 pagesEpoxy Bedding Systempravi34340% (1)

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kNo ratings yet

- Al Jazeera Rawa15Document1 pageAl Jazeera Rawa15hemajsuryaNo ratings yet

- BCB Solutions Business ProfileDocument9 pagesBCB Solutions Business ProfileJacaranda FM NewsNo ratings yet

- 4.cicocoat EPU 6Document2 pages4.cicocoat EPU 6Sibgathullah100% (1)

- 439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water LineDocument16 pages439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water Linearshad iqbalNo ratings yet

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- Conmix Utg 2011Document2 pagesConmix Utg 2011Fredj Ben SalemNo ratings yet

- Delfix 8-10Document2 pagesDelfix 8-10FAIYAZ AHMEDNo ratings yet

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Glass Fibre Grids MethodologyDocument4 pagesGlass Fibre Grids MethodologyRaghavNo ratings yet

- Cmci Cmci: Epoxy Grout System For Equipment BasesDocument2 pagesCmci Cmci: Epoxy Grout System For Equipment Basespravi3434No ratings yet

- Standard Construction Specs for Roads and Pavement MarkingsDocument3 pagesStandard Construction Specs for Roads and Pavement MarkingsRolando de GuzmanNo ratings yet

- Sika Seal 105Document2 pagesSika Seal 105Gabo Tellez100% (1)

- Technical Specification for Anti-Termite TreatmentDocument9 pagesTechnical Specification for Anti-Termite Treatmentkmandar99No ratings yet

- Remove Bathroom Suite Method StatementDocument2 pagesRemove Bathroom Suite Method StatementUbah ChigozieNo ratings yet

- Chemaflex 276 HDocument4 pagesChemaflex 276 HghazanfarNo ratings yet

- L. Construction Method StatementDocument17 pagesL. Construction Method StatementEQ13No ratings yet

- Masteremaco S 422Document3 pagesMasteremaco S 422shahidNo ratings yet

- Method NSG H For Beam or SlabDocument3 pagesMethod NSG H For Beam or SlabDave Robert HasibuanNo ratings yet

- Polyseal 1PU: One Part Polyurethane Joint SealantDocument2 pagesPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiNo ratings yet

- Catalogo Equipos de Riego VyrDocument194 pagesCatalogo Equipos de Riego VyrRaul Yancce Riego Tecnificado100% (2)

- 1 Cable Tray CatalogueDocument82 pages1 Cable Tray CatalogueHamouda YaseenNo ratings yet

- Rib Septic Tank Installation StepsDocument2 pagesRib Septic Tank Installation StepsDianna LambertNo ratings yet

- Fenomastic Pure Colours Enamel MattDocument4 pagesFenomastic Pure Colours Enamel MattAslam KhanNo ratings yet

- Concure WBDocument2 pagesConcure WBR.ThangarajNo ratings yet

- Renderoc FC (1) Fairing Coat PDFDocument4 pagesRenderoc FC (1) Fairing Coat PDFPrashant MankarNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Davies 5 700 Liquid Tile Primer PDFDocument1 pageDavies 5 700 Liquid Tile Primer PDFKissa DolautaNo ratings yet

- Road Construction Method Statement - Method Statement HQDocument19 pagesRoad Construction Method Statement - Method Statement HQaugustine samuelNo ratings yet

- Ms 03 Fit Out WorksDocument18 pagesMs 03 Fit Out WorksHichem ZerradNo ratings yet

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoNo ratings yet

- Fosroc Renderoc Laxtra Plus: Constructive SolutionsDocument2 pagesFosroc Renderoc Laxtra Plus: Constructive SolutionsVincent Javate0% (1)

- Medium Curing Cutback Product Data SheetDocument1 pageMedium Curing Cutback Product Data SheetRaheelHashmiNo ratings yet

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- Standard BoQ TEMPLATE Market PlaceDocument4 pagesStandard BoQ TEMPLATE Market PlaceAntoine YabichinoNo ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- Mastertop 530 12-04Document3 pagesMastertop 530 12-04djrote4No ratings yet

- BASF Mastertop 538 DSDocument3 pagesBASF Mastertop 538 DSSaud PathiranaNo ratings yet

- Masteremaco - S 348 v2Document2 pagesMasteremaco - S 348 v2shahzadNo ratings yet

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 pagesMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-No ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- Standard Grout PDFDocument3 pagesStandard Grout PDFFrancois-No ratings yet

- Ferroflow 939: Iron Fortified Shrinkage Compensated GroutDocument2 pagesFerroflow 939: Iron Fortified Shrinkage Compensated GroutFrancois-No ratings yet

- FlowcableDocument4 pagesFlowcableFrancois-No ratings yet

- Masterflow 410 PCDocument3 pagesMasterflow 410 PCFrancois-No ratings yet

- MEYCO MP 367 Foam PDFDocument2 pagesMEYCO MP 367 Foam PDFFrancois-No ratings yet

- Meyco MP308 PDFDocument3 pagesMeyco MP308 PDFFrancois-No ratings yet

- Masterflow 524: High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 524: High Strength, Non Shrink Cementitious Construction GroutFrancois-No ratings yet

- MEYCO MP320 Questions & Answers PDFDocument12 pagesMEYCO MP320 Questions & Answers PDFFrancois-No ratings yet

- Meyco MP 357 GS PDFDocument2 pagesMeyco MP 357 GS PDFFrancois-No ratings yet

- Ferromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationDocument2 pagesFerromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationFrancois-No ratings yet

- Meyco MP 301 PDFDocument2 pagesMeyco MP 301 PDFFrancois-No ratings yet

- Meyco MP302 PDFDocument3 pagesMeyco MP302 PDFFrancois-No ratings yet

- MEYCO MP 364 Flex PDFDocument2 pagesMEYCO MP 364 Flex PDFFrancois-No ratings yet

- Meyco FIB 500 PDFDocument2 pagesMeyco FIB 500 PDFFrancois-No ratings yet

- RheoFIT 761 PDFDocument2 pagesRheoFIT 761 PDFFrancois-No ratings yet

- Meyco Fix Lube 1 PDFDocument2 pagesMeyco Fix Lube 1 PDFFrancois-No ratings yet

- Rheocrete 222+: Organic Corrosion Inhibiting AdmixtureDocument3 pagesRheocrete 222+: Organic Corrosion Inhibiting AdmixtureFrancois-No ratings yet

- MBrace RESIN SYSTEMS PDFDocument6 pagesMBrace RESIN SYSTEMS PDFFrancois-No ratings yet

- Meyco MP355 1K - TDS - 07 - PDFDocument2 pagesMeyco MP355 1K - TDS - 07 - PDFFrancois-No ratings yet

- Meyco FIB 600 PDFDocument2 pagesMeyco FIB 600 PDFFrancois-No ratings yet

- Rheoface 405: (Formerly Known As Surface Retarder)Document1 pageRheoface 405: (Formerly Known As Surface Retarder)Francois-No ratings yet

- Rheobuild 1030: High Range Water ReducerDocument2 pagesRheobuild 1030: High Range Water ReducerFrancois-No ratings yet

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 pagesPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-No ratings yet

- Primer SC PDFDocument3 pagesPrimer SC PDFFrancois-No ratings yet

- Micro Air 120 PDFDocument2 pagesMicro Air 120 PDFFrancois-No ratings yet

- Pozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteDocument2 pagesPozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-No ratings yet

- Pozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteDocument2 pagesPozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteFrancois-No ratings yet

- Geography Grade 7 1.1Document91 pagesGeography Grade 7 1.1Flo RenceNo ratings yet

- Syabas Water ApplicationDocument7 pagesSyabas Water ApplicationKen Chia0% (1)

- Care Sheet - Green IguanaDocument6 pagesCare Sheet - Green IguanaJohn GamesbyNo ratings yet

- How I Distill Ipa: WarningDocument6 pagesHow I Distill Ipa: WarningAidenNo ratings yet

- Design of An Ethylene Oxide Production Process PDFDocument13 pagesDesign of An Ethylene Oxide Production Process PDFGopi Krish100% (1)

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationAditya FebriantoNo ratings yet

- Importance of Groundwater as Major Drinking SourceDocument15 pagesImportance of Groundwater as Major Drinking SourcePRAKASH NNo ratings yet

- General Catalogue 0819 Gb-3Document186 pagesGeneral Catalogue 0819 Gb-3Omar SaeedNo ratings yet

- Protect and decorate concrete with Brushbond coatingDocument4 pagesProtect and decorate concrete with Brushbond coatingnavin jollyNo ratings yet

- NSTSE Class 7 Solved Paper 2010 PDFDocument25 pagesNSTSE Class 7 Solved Paper 2010 PDFpenumudi77 penumudi770% (1)

- Fire Weather - Agricultural Handbook 360Document236 pagesFire Weather - Agricultural Handbook 360Peter Whitmore100% (2)

- Wse3701 Assignment 1 Memorandum 2020Document8 pagesWse3701 Assignment 1 Memorandum 2020Richard BosmanNo ratings yet

- Optimize battery performance with AquaGen pro recombination systemDocument6 pagesOptimize battery performance with AquaGen pro recombination systemNguyễn Anh DanhNo ratings yet

- GFL-WDA - e Spesifikais AlatDocument19 pagesGFL-WDA - e Spesifikais Alatlabkimia unisbaNo ratings yet

- EV The Chinese Trap PDFDocument2 pagesEV The Chinese Trap PDFsenthilkumarNo ratings yet

- Fiber Reinforced Waterproof Cementitious MethodDocument3 pagesFiber Reinforced Waterproof Cementitious MethodlkovijayNo ratings yet

- 05 Activity 1 13 AnswerDocument7 pages05 Activity 1 13 AnswerAllyza RenoballesNo ratings yet

- VCX 400 Project ScheduleDocument4 pagesVCX 400 Project ScheduleHuu Nguyen DucNo ratings yet

- WEEK 2 Day 1 Chemical Reactivity Properties of MaterialsDocument43 pagesWEEK 2 Day 1 Chemical Reactivity Properties of MaterialsJaizy BartoloNo ratings yet

- SFBI - PretzelDocument2 pagesSFBI - PretzelSergio VelosoNo ratings yet

- Chapter 46 Thermal Recovery Petroleum Engineering HandbookDocument46 pagesChapter 46 Thermal Recovery Petroleum Engineering Handbooktarek senigraNo ratings yet

- Iwk-Ssapdc1 19Document6 pagesIwk-Ssapdc1 19Dzul M RamliNo ratings yet

- Jura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineDocument15 pagesJura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineyangNo ratings yet

- CWR - Sweet MelonDocument4 pagesCWR - Sweet MelonRusmin Nuryadin SastraatmadjaNo ratings yet