Professional Documents

Culture Documents

Otymer Communications: Ly Induced Changes in Kevlar" Fi Urfaee Evidenced

Uploaded by

VeeturiVarunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Otymer Communications: Ly Induced Changes in Kevlar" Fi Urfaee Evidenced

Uploaded by

VeeturiVarunCopyright:

Available Formats

Polymer Voi. 36 No. 23, pa.

4521-4523, 1995

Copyright c 1995 Eisevier Science Ltd

Printed in Great Britain. All rights reserved

0032-386i/95/$30.00+0.00

otymercommunications

ly induced changes in Kevlar” fi urfaee evidenced

illatt

DuPont (UK) Limited, Maydown Research Centre, PO Box 15, Londonderry BT47 1 TU, UK

and scoubes, R. Gauthier and A. Vigier

Universitk Claude Bernard Lyon I-URA CNRS 507, Laboratoire d’Etudes des Matkiaux Pastiques et

des Biomate’riaux, 43 Bd du I I Novembre 1918, 69622 Villeurbanne Ce’dex, France

(Received I May 1995)

Inverse gas chromatographic analysis of Kevlar yarns reveals a major surface property difference between

free-length annealed fibres and constant-length annealed fibres. The deviation in the retention diagram is

studied and discussed along with four possible hypotheses. A surface microstructure change is the most

realistic explanation of the observed phenomena.

(Keywords: PPTA; fibre surface; annealing; inverse gas chromatography)

Inlroduction in an oven at ! 30°C under atmospheric pressure in order

Inverse gas chromatography (i.g.c.) is a suitable to eliminate most of the sorbed water-S-6% by weight.

technique for detecting changes in the morphologic During this fibre preconditioning, two types of annealing

structure of polymers, for determining interaction are performed:

parameters (e.g. polymer-solvent or polymer-polymer), (i) The skein of yarn is hung freely in the oven (‘free-

and, more generally, for the characterization of the length annealed fibres’).

surface physicocochemical properties of advanced mate- (ii) The yarn is wound on a glass tube and placed in

rials in various forms’. the oven (‘constant-length annealed fibres’).

This paper describes a modification in the surface

microstructure of the poly(p-phenylene terephthalamide)

Column preparation. A treated skein of 160 fibre ends

(PPTA) based fibres (Kevlar) during annealing as

is pulled into a stainless steel column (internal diameter,

revealed by i.g.c. analysis. A very similar phenomenon,

4.7 mm; length, 80 cm). The packing factor of the column

namely the increase of the crystallinity rate and the

is 0.55-0.60, which guarantees an optimum reproducibility

growth of the microparacrystallites during annealing,

of the method. Usual precautions are taken to avoid

was observed by Chatzi et ai.=and by Hindeleh and

moisture and dust contamination of the fi

Abdo3. These authors refer to i.r. spectroscopy analysis,

after hydrogen exchange with D20 (ref. 2), and X-ray

Utromatographic measurements. The column is

diffraction observation to support their findings,

inserted in an Intersmat IGC 16 chromatograph

Annealing of Kevlar fibres provides a means to tailor

the molecular orientation which directly affects the equipped with a catharometer detector. The flow rate

crystalline parameters. This annealing effect is observed of carrier gas (helium) is carefully regulated at 25ml

min-’ (measured at 20°C) using a constant flow Brooks

at a lower ‘temperature (1OO’C) in the case of Kevlar-29

valve (model 8744). A purge of the column is performed

than for Kevlar-49 fibres. In both cases, the degree of

at 6O”C, in order to eliminate all molecules abie to desorb

orientation is larger when fibres are free-length annealed

at this temperature.

than when these fibres are annealed at constant length.

For this study, the saturated linear hydrocarbon, n-

.l?xperimental dodecane from Fluka, is used as a non-polar probe. The

Material. Finish-free Kevlar-29 fibres, supplied by retention time is given by the maximum value of the

E.I. DuPont de Nemours and Co., are used as received. peak, corresponding to the injected probe molecule. Its

These fibres are produced from the PPTA polymer, The net value, f,, is obtained by subtracting the retention time

yarn is made of 1000 filaments of 12 pm diameter and its of air. The specific retention volume Yg is given by:

specific H&ear density is 1670dtex (equivalent to

~g=jflli

O.l67gm-‘). m

where j is the James and Martin correcting factor which

Annealing. Skeins of Kevlar yarn are treated for 24 h

takes into account the pressure drop BP along the

*DuPont’s registered trademark for its high strength para-aramid

column, D is the flow rate of carrier, and IYE

is the mass of

fibres the stationary phase (Kevlar fibres) in the column.

i To whom correspondence should be addressed At a given temperature, several injections of the probe

Bheumaliy induced changes in Kevlaf: S. Webouillat et al.

shorter temperature intervals would lead to a better

defined, eventually smaller, discontinuity step, d. A

straight line with the same slope as in Figure lb is also

obtained when the columns are prepared with unpre-

conditioned, unannealed fibres,

Different hypotheses can be envisaged to explain the

curve discontinuity:

(i) Such a discontinuity is often observed by i.g.c.

for polymers which exhibit a glass transition

Free length annealed Fiber temperature, Tg, or a second order transition in

(First thermal cycle)

the studied range of temperature. It is not the case

here since a ‘Ts’ value of Kevlar is given around

345-375”C4;5, which is confirmed by a baseline

change around 360°C on a d.s.c. thermogram. On

Ln vg

dried Kevlar, no other phenomenon is observed

1

-1

at 100°C (ref. 5) on the d.s.c. curve, Furthermore,

this discontinuity would be reversible, which is

-2

not the case since a single segment is observed for

-3

the second temperature rise (Figure Ib).

-4

(ii) Another explanation would involve the desorption

-5

(at temperatures between 95 and 12PC), of fairly

-b

strongly sorbed water molecules located onto

-7

AH=69(kfmuie’J highly active sites. In order to verify this

-8 hypothesis, Kevlar fibres are rehydrated in the

-9 column using helium gas saturated with water.

-10 After another period of stabilization, a single

(b) 2 2.2 2.4 2.6 2.8 3 3.2 3.4

l:T IO’[K’J

straight line (as in F’igure lb) is obtained. This

means that during the preconditioning, all the

Figure 1 Variation of In YE0 for n-dodecane with reciprocal of the water molecules were desorbed, and the curve

temperature (column packing: free-length annealed Kevlar-29 fibres): discontinuity is not due to new accessible sites

(a) first temperature rise, (b) second temperature rise

created during the desorption of water.

(iii) A third hypothesis may be related to the

dimensional modifications of the column packing

molecule at different concentrations are performed using

with the temperature, which are well evidenced by

a micro-syringe. The smallest possible amount of probe

monitoring the pressure drop AP between the

has to be injected (using the head-space technique). T/go,

inlet and the outlet of the column. However, as

corresponding to the theoretical retention volume at ‘nil

the flow rate of carrier gas is rigorously main-

concentration’, is obtained by extrapolation of the

tained constant, the discontinuity cannot be due

collected data.

to dilatation phenomena.

According to Clapeyron’s equation, there is a linear

relationship between lnVgo and l/T. The slope gives (iv) A fourth hypothesis involves a morphological

modification of the material. This modification,

access, in our case, to the enthalpy of adsorption of the

concerning at least the surface of the fibres, would

probe molecule on the fibre surface. By comparing this

be due to the free annealing. As described by

value with the liquefaction energy of the gaseous probe

Windeleh and Abdo3, the annealing above 100°C

molecule, one can estimate the specific interactions

increases the degree of orientation, especially for

between the probe and the fibre surface’,

free-length annealed fibres, and involves the

Consequently, the calculation of the specific inter-

growth of microparacrystallites which can generate

actions requires the measurements of a fairly large

changes at the surface.

number of retention times at different isothermal stages.

Between 60 and 13O”C, measurements were done for In order to verify this hypothesis, a new set of

each 10°C step. Since, for each step, several days are measurements is conducted comparing free-length and

needed to obtain a good stabilization of the baseline, one constant-length annealed fibres (Figwe 2). A discontinuity

can easily appreciate the large time period of the is observed in the two cases. Figure 2 shows the remarkable

technique. reproducibility of the phenomenon observed in Figure la.

It is also worth noting that the curve interruption is

Results and discussion markedly reduced for constant-length annealed fibres.

Figure I represents the variation of lnV,s with the The crystallinity parameters are also affected, as

reciprocal of the temperature for the selected Kevlar fibre confirmed by X-ray diffraction measurements

after free-length annealing. Figure la, which corresponds (WAXS)-the (2 0 0) reflection peak increases by 14%

to the first temperature rise, shows two straight segments for free-length annealed fibres and only by 11% for

with a discontinuity (d) between 95 and 120°C. On the constant-length annealed fibres. This difference may

contrary, a single straight line (Figure Ib) is obtained for appear small, but remember that the Kevlar superficial

the second temperature rise. The experiments are zones are more ordered than the core’, and the

conducted at intervals of 10°C in order to produce the modifications are always developed from the surface

data within a reasonable time scale. It is possible that to the core.

4522 POLYMER Volume 36 Number 23 1995

Thermally induced changes h Kevlar: S.

of the curve discontinuity, the measured energy of

interaction is much higher] especially for the free-length

AH = 75[!dmoW] annealed fibres (98 kJ mol- , Fzgure la). Su& a significant

-2

difference in the case of a non-polar molecule, may

-3

involve the condensation of n-dodecane in the surface

-3

micropores. These micropores would have to be of a size

-5

relatively close to the size of the condensate.

-6

The need then remains for an explanation of the

-1 disappearance, after the first thermal cycle, of this energy

-8 phenomenon and of the curve discontinuity d. The

-9 complete thermal cycle consist of 8 isothermal steps,

,II

-1v from 60 to 130°C each lasting several days. It is then

2 2.2 2.4 2.6 2.8 3 3.2 3.4

i/TIO'[K'j

possible that these prolonged periods, which, due to the

column compactness, could be considered 2s equivalent

Figure 2 Variation of in i/g0 for n-dodecane with reciprocal of the to the constant-length annealing conditions, are favour-

temperature (column of Kevlar-29 fibres, first temperature rise) for (m) able to a relaxation of internal stresses7 leading to a

free-!ength annealed fibres, and (x) constant-length annealed fibres further modification or even a disappearance of the

previous orientation increase. As a result, the behaviour

becomes similar to that of unannealed hbres or to the

Consequently, one can expect that the difference in constant-length annealed fibre as shown in Figure 2.

surface crystallinity is higher than the mean bulk value

Conclusion

given by X-ray measurements. It is then logical to

consider that such a variation of surface orientation A modification of the microstructure of Kevlar-29

would be observable by i.g.c., a well respected technique fibres during annealing was evidenced by i.g.c. The

in terms of surface analysis. observed phenomena are not only in agreement, but

This hypothesis, as outlined in paragraph (iv), is also further complete the previously described effects of

supported by the energy values obtained prior to and annealing. For example, the increase of the size of the

after the curve discontinuity. As exhibited in Figures la microcrystallites generates micropores at the surface,

and 2, the enthalpic variations, AH, corresponding to where molecules such as n-dodecane may condense

the adsorption of n-dodecane on the Kevlar surface, are with high interaction energies. This effect is accentuated

different before and after the curve discontinuity. This is by the annealing method. Free-length annealed fibres

especially noticeable for the free-length annealed fibres. are more clearly subject to these microstructural

For temperatures above 120°C after the curve modifications.

discontinuity, AH is in the range 69-72 kJmol_‘, References

i.e. M 20 kJmol_” above the liquefaction energy of n-

Lloyd, D. R., Ward, T. C. and Schreiber, II. P. ‘Inverse Gas

dodecane (52 kJ mol-I), although no specific interactions Chromatography’, ACS Symp. Ser. 391, American Chemical

between the hydrocarbon molecules and the poly-aramid Society, Washington DC, 1989

chains are expected. A similar result was previously Chatzi, E. G., Urban, M. W., Ishida, II. and Kiinig, J. L. Polymer

described6 for the adsorption of n-alkanes on Kevlar 1986,27; 1850

Hindeleh, A. M. and Abdo, S. M. Polymer 1989; 30, 218

fibres, and was interpreted in terms of specific interactions Butta, E., de Petris, S., Frosini, V. and Pasqirini, M. Eur. Polym.

with the aromatic rings of Kevlar polymer. The results J. 1971,7, 387

obtained in the present study correlate very well with the Yang, H. H. ‘Aromatic High-Strength Fibres’, Wiley, New

n-dodecane adsorption energy obtainable by extrapo- York, 1989, Ch. 2, p. 191

Gozdz, A. S. and Weigmann, H. D. J. Appi. Polym. Sci. 1984,

lation of the data published by Gozdz et ai. (69-72

29, 3965

versus M 64 kJ mol- )” Wu, Z., Zhang, A., Cheng, S. Z. D., Huang, B. and Qian, B.

For temperatu.res below 95°C i.e. before the appearance J. Polym. Sci., Polym. Phys. Edn 1990, 28, 2565

OLYMER Volume 36

You might also like

- Experiments in Textile and Fibre ChemistryFrom EverandExperiments in Textile and Fibre ChemistryRating: 5 out of 5 stars5/5 (1)

- The EFTTRA-T4 Experiment On Americium TransmutationDocument12 pagesThe EFTTRA-T4 Experiment On Americium TransmutationWalid BadrNo ratings yet

- 1 s2.0 S0032386114011628 MainDocument8 pages1 s2.0 S0032386114011628 MainRafael CardosoNo ratings yet

- Crystallization Kinetics of Pure and Fiber-ReinforcedDocument7 pagesCrystallization Kinetics of Pure and Fiber-Reinforcedelwathig2011No ratings yet

- Factors Controlling The Performance of Catalytic Dehydrogenation of Ethylbenzene in Palladium Composite Membrane ReactorsDocument9 pagesFactors Controlling The Performance of Catalytic Dehydrogenation of Ethylbenzene in Palladium Composite Membrane ReactorsFranciscoBarrancoLopezNo ratings yet

- Criscuoli Basile Drioli 2000 An Analysus of The Performance of Membrane Reactors For The WGSR Using Gas Feed MixturesDocument12 pagesCriscuoli Basile Drioli 2000 An Analysus of The Performance of Membrane Reactors For The WGSR Using Gas Feed MixturesAnonymous uCYIu1No ratings yet

- Development of Polyester and Polyamide Conductive Fibre: Polymer Fibres 2004Document7 pagesDevelopment of Polyester and Polyamide Conductive Fibre: Polymer Fibres 2004api-3733260No ratings yet

- GFRP ChinaDocument3 pagesGFRP ChinaKumarNo ratings yet

- PyrolysisDocument18 pagesPyrolysishope worldNo ratings yet

- Comparison and Analysis of Thermal Degradation Process of Aramid Fibers (Kevlar 49 and Nomex)Document5 pagesComparison and Analysis of Thermal Degradation Process of Aramid Fibers (Kevlar 49 and Nomex)dsimon2No ratings yet

- The Effect of Temperature on Photochemical Degradation of TextilesDocument6 pagesThe Effect of Temperature on Photochemical Degradation of TextilesnileshbagaleNo ratings yet

- Thermo-Oxidative Stress Relaxation in Carbon-Filled SBR: Plastics Rubber and Composites April 2021Document17 pagesThermo-Oxidative Stress Relaxation in Carbon-Filled SBR: Plastics Rubber and Composites April 2021Amina DinariNo ratings yet

- Charoensirisomboon 1998Document5 pagesCharoensirisomboon 1998varsha patilNo ratings yet

- Fabrication and Sintering Characteristics of Doctor Blade YBCO-Ag TapesDocument11 pagesFabrication and Sintering Characteristics of Doctor Blade YBCO-Ag TapesAtikorn WongNo ratings yet

- N O N U N I F O R M Catalyst Distribution For Inorganic Membrane Reactors: Theoretical Considerations and Preparation TechniquesDocument16 pagesN O N U N I F O R M Catalyst Distribution For Inorganic Membrane Reactors: Theoretical Considerations and Preparation TechniquesJean Bosco VuningomaNo ratings yet

- 4Document5 pages4Gustavo Gabriel JimenezNo ratings yet

- Polyester WeatherabilityDocument10 pagesPolyester Weatherabilitynikopigni2No ratings yet

- Performance Analysis of Four-Bed H PSA Process Using Layered BedsDocument13 pagesPerformance Analysis of Four-Bed H PSA Process Using Layered BedsRobert Solano MontoyaNo ratings yet

- Gamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsDocument13 pagesGamma Ray Absorption Measurements, Laboratory Experiments in Bottomhole ConditionsBOURECHAK TayebNo ratings yet

- 1 s2.0 S0167577X21022254 MainDocument3 pages1 s2.0 S0167577X21022254 MainanshuNo ratings yet

- Bubble Size Distribution in Laboratory Scale Flotation CellsDocument9 pagesBubble Size Distribution in Laboratory Scale Flotation CellsJose Luis Barrientos RiosNo ratings yet

- Reinforcing rubbery epoxy with carbon nanofibresDocument5 pagesReinforcing rubbery epoxy with carbon nanofibresSara TeixeiraNo ratings yet

- The Cold Drawing of Amorphous Polyethylene Terephthalate: Department of Physics, University of Leeds, Leeds, UKDocument6 pagesThe Cold Drawing of Amorphous Polyethylene Terephthalate: Department of Physics, University of Leeds, Leeds, UKapi-3733260No ratings yet

- On The Hydrolytic Stability of Polyester YarnsDocument12 pagesOn The Hydrolytic Stability of Polyester YarnsAnnie LauNo ratings yet

- Diethelm2004 Article PlanarAndTubularPerovskite-typDocument7 pagesDiethelm2004 Article PlanarAndTubularPerovskite-typDaniela De Araujo SampaioNo ratings yet

- Journal of Nuclear Materials: A 1 A B B B B C C C D D e F F G G A BDocument4 pagesJournal of Nuclear Materials: A 1 A B B B B C C C D D e F F G G A BAnonymous 1hOgJqwZuzNo ratings yet

- Cena2016 Impéance ConductivitéDocument9 pagesCena2016 Impéance ConductivitéمحمدNo ratings yet

- Thermally Induced Structural Changes in Nomex Fibres: Anjana Jain and Kalyani VijayanDocument6 pagesThermally Induced Structural Changes in Nomex Fibres: Anjana Jain and Kalyani VijayanSana AshfaqueNo ratings yet

- Remnant Life Assessment of Platformer Heater T9 Tubes Using Api 579 Omega MethodDocument9 pagesRemnant Life Assessment of Platformer Heater T9 Tubes Using Api 579 Omega Methodsanu patilNo ratings yet

- Ijftr 30 (3) 278-282Document5 pagesIjftr 30 (3) 278-282anil taleleNo ratings yet

- Nano-TiO2 Cotton Fibers by Self-Assembly for Photocatalytic DegradationDocument4 pagesNano-TiO2 Cotton Fibers by Self-Assembly for Photocatalytic DegradationjulianNo ratings yet

- Platinum Resistojets for Space StationsDocument9 pagesPlatinum Resistojets for Space StationsAbhishek DadhwalNo ratings yet

- Thermal Aging of Plasticized PVCDocument6 pagesThermal Aging of Plasticized PVCHaiLy NguyenNo ratings yet

- Ijftr 20 (4) 185-191Document7 pagesIjftr 20 (4) 185-191anowartexNo ratings yet

- The Influence Drawing, Twisting, Heat Setting, and Untwisting On The Structure and Mechanical Properties of Melt-Spun High-Density Polyethylene FiberDocument25 pagesThe Influence Drawing, Twisting, Heat Setting, and Untwisting On The Structure and Mechanical Properties of Melt-Spun High-Density Polyethylene Fiberapi-3733260No ratings yet

- Probing The Wetted Perimeter in A He II Two-Phase Pipe-Flow Experiment Using A Capacitive SensorDocument9 pagesProbing The Wetted Perimeter in A He II Two-Phase Pipe-Flow Experiment Using A Capacitive SensorThibault PierreNo ratings yet

- abdel-azim1995Document6 pagesabdel-azim19951584706055No ratings yet

- Adv Funct Mater (2020) 1910555 - Functional Coatings On High-Performance Polymer FibersDocument6 pagesAdv Funct Mater (2020) 1910555 - Functional Coatings On High-Performance Polymer FibersAlexandre Ferro RochaNo ratings yet

- Communications: Ian O'Connor, Hugh Hayden, Jonathan N. Coleman, and Yurii K. Gun'koDocument4 pagesCommunications: Ian O'Connor, Hugh Hayden, Jonathan N. Coleman, and Yurii K. Gun'koHeriberto OliveiraNo ratings yet

- Effect of Twist Level On Tire Cord Performance PDFDocument5 pagesEffect of Twist Level On Tire Cord Performance PDFMarcus NguyễnNo ratings yet

- Thesis Title Defence (Ali Anjum)Document17 pagesThesis Title Defence (Ali Anjum)HusnainNo ratings yet

- The Elimination of The Yield Point Phenomenon in A New Zirconium AlloyDocument5 pagesThe Elimination of The Yield Point Phenomenon in A New Zirconium Alloyle hoangNo ratings yet

- Kuralon Pva Fiber in Alkaline Condition PDFDocument15 pagesKuralon Pva Fiber in Alkaline Condition PDFSebastianNo ratings yet

- Bikiaris 1996Document6 pagesBikiaris 1996Sy Nguyen VietNo ratings yet

- Microwave Sintering of Hydroxyapatite Ceramics PDFDocument8 pagesMicrowave Sintering of Hydroxyapatite Ceramics PDFfishvalNo ratings yet

- J Carbpol 2010 11 022Document5 pagesJ Carbpol 2010 11 022orang_udikNo ratings yet

- Thermal Conductivity of Rigid Foam InsulationsDocument8 pagesThermal Conductivity of Rigid Foam InsulationsmateuszNo ratings yet

- Bucky PaperDocument22 pagesBucky PaperShreyashkumar ZingadeNo ratings yet

- Investigation of Crosslinking in The Thermo Oxidative Aging of Nitrile-Butadiene RubberDocument5 pagesInvestigation of Crosslinking in The Thermo Oxidative Aging of Nitrile-Butadiene RubberRossana IervolinoNo ratings yet

- 1 s2.0 S0966979514001277 MainDocument6 pages1 s2.0 S0966979514001277 MainkasturiNo ratings yet

- Nano Silica Modified Carbon-Phenolic CompositesDocument4 pagesNano Silica Modified Carbon-Phenolic CompositesAbrizal HaryadiNo ratings yet

- Mechanical and Thermal Characterization of Clay With A View To Popularizing Its Use As An Ecological Material in ConstructionDocument10 pagesMechanical and Thermal Characterization of Clay With A View To Popularizing Its Use As An Ecological Material in ConstructionIJAR JOURNALNo ratings yet

- A Way To Control The Gold Nanocrystals Size UsingDocument8 pagesA Way To Control The Gold Nanocrystals Size UsingErrafi WissalNo ratings yet

- Magnetron Sputtered Transparent Conducting Cdo Thin Films: Journal of Electronic Materials, Vol. 25, No. 4, 1996Document6 pagesMagnetron Sputtered Transparent Conducting Cdo Thin Films: Journal of Electronic Materials, Vol. 25, No. 4, 1996Anonymous cYpEVvoNo ratings yet

- The Dielectric Properties of Glass-®bre-Reinforced Epoxy Resin During PolymerisationDocument6 pagesThe Dielectric Properties of Glass-®bre-Reinforced Epoxy Resin During PolymerisationOliver RisteskiNo ratings yet

- Thermal Stability of Keratin Fibers Affected by pHDocument8 pagesThermal Stability of Keratin Fibers Affected by pHEduardo TarangoNo ratings yet

- Raman Spectrum of Modified PAN-Based Carbon Fibers During GraphitizationDocument4 pagesRaman Spectrum of Modified PAN-Based Carbon Fibers During Graphitizationapi-3733260No ratings yet

- Drying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesDocument4 pagesDrying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesAnthony MarasiganNo ratings yet

- Polymerization Study and Rheological Behavior of A RTM6 Epoxy Resin System During Preprocessing StepDocument9 pagesPolymerization Study and Rheological Behavior of A RTM6 Epoxy Resin System During Preprocessing StepNico PonsNo ratings yet

- Fusion Engineering and DesignDocument5 pagesFusion Engineering and DesignAnonymous 1hOgJqwZuzNo ratings yet

- Composite Materials Journal of Thermoplastic: A New Penetration Equation For Ballistic Limit AnalysisDocument24 pagesComposite Materials Journal of Thermoplastic: A New Penetration Equation For Ballistic Limit AnalysisVeeturiVarunNo ratings yet

- International Journal of Impact Engineering: E. Tapie, V.P.W. Shim, Y.B. GuoDocument12 pagesInternational Journal of Impact Engineering: E. Tapie, V.P.W. Shim, Y.B. GuoVeeturiVarunNo ratings yet

- Impact Tensile Behavior Analysis of Twaron Fiber Tows From Fast Fourier TransformDocument9 pagesImpact Tensile Behavior Analysis of Twaron Fiber Tows From Fast Fourier TransformVeeturiVarunNo ratings yet

- Applied SciencesDocument17 pagesApplied SciencesVeeturiVarunNo ratings yet

- Finite Element Micromechanics Failure Criteria Fiber CompositesDocument19 pagesFinite Element Micromechanics Failure Criteria Fiber CompositesVeeturiVarunNo ratings yet

- Comparison of Ballistic Impact Behavior of Carbon Fiber/Epoxy Composite and Steel Metal StructuresDocument10 pagesComparison of Ballistic Impact Behavior of Carbon Fiber/Epoxy Composite and Steel Metal StructuresVeeturiVarunNo ratings yet

- Polymers 11 00160Document15 pagesPolymers 11 00160VeeturiVarunNo ratings yet

- Jin2012 Article EffectsOfLightStabilizerOnTheUDocument7 pagesJin2012 Article EffectsOfLightStabilizerOnTheUVeeturiVarunNo ratings yet

- Phadnis 2013 J. Phys. Conf. Ser. 451 012019Document9 pagesPhadnis 2013 J. Phys. Conf. Ser. 451 012019VeeturiVarunNo ratings yet

- A Basic Introduction of RheologyDocument20 pagesA Basic Introduction of RheologyLina Mariana Prieto AmadoNo ratings yet

- Astm D 3171 2015Document11 pagesAstm D 3171 2015rangelegleNo ratings yet

- Crystals 09 00389 PDFDocument10 pagesCrystals 09 00389 PDFVeeturiVarunNo ratings yet

- Prediction of Impact Damage in Composite Plates: J.P. Hou, N. Petrinic, C. Ruiz, S.R. HallettDocument9 pagesPrediction of Impact Damage in Composite Plates: J.P. Hou, N. Petrinic, C. Ruiz, S.R. HallettVeeturiVarunNo ratings yet

- Ballistic Performance of Unidirectional Glass Fiber Laminated Composite Plate Under Normal and Oblique ImpactDocument8 pagesBallistic Performance of Unidirectional Glass Fiber Laminated Composite Plate Under Normal and Oblique ImpactVeeturiVarunNo ratings yet

- Phadnis 2013 J. Phys. Conf. Ser. 451 012019Document9 pagesPhadnis 2013 J. Phys. Conf. Ser. 451 012019VeeturiVarunNo ratings yet

- Ultra High Molecular Weight Polyethylene: Mechanics, Morphology, and Clinical BehaviorDocument11 pagesUltra High Molecular Weight Polyethylene: Mechanics, Morphology, and Clinical BehaviorVeeturiVarunNo ratings yet

- Finite Element Micromechanics Failure Criteria Fiber CompositesDocument19 pagesFinite Element Micromechanics Failure Criteria Fiber CompositesVeeturiVarunNo ratings yet

- Annurev Ms 25 080195 001455 PDFDocument31 pagesAnnurev Ms 25 080195 001455 PDFVeeturiVarunNo ratings yet

- Annurev Ms 25 080195 001455 PDFDocument31 pagesAnnurev Ms 25 080195 001455 PDFVeeturiVarunNo ratings yet

- Direct Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneDocument13 pagesDirect Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneVeeturiVarunNo ratings yet

- Direct Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneDocument13 pagesDirect Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneVeeturiVarunNo ratings yet

- GuptaS - Dis (Final Comments 3) PDFDocument219 pagesGuptaS - Dis (Final Comments 3) PDFVeeturiVarunNo ratings yet

- Direct Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneDocument13 pagesDirect Correlation Between Modulus and The Crystalline Structure in Isotactic PolypropyleneVeeturiVarunNo ratings yet

- Ultra High Molecular Weight Polyethylene Fiber From DSM DyneemaDocument4 pagesUltra High Molecular Weight Polyethylene Fiber From DSM DyneemaVeeturiVarunNo ratings yet

- Polymers 12 00711 PDFDocument13 pagesPolymers 12 00711 PDFVeeturiVarunNo ratings yet

- Review Paper-Treatment Methods, Materials and CharacterizatioDocument4 pagesReview Paper-Treatment Methods, Materials and CharacterizatioVeeturiVarunNo ratings yet

- 84 17 60 3020 PDFDocument7 pages84 17 60 3020 PDFVeeturiVarunNo ratings yet

- Effect of Accelerated Ageing Conditions On The Degradation Process of Dyneema (R) Polyethylene CompositesDocument7 pagesEffect of Accelerated Ageing Conditions On The Degradation Process of Dyneema (R) Polyethylene CompositesVeeturiVarunNo ratings yet

- GuptaS - Dis (Final Comments 3) PDFDocument219 pagesGuptaS - Dis (Final Comments 3) PDFVeeturiVarunNo ratings yet

- Annurev Ms 25 080195 001455 PDFDocument31 pagesAnnurev Ms 25 080195 001455 PDFVeeturiVarunNo ratings yet

- E-Store PricelistDocument43 pagesE-Store PricelistDibya Ranjan Dash100% (1)

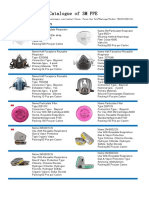

- Catalogue of 3M PPE and Safety EquipmentDocument3 pagesCatalogue of 3M PPE and Safety EquipmentSothearaThengNo ratings yet

- Idoc - Pub Bs en 13369 TolerancesDocument6 pagesIdoc - Pub Bs en 13369 TolerancesRai Singh MalhiNo ratings yet

- Textile Fibers: Study of Cellulosic Fibers (Cotton)Document31 pagesTextile Fibers: Study of Cellulosic Fibers (Cotton)Rashedul IslamNo ratings yet

- Flow Chart of Carded Yarn 2nd ClassDocument1 pageFlow Chart of Carded Yarn 2nd ClassSelim RezaNo ratings yet

- 01 Scagliola+info+sheet Vogley Woods 2021Document8 pages01 Scagliola+info+sheet Vogley Woods 2021blackestsheepNo ratings yet

- Mud Plug ProcedureDocument4 pagesMud Plug Proceduremahdi_g100% (1)

- Kmno4 and K2cr2o7 PDFDocument6 pagesKmno4 and K2cr2o7 PDFBrown BoyNo ratings yet

- KNS1042-Sem1-1819-Project VisitDocument2 pagesKNS1042-Sem1-1819-Project Visitjustine2109No ratings yet

- Uni-Seals Spiral Wound Gasket Product CatalogDocument1 pageUni-Seals Spiral Wound Gasket Product CatalogademilsoncaetanooNo ratings yet

- GalvInfoNote - 3 - 4 The Salt Spray TestDocument4 pagesGalvInfoNote - 3 - 4 The Salt Spray TestKYAW SOENo ratings yet

- Module No. 11: Piping Systems Difference Between Pipe and TubeDocument8 pagesModule No. 11: Piping Systems Difference Between Pipe and TubeGeoffrey GolbequeNo ratings yet

- Sourcing Ass 1 P.gayathri and PadmasriDocument48 pagesSourcing Ass 1 P.gayathri and PadmasriSatadeep DattaNo ratings yet

- Phosphate Waste Rocks Recycling in Ceramic Wall Tiles - Technical PerformancesDocument11 pagesPhosphate Waste Rocks Recycling in Ceramic Wall Tiles - Technical Performancesali.messaiNo ratings yet

- Terminals TEDocument102 pagesTerminals TEРоман ДяченкоNo ratings yet

- Thermally Curable Polystyrene Via Click ChemistryDocument4 pagesThermally Curable Polystyrene Via Click ChemistryDanesh AzNo ratings yet

- MP Dec2012 - Coating Flange FaceDocument2 pagesMP Dec2012 - Coating Flange FaceUgoRibeiroNo ratings yet

- FacultyDocument13 pagesFacultyLao ZhuNo ratings yet

- Optical Fiber Cable SpecificationDocument2 pagesOptical Fiber Cable Specificationfermac telecomunicacionesNo ratings yet

- CMB Company ProfileDocument8 pagesCMB Company ProfileChris BorresNo ratings yet

- A 792 GalvalumeDocument5 pagesA 792 GalvalumeKapa SandeepNo ratings yet

- d30 - ENERTITE MD 1602-10 - Ed04 - ENDocument6 pagesd30 - ENERTITE MD 1602-10 - Ed04 - ENMangalagiu BogdanNo ratings yet

- 1100 Unlocking Corrosion MythDocument76 pages1100 Unlocking Corrosion MythAbdul Maabood Hassan AlviNo ratings yet

- ICP 0012 - Long Life High Output Tubular AnodesDocument4 pagesICP 0012 - Long Life High Output Tubular AnodesVCNo ratings yet

- Act - Red Mud PolymerDocument39 pagesAct - Red Mud PolymerNaGamani KanDanNo ratings yet

- Sikalastic®-8440: Product Data SheetDocument3 pagesSikalastic®-8440: Product Data SheetGeorge EnescuNo ratings yet

- Technicals of 316/lDocument2 pagesTechnicals of 316/lASHISH DOSHINo ratings yet

- Preparation of Natural Rubber Composites With High Silica Content Using A Wet Mixing ProcessDocument13 pagesPreparation of Natural Rubber Composites With High Silica Content Using A Wet Mixing Processเอกฤกษ์ พุ่มนกNo ratings yet

- Iron & Steel: Sources, Uses, Structure, ChemistryDocument32 pagesIron & Steel: Sources, Uses, Structure, ChemistryDeepak jose vargheseNo ratings yet

- OGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025Document23 pagesOGA - Chemical Series - Plastic Recycling Market Outlook 2019-2025ambarish ramNo ratings yet