Professional Documents

Culture Documents

Harmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor Drives

Uploaded by

NationalinstituteDsnrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Harmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor Drives

Uploaded by

NationalinstituteDsnrCopyright:

Available Formats

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct

Torque Controlled Induction Motor Drives

R. Abdollahi

Electrical Engineering. Department

Shahab Danesh Institute of Higher Education

Qom, Iran

rohollah.abdollahi@yahoo.com

ABSTRACT

This paper presents the design and analysis of a transformer based 36-pulse ac-dc converters which supplies direct torque

controlled induction motor drives (DTCIMD’s) in order to have better power quality conditions at the point of common

coupling. The converters output voltage is accomplished via two paralleled eighteen-pulse ac-dc converters each of them

consisting of nine-phase diode bridge rectifier. The design procedure of magnetics is in a way such that makes it suitable for

retrofit applications where a six-pulse diode bridge rectifier is being utilized. The 36-pulse structure improves power quality

criteria at ac mains and makes them consistent with the IEEE-519 standard requirements for varying loads. Furthermore,

near unity power factor is obtained for a wide range of DTCIMD operation. A comparison is made between 6-pulse and 36-

pulse converters (Polygon, Fork, and Hexagon) from view point of power quality indices. Results show that input current

total harmonic distortion (THD) is less than 4% for the 36-pulse topologies at variable loads. The Delta/Hexagon connected

platform could simplify the resulted configuration for the converters and reducing the costs.

Keywords: AC–DC converter, power quality, 36-pulse rectifier, direct torque controlled induction motor drive

(DTCIMD).

1. Introduction

Recent advances in solid state conversion prominent standards in this field are IEEE standard

technology has led to the proliferation of variable 519 [2] and the International Electrotechnical

frequency induction motor drives (VFIMD’s) that are Commission (IEC) 61000-3-2 [3].

used in several applications such as air conditioning,

blowers, fans, pumps for waste water treatment According to considerable growth of Static Power

plants, textile mills, rolling mills etc [1]. The most Converters (SPC’s) that are the major sources of

practical technique in VFIMD’s is direct torque harmonic distortion and as a result their power

controlled strategy in that it offers better performance quality problems, researchers have focused their

rather than the other control techniques. Direct attention on harmonic eliminating solutions. For

Torque controlled technique is implemented in DTCIMD’s one effective solution is to employ

voltage source inverter which is mostly fed from six- multipulse AC-DC converters. These converters

pulse diode bridge rectifier, Insulated gate bipolar are based on either phase multiplication or phase

transistors (IGBT’s) are employed as the VSI shifting or pulse doubling or a combination [4]-[19].

switches. The most important drawback of the six- Although, in the conditions of light load or small

pulse diode-bridge rectifier is its poor power factor source impedance, line current total harmonic

injection of current harmonics into ac mains. The distortion (THD) will be more than 5% for up to 18-

circulation of current harmonics into the source pulse AC-DC converters. A Hexagon-Connected

impedance yields in harmonic polluted voltages at the Autotransformer-Based 24-pulse AC-DC converter

point of common coupling (PCC) and consequently is reported in [7] which has THD variation of 4.48%

resulting in undesired supply voltage conditions for to 5.65% from full-load to light-load (20% of full-

costumers in the vicinity. The value of current load). A Zigzag-Connected Autotransformer-Based

harmonic components which are injected into the grid 24-pulse AC-DC converter is reported in [13] which

by nonlinear loads such as DTCIMD’s should be has THD variation of 4.51% to 5.77% from full-load

confined within the standard limitations. The most to light-load (20% of full-load).

Journal of Applied Research and Technology 135

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

Another T-Connected Autotransformer-Based topologies require higher rating magnetics,

24-Pulse AC–DC Converter has also been resulting in the enhancement of capital cost. As is

presented in [14], however, the THD of the mentioned before, the Delta/Hexagon connected

supply current with this topology is reported to platform could simplify the resulted configuration

vary from 2.46% to 5.20% which is more than for the converters and reducing the costs (shown in

5% when operating at light load. The 36-pulse Fig. 3). The Delta/Hexagon scheme has an

one was designed for vector controlled induction optimized configuration in this regard. The

motor drives in [17] which has THD variation of proposed design method will be suitable even

2.03% to 3.74% from full-load to light-load (20% when the transformer output voltages vary while

of full-load) respectively but the dc link voltage is keeping its 36-pulse operation. In the 36-pulse

higher than that of a 6-pulse diode bridge structure, two nine-leg diode-bridge rectifiers are

rectifier, thus making the scheme nonapplicable paralleled via two interphase transformers (IPTs)

for retrofit applications. and fed from a transformer. Hence, a 36-pulse

output voltage is obtained. Detailed design tips of

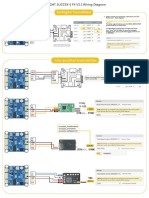

The delta/polygon-connected transformer-based the IPT and totally the whole structure of 36-pulse

36-pulse ac-dc converter (shown in Fig. 1) for ac-dc converter are described in this paper and the

power quality improvement in [18] which has THD proposed converter is modeled and simulated in

variation of 2.92% to 3.89% from full-load to light- MATLAB to study its behavior and specifically to

load (20% of full-load) respectively and Delta/ analyze the power quality indices at ac mains.

Fork-Connected Transformer-based 36-pulse ac– Furthermore, a 36-pulse ac-dc converter consisting

dc converter (shown in Fig. 2) have been reported of a delta/hexagon transformer, two eighteen-pulse

[19] for reducing the total harmonic distortion diode bridge rectifiers paralleled through two IPTs,

(THD) of the ac mains current. But these and with a DTCIMD load Fig. 3.

Figure 1. Transformer configuration, Winding arrangement, and Phasor representation of trans

former for 36-pulse AC-DC converter having delta/Polygon connected secondary winding [18].

136 Vol. 13, February 2015

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

Figure 2. Transformer configuration, Winding arrangement, and Phasor representation

of transformer for 36-pulse AC-DC converter having delta/fork connected secondary winding [19].

Figure 3. Delta/hexagon-transformer configuration for 36-pulse ac–dc conversion.

Simulation results of six-pulse and proposed 36- Accordingly, each bridge rectifier consists of

pulse ac-dc converters feeding a DTCIMD load are nine common-anode and nine common-cathode

scheduled and various quality criteria such as THD diodes (two nine-leg rectifiers). Phasor diagram

of ac mains current, power factor, displacement of delta/hexagon transformer is shown in Fig. 4.

factor, distortion factor, and THD of the supply

voltage at PCC are compared. 2.1 Design of Proposed Transformer for 36-Pulse

AC–DC Converter

2. Proposed 36-Pulse AC–DC Converter

The hexagon transformer winding arrangement

In order to implement a 36-pulse ac-dc converter for 36-pulse AC-DC conversion is shown in Fig. 5

through paralleling two bridge rectifiers, i.e. two 18- and its connection along with phasor diagram.

pulse rectifiers, two sets of nine-phase voltages with The aforementioned two voltage sets are called

a phase difference of 40 degrees between the as (Va1, Va2, Va3, Va4, Va5, Va6, Va7, Va8,

voltages of each group and 10 degrees between the Va9) and (Vb1, Vb2, Vb3, Vb4, Vb5, Vb6, Vb7,

same voltages of the two groups are required. Vb8, Vb9) that are fed to rectifiers I and II,

Journal of Applied Research and Technology 137

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

respectively. The same voltages of the two Input voltages for converter I are:

groups, i.e. Vai and Vbi, are phase displaced of

Va1 ? VA - K1VC / K 2 VB

10 degrees. V¬a1 and Vb1 has a phase shift of

Va 2 ? VA - K 3VB / K 4 VC

Va 3 ? VA / K 5VA / K 6 VC

+5 and -5 degrees from the input voltage of phase

Va 4 ? V B - K1VA / K 2 VC

A, respectively. According to phasor diagram, the

Va 5 ? VB - K 3VC / K 4 VA

nine-phase voltages are made from ac main

phase and line voltages with fractions of the Va 6 ? VC - K 5VB / K 6 VA

primary winding turns which are expressed with Va 7 ? VC - K1VB / K 2 VA

the following relationships. Consider three-phase Va 8 ? VC - K 3VA / K 4 VB

voltages of primary windings as follows: Va 9 ? VA - K 5VC / K 6 VB (4)

VA ? Vsæ0C, VB ? Vsæ / 120C , VC ? Vsæ120C. (1) Input voltages for converter II are:

Va1 ? VA - K1VB / K 2 VC

Va 2 ? VA - K 5 VB / K 6 VC

Where, nine-phase voltages are:

Va 3 ? VB - K 3VA / K 4 VC

Va1 ? Vs æ - 5C , Va 2 ? Vsæ / 35C , Va 3 ? Vsæ / 75C , Va 4 ? V B - K1VC / K 2 VA

Va 4 ? Vs æ / 115C , Va 5 ? Vsæ / 155C , Va 6 ? Vsæ / 195C , Va 5 ? VB - K 5 VC / K 6 VA

Va 6 ? VC - K 3VB / K 4 VA

Va 7 ? Vs æ / 235 , Va 8 ? Vsæ / 275 , Va 9 ? Vsæ / 315 .

Va 7 ? VC - K1VA / K 2 VB

C C C

(2)

Va 8 ? VC - K 5 VA / K 6 VB

Vb1 ? Vsæ / 5C , Vb 2 ? Vs æ / 45C , Vb3 ? Vsæ / 85C , Va 9 ? VA - K 3VC / K 4 VB (5)

Vb 4 ? Vsæ / 125C , Vb5 ? Vsæ / 165C , Vb 6 ? Vsæ / 205C ,

Vb7 ? Vsæ / 245C , Vb8 ? Vsæ / 285C , Vb9 ? Vsæ / 325C. (3) VAB ? 3VAæ30C , VBC ? 3VBæ30C , VCA ? 3VCæ30C. (6)

Figure 4. Phasor representation of transformer for 36-pulse

AC-DC converter having hexagon connected secondary winding.

Figure 5. Winding arrangement of transformer for 36-pulse

AC-DC converter having hexagon connected secondary winding.

138 Vol. 13, February 2015

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

Constants K1-K6 are calculated using (2)-(6) to Va1 ? VA - K1VC - K 2 VB

obtain the required windings turn numbers to have Va 2 ? VA - K 3VB - K 4 VC

the desired phase shift for the two voltage sets: Va 3 ? VA / K 5VA - K 6 VC

Va 4 ? V B - K1VA - K 2 VC

K1 ? 0.05411, K 2 ? 0.04651, K3 ? 0.5120, Va 5 ? VB - K 3VC - K 4 VA

K 4 ? 0.1503, K 5 ? 0.7011, K 6 ? 0.1153. (7) Va 6 ? VC - K 5 VB - K 6 VA

Va 7 ? VC - K1VB - K 2 VA

Va 8 ? VC - K 3VA - K 4 VB

Heading: numbered sequentially in Arabic

Va 9 ? VA - K 5VC - K 6 VB

numerals, left justified, in 10-point Arial Italics font,

upper and lower case letters. (9)

2.2 Design of Transformer for Retrofit Applications Input voltages for converter II are:

The value of output voltage in multipulse rectifiers Va1 ? VA - K1VB - K 2 VC

boosts relative to the output voltage of a six-pulse Va 2 ? VA - K 5VB - K 6 VC

converter making the multipulse rectifier Va 3 ? VB - K 3VA - K 4 VC

inappropriate for retrofit applications. For instance, Va 4 ? V B - K1VC - K 2 VA

with the transformer arrangement of the proposed Va 5 ? VB - K 5VC - K 6 VA

36-pulse converter, the rectified output voltage is Va 6 ? VC - K 3VB - K 4 VA

Va 7 ? VC - K1VA - K 2 VB

17% higher than that of six-pulse rectifier. For

Va 8 ? VC - K 5VA - K 6 VB

retrofit applications, the above design procedure is

Va 9 ? VA - K 3VC - K 4 VB

modified so that the dc-link voltage becomes equal

to that of six-pulse rectifier. This will be (10)

accomplished via modifications in the tapping

positions on the windings as shown in Fig. 6. It Accordingly, the values of constants K1-K6 are

should be noted that with this approach, the changed for retrofit applications as:

K1 ? 0.2136, K 2 ? 0.12994 , K 3 ? 0.59428,

desired phase shift is still unchanged. Similar to

K 4 ? 0.04364 , K 5 ? 0.75154 , K 6 ? 0.0727.

section II part 1, the following equations can be

derived as: (11)

VS ? 0.8314 VA (8)

The values of K 1-K6 establish the essential turn

numbers of the transformer windings to have the

required output voltages and phase shifts. To

Input voltages for converter I are: ensure the independent operation of the rectifier

groups, interphase transformers (IPTs), which

are relatively small in size, are connected at the

output of the rectifier bridges. With this

arrangement, the rectifier diodes conduct for 120

per cycle. The kilovoltampere rating of the

transformer is calculated as [4]:

kVA ? 0.5 Â VwindingI winding (12)

Where, Vwinding is the voltage across each

transformer winding and Iwinding indicates the

full load current of the winding. The apparent

power rating of the interphase transformer is

also calculated in a same way. Another

important parameter related to the AC-DC

Figure 6. Phasor diagram of voltages in the converters is transformer utilization factor (TUF)

proposed transformer connection alongwith that indicates the relative size of transformers is

modifications for retrofit arrangement. defined as:

Journal of Applied Research and Technology 139

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

kVA ? PDC / Â Vsec I sec (13) limitations of the IEEE standard 519. These

harmonic spectrums are obtained when

Where Vsec and Isec is rms voltage and current induction motor operates under light load (20%

rating of secondary winding. of full load) and full load conditions.

400

3. Matlab Simulation

300

The designed configurations were simulated 200

using SIMULINK and power system block set

Transformer output voltage (V)

100

(PSB) toolboxes. In this model, a three-phase 460

V and 60 Hz network is utilized as the supply for 0

the 36-pulse converter. The designed transformer -100

is modeled via three multi-winding transformers. -200

Multi-winding transformer block is also used to

-300

model IPT. At the converter output, a series

inductance (L) and a parallel capacitor (C) as the -400

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

dc link are connected to IGBT-based Voltage Time (Sec)

Source Inverter (VSI). VSI drives a squirrel cage Figure 7. Transformer output voltage.

induction motor employing direct torque control

strategy. The simulated motor is 50 hp (37.3 kW), 10

4-pole, and Y-connected. Detailed data of motor 8

are listed in Appendix. Simulation results are

Voltage waveform across the interphase transformer (V)

depicted in Figs. 7-17. Power quality parameters

are also listed in Table I for 6-pulse and 36-pulse 4

ac-dc converters. 2

4. Results and Discussion

-2

Table I lists the power quality indices obtained -4

from the simulation results of the 6-pulse and 36- -6

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

pulse converters. Fig. 7 depicts two groups of Time (Sec)

nine-phase voltage waveforms with a phase shift

Figure 8. Voltage waveform across the IPT.

of 10 degrees between the same voltages of

each group. The voltage across the interphase 700

transformer (shown in Fig. 8) has a frequency

equal to 9 times that of the supply which results 600

in a significant reduction in volume and cost of

36-pulse ac–dc converter output voltage (V)

500

magnetics. The 36-pulse converter output

voltage (shown in Fig. 9) is almost smooth and 400

free of ripples and its average value is 605.7 300

volts which is approximately equal to the DC link

200

voltage of a six-pulse rectifier (607.6 volts). This

makes the 36-pulse converter suitable for retrofit 100

applications. Input current waveforms and its

0

harmonic spectrum of the 6-pulseand 36-pulse 0 0.002 0.004 0.006 0.008 0.01

Time (Sec)

0.012 0.014 0.016 0.018 0.02

converters extracted and shown in Figs. 10-17,

respectively to check their consistency with the Figure 9. 36-pulse ac–dc converter output voltage.

140 Vol. 13, February 2015

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

20

10

Obviously, for 6-pulse converter, fifth and

0

seventh order harmonics are dominant. Hence,

-10

input current THD of this converter will be

-20

relatively a large amount and is equal to 28.53%

0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1

Time (s) and 52.53% for full load and light load conditions

Fundamental (60Hz) = 10.33 , THD= 52.53% that are not within the standard margins. It is

100

observed from the results that the THD of ac

80

mains current at light load (20%) in Topology

60

Polygon is 3.82, shown in Fig. 12, and that at full

load is 2.92%, as shown in Fig. 13. Similarly,

40

Fig. 14 shows the THD of ac mains current at

20 light load in Topology Fork as 3.47% and at full

0

load as 1.59%, shown in Fig. 15.

0 500 1000 1500 2000 2500 3000 3500 4000 4500

Frequency (Hz) g y ( ) y

20

Figure 10. Input current waveform of six-pulse

Is (A)

ac–dc converter at light load and its harmonic 0

spectrum. (50hp load).

-20

0.9 0.92 0.94 0.96 0.98 1

50 Time (s)

0

-50

Fundamental (60Hz) = 10.57 , THD= 3.89%

100

0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1

Mag (% of Fundamental)

Time (s)

80

Fundamental (60Hz) = 52.69 , THD= 28.53%

100 60

80 40

60 20

40 0

0 10 20 30 40 50

20

Harmonic order

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500

Figure 12. Input current waveform of 36-pulse

Frequency (Hz)

ac–dc converter at light load and its harmonic

spectrum for Topology polygon.

Figure 11. Input current waveform of six-pulse (50hp load).

ac–dc converter at full load and its harmonic

spectrum. (50hp load).

AC Mains

Current ISA % THD of ISA, Distortion Displacement Power Factor, DC Voltage

% (A) at Factor, DF Factor, DPF PF (V)

Sr. THD

Topology

No. of

Vac Light Full Light Full Light Light Full Full Light Full Light Full

Load Load Load Load Load Load Load Load Load Load Load Load

1 6-pulse 5.64 10.33 52.69 52.53 28.53 0.8850 0.8730 0.9485 0.9599 0.9858 0.9881 616.6 607.6

36-pulse

2 2.93 10.57 52.52 3.89 2.92 0.9992 0.9993 0.9994 0.9986 0.9986 0.9979 611.7 608.1

polygon

36-pulse

2 2.16 10.47 52.43 3.65 1.59 0.9993 0.9995 0.9993 0.9980 0.9986 0.9976 611.7 607.9

Fork

36-pulse

2 1.86 10.53 52.23 3.26 1.88 0.9995 0.9981 0.9966 0.9997 0.9986 0.9969 611.1 605.7

Hexagon

Table 1. Comparison of Simulated Power Quality Parameters of the DTCIMD Fed from Different AC-DC Converters.

Journal of Applied Research and Technology 141

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

50

50

Is (A)

0

0

-50

-50

0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1

-100 Time (s)

0.9 0.92 0.94 0.96 0.98 1

Time (s) 100

Fundamental (60Hz) = 52.38 , THD= 1.59%

Fundamental (60Hz) = 52.52 , THD= 2.92% 80

100

Mag (% of Fundamental)

60

80

40

60 20

40 0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Frequency (Hz)

20

Figure 15. Input current waveform of 36-pulse

0

0 10 20 30 40 50 ac–dc converter at full load and its harmonic

Harmonic order spectrum for Topology Fork. (50hp load).

g y ( ) y

Figure 13. Input current waveform of 36-pulse 20

ac–dc converter at full load and its harmonic 10

spectrum for Topology polygon. (50hp load). 0

-10

On the other hand, as shown in Figs. 16-17, -20

0.9 0.91 0.92 0.93 0.94 0.95

Time (s)

0.96 0.97 0.98 0.99 1

Hexagon connected 36-pulse converter has an Fundamental (60Hz) = 10.53 , THD= 3.26%

100

acceptable current THD (3.26% for light load and

1.88% for full load conditions). In this 80

configuration, low order harmonics up to 33rd 60

are eliminated in the supply current. In general, 40

the largely improved performance of the 36- 20

pulse converter makes the power quality indices

such as THD of supply current and voltage 0

0 500 1000 1500 2000 2500

Frequency (Hz)

3000 3500 4000 4500 5000

(THDi and THDv), displacement power factor

(DPF), distortion factor (DF), and power factor Figure 16. Input current waveform of 36-pulse

(PF) satisfactory for different loading conditions. ac–dc converter at light load and its harmonic

g y ( ) y

spectrum for Topology Hexagon. (50hp load).

20

10

50

0

0

-10

-50

-20

0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1

Time (s) 0.9 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1

Time (s)

Fundamental (60Hz) = 10.51 , THD= 3.47% Fundamental (60Hz) = 52.23 , THD= 1.88%

100 100

80 80

60 60

40 40

20 20

0 0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Frequency (Hz) Frequency (Hz)

Figure 14. Input current waveform of 36-pulse Figure 17. Input current waveform of 36-pulse

ac–dc converter at light load and its harmonic ac–dc converter at full load and its harmonic

spectrum for Topology Fork. (50hp load). spectrum for Topology Hexagon. (50hp load).

142 Vol. 13, February 2015

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

The aforementioned criteria are listed in Table I for

the three types of converters. The converter in

Topology Polygon, Fork, and Hexagon needs

magnetics of 124.84%, 132.54%, and 106.35% of

the drive rating respectively. The Delta/Hexagon

connected platform could simplify the resulted

configuration for the converters and reducing the

costs. It can be observed that the TUF for

Delta/Hexagon connected 36-pulse AC-DC

converter is 89.46% which is better than the

Delta/Polygon and Delta/Fork connected

transformers used for 36-pulse AC-DC converter.

5. Conclusion

This paper presents the design and analysis of a

transformer based 36-pulse ac-dc converters

which supplies direct torque controlled induction

motor drives (DTCIMD’s) in order to have better

power quality conditions at the point of common

coupling. The 36-pulse converter output voltage is

accomplished via two paralleled eighteen-pulse ac-

dc converters each of them consisting of nine-

phase diode bridge rectifier. Afterwards, the

proposed design procedure was modified for

retrofit applications. Simulation results prove that,

for the 36-pulse topology, input current distortion

factor is in a good agreement with IEEE 519

requirements. Current THD is less than 4% for

varying loads. It was also observed that the input

power factor is close to unity resulting in reduced

input current for DTCIMD load. Thus, the 36-pulse

ac–dc converter can easily replace the existing 6-

pulse converter without much alteration in the

existing system layout and equipment. The

Delta/Hexagon connected platform could simplify

the resulted configuration for the converters and

reducing the costs. The Delta/Hexagon scheme

has an optimized configuration in this regard. The

Delta/Hexagon design method will be suitable

even when the transformer output voltages vary

while keeping its 36-pulse operation.

Journal of Applied Research and Technology 143

Harmonic Mitigation using 36-Pulse AC-DC Converter for Direct Torque Controlled Induction Motor Drives, R. Abdollahi / 135-144

References [13] R. Abdollahi, “Pulse Doubling in Zigzag-Connected

Autotransformer-Based 12-Pulse AC-DC Converter for

[1] B. K. Bose, Modern Power Electronics and AC Power Quality Improvement”,Journal of ELECTRICAL

Drives. Singapore: Pearson Education, 1998. ENGINEERING, VOL. 63, NO. 6, 2012.

[2] IEEE Standard 519-1992, IEEE Recommended [14] B. Singh, G. Bhuvaneswari, and V. Garg, “T-

Practices and Requirements for Harmonic Control in Connected Autotransformer-Based 24-Pulse AC–DC

Electrical Power Systems. NewYork: IEEE Inc., 1992. Converter for Variable Frequency Induction Motor

Drives” IEEE Transactions on Energy Conversion , Vol.

[3] IEC Standard 61000-3-2:2004, Limits for harmonic 21, no. 3, pp. 663- 672 , Sept. 2006.

current emissions, International Electromechanical

Commission. Geneva, 2004. [15] R. Abdollahi, “A Novel T-Connected Autotransformer

Based 30-Pulse AC-DC Converter for Power Quality

[4] D. A. Paice, Power Electronic Converter Harmonics: Improvement in Direct Torque Controlled Induction Motor

Multipulse Methods for Clean Power. New York: IEEE Drives, Int. J. Emerg. Sci., 2(1), 87-102, March 2012.

Press, 1996.

[16] R. Abdollahi, A. Jalilian, “Fork-Connected

[5] B. Singh, G. Bhuvaneswari, and V. Garg, “Harmonic Autotransformer Based 30-Pulse AC-DC Converter for

Mitigation in AC–DC Converters for Vector Controlled Power Quality Improvement, International Journal on

Induction Motor Drives” IEEE Transactions on Energy Electrical Engineering and Informatics - Volume 4,

Conversion, Vol. 22, no. 3, pp. 637 - 646, Sept. 2007. Number 2, July 2012.

[6] A. Darvishi, A. Alimardani, B. Vahidi, S. H. Hosseinian,

[17] B. Singh and S. Gairola, “Design and Development

“Shuffled Frog-Leaping Algorithm for Control of Selective

of a 36-Pulse AC-DC Converter for Vector Controlled

and Total Harmonic Distortion”, Journal of Applied

Induction Motor Drive,” in Proc. IEEE Conf. Power

Research and Technology, Vol. 12, February 2014.

Electron. Drives Syst. PEDS’07, pp. 694–701, 2007.

[7] R. Abdollahi, “Hexagon-Connected Transformer-

Based 20-Pulse AC–DC Converter for Power Quality [18] R. Abdollahi, “Study of Delta/Polygon-Connected

Improvement, J. Electrical Systems 8-2, 2012. Transformer-Based 36-Pulse AC-DC Converter for

Power Quality Improvement, Archives of Electrical

[8] T.R.Sumithira, A.Nirmal Kumar, Elimination of Engineering, VOL. 61(2), pp. 277-292 (2012).

Harmonics in Multilevel Inverters Connected to Solar

Photovoltaic Systems Using ANFIS: An Experimental [19] R. Abdollahi, “Delta/ Fork-Connected Transformer-

Case Study, Journal of Applied Research and based 36-Pulse AC-DC Converter for Power Quality

Technology, Vol. 11, February 2013. Improvement”, Journal of Electrical and Control

Engineering, Vol. 2, No. 2, pp. 20-26, 2012.

[9] R. Abdollahi, A. Jalilian, “Application of Pulse

Doubling in Star-Connected Autotransformer Based 12- Appendix

Pulse AC-DC Converter for Power Quality Improvement,

International Journal of Electrical and Electronics Motor and Controller Specifications:

Engineering, 5:4, 2011.

Three-phase squirrel cage induction motor—50 hp (37.3

[10] B. Singh, G. Bhuvaneswari, and V. Garg, “A Novel kW), three phase, four pole, Y-connected, 460 V, 60 Hz.

Polygon Based 18-Pulse AC–DC Converter for Vector Rs = 0.0148 Ω; Rr = 0.0092 Ω; Xls = 1.14Ω; Xlr = 1.14

Controlled Induction Motor Drives” IEEE Transactions on Ω, XLm = 3.94 Ω, J = 3.1 Kg • m2.

Power Electronics, vol. 22, no. 2, March 2007.

Controller parameters: PI controller Kp = 300; Ki = 2000.

[11] B. Singh, V. Garg, and G. Bhuvaneswari , “A Novel DC link parameters: Ld = 2 mH; Cd = 3200 μF. Source

T-Connected Autotransformer-Based 18-Pulse AC–DC impedance: Zs = j0.1884 Ω (=3%).

Converter for Harmonic Mitigation in Adjustable-Speed

Induction-Motor Drives” IEEE Transactions on Industrial

Electronics , vol. 54, no. 5, October 2007.

[12] R. Abdollahi, A. Jalilian, “Application of Pulse

Doubling in Hexagon-Connected Transformer-Based 20-

Pulse AC-DC Converter for Power Quality Improvement,

PRZEGLĄD ELEKTROTECHNICZNY (Electrical

Review), ISSN 0033-2097, R. 88 NR 10a/2012.

144 Vol. 13, February 2015

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- M02-Basic Integrated Security SystemDocument132 pagesM02-Basic Integrated Security SystemTariku TesfayeNo ratings yet

- Medium Voltage Industrial VSDDocument11 pagesMedium Voltage Industrial VSDAhmed El SebaiiNo ratings yet

- Machine LearningDocument35 pagesMachine LearningSai Sudhar Sun100% (3)

- Single Phase To Three Phase SystemDocument57 pagesSingle Phase To Three Phase SystemASK projectsNo ratings yet

- SUCCEX-E F4 V2.1 Wiring Diagram 201006Document3 pagesSUCCEX-E F4 V2.1 Wiring Diagram 201006jhon alexander barbosa avendaño100% (3)

- Important Questions - APS - IDocument3 pagesImportant Questions - APS - IAakash MehtaNo ratings yet

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- Compliance (NBA) Report - 11-220-201525 - 1 - 2019 - 11 - 47 - 15 PDFDocument52 pagesCompliance (NBA) Report - 11-220-201525 - 1 - 2019 - 11 - 47 - 15 PDFAnil Kumar B67% (3)

- MTCWEDocument6 pagesMTCWEAnanda Dwi75% (4)

- Zigzag Connected Autotransformer-Based 24-Pulse AC-DC ConverterDocument12 pagesZigzag Connected Autotransformer-Based 24-Pulse AC-DC ConverterMiguel OchoaNo ratings yet

- Tpel 2006 889903Document10 pagesTpel 2006 889903Mustafizur RahmanNo ratings yet

- A Zigzag Connected Auto-Transformer Based 24-Pulse AC-DC ConverterDocument8 pagesA Zigzag Connected Auto-Transformer Based 24-Pulse AC-DC ConverterbgraoNo ratings yet

- 125 130 PDFDocument6 pages125 130 PDFJubin JainNo ratings yet

- Singh 2006Document10 pagesSingh 2006martin.teruelNo ratings yet

- Comparative Analysis of Multipulse AC-DC Converter Using Zig-Zag TransformerDocument5 pagesComparative Analysis of Multipulse AC-DC Converter Using Zig-Zag TransformerVits 19204 sarithaNo ratings yet

- 88-Pulse AC-DC Converter For Power Quality ImprovementDocument9 pages88-Pulse AC-DC Converter For Power Quality ImprovementInternational Journal of Science and Engineering InvestigationsNo ratings yet

- 24 Pulse Polygon Connected Auto TransformerDocument12 pages24 Pulse Polygon Connected Auto TransformerMustafizur RahmanNo ratings yet

- Matrix Converter - ReportDocument31 pagesMatrix Converter - ReportAmal P Nirmal100% (2)

- 31 2 Level, 48 PulseDocument6 pages31 2 Level, 48 PulseSumit MaheshwariNo ratings yet

- Report of Project 18pulseDocument6 pagesReport of Project 18pulsedhaval2430100% (1)

- XiaoDocument16 pagesXiaomartin.teruelNo ratings yet

- Improvement of Power Factor and Harmonic Reduction With VSC For HVDC SystemDocument7 pagesImprovement of Power Factor and Harmonic Reduction With VSC For HVDC SystemGiwrgos GewrgiadisNo ratings yet

- Vidyasagarvs 2016Document6 pagesVidyasagarvs 2016martin.teruelNo ratings yet

- Comparative AnalysisDocument6 pagesComparative AnalysisDrVikas Singh BhadoriaNo ratings yet

- Jpe 8-2-1Document12 pagesJpe 8-2-1Jeevananthan SeenithangamNo ratings yet

- Ee 09 L 10smpc Model QpaperDocument2 pagesEe 09 L 10smpc Model QpaperGīřïşh McNo ratings yet

- A Review On Single Phase To Three Phase Power Converters: Kaushal W. Kakad & Nitin R. BhasmeDocument10 pagesA Review On Single Phase To Three Phase Power Converters: Kaushal W. Kakad & Nitin R. BhasmeTJPRC PublicationsNo ratings yet

- Design and Control of A Bi-Directional Resonant DC-DC Converter For Automotive Engine/Battery Hybrid Power GeneratorsDocument7 pagesDesign and Control of A Bi-Directional Resonant DC-DC Converter For Automotive Engine/Battery Hybrid Power GeneratorsIfan Seven SeasNo ratings yet

- Design and Analysis of 24 Pulse Ac-Dc Converter: May 2015, Volume 2, Issue 5 JETIR (ISSN-2349-5162)Document8 pagesDesign and Analysis of 24 Pulse Ac-Dc Converter: May 2015, Volume 2, Issue 5 JETIR (ISSN-2349-5162)anuragpugaliaNo ratings yet

- Auto ZigzagDocument9 pagesAuto Zigzaggeetha babuNo ratings yet

- IEEE Power System Paper-Novel Controllers For The 48-Pulse VSC STATCOM and SSSC For Voltage Regulation and Reactive Power CompensationDocument13 pagesIEEE Power System Paper-Novel Controllers For The 48-Pulse VSC STATCOM and SSSC For Voltage Regulation and Reactive Power CompensationAnoop MathewNo ratings yet

- A Novel Approach For A Sinusoidal Output Inverter: Irfan AlanDocument6 pagesA Novel Approach For A Sinusoidal Output Inverter: Irfan AlanKari Romero GuizasolaNo ratings yet

- A New Method For DC-AC Conversion Using Simplified Multilevel Inverter - Design and Analysis Using PSIM 1. V.Gowri Shankar, 2.C.UdhayashankarDocument7 pagesA New Method For DC-AC Conversion Using Simplified Multilevel Inverter - Design and Analysis Using PSIM 1. V.Gowri Shankar, 2.C.UdhayashankarraghuevmNo ratings yet

- Simulation Current Controlled: Converter-InverterDocument5 pagesSimulation Current Controlled: Converter-InverterVivek VickyNo ratings yet

- 6pulse and 12pulse RDocument6 pages6pulse and 12pulse Rmathew_john0077393No ratings yet

- Ijsron2013794 PDFDocument5 pagesIjsron2013794 PDFRaviIdhayachanderNo ratings yet

- A Compact Autotransformer Based 12-Pulse Rectifier CircuitDocument6 pagesA Compact Autotransformer Based 12-Pulse Rectifier Circuitalex696No ratings yet

- Harmonic Mitigation in AC-DC Converters For Induction Motor Drives by Vector ControlledDocument8 pagesHarmonic Mitigation in AC-DC Converters For Induction Motor Drives by Vector ControlledInternational Journal of computational Engineering research (IJCER)No ratings yet

- Aredes2001 Article MultipulseConvertersAndControlDocument9 pagesAredes2001 Article MultipulseConvertersAndControlAbhay KotnalaNo ratings yet

- Boost Detailed Design PDFDocument22 pagesBoost Detailed Design PDFshivaNo ratings yet

- Bi-Directional DC-to-DC Converter For Solar Applications With Battery BackupDocument5 pagesBi-Directional DC-to-DC Converter For Solar Applications With Battery BackupPaulius BruneikaNo ratings yet

- Naresh DC Re Injection FinalDocument6 pagesNaresh DC Re Injection FinalRamu ThommandruNo ratings yet

- A New Single-Phase Single-Stage Three-Level Power Factor Correction AC-DC ConverterDocument12 pagesA New Single-Phase Single-Stage Three-Level Power Factor Correction AC-DC Convertersurya_v988No ratings yet

- Class D TheoryDocument10 pagesClass D TheorymushabagnrNo ratings yet

- Theoretical Analysis of DC Link Capacitor Current Ripple Reduction in The HEV DC-DC Converter and Inverter System Using A Carrier Modulation MethodDocument8 pagesTheoretical Analysis of DC Link Capacitor Current Ripple Reduction in The HEV DC-DC Converter and Inverter System Using A Carrier Modulation MethodVanHieu LuyenNo ratings yet

- A Novel Quadratic Boost Converter With Low Current and Voltage Stress On PowerDocument20 pagesA Novel Quadratic Boost Converter With Low Current and Voltage Stress On PowerfarhaniNo ratings yet

- Multipulse Converters and Controls For HVDC and FACTS SystemsDocument9 pagesMultipulse Converters and Controls For HVDC and FACTS SystemssanjusNo ratings yet

- Matteini PHD Part1Document15 pagesMatteini PHD Part1Anonymous EnggrUsmNo ratings yet

- Technote: Series vs. Parallel Connection of Multipulse RectifiersDocument2 pagesTechnote: Series vs. Parallel Connection of Multipulse Rectifiersmkashkooli_scribdNo ratings yet

- A New Single-Phase Single-Stage Three-LevelDocument12 pagesA New Single-Phase Single-Stage Three-LevelGururaj BandaNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document9 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- v42 63Document5 pagesv42 63Bala KumarNo ratings yet

- Eee-Pp-001 - 0107Document7 pagesEee-Pp-001 - 0107anuragpugaliaNo ratings yet

- Lecture 11Document14 pagesLecture 11Pranav KharbandaNo ratings yet

- Calculation of Modulation Index of PWM Wave Form Feed To Inverter Feed Induction MotorDocument18 pagesCalculation of Modulation Index of PWM Wave Form Feed To Inverter Feed Induction MotorSathishkumar MalipeddiNo ratings yet

- Harmonic Analysis of 6-Pulse and 12-Pulse Converter Models: JournalDocument6 pagesHarmonic Analysis of 6-Pulse and 12-Pulse Converter Models: JournalAshish JadhavNo ratings yet

- Multi Pulse Converter Based HVDCDocument13 pagesMulti Pulse Converter Based HVDCNetra Ray100% (1)

- A New Dual Boost DC/DC Converter With A Voltage Conversion GainDocument6 pagesA New Dual Boost DC/DC Converter With A Voltage Conversion GainNiharika DeshpandeNo ratings yet

- 4 Gaiceanu2014Document6 pages4 Gaiceanu2014HernandaBudiSantosoNo ratings yet

- DC Transformers 77Document15 pagesDC Transformers 77Keshavamurthy MurthyNo ratings yet

- Term Project Power D&TDocument6 pagesTerm Project Power D&TThamer SE AlkhamiisNo ratings yet

- Optimal Design of The Power Transformer With ANSYS Maxwell For Bidirectional Battery ChargerDocument9 pagesOptimal Design of The Power Transformer With ANSYS Maxwell For Bidirectional Battery ChargerlordgtyNo ratings yet

- New Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsDocument7 pagesNew Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsMaikPortnoyNo ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- IJTRD163Document5 pagesIJTRD163NationalinstituteDsnrNo ratings yet

- Java and PHP ListDocument2 pagesJava and PHP ListNationalinstituteDsnrNo ratings yet

- Budgets and Budgetary Control of NFC (Nuclear Fuel Complex)Document4 pagesBudgets and Budgetary Control of NFC (Nuclear Fuel Complex)NationalinstituteDsnrNo ratings yet

- BCA Project ListDocument1 pageBCA Project ListNationalinstituteDsnrNo ratings yet

- IOT Covid Patient Health Monitor in QuarantineDocument1 pageIOT Covid Patient Health Monitor in QuarantineMark Carey AbeciaNo ratings yet

- PGDBA Project Report GuidelinesDocument7 pagesPGDBA Project Report GuidelinesRahul sharmaNo ratings yet

- A Data Mining Based Model For Detection of Fraudulent Behaviour in Water ConsumptionDocument7 pagesA Data Mining Based Model For Detection of Fraudulent Behaviour in Water ConsumptionNationalinstituteDsnrNo ratings yet

- Assessing The Effectiveness of Riparian Restoration Projects Using Landsat and Preception Data From The Cloud Computing ApplicationDocument5 pagesAssessing The Effectiveness of Riparian Restoration Projects Using Landsat and Preception Data From The Cloud Computing ApplicationNationalinstituteDsnrNo ratings yet

- Social Distancing Monitoring Robot For QueueDocument2 pagesSocial Distancing Monitoring Robot For QueueNationalinstituteDsnrNo ratings yet

- Project DocumentDocument7 pagesProject DocumentChaitu MunirajNo ratings yet

- Heart Beat Monitoring and Intimate by GSM at Abnormal Condition1522869000Document2 pagesHeart Beat Monitoring and Intimate by GSM at Abnormal Condition1522869000NationalinstituteDsnrNo ratings yet

- Future of Depository With Introduction of Payment Bank: A Game Changer To Capital MarketDocument1 pageFuture of Depository With Introduction of Payment Bank: A Game Changer To Capital MarketNationalinstituteDsnrNo ratings yet

- Project Report ON Antenna Design, Simulation and FabricationDocument98 pagesProject Report ON Antenna Design, Simulation and FabricationAnuj DeshpandeNo ratings yet

- A Study On Depository System With Reference To Axis Bank LimitedDocument1 pageA Study On Depository System With Reference To Axis Bank LimitedNationalinstituteDsnrNo ratings yet

- Python Programming NotesDocument142 pagesPython Programming NotesSantosh KBNo ratings yet

- Sensor Guided Robotics Using Ir Sensors and by Programming Micro Controller1550049190Document1 pageSensor Guided Robotics Using Ir Sensors and by Programming Micro Controller1550049190NationalinstituteDsnrNo ratings yet

- Intelligent Letter Box Using Arduino and GSM1554330059Document2 pagesIntelligent Letter Box Using Arduino and GSM1554330059NationalinstituteDsnrNo ratings yet

- Electric Vehicle To Power Grid Integration UsingDocument16 pagesElectric Vehicle To Power Grid Integration UsingNationalinstituteDsnrNo ratings yet

- Voice Controlled Robotic Vehicle1534238864Document2 pagesVoice Controlled Robotic Vehicle1534238864NationalinstituteDsnrNo ratings yet

- Antanna Major Project PPT 21-2021Document26 pagesAntanna Major Project PPT 21-2021NationalinstituteDsnrNo ratings yet

- Password Based Door Lock System1533624509Document3 pagesPassword Based Door Lock System1533624509NationalinstituteDsnrNo ratings yet

- Sign Language To Speech Translation System For Deaf and Dumb1536414651Document2 pagesSign Language To Speech Translation System For Deaf and Dumb1536414651NationalinstituteDsnrNo ratings yet

- Opinion Minning On Feedback Management SystemDocument10 pagesOpinion Minning On Feedback Management SystemNationalinstituteDsnrNo ratings yet

- Image Retrieval Based On Chrominance Feature of The HMMD Color SpaceDocument2 pagesImage Retrieval Based On Chrominance Feature of The HMMD Color SpaceNationalinstituteDsnrNo ratings yet

- ECE517 Project Fall2019 PDFDocument1 pageECE517 Project Fall2019 PDFNationalinstituteDsnrNo ratings yet

- BTech Thesis GuidelinesDocument17 pagesBTech Thesis Guidelinesvempadareddy100% (1)

- Modeling of Arduino-Based Prepaid Energy Meter Using GSM TechnologyDocument3 pagesModeling of Arduino-Based Prepaid Energy Meter Using GSM TechnologyNationalinstituteDsnrNo ratings yet

- Color Based Image Retrieval SystemDocument3 pagesColor Based Image Retrieval SystemNationalinstituteDsnrNo ratings yet

- ECE517 Project Fall2019 PDFDocument1 pageECE517 Project Fall2019 PDFNationalinstituteDsnrNo ratings yet

- MIC 1500 - 3300TL-X DatasheetDocument2 pagesMIC 1500 - 3300TL-X DatasheetDiego Andres Loaiza OviedoNo ratings yet

- Ferrite Circulator SwitchesDocument2 pagesFerrite Circulator SwitchesAmit KumarNo ratings yet

- Controle F6 TS Versão 4.0.1 S280!70!7Document44 pagesControle F6 TS Versão 4.0.1 S280!70!7adelmo souzaNo ratings yet

- 1) Professional Brochure For Printing1-6Document8 pages1) Professional Brochure For Printing1-6api-3833673No ratings yet

- RRU5935E Hardware DescriptionDocument21 pagesRRU5935E Hardware DescriptionAlexandra TomescuNo ratings yet

- Master Control SwitchingDocument4 pagesMaster Control SwitchingJosé Juan PifanoNo ratings yet

- Bee - Ii-I CseDocument156 pagesBee - Ii-I CseshivakumarkondakavalNo ratings yet

- 8051 Microcontroller & Programming in C: Presented By: Rana Das N Abhijit Suman Pal Guided By: BappaditaDocument21 pages8051 Microcontroller & Programming in C: Presented By: Rana Das N Abhijit Suman Pal Guided By: BappaditaranaNo ratings yet

- Network Topology PDFDocument3 pagesNetwork Topology PDFLatonya ReidNo ratings yet

- USRM IandO GuideDocument414 pagesUSRM IandO GuideEduardo GarciaNo ratings yet

- Design of Elliptical Patch Antenna With Single & Double U-Slot For Wireless Applications: A Comparative ApproachDocument7 pagesDesign of Elliptical Patch Antenna With Single & Double U-Slot For Wireless Applications: A Comparative ApproachIJMERNo ratings yet

- Harris An PRC 150c Type 1 HF RadioDocument2 pagesHarris An PRC 150c Type 1 HF RadioAKsentinel100% (2)

- Manual Do Proprietário: Yamaha Home Keyboards Home Page (English Only) Yamaha Manual LibraryDocument118 pagesManual Do Proprietário: Yamaha Home Keyboards Home Page (English Only) Yamaha Manual LibraryHector ZicaNo ratings yet

- NF8 Series: (NF8/NF8-V) Socket 754 System Board User's ManualDocument56 pagesNF8 Series: (NF8/NF8-V) Socket 754 System Board User's ManualbalaznNo ratings yet

- TMN Networking: at The Speed of IdeasDocument112 pagesTMN Networking: at The Speed of IdeasplirkNo ratings yet

- Literature Survey: Product DescriptionDocument6 pagesLiterature Survey: Product DescriptionBryan Rex AnggaNo ratings yet

- HID iCLASS SecurityDocument13 pagesHID iCLASS SecurityMrJohnGalt09No ratings yet

- EC8392-DE Question Bank With Answers 1Document44 pagesEC8392-DE Question Bank With Answers 1shanthiantony100% (1)

- SEMIKRON DataSheet SK 70 KQ 24302500Document3 pagesSEMIKRON DataSheet SK 70 KQ 24302500Mateus RibeiroNo ratings yet

- 294 605 BC De250 Spec SheetDocument2 pages294 605 BC De250 Spec SheetMaikel Borges IglesiasNo ratings yet

- Delta - Ia Hmi - Dop B07S415 E415 PS415 S515 E515 PS515 - Q - TC en SC Tur - 20160714Document8 pagesDelta - Ia Hmi - Dop B07S415 E415 PS415 S515 E515 PS515 - Q - TC en SC Tur - 20160714Paulo Cesar ChemelloNo ratings yet

- Technical Specification 1 1Document71 pagesTechnical Specification 1 1Kenng ToonNo ratings yet

- Report VivaDocument66 pagesReport VivaVanditaa SethiNo ratings yet

- Exam in Digital Communications, EITG05: October 26, 2017Document7 pagesExam in Digital Communications, EITG05: October 26, 2017Abdelhakim KhlifiNo ratings yet

- Generic Memory Compiler PDFDocument2 pagesGeneric Memory Compiler PDFAnonymous Wu14iV9dqNo ratings yet

- Synopsis On Underground Cable Fault DetectionDocument4 pagesSynopsis On Underground Cable Fault DetectionROBOMAXX100% (1)